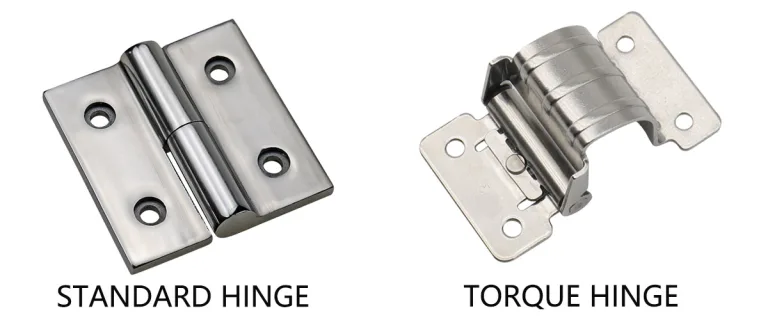

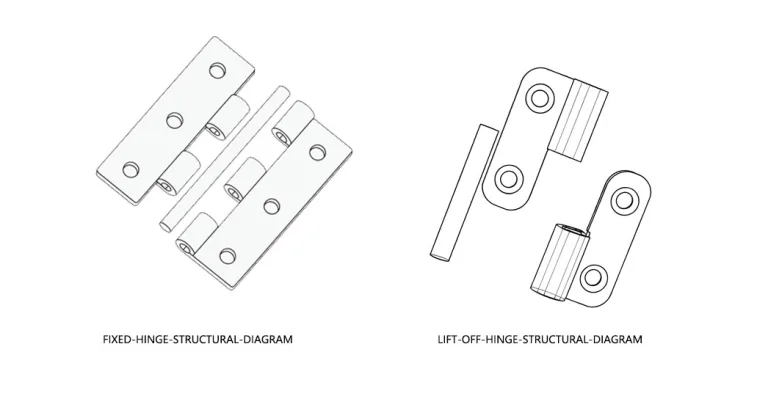

Torque hinges represent a critical advancement over traditional hinges by generating internal resistance (via springs or friction discs) to hold loads at any position. This eliminates the need for external supports, driving adoption across industrial and consumer sectors. Market data shows:

2024 Global Market: $450 million Projected CAGR: 6%+ (2025–2030) Technology Progression:Gen 1 : Fixed-torque designsGen 2 : User-adjustable torque (threaded/cam mechanisms) Physics: T=F×dT =F ×d (Torque = Force × Moment Arm) Units: Primary: N·m (Newton-meters); Alternate: lbf·in (e.g., 1 N·m ≈ 8.85 lbf·in) Operational Modes:Constant Torque : <±10% variation across rotation (e.g., Southco’s spring-clamp technology)Dynamic Torque : Must accommodate inertial loads (safety factor ≥1.5x static torque) Curve Type Key Metrics Validation Standard Torque-Angle (T-θ) Breakaway torque ≤ 120% running torque ASTM F1574 Torque-Life <15% decay after 20k cycles IEC 60068-2 (Cyclic test) Torque-Temperature ±20% drift at -40°F to 185°F (-40°C–85°C) MIL-STD-810H, Method 503

Design Torque Range (N·m) Lifetime Cycles Industrial Use Case Clock Spring 0.1–5.0 20k–50k CNC machine guards (5–50 lb doors) Leaf Spring 0.2–0.8 >50k Control panel mounts

Real-World Example: DMG MORI 5-axis machines use dual-coil spring hinges to replace hydraulic stays, supporting 22 lb (10 kg) doors at 180° positions.

Symmetric Friction Discs: Reell Precision’s design achieves 95% torque consistency (50k+ cycles) Dual Spring + Clutch: Enables asymmetric torque (e.g., train seat armrests: 1.5 N·m stowed / 0.8 N·m deployed) Compliance: FMVSS 302 flammability + AAR S-4200 vibration specs Type Advantage Sector Application Threaded Preload Cost-effective field tuning Medical monitor tilt arms Cam + Belleville Precision multi-stage control Aerospace access panels

Component U.S. Standard Materials Critical Properties Structural Body 316L Stainless (ASTM A276) Salt spray resistance >500 hrs Springs 17-7 PH Stainless (ASTM A313) Fatigue strength: 200 ksi Friction Elements PEEK + 30% GF Nylon (UL 94 V-0) PV limit: 15,000 psi·fpm Coatings TiN + MoS₂ dry film Coefficient of friction: 0.08

Spring Fabrication: Stress-relieving + shot peening per AMS 2430 Assembly: Laser-aligned preload (±0.002″ tolerance) Testing: 100% in-line torque profiling (automated SPC) Machine Safeguarding: Torque ≥ W×L22W ×L (e.g., 24.5 N·m for 11 lb door @ 10″ moment arm) Rail & Transit: Complies with APTA PR-M-S-018 vibration + NFPA 130 fire standards Energy Enclosures: IP65-rated integrated hinge-seal assemblies (NEMA 4X equivalent) Product Category Engineering Breakthrough Performance Benchmark Ultra-thin Laptops Nitrided shafts + flat wire springs 0.3″ thickness, 100k cycles Automotive Displays Synthetic hydrocarbon lubricants -40°F to 250°F operational AR/VR Headsets NiTi microsprings (Ø≤0.24″) Torque: 0.01 N·m @ 50k cycles

