Medical Device Design: A Position Control Hinge Guide

The Difference Between Traditional Hinges and Position Control Hinges

Introduction: Why Aren’t Standard Hinges “Good Enough”?

Imagine a scenario: a monitor screen slowly drooping during surgery, or an analyzer cover suddenly slamming shut while changing a sample. The root of these mechanical failures often lies in overlooking a critical component—the position control hinge.

Unlike standard hinges, which only provide a pivot point, position control hinges (also called friction hinges or torque hinges) integrate a precision friction mechanism internally that generates controlled, constant rotational resistance (torque). This torque counteracts the gravity of a load, such as a screen or lid, allowing it to be held steady at any angle—achieving a “stay-put” function without the need for additional gas springs or support rods.

In demanding medical and laboratory environments, hinge performance transcends convenience; it is directly linked to patient safety, operator ergonomics, equipment precision, and the asset protection of expensive devices. Therefore, this guide will deeply analyze the two core pillars of selection: “Precision” and “Reliability.”

Part One: Interpreting the Core Pillars: Precision and Reliability

When selecting position control hinges for high-specification equipment, the two complementary concepts of “Precision” and “Reliability” must be quantified.

Pillar One: The True Meaning of “Precision”

Precision refers to the quality and consistency of the torque output, a quality the user can directly perceive. Key metrics include:

- Low Spring-Back: Refers to the slight “rebound” of a screen after being released. In medical imaging or microscopy applications, even a millimeter of drift can lead to errors. High-precision hinges must minimize spring-back.

- Zero Backlash: Refers to the “free play” or “looseness” in a mechanical transmission. High backlash leads to imprecise positioning and drift, especially in vibrating environments like mobile medical carts. Zero backlash is a prerequisite for achieving absolute positional stability.

- Smooth Motion Feel: Stems from the consistency of torque output. If the static torque (breakaway torque) is much greater than the dynamic torque (torque to maintain motion), the user will feel a distinct “stiction” or “judder.” High-quality hinges minimize this difference through advanced design and special lubricants.

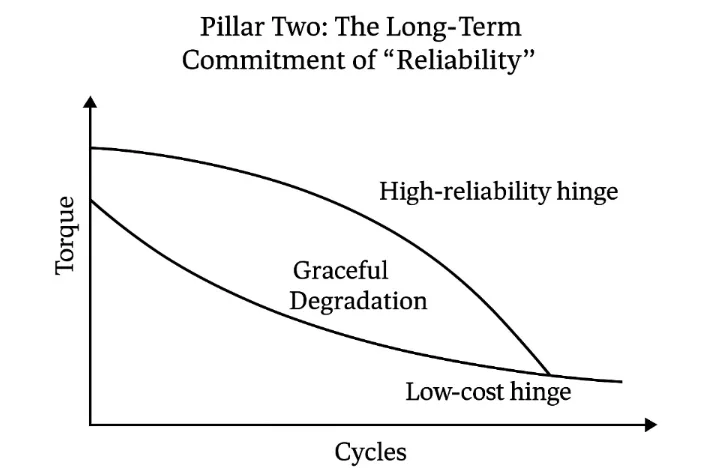

Pillar Two: The Long-Term Commitment of “Reliability”

Torque Decay Curve: Comparison Between High-Reliability and Low-Cost Hinges

Reliability focuses on the hinge’s ability to maintain its initial performance throughout its entire service life. Key metrics include:

- Cycle Life & Torque Decay: Industry standards are often 20,000 cycles or more. However, the cycle count must be considered alongside the torque decay rate. A high-reliability hinge, after completing its rated life, should have torque decay controlled within a strict range (e.g., less than 20% of the initial value), which depends on the internal friction materials and grease.

- Environmental Tolerance: The hinge must maintain stable torque output under varying temperature and humidity conditions.

- Failure Mode: The ideal failure mode should be “Graceful Degradation”—that is, torque decreases slowly and predictably over time, rather than a catastrophic sudden fracture, seizure, or complete loss of torque, allowing for predictive maintenance.

Part Two: Selection Framework (I) — Quantifying Key Engineering Parameters

The first step in selecting a position control hinge is rigorous engineering calculation, not estimation by feel.

