리프트 오프 힌지: 편의성 대 보안성(심층 분석)

In modern industrial maintenance, data center management, and specialty vehicle manufacturing, “downtime” is one of the greatest costs. When frequent service or cleaning is required, traditional fixed hinges become a bottleneck to efficiency.

This is where Lift-Off Hinges, also known as Detachable Hinges or Flag Hinges, come into play. Their design is built for a single, clear purpose: to allow a door or panel to be “lifted off” and removed entirely without tools.

But is this convenience suitable for every scenario? Does this design sacrifice security or durability?

This article provides a deep-dive analysis of the core advantages and potential drawbacks of lift-off hinges, explores key applications, and offers a detailed selection guide to help you decide if they are the right choice for your next project.

What Exactly is a Lift-Off Hinge? Deconstructing the Mechanism

도구 없이 도어를 제거하는 수직 리프트 오프 모션.

The Core Mechanic: Two Independent Leaves Working in Concert

Definition

Explaining its construction—it consists of two separate leaves. One leaf (typically on the frame) features a fixed pin. The other leaf (typically on the door) has an open knuckle or sleeve that slides over the pin.

The Workflow

Describing the “lift-to-remove” action. Emphasizing that the door must be opened to a certain angle (usually 90° or 180°) before it can be lifted free.