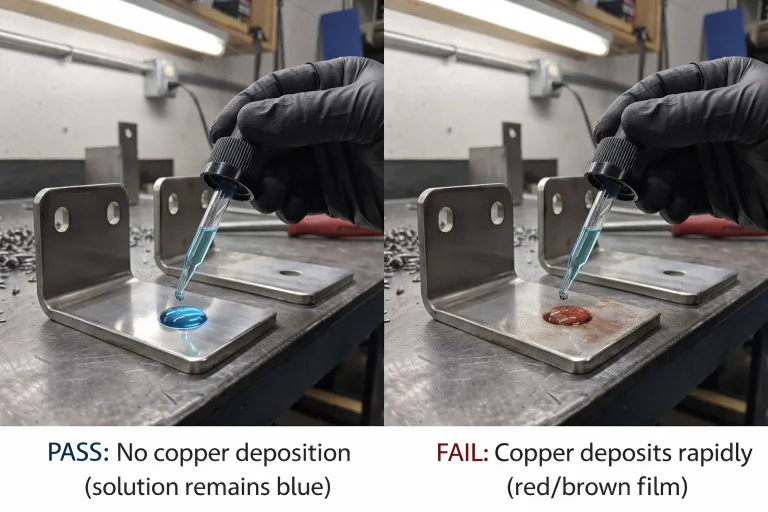

Infection Control: EPA-registered Agion® antimicrobial coatings Chemical Resistance: Peracetic acid-compatible materials (ISO 15883) Drop Testing: 6 ft. MIL-STD-810G compliance for handheld terminals Torque Calculation:Treq=(W×L×sinθ2)×SF+(Wg×a×L)Treq =(2W ×L ×sinθ )×SF +(gW ×a ×L )(SF = Safety Factor ≥1.5) Environmental Mapping: Temperature, chemicals, ingress protection (IP/NEMA) Life Validation: IEC 60529 (dust/moisture) + ASTM E8 (material tensile test) Compliance: UL 94 (flammability), RoHS, REACH Failure Root Cause Mitigation Strategy Torque fade Lubricant degradation PTFE-impregnated composites Cold temperature lock Grease crystallization Synthetic ester-based lubricants Fretting corrosion Micro-motion wear CrN-coated bearing surfaces

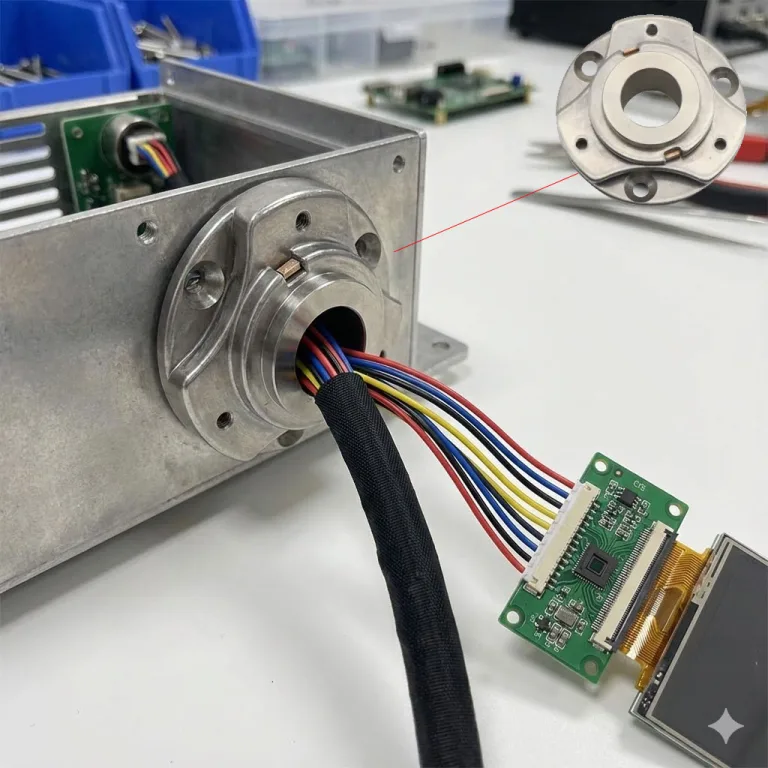

Smart Integration:Strain gauges for real-time torque telemetry Bluetooth-enabled predictive maintenance Material Science:Carbon fiber springs (40% weight reduction) Bio-based lubricants (ISO 15380 compliance) Micro-Manufacturing:MEMS-fabricated nano-hinges (Ø<0.04″) Additive-manufactured topology-optimized structures Torque hinges are transitioning from mechanical components to intelligent motion-control interfaces. Their role in surgical robotics, electric vehicles, and Industry 4.0 systems will expand, driven by demands for precision, durability, and connectivity.