Heavy-Duty Hinge Selection: A Complete Engineering Guide

Introduction: Why Correct Heavy-Duty Hinge Selection Matters

The Problem Starts Here

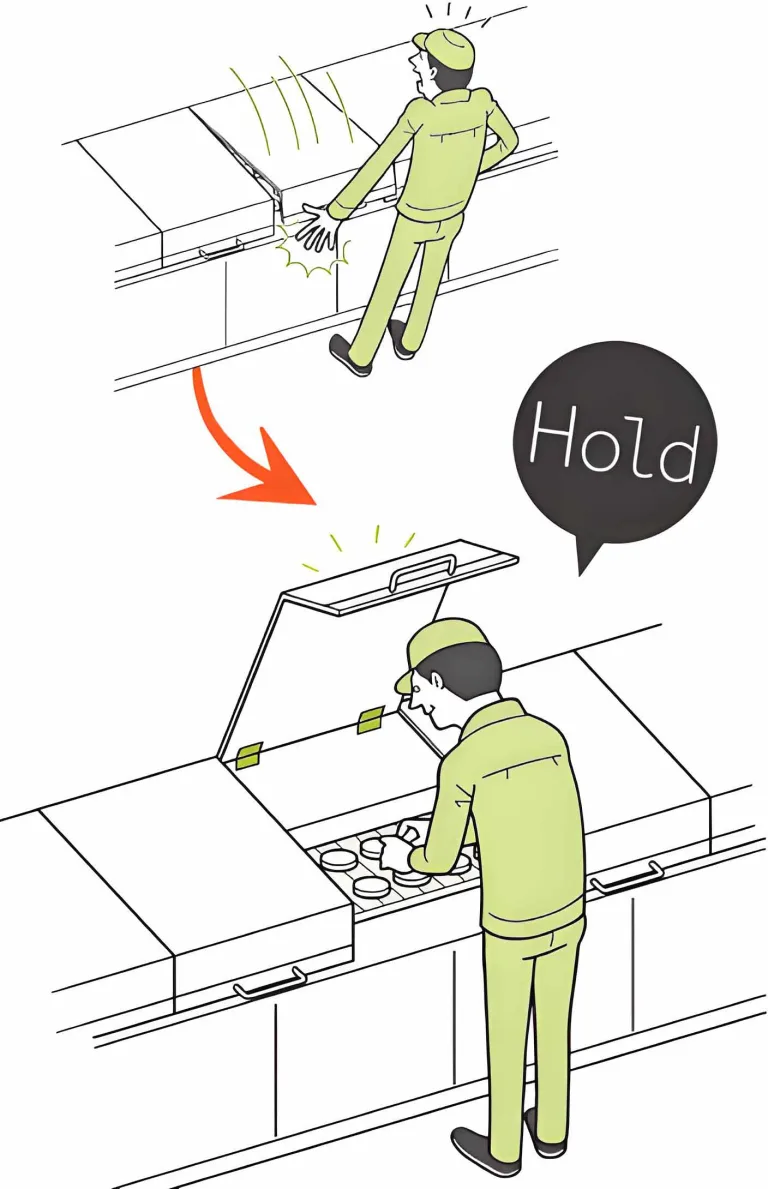

Heavy-duty lids and panels—such as industrial machine guarding, large storage container lids, and ground access hatches—present a significant engineering challenge. They are not just heavy; they are inherently hazardous when operated.

The Cost of Getting It Wrong

Choosing the wrong hinge leads to catastrophic consequences. These are not hypotheticals; they are common failure modes in the field:

- Operator Safety Risks: Sudden lid closure, leading to severe finger, limb, or head-crushing injuries OSHA Caught-In or -Between Hazards

- Operator Fatigue and Injury: Requiring excessive force to lift a lid violates ergonomic principles and directly causes muscle strain and chronic back injuries OSHA Ergonomics Guidelines

- Equipment Damage: Lids slamming against frames cause costly structural damage, seal failure, or the misalignment of precision components.

