Expositores de dispositivos médicos soltos? Dobradiças de torque travam os ângulos com precisão

Expositor médico com dobradiça de binário para ângulo ajustável

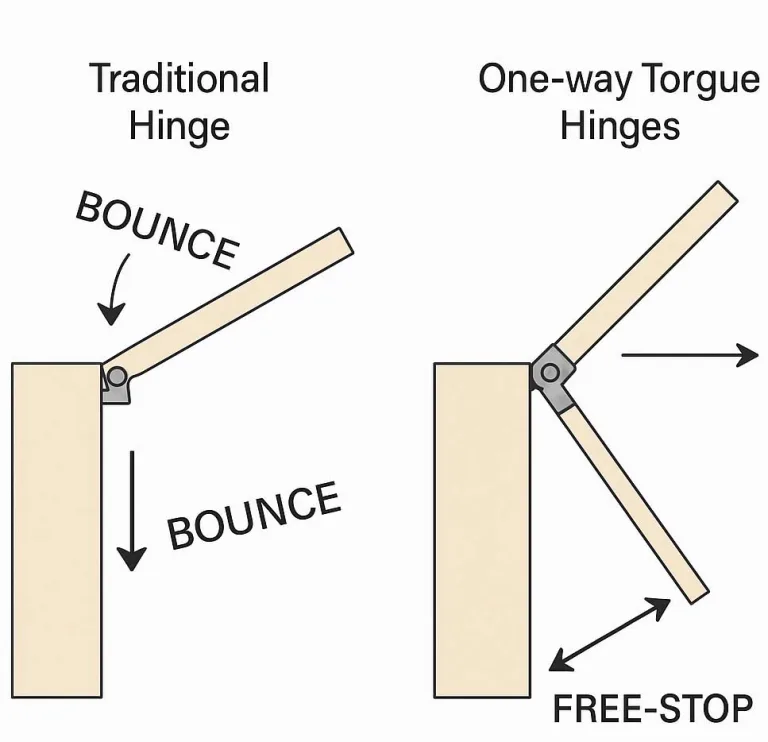

Nos blocos operatórios ou salas de exame, o pessoal médico ajusta frequentemente o ângulo dos ecrãs do equipamento. As dobradiças convencionais fazem frequentemente com que os ecrãs se soltem ou deslizem para baixo, afectando gravemente a eficiência operacional e a precisão do diagnóstico. As dobradiças de binário resolvem este desafio. Como o nome sugere, as dobradiças de binário mantêm um ângulo fixo sob força, permitindo que os ecrãs mantenham qualquer posição sem apoio adicional. Ao incorporar o binário adequado em placas de fricção internas ou mecanismos de amortecimento, a dobradiça gera uma resistência estável contra o ecrã, permitindo a funcionalidade de bloqueio automático.

Este artigo explora o papel crítico das dobradiças de binário no equipamento médico, os seus princípios técnicos, critérios de seleção e tendências futuras.

Requisitos especiais para dobradiças em dispositivos médicos: Porque é que as dobradiças padrão são insuficientes

Elevada precisão e estabilidade

Os ecrãs médicos têm de fornecer imagens nítidas em ângulos precisos; qualquer oscilação pode induzir em erro o diagnóstico. As dobradiças de binário proporcionam uma resistência quase constante, mantendo os ecrãs estáveis em ângulos definidos e eliminando o desvio do ângulo ou a instabilidade causada pelo afrouxamento da dobradiça.

Design estéril e resistente à corrosão

Os ambientes médicos exigem esterilização frequente. Os materiais das dobradiças utilizam normalmente aço inoxidável AISI 304/316, resistente à corrosão por desinfectantes, com superfícies lisas que facilitam a limpeza e evitam a proliferação de bactérias. Isto garante que as dobradiças de torque mantêm a segurança higiénica a longo prazo sem enferrujar ou contaminar o ambiente.