Torque: The Core of Everything

Static Torque, also known as breakaway torque, determines the “holding force” of the hinge; Dynamic Torque determines the “feel” when the user makes adjustments. In a quality hinge, the static torque should be slightly higher than the dynamic torque, but the difference should not be too large.

How to Accurately Calculate Torque Requirements?

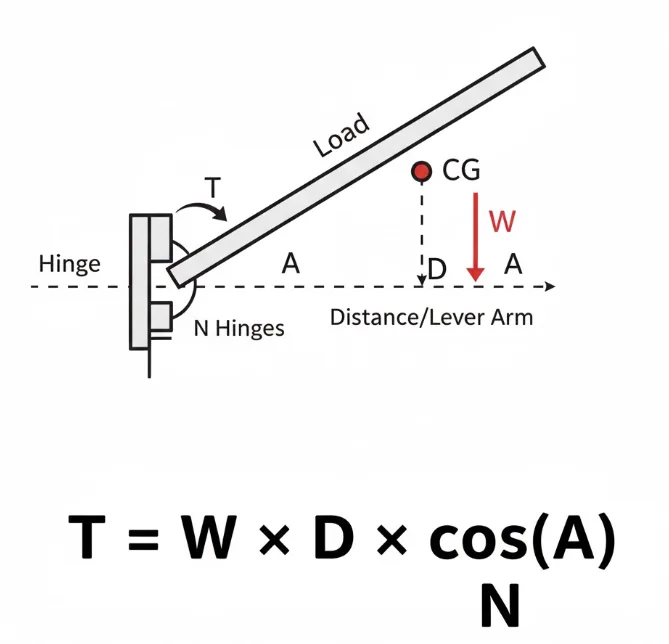

Torque Calculation Principle Diagram

Accurate calculation is the cornerstone of successful selection.(See fundamental torque calculation principles)

The required torque is determined by the load’s weight, the position of its center of gravity, and the opening angle.

Calculation Formula:

$$T = \frac{W \times D \times \cos(A)}{N}$$

Where:

- T = Torque required per hinge (Unit: N·m)

- W = Weight of the load (Unit: N). Note: Mass (kg) must be multiplied by g ≈ 9.81 m/s².

- D = Perpendicular distance from the load’s center of gravity (CG) to the hinge’s axis of rotation (Unit: m).

- A = Angle of the load when opened (When the load is horizontal, A=0, cos(A)=1, and the required torque is at its maximum).

- N = Number of hinges used.

Calculation Key Point: The most common error in calculation is using the geometric center instead of the center of gravity (CG). For devices with unevenly distributed components (like monitors), the true CG must be determined through 3D modeling or actual measurement, otherwise, the calculation results will have significant deviation.

Example: Calculating Torque for a 5.0kg Monitor Screen

- Parameters: Load m = 5.0 kg (i.e., W ≈ 49 N); Center of Gravity D = 0.125 m; Hinges N = 2.

- Calculation: Maximum total torque = 49 N × 0.125 m = 6.125 N·m.

- Torque per hinge T: 6.125 / 2 = 3.06 N·m.

- Selection Consideration: In engineering practice, a safety margin of at least 20% is typically added (i.e., 3.06 × 1.2 = 3.67 N·m). Furthermore, the manufacturer’s torque tolerance (e.g., ±20%) must be considered to ensure the lower limit of the selected model’s torque range still meets the demand with the safety margin.

Symmetric Torque vs. Asymmetric Torque

- Symmetric Torque: Opening and closing resistance are the same, suitable for most screens.

- Asymmetric Torque: Opening and closing torques are different (e.g., “easy to lift, hard to close”). This design can effectively prevent the top covers of lab incubators or heavy analyzers from “slamming shut” unexpectedly, greatly enhancing operator safety.

Range of Motion and Space Constraints

Select the appropriate motion angle (e.g., 90°, 180°, 360°) and mounting style (e.g., surface mount, concealed mount) based on the application’s needs. Compact hinges can provide high torque in limited spaces, but it must be ensured that the mounting area’s structure is sufficiently strong.

For high-value equipment, consider selecting hinges with overload protection (clutch function). When the device is subjected to an unexpected, large external force, the clutch allows internal slippage, absorbing the impact and protecting the expensive screen or main body of the device from damage.