- Premature Failure: The hinge wears, bends, or breaks long before its expected lifecycle, resulting in high repair costs and unplanned downtime.

The Goal of This Guide

This is not a product catalog. It is a problem-solving methodology. We will walk you through a systematic engineering decision process to ensure you get the selection right the first time.

Before we look at a single hinge, the first step must be to precisely understand the object we need to move.

Step One: Critical Data Collection (Define Your Application Parameters)

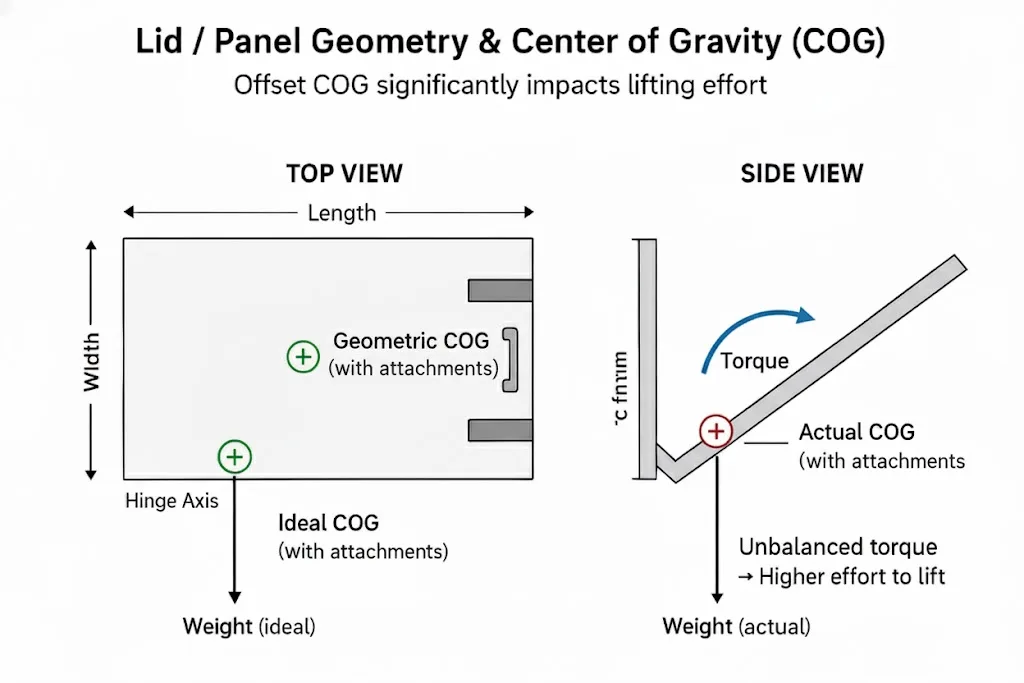

Lid / Panel Geometry & Center of Gravity (COG) Offset Impact on Lifting Torque

소개

This is the most critical step in the entire process. Without accurate data, all subsequent calculations are invalid. You must treat these parameters as you would an engineering blueprint.

The 6 Core Parameters You Must Collect

Precise Lid/Panel Geometry

- Length, Width, and Thickness.

Precise Lid/Panel Weight (W)

- How to get it: Use the mass properties function in your CAD software or physically weigh the part after fabrication.

Lid/Panel Center of Gravity (COG)

- Why COG is more important than weight: Its location dictates the *trueforce required to move the lid.

- How to find it: For a uniform panel, it is at the geometric center. For panels with attachments (stiffeners, handles, windows), you must calculate it or find it in your CAD model.

Lid/Panel Material

- Examples: A36 Carbon Steel, 304 Stainless Steel (per ASTM A240), 6061 Aluminum (per ASTM B209), or composites.

- This directly impacts weight, rigidity, and the mounting method.

Mounting Frame Geometry and Material

- What are you mounting the hinge to? Is it thin-wall sheet metal, a thick steel plate, or concrete? This determines the required fastener type.

