How Torque Hinges Improve Electrical Cabinet Efficiency

Introduction: Why Accessibility and Maintainability Matter for Electrical Cabinets

Electrical cabinets play a critical role in industrial automation, power distribution, and control systems, safeguarding and managing internal electrical components. These enclosures protect against dust and moisture, extending equipment lifespan. More importantly, their enclosed structures isolate live parts, reducing electric shock risks and complying with safety regulations such as IEC 61140 (Protection against electric shock) et IEC 60529 (IP ratings) [IEC Official Website]. However, designing and maintaining electrical cabinets presents significant challenges. Complex internal wiring and confined spaces often make tight corners difficult to access for repairs. If maintenance personnel cannot quickly open and secure cabinet doors, routine inspections and component replacements become cumbersome and time-consuming. To overcome these issues, many manufacturers are adopting a clever mechanical solution: torque hinges.

What Are Torque Hinges? How Do They Work?

Charnière à couple de 360° qui maintient la position à n'importe quel angle

A torque hinge, also known as a constant-torque hinge or friction hinge, is a specially designed hinge that provides continuous resistance through internal friction or spring mechanisms across any angle range, thereby holding the door panel in position. In other words, the torque hinge automatically locks the door panel in the open position without requiring additional support devices. Its internal structure typically includes two hinge bodies with embedded friction discs, spring washers, or plastic shims. When the cabinet door opens or closes, these components generate resistance, smoothly controlling the hinge movement. Many torque hinge models also allow resistance adjustment via screws or regulating devices to accommodate different door weights and usage requirements. Common materials include stainless steel, zinc alloy, and aluminum alloy. Stainless steel versions, prized for superior corrosion resistance, are frequently used in outdoor or harsh environments.

Role of Torque Hinges in Electrical Cabinets

Once installed, the cabinet door with torque hinges can hold any position

Enhanced Accessibility

- Angle-Lock Capability: Torque hinges enable cabinet doors to remain open at any angle without external struts or limiters.

- Hands-Free Operation: Once the door is secured, maintenance personnel can work with both hands simultaneously, eliminating the need to hold the door open. This significantly improves maintenance and wiring convenience.

- Eliminates Auxiliary Components: Once the door is fixed, auxiliary devices are unnecessary.

Enhanced Maintenance Efficiency

- Accelerated maintenance: Torque hinges enable quick and reliable door opening and securing, significantly reducing time for routine inspections and component replacements.

- Prevents Accidental Closure: Robust damping torque prevents cabinet doors from slamming shut, eliminating pinch hazards or impact accidents caused by unexpected door closure.

- Smooth Operation: Torque hinges provide continuous damping, ensuring doors open and close slowly and evenly. Even heavy doors avoid slamming, protecting equipment and extending component lifespan.

Design Advantages of Torque Hinges for Electrical Cabinets

Controlled Motion and Stability

- Constant Torque Output: Precisely engineered to deliver near-constant resistance throughout the opening/closing cycle, ensuring stable door panel positioning at any angle.

- Cushioned Closure: Uniform damping allows doors to close slowly and evenly, preventing abrupt impacts even with heavy panels. This significantly reduces inertia and noise while protecting internal components from shock.

