Sicherung der öffentlichen Infrastruktur: Warum Outdoor-Schränke verdeckte Scharniere benötigen

Dieser Artikel enthält eine eingehende technische Analyse der entscheidenden Rolle Verdeckte Scharniere bei der Sicherheit von öffentlichen Einrichtungen spielen. Wir untersuchen, wie diese Hardware-Lösung spezifische Risiken abschwächt, die in EN 1627 (körperliche Angriffe) und ISO 9223 (Umweltkorrosion). Auf der Grundlage von Feldversagensdaten und internen Tests bieten wir eine quantifizierbare Auswahlhilfe, die von der Materialkunde bis zu Belastungsberechnungen reicht.

Einführung

In der Telekommunikations-, Transport- und Versorgungsbranche werden Schaltschränke für den Außenbereich - wie z. B. 5G-Basisstationen, Fahrkartenautomaten und Verteilerkästen am Straßenrand - häufig in unüberwachten Umgebungen eingesetzt. Diese Einheiten beherbergen hochwertige elektronische Komponenten, sind jedoch ständigen, schweren Sicherheitsbedrohungen ausgesetzt.

Basierend auf unseren Beobachtungen in der BrancheDie Bedrohungen für die Schränke der öffentlichen Einrichtungen stammen hauptsächlich aus zwei Quellen:

- Menschlicher Vandalismus und Diebstahl: Gezielte physische Angriffe mit Hebelwerkzeugen (Brechstangen), Bohrern oder Winkelschleifern.

- Erosion der Umwelt: Strukturelle Verschlechterung durch extreme Witterungsbedingungen, die die physischen Abwehrkräfte des Gehäuses mit der Zeit exponentiell schwächen.

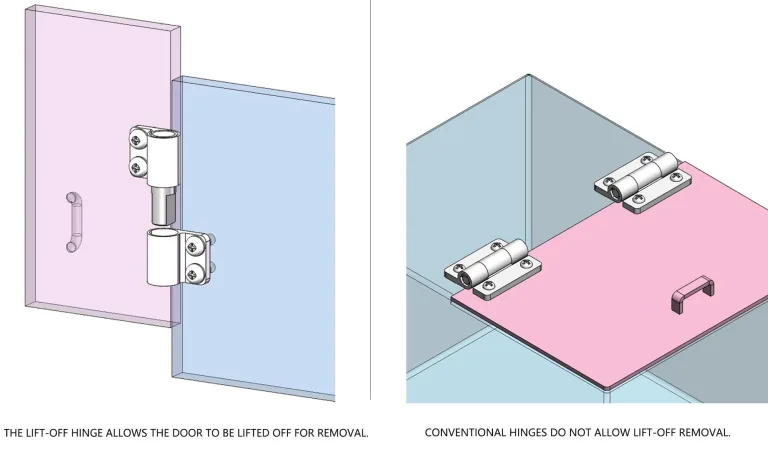

Bei der traditionellen Schrankkonstruktion sind freiliegende Beschläge - insbesondere Außenscharniere - statistisch gesehen das "schwächste Glied". Ein Angreifer braucht nur den externen Stift abzuschneiden, um komplexe Mehrpunktverriegelungssysteme vollständig zu umgehen.

Die Einführung von verdeckten Scharnieren ist nicht nur eine ästhetische Entscheidung, sondern auch der entscheidende technische Weg zur Behebung dieser systemischen Schwachstelle.

Dieser Artikel dient als technischer Leitfaden für Industriedesigner und Beschaffungsverantwortliche. Wir werden die Mechanik von verdeckten Scharnieren analysieren, ihre Vorteile anhand von Vergleichsdaten nachweisen und standardisierte Auswahlkriterien aufzeigen.

Sicherheitsherausforderungen und Anforderungen an den Vandalismusschutz

Bei der Konstruktion von Schränken für den Außenbereich müssen wir zunächst die Risiken quantifizieren. Nach einer Fehleranalyse vor Ort beginnen Schrankbrüche häufig mit dem strukturellen Zusammenbruch des Scharniersystems.