Elevada capacidade de carga e durabilidade

Os ecrãs médicos excedem frequentemente o equipamento padrão em tamanho e peso, exigindo dobradiças que suportem cargas pesadas, mantendo a estabilidade a longo prazo. As dobradiças de binário de qualidade superior proporcionam uma saída de binário consistente mesmo após dezenas de milhares de testes de fadiga, excedendo frequentemente os 20.000 ciclos(Relativamente às normas de ensaio à fadiga). Isto assegura um desempenho de amortecimento consistente sem degradação significativa, garantindo um funcionamento fiável durante períodos prolongados.

Suavidade operacional

O pessoal médico necessita frequentemente de ajustar rapidamente os ângulos do ecrã com uma só mão. As dobradiças devem proporcionar uma resistência uniforme e um funcionamento suave. As dobradiças de binário controlam a velocidade do movimento através de fricção interna, não necessitando de apoio quando libertadas e fechando lenta e suavemente para evitar impactos súbitos. Isto permite que os médicos e enfermeiros ajustem sem esforço os ecrãs com uma mão, evitando interrupções no fluxo de trabalho ou lesões nos dedos causadas por dobradiças defeituosas.

Estas caraterísticas ditam coletivamente que as dobradiças para equipamento médico devem ter um desempenho excecional. As dobradiças industriais normais têm dificuldade em cumprir estes requisitos rigorosos, sendo necessário utilizar dobradiças de binário especificamente concebidas para aplicações médicas. Ao selecionar as dobradiças, verifique se possuem certificações relevantes e se os seus materiais e construção cumprem as normas de qualidade médica para garantir a segurança e fiabilidade do equipamento.

Análise da tecnologia de base das dobradiças de binário

A chave para as dobradiças de binário reside na resistência gerada pela fricção. Quando o utilizador move o ecrã, as placas de fricção dentro da dobradiça criam uma resistência que contraria o binário de rotação aplicado, permitindo o bloqueio automático em qualquer ângulo. Por outras palavras, desde que o binário nominal da dobradiça exceda o binário de rotação gerado pelo ecrã, o ecrã permanece firmemente bloqueado no ângulo definido.

Componentes principais

A dobradiça de binário é constituída essencialmente por um veio de liga de precisão, discos de fricção em aço inoxidável ou materiais sintéticos resistentes ao desgaste e molas de pré-carga.

- O veio de liga de alta resistência assegura a integridade estrutural.

- Os discos de fricção - normalmente compostos por polímeros ou compósitos de fibras - oferecem uma resistência excecional ao desgaste e à fadiga.

- As molas (por exemplo, molas de disco) aplicam uma pré-carga às superfícies de atrito, permitindo uma resistência ao atrito estável e controlável.

Estes componentes funcionam em sinergia para proporcionar uma saída de binário previsível e constante para o ecrã.

Cálculo do binário

As fórmulas básicas da física determinam o valor do binário necessário. Especificamente, o binário necessário $\tau$ é igual ao produto da força externa F (que representa o peso do ecrã) e a distância do braço de alavanca d ($\tau = F \times d$). Aqui, F pode ser obtido multiplicando a massa pela força gravitacional, enquanto d é a distância horizontal entre o centro de gravidade do ecrã e o eixo da dobradiça. Assegurar que o valor nominal da dobradiça de binário selecionada excede o momento gerado pelo biombo para garantir um posicionamento seguro em qualquer ângulo. Uma prática comum é selecionar um binário ligeiramente superior ao valor calculado para ter em conta factores como o envelhecimento do material de fricção.

Ajustamento e tolerância

As dobradiças de binário apresentam normalmente um mecanismo de ajuste, permitindo uma afinação fina da saída de binário através de parafusos ou botões para acomodar as variações de peso do ecrã. Note-se que os fabricantes especificam normalmente um intervalo de tolerância de binário, como ±20%. Durante a seleção, certifique-se de que a estabilidade do ecrã se mantém dentro deste intervalo de tolerância. Ao montar, emparelhe as dobradiças com valores de binário correspondentes para evitar que um dos lados fique demasiado apertado ou demasiado solto.