Motion and Positioning Requirements

- What angle does the lid need to open to? (e.g., 90°, 105°, 180°).

- What is the mounting orientation? (Is it a horizontal lid (top-opening), a vertical door (side-opening), or angled?).

With this raw data collected, we can begin the engineering calculations.

Step Two: Core Calculations (Understanding and Quantifying Forces)

Torque Calculation and Safety Factor (Force × Distance)

소개

Hinge selection is a science of “torque,” not just “weight.” A 50 kg lid that is very wide can be far more difficult and dangerous to operate than a narrow 50 kg lid.

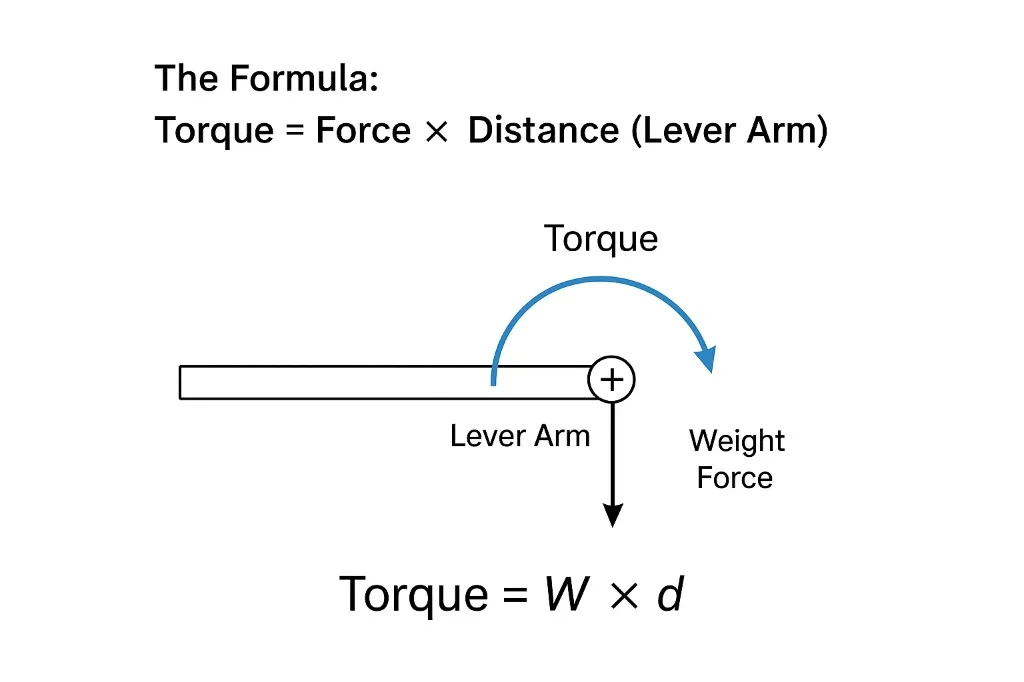

Key Concept: What is Torque?

- Torque is the rotational force that causes an object to rotate HyperPhysics – Torque

- The Formula: Torque = Force × Distance (Lever Arm)

- In This Application: Torque = Lid Weight × Horizontal Distance from the Hinge Pivot to the Lid’s COG.

How to Calculate Your “Maximum Lid Torque”

This is the decisive value for selecting any assisted or counterbalance hinge.

Determine the Lever Arm

- This is the horizontal distance from the hinge’s pivot point to the Center of Gravity (COG) when the lid is in the closed (horizontal) position.

Perform the Calculation

- Formula: Torque (N·m) = Weight (kg) × 9.81 (m/s²) × Lever Arm (m)

- Note: 9.81 m/s² is the acceleration due to gravity.

Calculation Example

- Application: A uniform steel access hatch.

- Weight (W): 40 kg

- Geometric Width: 1.0 m (hinged at the far edge)

- COG: Uniform, located at the geometric center, 0.5 m from the hinge pivot.