Risiken durch physische Angriffe: Von Brechstangen bis zum Schneiden

Bei herkömmlichen Außenscharnieren sind die Befestigungsschrauben und -stifte für den Angreifer sichtbar.

- Pin-Zerstörung: Die Angreifer verwenden eine hydraulische Schere oder eine Bügelsäge, um den Stift zu durchtrennen. Sobald der Bolzen durchtrennt ist, löst sich die Tür auf der nicht verriegelnden Seite.

- Entfernen von Verschlüssen: Wenn für die äußeren Scharniere Standardschrauben verwendet werden, kann man sie mit einem einfachen Schraubenzieher unbefugt demontieren.

Experteneinblick: Bei öffentlichen Einrichtungen besteht das Ziel der Gestaltung darin treffen EN 1627 Klasse RC3. Dies erfordert, dass der Schrank einem anhaltenden Angriff mit Brechstangen und Schraubenziehern über einen Zeitraum von mindestens drei Monaten standhält. 5 Minuten. Externe Scharniere bestehen diesen Test oft in weniger als 60 Sekunden.

Korrosionsgefahren für die Umwelt: Der unsichtbare Kraftkiller

Korrosion ist ein Sicherheitsproblem, nicht nur ein ästhetisches.

- Spaltkorrosion: Regenwasser und Salzsprühnebel sammeln sich an der Schnittstelle zwischen dem äußeren Scharnier und dem Schrankkörper.

- Verschlechterung der Festigkeit: Gewöhnlicher Kohlenstoffstahl in küstennaher Umgebung (ISO 9223 Kategorie C4) können schnell ihre strukturelle Integrität verlieren.

- Datenpunkt: Materialwissenschaftliche Grundsätze weisen darauf hin, dass ungeeignete Materialien nach längerer Einwirkung von Salzsprühnebel eine kritische Verringerung der Tragfähigkeit erfahren können (simuliert durch ASTM B117). Ein korrodiertes Scharnier verliert seine Dehnbarkeit, wird spröde und kann bei einem Aufprall zerbrechen.

- Profi-Tipp: Fordern Sie immer einen Salzsprühnebeltestbericht eines Drittanbieters (von akkreditierten Labors wie SGS oder TÜV) an, um die Korrosionsbeständigkeit der Scharniere, die Sie beschaffen möchten, zu überprüfen.

Schlüsselmetrik: IK-Schutzart

Bei der Bewertung der Stoßfestigkeit ist die IK10-Einstufung (pro IEC 62262) ist obligatorisch.

- Definition: Das Gehäuse muss einem direkten Schlag mit einem 5 kg schweren Stahlhammer aus 400 mm Höhe (20 Joule) standhalten.

- Auswirkung: Wenn das Scharnier als Drehpunkt fungiert und bricht, fällt der Schrank durch. Verdeckte Konstruktionen, bei denen sich die Belastungspunkte im Inneren des Stahlrahmens befinden, bestehen diesen Test naturgemäß mit größerer Sicherheit.

Technische Definition und Arbeitsprinzipien

Was ist ein verdecktes Scharnier?

A Verdecktes Scharnier (oder Industrie-Innenscharnier) ist eine Verbindungskomponente, bei der sich der Montagekörper vollständig zwischen dem Schrankrahmen und der Türrückführung befindet. Im geschlossenen Zustand sind keine Komponenten von außen sichtbar oder zugänglich.

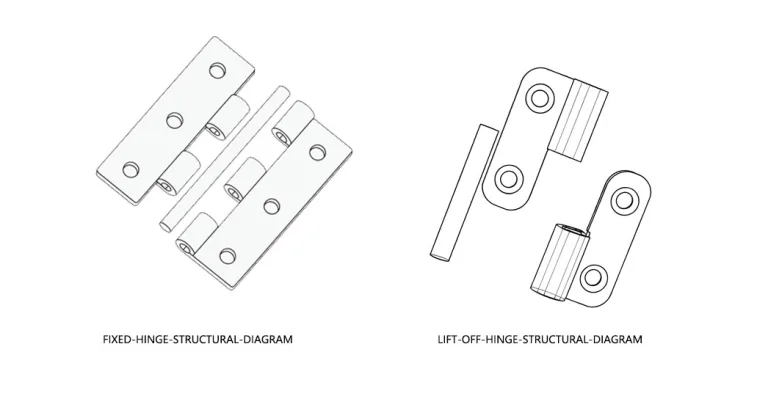

Strukturelle Konstruktionstypen

U-Pin-Struktur

- Mechanismus: Verwendet eine U-förmig gebogene Stahlplatte oder ein Gussteil, das sich um einen innen befestigten Stift dreht.