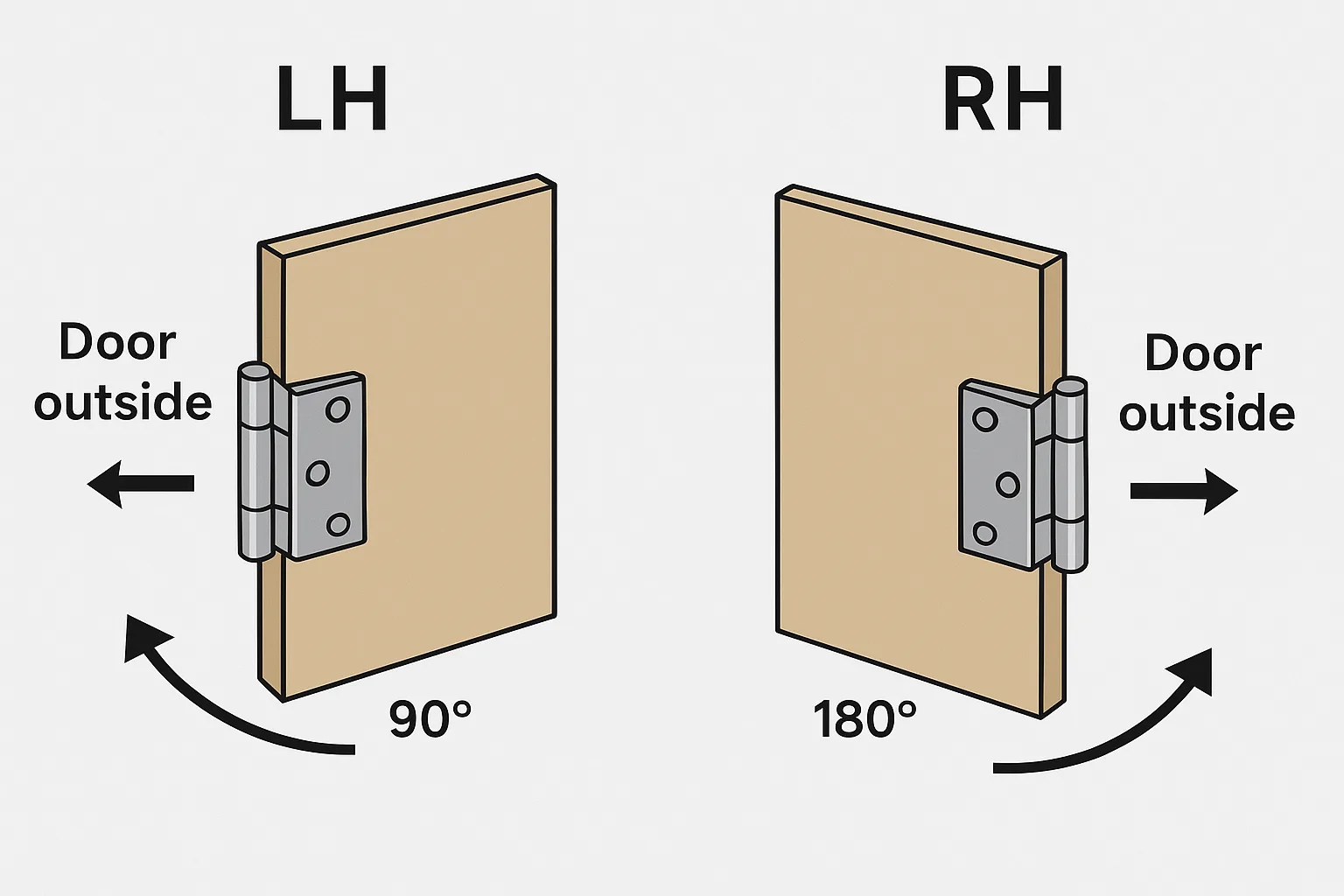

The Critical Distinction: Left-Hand (LH) vs. Right-Hand (RH) Configurations

The Critical Distinction: Left-Hand (LH) vs. Right-Hand (RH) Configurations

This is the single most critical feature of a lift-off hinge.

Detailed Explanation

How to determine the “handing” (e.g., standing outside the door, if the hinges are on your left and the door swings out toward you, you need a Left-Hand hinge).

According to ANSI/BHMA A156.1-2021 (Butts and Hinges), hinges are defined as “handed” products that must be correctly specified during design and procurement.

Emphasis

Once manufactured and installed, the handing cannot be changed. This is one of the biggest pitfalls in procurement and design.

Determining the correct Left-Hand or Right-Hand hinge is crucial; see our detailed LH/RH selection and installation guide for step-by-step instructions, including diagrams and industry standards reference.

Main Types and Materials

By Mounting

Surface-mount, weld-on, countersunk.

자료별

| 재료 | Properties | Ideal Application |

|---|---|---|

| Stainless Steel (304/316) | Excellent corrosion resistance, hygienic grade | Food processing, medical, marine, high-corrosion environments |

| Steel / Zinc-Plated Steel | High strength, heavy-duty load capacity | Industrial enclosures, heavy-duty doors, high-strength applications |

| Aluminum | Lightweight, corrosion-resistant | Aerospace, lightweight doors, weight-sensitive applications |

| Nylon / Plastic | Insulative, lightweight, cost-effective | Electrical cabinets (non-conductive), light-duty applications |

Core Advantages: Why Lift-Off Hinges are an Industrial Favorite

Maximized Maintenance Efficiency

Value: Enables full 360° access for inspection, repair, and part replacement—no obstruction, no partial openings.

Scenario: In electrical cabinets or complex machinery, technicians can remove the door completely for full visibility and workspace.

Result: Reduced downtime and labor costs through faster service operations.

Lift-off hinges enable full door removal for maintenance and cleaning—learn more about easy disassembly and hygiene benefits

in our step-by-step guide, which details applications in industrial, medical, and food processing environments.

Simplified Installation and Transport

Value: Enhances assembly efficiency and worker safety.

Scenario: For large or heavy enclosures (e.g., server racks, acoustic chambers), the frame can be installed first, followed by an easy door placement on hinge pins.

Result: Lower installation risk and faster setup time.

Hygienic and Easy-to-Clean Design

Value: Meets strict hygiene standards (NSF, FDA, etc.).

Scenario: In food, pharmaceutical, or medical environments, lift-off hinges allow complete door removal for thorough cleaning and sterilization.

Result: Eliminates bacterial buildup risks—essential for sanitary compliance.

Optimized Space Utilization and Emergency Access

Value: Provides flexibility in constrained environments.

Scenario: In narrow corridors or data center aisles, removing the door creates a temporary wide passage for large equipment or safe egress.

Result: Improved operational adaptability and safety.

Streamlined Supply Chain Modularity

Value: Enables flexible, modular assembly.

Scenario: Manufacturers can standardize door and frame designs, installing left- or right-hand hinges only at final assembly.

Result: Simplifies inventory management and reduces SKU complexity.

Key Disadvantages (The “Cons”): When to Avoid Lift-Off Hinges

However, no hardware solution is perfect. You must be aware of these limitations before committing to a design.

The Security and Theft Risk

The Core Problem

Easy to remove = easy for unauthorized personnel to remove.

In-Depth Analysis

This is the hinge’s greatest “Achilles’ Heel.” They are absolutely unsuitable for exterior security doors, safes, or any application needing to defend against physical intrusion. Even internally, if the contents of the cabinet are of high value, you should think twice.