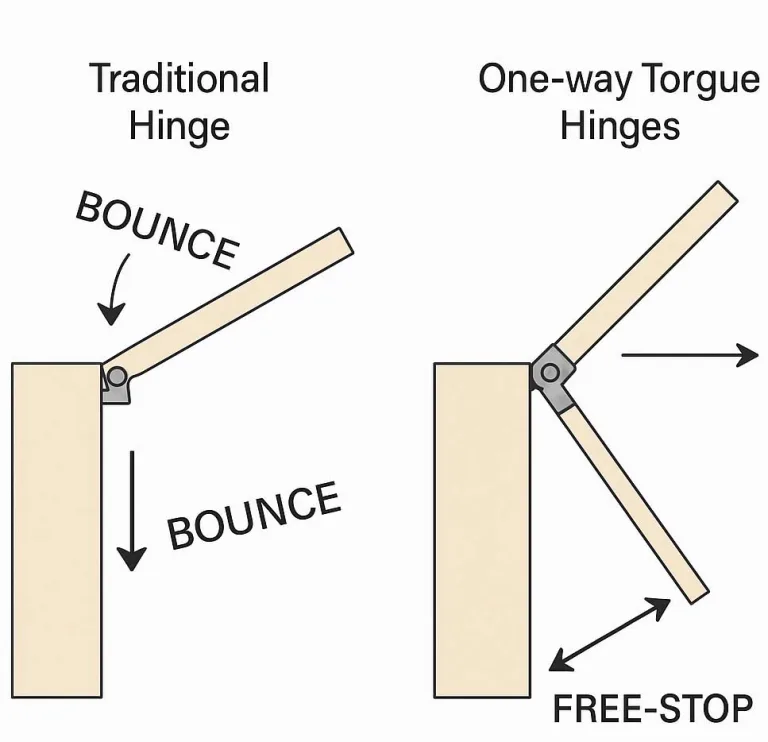

- Eliminates Support Components: Unlike traditional designs requiring gas struts, hydraulic stays, or multi-stage stops, the torque hinge inherently provides braking and positioning functions. It supports door weight without additional devices, resulting in a simpler, more reliable structure.

Space-Saving Structural Design

- Compact Size: The torque hinge features a small, thin-walled body, making it ideal for space-constrained applications like electrical cabinets. It enables flush mounting, occupying minimal space.

- Clean Aesthetics: By eliminating external supports or guide rails, both internal and external cabinet space is maximized, resulting in a tidier, more visually appealing design.

Industrial-Grade Durability

- High-Strength Materials: The commonly used 304 stainless steel exhibits excellent corrosion resistance, making it suitable for harsh environments like chemical plants and power facilities. Wear-resistant friction components and structural design withstand intense vibrations and frequent operation.

- Longue durée de vie : High-quality friction discs and spring mechanisms maintain consistent resistance after tens of thousands of cycles, with minimal fatigue or loosening.

Safety and Compliance

- Reduced Pinch Hazards: Torque hinges reliably prevent door panels from accidental drop, significantly lowering risks of operator pinching or impact injuries.

- Enhanced Compliance: Stable, controlled door movement helps electrical cabinets meet safety standards (e.g., IEC/UL certifications) for protective doors. Uniform closure also improves equipment quality perception and user experience.

How to Select the Right Torque Hinge for Electrical Cabinets

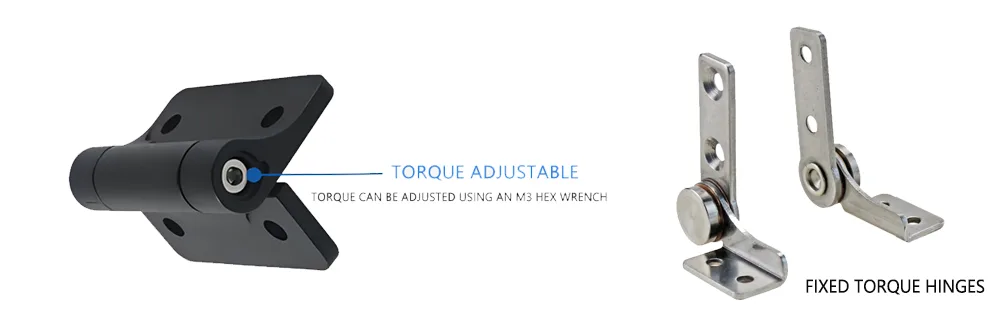

Fixed vs. Adjustable Torque Hinges

Fixed Torque vs. Adjustable Torque Hinges

- Fixed-torque hinges: Simple construction with constant, non-adjustable torque output. Suitable for lightweight doors or fixed-load applications, offering relatively lower cost.

- Adjustable-torque hinges: Incorporate adjustable components (e.g., adjustment screws or variable springs) to modify resistance based on door weight or operational requirements. For heavy-duty or frequently opened cabinet doors, adjustable torque hinges offer flexibility and precision.

Sélection des matériaux

- Stainless Steel: Provides optimal corrosion resistance. Suitable for outdoor electrical cabinets, coastal environments, or chemical plants.

- Zinc Alloy: Lower cost with good aesthetic appeal, suitable for standard indoor environments.

- Aluminum Alloy: Lightweight, reduces door weight for portable or lightweight equipment (e.g., small distribution boxes or cabinets).