- Anwendung: Szenarien mit hoher Belastung, bei denen Einfachheit und Langlebigkeit von größter Bedeutung sind.

Mehrgliedriger Mechanismus (7-Bar)

- Bewegung Trajektorie: Ermöglicht es der Tür, sich vor dem Drehen nach außen zu bewegen ("werfen").

- Vorteil: Kritisch bei Schränken mit dicken Schaumstoffdichtungen, die verhindern, dass die Türkante am Rahmen anliegt.

Schnellspanner & Federspanner

- Betrieb: Verfügt über einen einziehbaren Stift, der nur von der innerhalb.

- Nutzen: Ermöglicht den werkzeuglosen Ausbau der Tür zu Wartungszwecken, jedoch nur nach die Tür wurde rechtmäßig entriegelt.

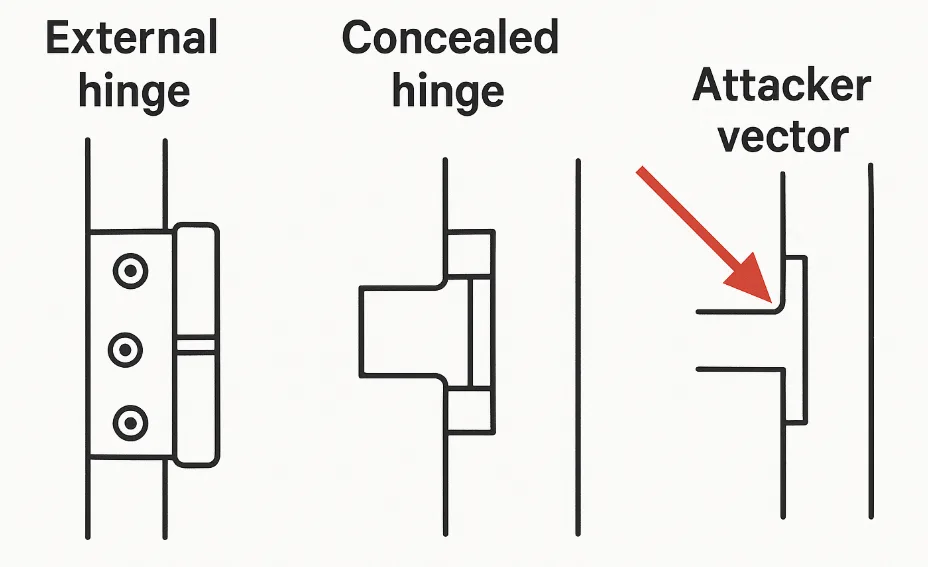

Vergleichende Analyse: Extern vs. Verdeckt

| Bewertung Dimension | Traditionelles Außenscharnier | Verdecktes Scharnier | Vorteilsanalyse |

| Sicherheit | Stift freigelegt; Schnittzeit < 60s | Vollständig versteckt; kein Angriffspunkt | Erhöht die Einbruchszeit erheblich |

| Versiegeln | Erfordert das Schneiden der Dichtung | Befindet sich im Inneren der Dichtung | Gewährleistet IP65/IP66-Konformität |

| Vandalismus | Anfällig für Neugierde | Geschützt durch eine Stahltür | Die Kraft wird auf den Rahmen übertragen |

| Maximale Öffnung | 180° - 270° | 90° - 120° (Standard) | Externer bietet breiteren Zugang |

Kernvorteile im vandalensicheren Design

Eliminierung externer Angriffspunkte: Zeit ist Sicherheit

Das Ziel der Sicherheitstechnik ist es Angriffszeit verlängern.

- Die Realität: Die Zerstörung eines freiliegenden Scharniers ist eine geräusch- und arbeitsarme Aufgabe.