The Handing Nightmare (Rigid Configuration)

The Core Problem

Complexity in procurement and design.

In-Depth Analysis

Re-stating the LH/RH problem. One purchasing error (ordering 100 LH hinges when you needed RH) can bring an entire production line to a halt. This also increases inventory complexity (doubling the SKUs).

Load Capacity and Stability (Relatively Speaking)

The Core Problem

Potential risk under heavy dynamic loads.

Comparison

Compared to heavy-duty continuous (piano) hinges or multi-point weld-on barrel hinges, the single pin of a lift-off hinge may experience faster wear, especially when supporting extremely heavy doors (e.g., over 200kg / 440lbs) or in high-frequency use.

Potential Issues in High-Vibration Environments

The Core Problem

The door can “jump” or “walk” off the pin due to severe vibration.

Scenario Analysis

When used on specialty vehicles, marine engine rooms, or vibrating machinery, constant, violent shaking can cause the door to dislodge. This requires additional locking mechanisms (like compression latches) to hold the door firmly in place.

Dependence on Installation Precision

The Core Problem

High alignment requirements.

In-Depth Analysis

The leaves of both (or all three) hinges must be aligned on a perfectly vertical axis. If they are misaligned, the door will bind, making it extremely difficult to lift off or replace.

Proper installation and alignment are critical; follow our detailed installation instructions to ensure smooth operation and avoid misalignment issues. The guide includes tools, step-by-step procedures, and common mistakes to prevent.

Application Analysis: Where Lift-Off Hinges Shine

| Category | Examples | Reason / Advantage |

|---|---|---|

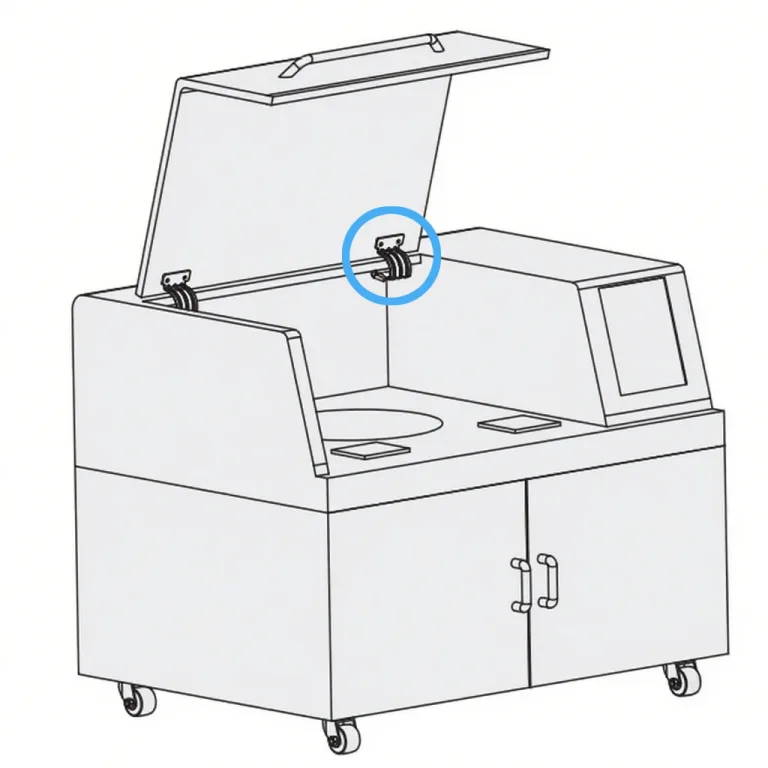

| Industrial Machinery & Automation | CNC machine guards, robotic work cell safety doors, conveyor belt access panels | Requires frequent maintenance, calibration, and tool changes |

| Electrical Enclosures & Data Centers | Server racks (especially side panels), NEMA enclosures, PDU cabinets | Easy access for wiring, component upgrades, and airflow management |

| Medical, Pharmaceutical & Food Processing | Stainless steel cabinetry, sterilization equipment, modular cleanroom panels | Strict hygiene and complete washdown requirements |

| Specialty Vehicles & Transport (Interior) | RV interior storage lockers, ambulance equipment bays, marine internal access hatches | Limited space requiring maximum access for internal repairs |

| Modular Construction & Exhibits | Temporary partition walls, mobile kiosks, trade show booths | Need for rapid setup and teardown |

The Ultimate Selection Guide: How to Choose the Right Hinge

If you’ve determined a lift-off hinge is the right direction, follow this checklist to avoid common purchasing errors.

