Adjustable Torque Hinges – PA6 & Zinc Alloy Options

PRODUCT PARAMETERS

Manufacturer: HTAN

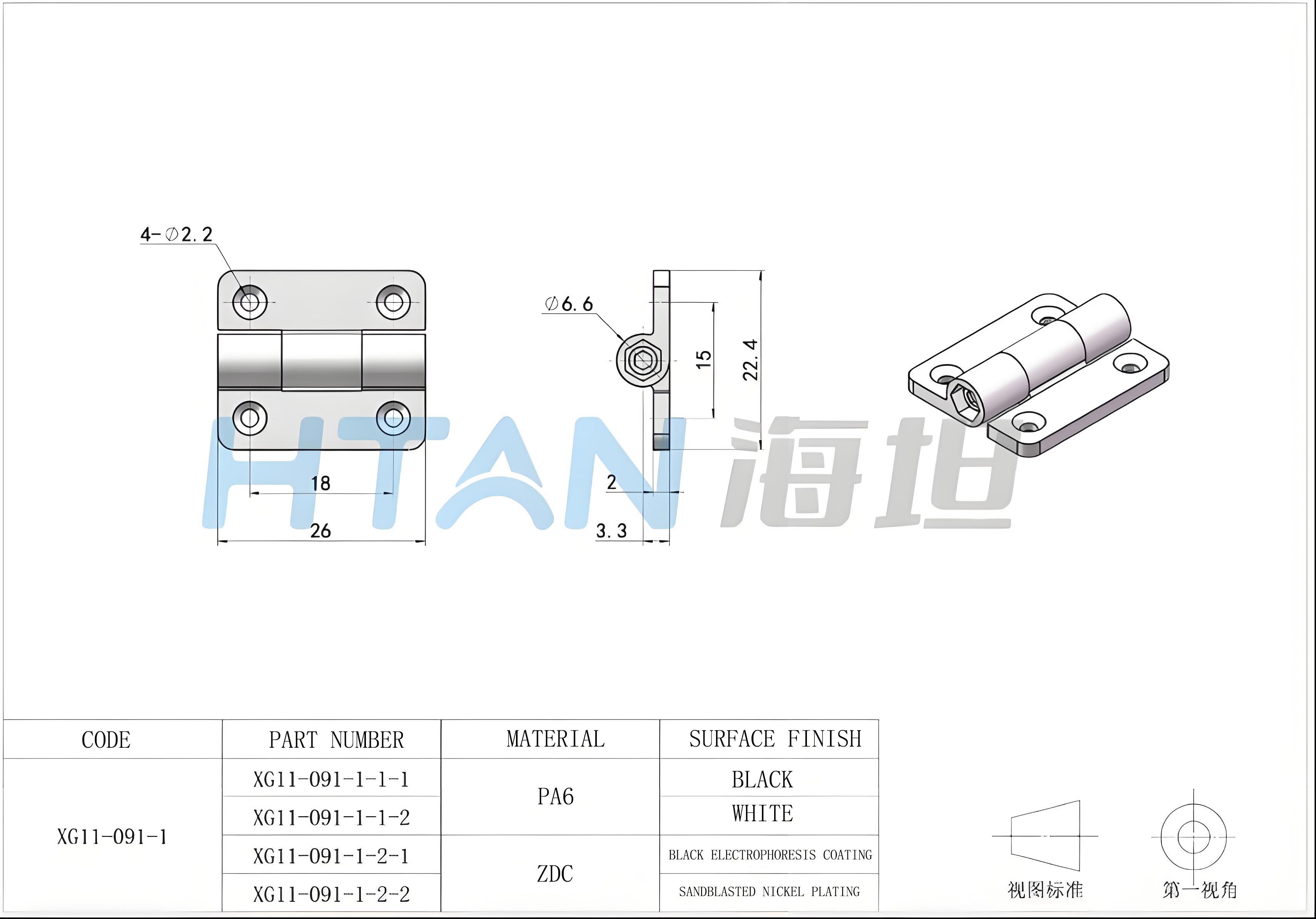

Model: XG11-091-1

Unit Price:

MOQ: no request

Lead Time:7~15days

Customizable: Yes

Description

Request A Quote

Description

PA6 is wear-resistant and lightweight, while zinc alloy is sturdy and durable. It is suitable for industrial control cabinets, instruments, and medical equipment housings, ensuring that the cover can stay at any angle, improving operational safety and convenience.

Product Features

| Key Features | Details |

|---|---|

| Adjustable Torque Design | Torque resistance can be easily adjusted using a Phillips screwdriver, enabling precise positioning and stable holding at any angle. |

| Multiple Torque Ranges | Various torque options (0.1 N·m – 0.5 N·m) are available across models to meet different application requirements. |

| Material Versatility | Offered in PA6 (lightweight and wear-resistant) and zinc alloy (sturdy and durable), catering to both lightweight and heavy-duty usage needs. |

| Various Surface Finishes | Surface treatments include Black, White, Black Electrophoresis Coating, and Sandblasted Nickel Plating, ensuring both aesthetics and corrosion resistance. |

| Wide Application Compatibility | Ideal for industrial control cabinets, instrumentation panels, and medical equipment housings where panel positioning and ease of operation are essential. |

| Secure Locking Mechanism | Equipped with a locking nut to secure torque settings after adjustment, enhancing operational safety and stability. |

Model: XG11-091-1

| Model | Material | Surface Finish | Torque Range |

|---|---|---|---|

| XG11-091-1-1-1 | PA6 | Black | 0.1 N·m – 1.0 N·m |

| XG11-091-1-1-2 | PA6 | White | 0.1 N·m – 1.0 N·m |

| XG11-091-1-2-1 | ZDC | Black Electrophoresis Coating | 0.1 N·m – 1.0 N·m |

| XG11-091-1-2-2 | ZDC | Sandblasted Nickel Plating | 0.1 N·m – 1.0 N·m |

Torque Adjustment Guide

- Use a Phillips screwdriver to loosen the adjustment screw.

- Rotate the hinge to the desired position and test the torque resistance.

- If greater torque is required, turn the adjustment screw clockwise in small increments.

- If less torque is required, turn the adjustment screw counterclockwise.

- Test the torque after each adjustment until the desired resistance is achieved.

- Once satisfied, tighten the lock nut to secure the adjustment.

Drawings