- Der verdeckte Vorteil: Bei innenliegenden Scharnieren muss ein Angreifer die 1,5 bis 2,0 mm dicke Stahlhaut der Tür durchschneiden, um an die Beschläge zu gelangen. Feldsimulationen zeigen, dass dies den Aufwand erhöht, der erforderlich ist, um die Scharnierseite von Sekunden bis über 5 MinutenDadurch wird in der Regel der Versuch vereitelt oder es werden Sensoren ausgelöst.

Verbesserung der Abdichtungsleistung (IP65/IP66)

Bei Außenanwendungen verursacht das Eindringen von Wasser elektrische Kurzschlüsse.

- Das Problem: Bei außenliegenden Scharnieren müssen oft Durchgangslöcher gebohrt oder der Schaumstoffdichtungsstreifen unterbrochen werden.

- Die Lösung: Verdeckte Scharniere sind an der Innenbereich des Dichtungsrands. Dies ermöglicht eine kontinuierliche, ununterbrochene Versiegelungslinie.

- Einhaltung der Normen: Diese Kontinuität ist oft der entscheidende Faktor für vorbei an NEMA 4X oder IP66 (starker Wasserstrahl) Zertifizierungsprüfungen.

Verhinderung der unbefugten Demontage

Dadurch entsteht eine logische Sicherheitsschleife.

- Mechanismus: Die Befestigungsschrauben sind im geschlossenen Zustand durch den Türrahmen blockiert.

- Ergebnis: Es ist physisch unmöglich, die Tür aufzuschrauben, ohne zuvor das Hauptschloss zu überwinden. Dadurch wird der Vektor "Schlossumgehung" vollständig eliminiert.

Werkstoffkunde: Die Auswahl des richtigen Scharniermaterials

Basierend auf ISO 9223 Korrosionskategorien, empfehlen wir das folgende Auswahlprotokoll:

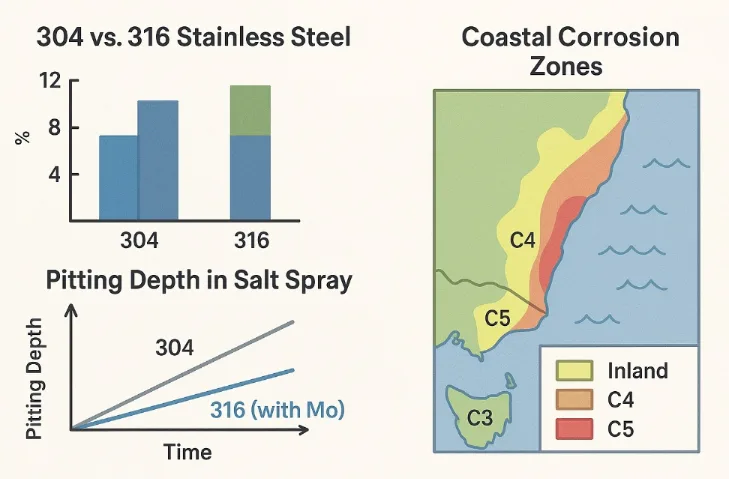

Rostfreier Stahl (304 vs. 316)

- 304 Edelstahl (AISI 304):

- Umwelt: Städtisches Binnenland, Industriegebiete (C3 Korrosivität).

- Leistung: Ausreichend für den Standardeinsatz im Freien.

- 316 Edelstahl (AISI 316):

- Umwelt: Küstenregionen, Chemieanlagen, Offshore (C4/C5 Korrosivität).

- Technische Grundlage: Der Zusatz von 2-3% Molybdän verbessert die Beständigkeit gegen Lochfraßkorrosion, die durch Chloride (Salz) verursacht wird, erheblich.

- Profi-Tipp: Für Installationen innerhalb 5 km einer Küstenlinieist 316 vorgeschrieben. Unsere Daten zeigen, dass 304 in diesen Zonen innerhalb von 12-24 Monaten strukturellen Rost entwickeln kann.

Kohlenstoffstahl (verzinkt/vernickelt)

- Risiko: Sobald die Beschichtung zerkratzt ist (häufig bei der Installation), oxidiert das Grundmetall schnell.

