Comparing Weld-On and Bolt-On Hinges: Key Performance Differences and Ideal Uses

Hinges are fundamental components for doors, windows, and equipment enclosures, forming a massive global market. According to Grand View Research (2024), the global door hinge market size was valued at approximately $9.5 billion in 2024 and is expected to grow steadily in the coming years.

By installation method, hinges are primarily categorized into:

- Weld-On Hinges: Permanently fused to the frame and door via welding.

- Bolt-On Hinges (also known as Screw-On or Standard Hinges): Installed using screws or bolts, allowing disassembly.

As durability and security become increasingly important, weld-on hinges are emerging as the preferred choice for heavy-duty, tamper-resistant applications.

Terminology and Hinge Types

Weld-On Hinges

- Installed via welding (MIG, TIG, Stick)

- Provide a permanent, non-removable bond

- Common materials: 304/316L stainless steel, forged alloy steel

- Examples: Barrel hinges, bullet hinges, pintle hinges

Bolt-On Hinges

- Attached using screws or bolts

- Allow for easy disassembly and replacement

- Variants include:

- Light-duty (residential): e.g., 2 Ball Bearing (2BB) hinges

- Medium-duty (commercial): 4BB hinges

- Heavy-duty (industrial): roller bearing or thick-leaf designs

Structural Differences

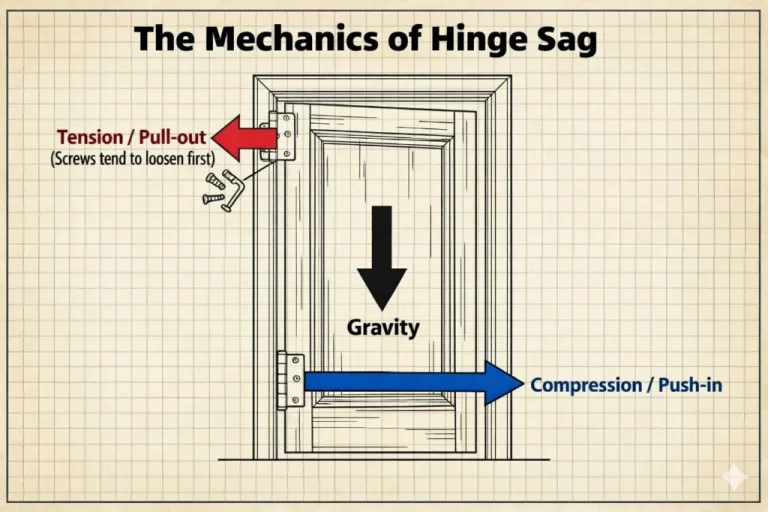

Load Path Efficiency

- Weld-on hinges transfer load directly through welded joints—more uniform stress distribution and less movement.

- Bolt-on hinges distribute load across multiple fasteners and interfaces—higher risk of play or failure under stress.

Material Thickness

- Weld-on: Often ≥ 6 mm thick; stronger under shear and torsion

- Bolt-on: Typically 2–5 mm thick; suitable for lighter loads

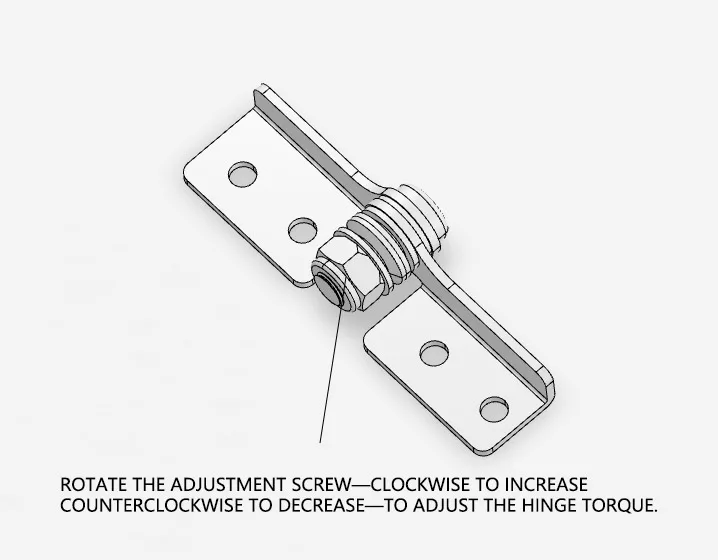

Pin Configuration

- Weld-on hinges often use non-removable pins for anti-tamper design

- Bolt-on hinges typically feature removable pins for maintenance

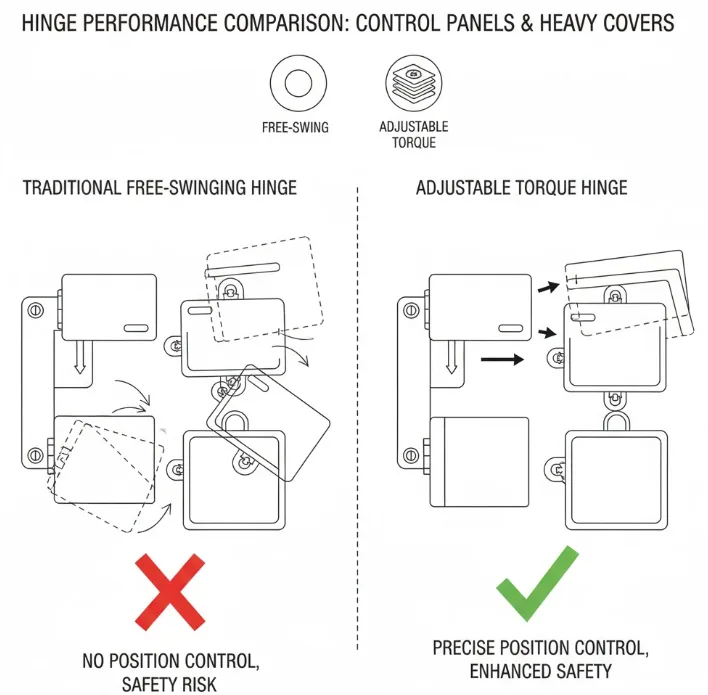

Mechanical Performance: Load, Fatigue, Impact

Static Load Capacity

- Weld-on hinges withstand significantly more torque and radial load without deformation.

