Lift-Off Torque Hinge: Principle, Design, Application, and Frontiers

Contemporary precision equipment places demanding requirements on hinges: “concealed, zero backlash, and repeatedly removable.” Traditional hinges often struggle to balance both easy disassembly and reliable positioning.

Lift-Off Torque Hinges (LOTH), introduced by manufacturers like HTAN, are a cross-disciplinary solution designed for this purpose. They fuse the “free-stop” characteristic of constant torque hinges with quick-disassembly functionality:

- An internal friction mechanism provides torque, allowing the door panel to remain stationary at any angle without wobbling;

- Simultaneously, the hinge features an axially removable design, enabling direct detachment of the door panel without any tools.

At HTAN, we’ve designed our XG11-070 series torque hinges for both horizontal and vertical installation, and they’ve successfully passed a rigorous 30,000-cycle life test.

This article will comprehensively explore Lift-Off Torque Hinges from Principle → Design → Manufacturing → Application → Trends, providing a one-stop reference for engineers and product managers.

Terminology and Concept Clarification

Lift-Off (Axial Removal)

Refers to the characteristic of a hinge enabling rapid separation by lifting.

Unlike ordinary hinges requiring screw removal, Lift-Off hinges allow the user to simply lift the door or panel, leaving one leaf attached to the door panel and the other to the frame.

Also known as:

- Detachable hinges

- Release hinges

Torque Hinge

Also called a constant torque hinge or position-locking hinge.

It provides constant rotational resistance through an internal friction structure, enabling the door panel to remain stable at any angle.

Key Benefits:

- Eliminates additional supports

- Improves operational convenience

- Prevents door wobbling due to vibration or gravity

Note:

Machine Design magazine states the driving force is constant regardless of hinge angle, and the hinge maintains that angle until moved again.

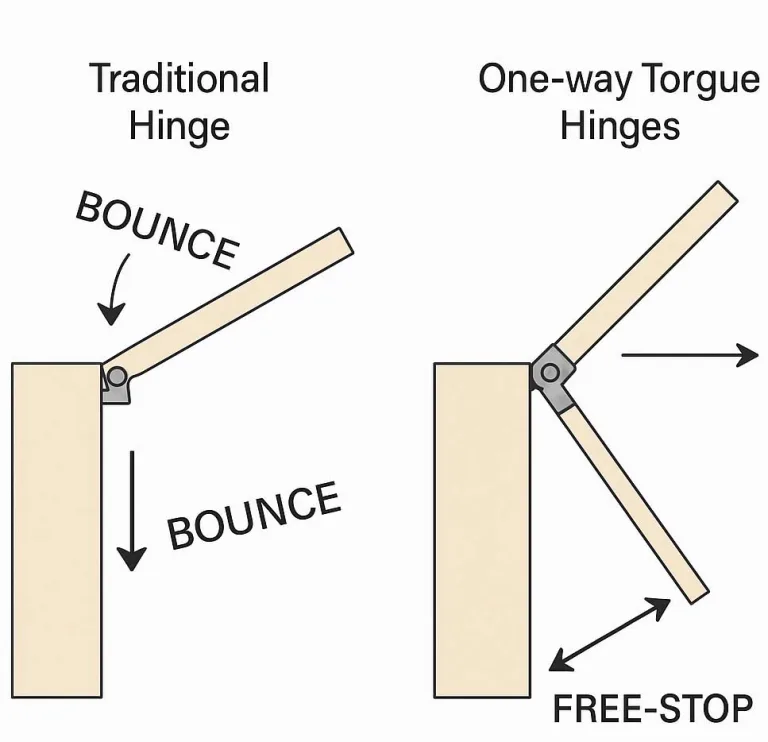

Distinction from Traditional Hinges

- Traditional Detent Hinges: Lock at fixed angles (e.g., 90°, 180°) via spring detents.

- Standard Lift-Off Hinges: Provide quick removal only; no torque support.

- LOTH: Combines constant torque positioning + tool-free axial removal.

Key Performance Indicators

- Rated torque

- Torque durability decay

- Axial pull-off force

- Life cycle count

- Environmental temperature drift

High-quality hinge benchmarks:

- Torque decay within ±15% after 30,000+ cycles

- Stable performance across -40°C to 85°C

- Corrosion and impact resistance

Deep Dive into Working Principle

Structural Composition

Male End (Drive Component)

- Contains the central shaft connected to the door

- Features a helical cam surface

- Assembled with a torque mechanism: disc spring stack, wave spring, or friction discs

- Supports torque generation and axial lift-off

Female End (Driven Component)

- Sleeve component fixed to the frame

- Contains helical grooves complementary to the male end

- Includes a spring-loaded locking mechanism (e.g., ball detents)

Torque Generation Mechanism

Torque is produced via:

- Spring preload +

- Helical wedge surface (geometry) → converting axial load into rotational resistance

Simplified formula:T ≈ kμF_preload × r_spiral

Where:

μ: friction coefficientF_preload: spring forcer_spiral: spiral radiusk: efficiency coefficient

Friction Material Pairings:

- Stainless steel + PEEK/MoS₂/PTFE

- All-metal pairs

Note: NASA studies show PEEK composites with PTFE and MoS₂ offer excellent durability and low friction.