- Fazit: Nicht empfohlen für kritische Infrastrukturen, die eine Lebensdauer von mehr als 10 Jahren erfordern.

Zinklegierung (Druckguß)

- Einschränkung: Zinklegierungen sind zwar kostengünstig, haben aber eine geringere Zugfestigkeit und sind spröde.

- Warnung: Unter IK10 Bei Aufpralltests ist die Wahrscheinlichkeit, dass Scharniere aus Zinklegierung brechen, deutlich höher als bei Edelstahl. Nur für kleinere, risikoärmere Gehäuse verwenden (Türgewicht < 20 kg).

Anwendungsszenarien: Einsatz von verdeckten Scharnieren

- Telekommunikation (5G/Glasfaser):

- Schwerpunkt: Versiegeln. Muss 960 Stunden Salzsprühnebeltests bestehen, um sicherzustellen, dass das Scharnier nicht festklemmt, und schützt so die Hochwärmeelektronik.

- Transport (Schiene/Autobahn):

- Schwerpunkt: Vibration. Wir empfehlen Scharniere mit POM (Polyacetal)-Buchsen. Dies verhindert Reibungskorrosion von Metall auf Metall, die durch die hochfrequenten Schwingungen der IEC 61373.

- Finanzen (ATM/Kiosk):

- Schwerpunkt: Brachiale Gewalt. Muss aus hochfestem 304/316 Stahl bestehen. Konstruktion mit einer Mehrpunktanordnung (3-4 Scharniere), um die Belastung durch die Brechstange zu verteilen.

Auswahl-Leitfaden: Wie Ingenieure auswählen sollten

Lastberechnung und Sicherheitsfaktor

Verlassen Sie sich nicht allein auf die Schätzung des statischen Gewichts.

- Kalkulation: Gesamtgewicht der Tür + montierte Ausrüstung.

- Sicherheitsfaktor: Wir empfehlen eine Sicherheitsfaktor von 1,5 bis 2,0.

- Warum? Zur Berücksichtigung von Dynamisches Laden (Windböen bis zu 120 km/h) und möglicher Missbrauch (Techniker lehnen sich an die Tür).

- Beispiel: Bei einer 40 kg schweren Tür sollte der Scharniersatz für 60 kg bis 80 kg ausgelegt sein.

Öffnungswinkel und Wartung

- 90° vs. 120°: Wenn der Schrank ausziehbare Rackserver enthält, ist eine 90°-Öffnung nicht ausreichend. Stellen Sie sicher, dass die Scharniergeometrie mindestens 120° Spielraum zulässt.

3D-Modellierung und Interferenzkontrollen

Da der Ausschlag" eines verdeckten Scharniers komplex ist, sind 2D-Zeichnungen fehleranfällig.

- Bewährte Praxis: Importieren Sie immer die spezifische STEP-Datei in Ihre CAD-Baugruppe (z. B. SolidWorks) und führen Sie eine Kollisionserkennungssimulation durch. Sie können diese 3D-Modelle direkt von der Registerkarte "Spezifikationen" auf unserer Website herunterladen.Verdecktes Scharnier Produktseiten]

Schlussfolgerung

In der Infrastruktur öffentlicher Einrichtungen ist die Sicherheit eine Kernfunktion, keine Besonderheit. Die Umstellung von externer Hardware auf Verdeckte Scharniere schaltet den häufigsten physischen Angriffsvektor grundlegend aus und gewährleistet IP66 Konformität und verlängert die Lebensdauer in korrosiven Umgebungen.

Aktion der Industrie:

Mit der zunehmenden Verbreitung verteilter Infrastrukturen (5G, Laden von Elektrofahrzeugen) steigen die Anforderungen an die Sicherheit von Gehäusen. Wir raten Ingenieurteams dringend, Spezifikationen für verdeckte Scharniere bereits in der Konzeptionsphase zu berücksichtigen. Das Nachrüsten interner Scharniere in ein endgültiges Blechdesign ist kostspielig und oft mit technischen Kompromissen verbunden. Beginnen Sie mit der richtigen Hardware, um eine undurchdringliche Verteidigung aufzubauen.