Em resumo, o núcleo técnico das dobradiças de binário reside no fornecimento de uma resistência estável através de estruturas de fricção internas, combinadas com um binário cientificamente calculado com base em parâmetros de visualização. A compreensão destes princípios ajuda a selecionar modelos de dobradiças de binário adequados para equipamento médico.

Considerações chave para a seleção de dobradiças de torque

Determinar o valor do binário

Antes de selecionar uma dobradiça de binário, calcule o binário teórico com base no peso e no centro de gravidade do ecrã:

τ=F×d

em que FFF é a força do peso (N) e ddd é a distância do eixo da dobradiça ao centro de gravidade (m). Para um autobloqueio fiável, escolher uma dobradiça com um binário nominal ligeiramente superior ao valor calculado.

| Visor Peso (kg) | Distância CG (m) | Binário teórico (N-m) | Binário nominal recomendado (N-m) |

|---|---|---|---|

| 5 | 0.15 | 7.35 | 8-9 |

| 10 | 0.2 | 19.6 | 22 |

| 15 | 0.25 | 36.75 | 40 |

Durabilidade e vida útil à fadiga

As dobradiças médicas têm de passar por rigorosos testes de fadiga para garantir a fiabilidade a longo prazo. As dobradiças de binário de alta qualidade apresentam uma variação mínima da saída de binário após dezenas de milhares de ciclos de abertura/fecho, excedendo frequentemente os 20.000 ciclos. Solicite relatórios de testes de vida útil ou dados de certificação aos fornecedores durante a seleção para garantir que as dobradiças não falharão devido à degradação por fadiga ou fricção na utilização real.

Compatibilidade material e ambiental

Dê prioridade às dobradiças de aço inoxidável (por exemplo, 304, 316) para garantir a resistência à corrosão e a tolerância à exposição a desinfectantes. Os acabamentos de superfície devem ser lisos, sem fendas, para facilitar a limpeza e a esterilização. Para os componentes de fricção interna, selecione plásticos de engenharia de qualidade médica ou compósitos de fibra para evitar a libertação de químicos nocivos. Para além disso, os materiais devem manter um desempenho estável em funcionamento de alta frequência e temperaturas extremas, sem envelhecimento devido a flutuações de temperatura ou agentes de limpeza.

Métodos de instalação e integração

Selecione os métodos de montagem adequados com base na estrutura do equipamento. As opções mais comuns incluem a montagem em painel e a montagem embutida.

- As dobradiças embutidas requerem cortes precisos no armário, mas oferecem uma aparência perfeita.

- A montagem em painel é mais simples, mas consome um pouco mais de espaço.

Durante a instalação, certifique-se de que o eixo de rotação da dobradiça está alinhado com a orientação do design do ecrã para um ajuste ótimo. Deixe espaço suficiente para evitar interferências com os componentes circundantes durante o movimento da dobradiça.

| Tipo de montagem | Profundidade necessária (mm) | Tolerância do furo (mm) | Gama de rotação (°) | Folga (mm) |

|---|---|---|---|---|

| Montagem em painel | 20 | ±0.2 | 180 | ≥5 |

| Montagem embutida | 18 | ±0.15 | 180 | ≥5 |

Seleção de fornecedores

As dobradiças médicas são componentes críticos; dê prioridade a fabricantes com certificações profissionais e conhecimentos técnicos. Marcas mundialmente reconhecidas como Hanaya, Sugatsune, Southco e HTAN possuem uma vasta experiência em tecnologia de dobradiças de binário.

| Fornecedor | Certificações ISO/FDA | Taxa de adoção de produtos | Apoio técnico | Capacidade de personalização |

|---|---|---|---|---|

| Hanaya | ISO 13485 | 80% | Sim | Sim |

| HTAN | ISO/FDA | 85% | Sim | Sim |

| Sugatsune | ISO 13485 | 75% | Sim | Sim |

| Southco | ISO/FDA | 70% | Sim | Sim |

Aplicações inovadoras e tendências futuras das dobradiças de binário

À medida que a tecnologia médica avança, as dobradiças de torque encontram aplicações em expansão.