- Calculation:

Torque = 40 kg × 9.81 m/s² × 0.5 m

Maximum Torque = 196.2 N-m

Define Your Operational Goal

With your torque value, you must now define what the hinge system needs to do.

Pure Hinging (Support Only)

- The user must lift the full weight. The hinge only provides a pivot.

- Suitable for “heavy-duty” lids with relatively low torque.

Lift-Assist

- Reduces the user’s “perceived lift weight” to make opening easier.

- For example, reducing a 40 kg perceived force to 5 kg to meet ergonomic standards (see ISO 11228-2 for push/pull recommendations).

Counterbalance

- The lid “hovers” at any angle within its range of motion, feeling virtually weightless. This is the safest, most ergonomic solution.

Damping / Soft-Close

- Controls the closing speed to prevent slamming. It provides no lift assistance.

Now you have a specific torque value (e.g., 196.2 N-m) and a clear operational goal (e.g., C: Counterbalance). You can finally start reviewing hinge solutions.

Step Three: Classifying and Selecting Hinge Solutions

소개

“Heavy-duty hinge” is not a single category; it is a spectrum of solutions. We will explore them based on the goal you defined in Step 2.

Solution Category : Standard Heavy-Duty Hinges (Non-Assisted)

What They Are:

- 웰드온 힌지

- Heavy-Duty Continuous Hinges (Reference standard ANSI/BHMA A156.26:2019 – Continuous Hinges)

- Pivot Hinges

Pros:

Structurally simple, extremely robust, relatively low cost, very long cycle life.

Cons:

Provide zero torque assistance. The operator bears the full weight and torque of the lid.

Best For:

“Goal A: Pure Hinging.” Often used in combination with external lift systems (Category 3).

Solution Category : Counterbalance Hinges (Built-in Assist)

What They Are:

- Mechanical Spring Counterbalance Hinges

- Torsion Spring Hinges

How They Work:

- Powerful spring mechanisms (mechanical, torsion, or gas) are integrated into the hinge body.

- Their output torque is precisely engineered to offset the lid torque you calculated in Step 2.

How to Select:

- Key: You must match your calculated torque value (e.g., 196.2 N-m) to the manufacturer’s “hinge torque rating.”

- Manufacturers provide a torque range (e.g., 190-210 N-m). Your calculated value must fall within this range.

Pros:

All-in-one solution, makes lids feel “weightless,” extremely safe, and highly ergonomic.

Cons:

Higher cost, often larger footprint, requires high installation precision.

Best For:

“Goal C: Counterbalance.” This is the optimal solution for heavy, top-opening access lids.

Solution Category: External Lift-Assist Systems (Used with Standard Hinges)

What They Are:

- Gas Springs / Struts

How They Work:

- They are separate components installed alongside Standard Heavy-Duty Hinges (Category 1) to provide lift-assist.

Key Challenge:

- Gas spring selection and mounting point calculations are notoriously complex.

- Incorrect mounting geometry will cause the spring to fail, provide the wrong force, or even prevent the lid from closing.

Pros:

Moderate cost, easily replaceable.

Cons:

Occupy extra space, complex installation calculations, sensitive to temperature, finite lifespan (will fail after X-thousand cycles).

Best For:

“Goal B: Lift-Assist.” Used when an all-in-one counterbalance hinge (Category 2) is not feasible due to cost or space.

Solution Category : Damping and Soft-Close

What They Are:

- Dampers or hinges with integrated damping.

How They Work:

- They provide a resistive force opposite the direction of motion to slow it down. They do not provide lift.

Best For:

“Goal D: Soft-Close.” Used to protect equipment and operators from slamming lids (especially on vertical doors).

Once the hinge function is defined, we must ensure it can survive in its intended environment.