Part Three: Selection Framework (II) — Material Science and Environmental Adaptability

In medical and laboratory environments, the choice of material determines the hinge’s reliability.

Body Materials: Stainless Steel, Aluminum, Zinc Alloys, and Engineering Plastics

Material selection requires balancing strength, corrosion resistance, and cost. (Learn more about how environment impacts material choice)

- Medical-Grade Stainless Steel (304, 316): Is the gold standard for medical applications. It has unparalleled corrosion resistance (can withstand chemical disinfectants), high strength, and is easy to clean. 316 stainless steel offers even stronger resistance to chlorides due to its molybdenum content.

- Engineering Plastics and Composites: Advantages include being lightweight (suitable for portable devices), cost-effective, and offering electromagnetic compatibility (EMC). However, one must be wary of Creep—the slow deformation of a material under continuous load, which can lead to a loss of preload on the friction core, thus causing permanent torque decay.

- Zinc Alloys/Aluminum Alloys: Provide a good strength-to-weight ratio and are easily formed into complex shapes via die-casting.

| Material Type | Corrosion/Chemical Resistance | Strength | Weight Ratio | Cleanability/Sterilizability | Long-Term Creep Resistance |

|---|---|---|---|---|---|

| Medical-Grade Stainless Steel (316) | Excellent | Excellent | Good | Excellent | Excellent |

| Aluminum Alloy (6061) | Good (requires anodizing) | Excellent | Good | Excellent | Excellent |

| Zinc Alloy (Zamak 3) | Fair (requires plating) | Fair | Fair | Excellent | Excellent |

| Engineering Plastic (PEEK) | Excellent | Good | Excellent | Good | Good |

| Engineering Plastic (PC) | Fair | Good | Good | Poor | Poor |

The Friction Core: The Secret of Grease

The constant torque in high-end position control hinges primarily comes from the viscous resistance between internal precision components and a layer of high-tech damping grease. The choice of grease is critical in determining performance, feel, and lifespan.

- Medical-Grade & Safety: Medical applications must use non-toxic, odorless, medical-grade (e.g., NSF H1 certified) grease.

- Performance: Must have extremely low oil bleed (to prevent grease from seeping out and contaminating equipment) and wide temperature stability (to ensure consistent torque in different environments).

- Compatibility: This is a common design trap. It is essential to ensure the grease is fully compatible with the plastics used. Many petroleum-based greases can cause plastics like PC and ABS to become brittle and crack, leading to structural failure.

Surface Treatment and Cleaning Tolerance

All exposed materials and surface treatments on the hinge must be able to withstand repeated wiping with strong disinfectants (such as alcohols, hydrogen peroxide). Anti-microbial coatings can serve as a value-added feature to help inhibit microbial growth. For Cleanroom applications, the hinge must not generate particulate contamination during motion.

Part Four: Selection Framework (III) — Compliance and Regulatory Certification

For medical devices, compliance is a mandatory ticket to market entry.

IEC 60601-1: Mechanical Safety and Stability

IEC 60601-1 is the globally recognized standard for the basic safety and essential performance of medical electrical equipment. Hinge performance is directly related to whether the final device can pass this certification.

- Tilt and Stability Test: The standard requires that equipment must not tip over on a 10° inclined plane. The hinge must provide sufficient static holding torque to prevent adjustable parts (like monitors) from swinging on their own during the tilt, which could change the equipment’s center of gravity and cause instability.

- Mechanical Hazards: The hinge design must avoid creating “Pinch Points” that could cause crushing injuries to operators or patients.

Supplier’s Quality System Certification

ISO 13485 vs. ISO 9001: ISO 9001 is a general quality management standard. In contrast, ISO 13485 is a standard specifically for the medical device industry, with its core focus shifting to patient safety and regulatory compliance. ISO 13485 places extreme emphasis on risk management, process validation, traceability, and exhaustive documentation.