Miniaturização e dispositivos portáteis

As tendências de miniaturização permitem a sua utilização em instrumentos cirúrgicos e dispositivos de monitorização portáteis. Por exemplo, as dobradiças de binário em miniatura podem ser integradas em endoscópios, braços robóticos e monitores de ECG portáteis, permitindo estruturas de dispositivos mais compactas, assegurando simultaneamente um movimento suave e duradouro.

Sistemas hospitalares inteligentes

Nas camas hospitalares inteligentes e nos sistemas de enfermarias, os futuros projectos podem combinar dobradiças de binário com sensores e mecanismos de ajuste elétrico para conseguir um ajuste automático do ângulo e um controlo remoto, aumentando ainda mais a automatização e o conforto nos cuidados aos doentes.

Telemedicina e cirurgia robótica

A crescente adoção da telemedicina e cirurgia robótica exige maior estabilidade e precisão das dobradiças. As dobradiças de binário da próxima geração utilizarão materiais de fricção avançados e técnicas de maquinação de precisão para cumprir os requisitos de posicionamento ao nível do mícron, suportando movimentos de alta precisão em robôs cirúrgicos e dispositivos de monitorização médica.

Integração da robótica e da IA

As soluções inovadoras de micro dobradiças de binário permitem um movimento de articulação mais flexível e fiável, facilitando operações de alta precisão em ambientes complexos. Em geral, as dobradiças de binário desempenharão um papel cada vez mais vital em dispositivos médicos portáteis, quartos de hospital inteligentes e equipamento inteligente. A sua integração com tecnologias de controlo de sensores irá impulsionar os dispositivos médicos para uma nova era de inteligência.

Conclusão: Dobradiça pequena, grande valor

Apesar do seu tamanho compacto, as dobradiças de binário têm um impacto direto na segurança e na capacidade de utilização do equipamento médico. Uma dobradiça de binário bem concebida garante uma retenção precisa do ângulo de visualização, um funcionamento suave e uma maior fiabilidade do dispositivo. Os fabricantes de dispositivos médicos devem dar prioridade à seleção de dobradiças desde a fase inicial do design, tratando-as como componentes críticos que requerem uma correspondência cuidadosa. Cada detalhe de hardware é importante para a vida e a saúde - uma dobradiça de binário despretensiosa é precisamente o que garante um posicionamento preciso do ecrã e uma maior longevidade do dispositivo. Só através de uma seleção rigorosa e de uma inovação contínua é que os dispositivos médicos podem oferecer o máximo valor de utilização, proporcionando segurança e comodidade tangíveis para médicos e doentes.

FAQ

P: As dobradiças de binário podem resolver o problema dos ecrãs soltos?

R: Sim. As dobradiças de binário utilizam a fricção para bloquear automaticamente o ecrã em qualquer ângulo, evitando o deslizamento.

P: Porque é que os expositores médicos não podem utilizar dobradiças normais?

R: As dobradiças standard são propensas a afrouxar e a apresentar ângulos instáveis, comprometendo a eficiência operacional e a precisão do diagnóstico.

P: Como é que as dobradiças de torque garantem a resistência à corrosão e a higiene?

R: Construído em aço inoxidável 304/316 com uma superfície lisa, fácil de limpar e resistente à corrosão por desinfectantes.

P: Como selecciono as dobradiças com os valores de binário adequados?

R: Calcule o binário necessário com base no peso do ecrã e no centro de gravidade e, em seguida, escolha dobradiças com valores de binário nominal ligeiramente superiores.

P: As dobradiças de torque podem suportar uma utilização prolongada?

R: As dobradiças de alta qualidade mantêm um desempenho estável após 10.000 ciclos e podem exceder 20.000 ciclos de vida útil.