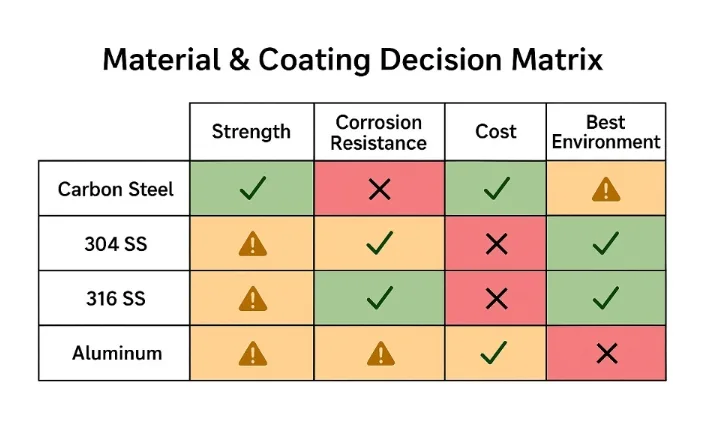

Step Four: Material, Coating, and Environmental Assessment

Material & Coating Decision Matrix

소개

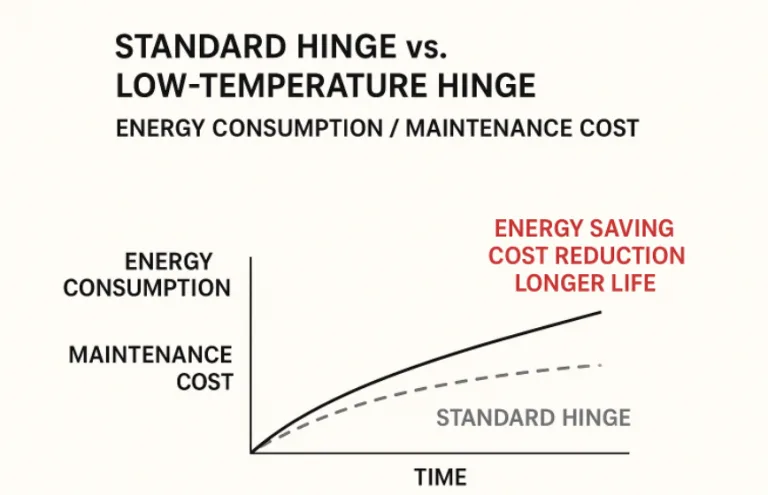

A functionally correct hinge that fails from corrosion is still the wrong choice. The environment dictates the material.

Base Material Selection

Use this table to guide your material decision:

| 재료 | Pros | Cons | Reference Standard | Best For… |

|---|---|---|---|---|

| 탄소강 | High strength, low cost | Very susceptible to rust | ASTM A36 / A108 | Dry, indoor environments (must be coated) |

| 304 스테인리스 스틸 | Good corrosion resistance, high strength | Higher cost than steel | ASTM A240 / A276 | Indoor, general outdoor, food processing |

| 316 스테인리스 스틸 | Excellent corrosion resistance (chloride-resistant) | Highest cost | ASTM A240 / A276 | Marine, coastal, chemical processing |

| Aluminum | Lightweight, good corrosion resistance | Much lower strength than steel | ASTM B221 / B209 | Light-load applications, not for main structural points |

Coatings and Finishes (for Carbon Steel)

Zinc Plating:

Basic rust protection for dry, indoor environments.

Hot-Dip Galvanizing:

A thick (>45µm) protective layer for outdoor environments. Durability and coating performance can be evaluated per ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus

Powder Coating:

Provides good protection and aesthetic color options, but a scratch can become a point of failure.

Pivot Pin and Bushing Details

The “pivot pin” and “bushings” determine the hinge’s service life. For heavy-duty applications, look for:

- Hardened steel pins.

- Bronze or Nylon bushings.

- Bushings reduce metal-on-metal friction and wear, which is especially important on stainless steel or aluminum hinges.

You have calculated the torque, selected the type, and specified the material. The final step is ensuring it is installed correctly and will last.