- Bolt-on hinges may experience screw pull-out under similar forces.

Fatigue Life (Cycle Durability)

- Welded joints eliminate play—enabling 500,000+ cycles without failure.

- Bolt-on types may require re-tightening or component replacement after 50,000–100,000 cycles.

Impact Resistance

- Weld-on models spread impact forces into the structure—ideal for high-shock applications.

- Bolt-on hinges may fail at screw holes under sudden impact loads.

Installation Process Comparison

Weld-On Hinge Installation

- Requires surface cleaning, positioning, tack weld, full weld, grinding, and finishing

- Tools: Welder (TIG/MIG), clamps, grinders

- Average time per hinge: 10–20 minutes (skilled welder)

Bolt-On Hinge Installation

- Involves marking, drilling, screwing, and alignment

- Tools: Drill, driver, level

- Average time per hinge: 3–5 minutes

Removability

- Weld-on hinges: Permanent; removal requires cutting

- Bolt-on hinges: Easily disassembled; parts reusable

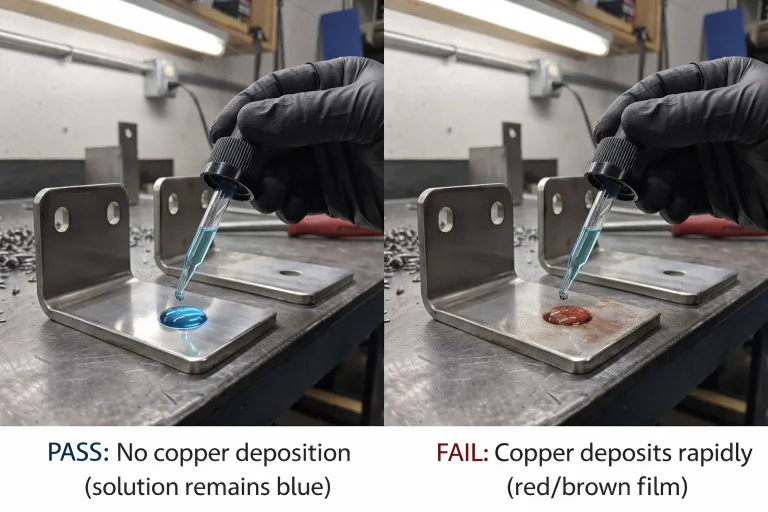

Corrosion Resistance & Environmental Suitability

Material Choices

- Weld-on hinges: 304/316L stainless steel or hot-dip galvanized steel

- Bolt-on hinges: Often plated or powder-coated steel

Salt Spray Test (ASTM B117)

- 316L stainless weld-on: 1,000+ hours corrosion resistance

- Zinc-plated bolt-on: May show corrosion after 100–300 hours

Temperature Extremes

- Welded joints maintain strength under high heat; may need post-weld heat treatment

- Bolt-on hinges risk fastener loosening and lubricant failure at extreme temperatures

Maintenance and Lifecycle Cost Analysis

Maintenance Frequency

- Weld-on hinges: Virtually maintenance-free post-installation

- Bolt-on hinges: Require periodic bolt tightening, pin lubrication, and cleaning

Common Failure Modes

- Weld-on: Weld fatigue or base metal cracking

- Bolt-on: Loose fasteners, worn bearings, stripped threads

Total Cost of Ownership (TCO)

- Weld-on: Higher upfront cost; lower lifetime maintenance

- Bolt-on: Lower initial cost; higher cumulative maintenance over 10+ years

Security and Vandal Resistance

Anti-Intrusion Design

- Weld-on: No removable parts; ideal for high-security applications

- Bolt-on: Exposed fasteners present potential attack points

Fire Resistance

- Steel weld-on hinges maintain strength near 800°C+

- Bolt-on hinges may fail as screws lose tension under heat

Common Application Scenarios

| Application Type | Recommended Hinge | Reason |

|---|---|---|

| Industrial Equipment | Weld-On Hinges | Shock, vibration, no maintenance |

| Residential Gates | Bolt-On Hinges | Style flexibility, easy adjustments |

| Refrigerated Trucks | Hybrid (Weld-On + Bolt-On) | Heavy-duty + serviceable access |

Hinge Selection Guide (Decision Matrix)

| Requirement | Best Option |

|---|---|

| Heavy Load (>500 kg) | Weld-On |

| Frequent Maintenance | Bolt-On |

| Marine/Corrosive Environment | Weld-On (316L SS) |

| High-Security Needs | Weld-On |

| Low Initial Budget | Bolt-On |

Conclusion

Weld-on hinges are the go-to solution for extreme environments, security-sensitive applications, and long-life industrial installations. Their robust structure, low maintenance needs, and superior fatigue life make them ideal for:

- Machinery doors

- Detention facilities

- Marine/offshore applications

Bolt-on hinges are best suited for:

- Light-to-medium duty access panels

- Projects requiring disassembly or style changes

- Budget-conscious installations

Optimal Strategy: Combine Both

Use weld-on hinges for main access and bolt-on hinges for secondary doors or removable panels. This hybrid approach ensures safety, performance, and maintainability across applications.