(Most Important): Confirm the Handing

Provide a clear diagram or use the “Golden Rule” to determine LH/RH. (e.g., “Stand on the outside of the enclosure. Which side are the hinges on?”)

Calculate Load & Moment

It’s not just about door weight. You must consider the door width (the moment arm)ANSI/BHMA A156.1-2021. Rule of Thumb: The wider the door, the greater the pulling force on the top hinge.Check the manufacturer’s “Max Load Rating.” Hinge Quantity: Is it better to use 2 heavy-duty hinges or 3 medium-duty ones?

Match Material to Environment

Reiterate: 316 SS for saltwater/chemical exposure; 304 SS for moisture/food; Steel for dry/high-strength; Plastic for insulation.

Compare Competitors: Lift-Off vs. Removable Pin Hinges

The table below clarifies the key differences:

| Feature / Type | Removable Pin Hinge | Lift-Off Hinge |

|---|---|---|

| Disassembly Method | Pin must be tapped out using a tool | No tools required |

| Loose Parts | Pin can be easily lost | No loose parts |

| Ease of Use | Requires effort and tools | Quick and convenient |

| Best For | Occasional door removal | Frequent door removal |

| 결론 | – | ✅ Clear winner for frequent removal |

결론

Lift-off hinges are a double-edged sword in industrial design, offering unmatched convenience, maintenance efficiency, and hygiene benefits. However, this ease of use comes at the cost of reduced physical security. In general, if your application is internal, requires frequent maintenance, and prioritizes hygiene or spatial flexibility, lift-off hinges are an excellent choice for improving operational efficiency. Conversely, for external, high-security, or high-vibration environments, heavy-duty fixed hinges combined with reliable locking mechanisms are the safer and more durable option.

자주 묻는 질문

Q1. How do I 100% confirm if I need a Left-Hand or Right-Hand hinge?

This is the most critical and easily-confused question. The industry standard is: Stand on the OUTSIDE of the door/enclosure (i.e., the side from which you would PULL the door toward you to open it). If the hinge knuckles are on your LEFT, you need a Left-Hand (LH) hinge. If the hinge knuckles are on your RIGHT, you need a Right-Hand (RH) hinge. Advice: Always test with a sample or provide a clear drawing to your supplier before placing a bulk order.

Q2. Are lift-off hinges really insecure? Are there ways to make them safer?

By design, they are not high-security. However, you can improve security with a hybrid approach: Solution 1 (Hybrid Install): Use two lift-off hinges and one fixed hinge (or a hinge with a security stud) on the same door. This prevents a simple “lift-off” theft but still allows removal after removing the fixed hinge. Solution 2 (Auxiliary Locking): This is the best way. Combine the hinges with one or more strong compression latches or a key lock. The lock provides the security, while the hinge provides the convenience after it’s been unlocked.

Q3. Are lift-off hinges harder to install than traditional hinges?

Yes, in one specific way: Alignment. The pins of the two (or more) hinges must be on a perfectly vertical line. If they are even slightly misaligned, the door will bind when you try to lift it or set it back in place. We highly recommend using a laser level or precision jig during installation, not just an eyeball estimate.

Q4. How do I know how many hinges my heavy door needs?

This is an engineering question that cannot be answered by “Total Door Weight ÷ Hinge Load Rating.” You must account for the Load Moment (the width of the door). Key Point: The wider the door, the more “pulling” force is exerted on the top hinge. A rule of thumb is that 75% of the radial load is borne by the top hinge. Always consult the manufacturer’s Load Charts or provide your door weight and width to an engineer for a proper calculation.

Q5. Is a “Flag Hinge” the same as a “Lift-Off Hinge”?

Yes, in the North American market, these terms (along with “Detachable Hinge”) are essentially interchangeable. The name “Flag Hinge” comes from the appearance of one leaf, which sticks out from the door like a flag. They all refer to the same design that allows a door to be vertically lifted off its pins.

Q6. Can I use them on vibrating equipment (like generator enclosures or specialty vehicles)?

We generally do not recommend it for high-vibration applications. The constant shaking can cause the door to “jump” or “walk” up the pin and dislodge, which is a major safety hazard. The Exception: If you must use them (e.g., for maintenance access), they must be paired with heavy-duty compression latches or other locking devices. The compressive force of the latch holds the door down firmly against the frame, preventing it from “jumping” vertically.