Step Five: Installation, Maintenance, and Safety Considerations

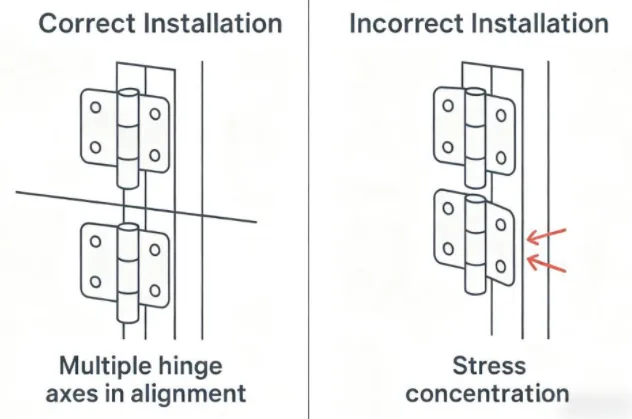

Hinge Alignment: Correct vs Incorrect Installation

소개

The best hinge in the world will fail quickly if installed improperly.

Key Point : Alignment

This is the most common installation failure.

- When using two or more hinges, their pivot pins must be in a single straight line (co-linear).

- Slight misalignment (even 1 mm) increases the load on the hinges exponentially, causing them to bind, squeak, and wear out extremely fast.

- Installation Tip: Use a long, straight rod, a level, or a laser level to ensure all hinge knuckles are perfectly aligned.

Key Point : Mounting Surface and Fasteners

- The mounting surface must be flat and rigid enough to handle the full torque transferred by the hinge.

- Avoid self-tapping screws for heavy-duty applications.

- Preferred: Through-bolts, nuts, and washers.

- Use graded fasteners (e.g., ISO 4014 / 4017 (bolts) and ISO 4032 (nuts)).

- Prevent 갈바닉 부식: Match the fastener material to the hinge material (e.g., 316 SS bolts for 316 SS hinges).

- In high-vibration environments, a thread-locking compound or locking nuts are mandatory.

Key Point : Weld-On Considerations

- Ensure hinges are perfectly aligned and fixtured *beforewelding.

- Control heat input to prevent the hinge’s pivot area from warping or seizing.

- If the hinge has nylon or plastic bushings, they must be removed before welding or protected from the heat.

Maintenance and Inspection

Cycle Life:

What does a manufacturer’s “20,000 cycle” rating mean? This is a rating based on lab testing, often defined by standards like ANSI/BHMA A156.1:2016 – Butts and Hinges. Your real-world life will depend on the load and environment.

Periodic Inspection:

Look for signs of wear (e.g., pin “walking,” lid sagging from bushing wear, hole elongation).

Lubrication:

Follow manufacturer recommendations. Many heavy-duty hinges with bushings are maintenance-free. Keep the pivot area clean from debris.

Conclusion: Your Heavy-Duty Hinge Selection Checklist

Recapping the Process

Selecting a heavy-duty hinge is an engineering process. It starts with data (weight, COG), moves to calculation (torque), and only then ends with product selection (type, material).

The Engineer’s Final Checklist

Before finalizing your design, confirm “yes” to all of the following:

- Do I have the precise weight and Center of Gravity (COG) of my lid?

- Have I calculated the maximum lid torque in N-m (or lb-in)?

- Have I clearly defined my operational goal (Hinging, Assist, or Counterbalance)?

- Does my selected hinge’s (or hinge + gas spring) torque rating match my calculation?

- Is my selected hinge material (e.g., 316 SS) appropriate for my operating environment (e.g., marine)?

- Do I have a clear installation plan to ensure all hinge pivots are perfectly co-linear?

- Have I specified the correct fasteners (material, type, and grade)?

Final Thought

Do not guess. The time invested in calculation upfront prevents safety incidents, equipment damage, and costly rework later. A smooth, safe, and easily operable heavy-duty lid is the direct result of quality engineering.