Lift-Off Triggering Process

- During use: Male cam and female groove remain engaged, offering constant torque

- For removal: Axial pull force disengages the locking ball → hinge separates

- Enables tool-free panel removal

Mechanical Model

- Treat as coupled axial force + torque problem

- Use simplified torque models and validate via multi-body simulation (e.g., Adams)

Materials and Manufacturing Processes

High-Strength Lightweight Material Matrix

| Component | Material Example | Features |

|---|---|---|

| Shaft Core | 17-4PH Stainless Steel / Ti-6Al-4V | High strength + corrosion resistance / high specific strength |

| Friction Discs | PEEK + MoS₂/PTFE / LCP + PTFE | Low friction, high wear resistance |

Precision Machining Chain

- 5-Axis Milling: For helical cams, ≤0.01 mm contour accuracy

- Surface Hardening:

- DLC on titanium (Hv >2000)

- Nitriding for steel parts

Micro-Assembly and Preload Control

- Disc Springs: Grouped by precise preload tolerance (±2 N·mm)

- Automated Assembly: Laser torque calibration ensures precision

Design for Manufacturability (DFM) Pitfalls

- Ensure helix surface has enough draft angle

- Deburr locking ball holes

- Use temperature-compensation grooves

- Involve process team early to avoid redesign

Performance Testing and Standards

- Torque-Angle Curve: Must stay ±5% from rated torque

- Axial Pull-Off Force: Test via ISO 81346-10 style methods

- Life Cycle Testing:

- Goal: Torque decay <15% after 20,000–30,000 cycles

- Environmental Reliability:

- Temperature (-40°C to 85°C)

- Salt spray (96 hours)

- Drop/shock tests (1 meter)

- Failure Mode Analysis (FMA):

- Torque decay

- Locking ball jamming

- Disc spring fatigue

- Surface coating delamination

Cross-Industry Application Cases

Image source: Sugatsune

Consumer Electronics

- Foldable Smartphones:

- Torque: 0.35 N·m

- Thickness: 2.1 mm

- 50,000-cycle drop-tested

Medical Devices

- Ultrasound Probe Holders:

- Tool-free disassembly

- 0.8 N·m torque

- Medical-grade materials

Automotive Electronics

- Flip-Up Screens:

- High-temp stability (up to 85°C)

- NVH vibration standard compliance

Aerospace

- Satellite Solar Panels:

- Torque ~3 N·m

- 35% weight savings vs. traditional locks

Industrial Automation

- Robot Teach Pendant Holders:

- IP54 sealing

- Quick disconnect with stable positioning

Design Guide and Selection Tools

Torque Calculation

T = kμF_pre r_spiral

Validated via FEA or simulation

Life Estimation

- Use Palmgren–Miner damage theory

- Combine with Archard wear model

- Include S-N fatigue curves

Quick Selection Table

| Load Level | Torque Range | Application Examples |

|---|---|---|

| Light | 0.1–0.5 N·m | Phones, wearables |

| Medium | 0.5–2.0 N·m | Medical mounts, in-car displays |

| Heavy | 2.0–10.0 N·m | Industrial machinery, aerospace mechanisms |

Tolerance Stack-Up & Temperature Compensation

- Temperature drift ~2–3% per 10°C

- Use symmetrical structures or compensation grooves

Common Design Pitfalls

- Oversized helix angle → Self-lock

- Weak spring → Accidental release

- Uneven disc spring preload → Torque imbalance

Simulation and Optimization

- Multi-body Dynamics: Simulate helix-friction interaction (MSC Adams)

- Thermo-mechanical Analysis: Model torque drift at high temp (ANSYS)

- Topology Optimization: Lightweight the sleeve by >20%

- Digital Twins: LSTM models trained on life-cycle torque decay data

Conclusion

The Lift-Off Torque Hinge (LOTH) bridges the market gap between:

- High-reliability quick-release hinges

- Constant torque positioning structures

It offers:

- Tool-free detachment

- Free-stop torque positioning

As manufacturing becomes standardized and cost-effective, LOTH is poised for rapid growth in consumer IoT and portable tech.

Future R&D should focus on:

- Creating industry standards

- Building cross-industry LOTH tech databases

- Promoting the shift from custom to standard components

FAQ

What is a Lift-Off Torque Hinge (LOTH)?

A hinge that combines constant torque with axial quick-disassembly. It holds any angle and allows tool-free removal by lifting.

How does LOTH differ from a standard Torque Hinge?

Standard torque hinges don’t support easy removal—LOTH does. It separates automatically with axial force, no tools required.

What are key considerations when designing LOTH?

- Match helical cam geometry with spring preload

- Ensure locking ball spring strength is optimized

- Maintain strict machining tolerances

- Avoid burrs and ensure surface hardness