Choosing a hinge supplier certified to ISO 13485 means their quality control and risk assessment capabilities can seamlessly integrate with the medical device manufacturer’s system, thereby significantly reducing supply chain risks and compliance costs.

| Evaluation Dimension | ISO 9001:2015 | ISO 13485:2016 |

|---|---|---|

| Core Focus | Customer Satisfaction, Continuous Improvement | Patient Safety, Regulatory Compliance |

| Risk Management | Risk-based thinking at the organizational level | Systematic risk management throughout the product life cycle |

| Documentation & Traceability | Controlled documents and records | Extremely strict documentation control and traceability |

| Regulatory Alignment | General-purpose | Explicit requirement to comply with applicable regulatory requirements |

RoHS & REACH

These are mandatory EU regulations that restrict specific hazardous substances (like lead, mercury) in products. Hinge suppliers must be able to provide complete material composition declarations to ensure the final medical device’s global compliance.

Part Five: Application Case Studies (Putting Theory into Practice)

Application Cases of Position Control Hinges in Medical and Laboratory Equipment

Patient Monitors and Diagnostic Displays

- Selection Focus: High cycle life (e.g., >50,000 cycles) and low torque decay; smooth feel (small difference between static/dynamic torque); wire management (e.g., hollow shaft design).

Surgical Booms and Microscopes

- Selection Focus: The most extreme precision requirements. Zero backlash and extremely low spring-back are the top priorities to ensure absolute positional stability during surgical procedures. Often requires customized solutions.

Laboratory Incubator and Analyzer Lids

- Selection Focus: Safety is paramount, preventing heavy lids from injuring operators. Asymmetric torque (easy open, slow close) or counter-balance/lift-assist hinges (to achieve a “zero-gravity” feel) are ideal choices.

Portable Ultrasound and Mobile Workstations (COWs)

- Selection Focus: Lightweight (prioritizing engineering plastics or aluminum alloys) and high holding force to resist shock and vibration during transport, ensuring screen position stability.

Part Six: Choosing a Partner: Standard vs. Customization

Standard Products vs. Customization

- Standard Products offer low cost and short lead times, but their fixed specifications may lead to design compromises (i.e., “over-engineered” or “under-performing”).

- Customization should be initiated when standard products cannot meet an application’s unique torque curve, space constraints, or material requirements.

- When choosing a customization partner, evaluating their engineering capabilities is crucial. A strong partner should have capabilities in design and simulation (CAE/FEA), rapid prototyping, in-house test labs (cycle life, environmental testing), and a medical-grade quality system (ISO 13485).

The Warning: Long-Term Dangers of Low-Cost Hinges

In the medical device field, using cheap hinges is a high-risk “saving.” Decisions should be based on “Total Cost of Ownership” (TCO), not just the initial purchase price.

The cost of an early failure from a low-cost hinge—resulting in field failures and repair costs, product recall costs, brand reputation damage, and even potential legal liability—far exceeds the few dollars saved initially. Investing in a well-designed and validated high-reliability hinge is a wise decision to mitigate product life-cycle risks from the source.

Conclusion

In modern medical and laboratory equipment, the position control hinge is a core engineering component that impacts equipment precision, operational reliability, user safety, and even brand value.

Successful hinge selection is a systematic engineering process that requires designers to look beyond a single torque parameter and conduct a comprehensive assessment: quantifying torque through rigorous engineering calculations; delving into material science to select appropriate materials and greases for the specific environment; and ensuring the supplier meets strict compliance certifications (like ISO 13485). Ultimately, selecting a technical partner with deep engineering capabilities and knowledge of industry regulations is the key to reducing TCO and ensuring product success.

FAQ

Q1: My hinge torque decreased after a period of use. Why?

A: This is typically caused by material creep (especially in plastic parts, leading to a loss of preload) or degradation of the grease (aging, oil bleed). A well-designed, high-reliability hinge will control this decay to a predictable, minimal range through advanced material and grease selection.

Q2: How do I balance cost and performance?

A: The key is to adopt a “Total Cost of Ownership” (TCO) perspective. A hinge with a slightly higher initial purchase cost but excellent reliability can save significant money over the product’s life cycle by avoiding expensive field repairs, warranty replacements, and brand reputation damage.

Q3: Do your hinges comply with the IEC 60601-1 standard?

A: This is a question that requires precise understanding. IEC 60601-1 is a certification standard for the final medical electrical equipment (System), not for an individual component. However, a responsible supplier will design, manufacture, and test its hinges to support and help your final device pass the relevant mechanical safety tests in IEC 60601-1 (for example, providing sufficient holding force to pass the 10° tilt stability test).