Specification and Load Matching

Selecting torque hinges requires determining the appropriate torque value based on door weight, dimensions, and center of gravity. For example, estimate the maximum torque required: For example, assuming a door mass of 0.8 kg and width of 0.4 m, the center of gravity is approximately 0.2 m from the hinge axis. The torque required to hold the door is:

T = m × g × L = 0.8 kg × 9.81 m/s² × 0.2 m = 1.57 N·m.

If two hinges are used, each hinge should provide at least 0.8 N·m of holding torque.

In general:

T_per_hinge = (m × g × L) / n,

where m is door mass, L is distance from hinge axis to center of gravity, and n is number of hinges.. If two hinges are used, each hinge must provide approximately 0.79 N·m of torque to provide stable support. A general formula can be approximated as: Recommended torque = (Door weight × Door width ÷ 2) ÷ Number of hinges. Actual selection should also consider operating angle, usage frequency, and resistance adjustment range. Refer to the hinge manufacturer’s specification sheet and calculation tools when necessary.

Practical Application Scenarios and Case Studies

Application of Torque Hinges in Distribution Panels and Power Cabinets

Automated Control Panels

In industrial automation, PLC control cabinets or operator panels frequently require access for inspection and maintenance. Torque hinges enable these cabinet doors to remain stationary at any desired angle, facilitating wiring and debugging by technicians. They are commonly used on control panel doors in manufacturing to reliably secure door positions and enhance maintenance efficiency.

Distribution Panels and Power Cabinets

Stable door control is critical in distribution cabinets or panels. Torque hinges enable smooth door opening and secure positioning at any angle, eliminating risks of accidental contact or malfunctions caused by sudden door closure. Additionally, torque hinges simplify maintenance procedures by ensuring safety without requiring additional support components. In numerous applications, this efficient locking function reduces human error and enhances system reliability.

Outdoor Electrical Cabinets

Outdoor electrical cabinets require waterproof and dustproof protection. Torque hinges with high protection ratings should be selected for such environments. Compared to standard hinges, they provide robust torque support while maintaining excellent protective performance.

Industrial Equipment Covers

Heavy machinery such as engines, generators, or large transformers often require access through removable covers during maintenance. Torque hinges enable these heavy covers to open smoothly and hold at the desired angle, ensuring safe working conditions for maintenance personnel. Whether in production line equipment or energy systems, torque hinges demonstrate exceptional adaptability and reliability.

Installation and Maintenance Guidelines for Torque Hinges

- Proper Installation: Ensure symmetrical upper/lower hinge placement with aligned axes. Test opening/closing functionality immediately after screw tightening. Post-installation testing under actual load conditions is recommended to verify door panel retention.

- Adjustable Type: For adjustable torque hinges, use manufacturer-recommended specialized tools (e.g., torque screwdrivers ) to precisely adjust damping screws. Avoid over-tightening, which may damage internal springs.

- Regular Inspection: Periodically check hinge fasteners for looseness and ensure smooth operation. If abnormal noise, reduced resistance, or surface corrosion occurs, promptly clean or replace the hinge.

- Cleaning and Maintenance: Torque hinges generally require no lubrication, as it may reduce friction effectiveness. Wipe surfaces with a dry cloth or neutral cleaner. Avoid direct contact of strong acids or alkalis with friction surfaces to extend service life.

Comparison Between Torque Hinges and Traditional Hinges

| Comparison Item | Charnières traditionnelles | Serrer les charnières |

|---|---|---|

| Opening/Closing Control | Free swing | Torque control, adjustable torque |

| Sécurité | Prone to pinching or auto-closing | Stable hold at any angle |

| Maintenance | Requires external supports (e.g., gas struts) | Built-in torque locking, no additional support needed |

| Applications | Standard cabinets, low-demand applications | High-performance electrical cabinets and complex industrial equipment |

Conclusion

Overall, torque hinges significantly enhance the operational convenience, safety, and maintenance efficiency of electrical cabinets. Through controllable motion and precise positioning, various torque hinges ensure stable door retention at any angle while eliminating the hazard of automatic door closure. Selecting the appropriate torque hinge represents a prudent and responsible decision, as its safety benefits and operational improvements far outweigh the initial investment. Therefore, we recommend that engineers and equipment purchasers consider incorporating torque hinge solutions early in electrical cabinet design. Understanding and choosing high-quality torque hinges can significantly optimize cabinet performance, enhance operational efficiency, and reduce long-term maintenance costs.