Custom Torque Hinges: 6 Critical Specs to Prevent Product Failure

In my consulting career, I have seen too many excellent product designs fail due to one inconspicuous component: the hinge.

The disaster scenario is common: The procurement department, rushing to meet a deadline, places an order based solely on a single line in a supplier’s catalog—”Rated Torque: 2.0 Nm.”

The result? When the hinge is installed on a medical terminal or industrial controller worth thousands of dollars, the screen slowly sags during vibration testing (a phenomenon we call “creep”), or the user has to use both hands and significant force just to pry the cover open.

At that stage, modifying molds or switching suppliers often costs 5 to 10 times the initial budget.

Purpose of This Article

This is not a basic definition guide. As a procurement manager or project lead, you don’t need to understand the tribology behind friction pads, but you must know how to list the correct technical parameters in your Request for Quotation (RFQ). This guide breaks down the 6 core specifications you must lock down for custom torque hinges (also known as positioning hinges) from a practical, “bottom-line” perspective.

Accurate Torque Calculation and Center of Gravity Analysis

Many procurement professionals simply ask engineers, “How much torque do we need?” The answer is often a single number. This is dangerous.

Don’t Just Look at Max Weight; Look at the “Worst Case”

Torque requirements are not constant. They depend on the Moment of Gravity. According to physics, the required holding force is greatest when the cover is in a horizontal position (0° or 180°).

Recommended Estimation Formula for Procurement:

$$T = L \times W \times f$$

- T (Target Torque): The required torque.

- L (Length): The distance from the hinge axis to the cover’s center of gravity (Note: This is not the total length of the cover. It is usually 1/2 the length, but if a heavy camera or component is mounted at the top, the center of gravity shifts outward).

- W (Weight): The total weight of the cover assembly.

- f (Safety Factor): The safety coefficient.

Why You Must Add a 20% Safety Factor

In the cases I have handled, the vast majority of failures occur because no margin was factored in.

- Friction Decay: Torque in all friction hinges drops slightly after the break-in period.

- Manufacturing Tolerance: The weight of the cover may fluctuate due to paint thickness or glass tolerances.

- Vibration Environment: If the equipment is used on vehicles or vibrating machinery, static friction can easily fail.

My Advice:

If the theoretical calculation is 1.0 Nm, order a 1.2 Nm or 1.3 Nm specification. It is better to be slightly tight (heavier tactile feel) than too loose (causing the cover to sag).

Static Torque vs. Dynamic Torque Distinction

This is the most confusing concept in procurement specifications and the primary culprit behind “poor tactile feel.”

Two Distinct Values

Supplier spec sheets usually list only one “Torque.” You must clarify which one it is:

- Static Torque (Breakaway Torque): The force required to initiate movement from a standstill.

- Function: Determines if the cover can hold its position.

- Dynamic Torque (Running Torque): The resistance felt during rotation.

- Function: Determines the smoothness of the operation.

The Ideal Ratio

In low-end hinges, Static Torque is often 30% or even 50% higher than Dynamic Torque.

- UX Consequence: The user feels significant resistance when starting to move the cover (a “stiction” effect), but once it starts moving, it suddenly becomes loose. This “jerky” feel makes your product feel cheap.

Procurement Action Guide:

When sourcing for high-end equipment (e.g., medical carts, aviation seats), include this clause in your spec sheet:

“The difference between Static Torque and Dynamic Torque must not exceed 10% – 15%.”

This forces the supplier to use premium grease and precision shafts. While the cost will rise, the tactile quality will improve dramatically.

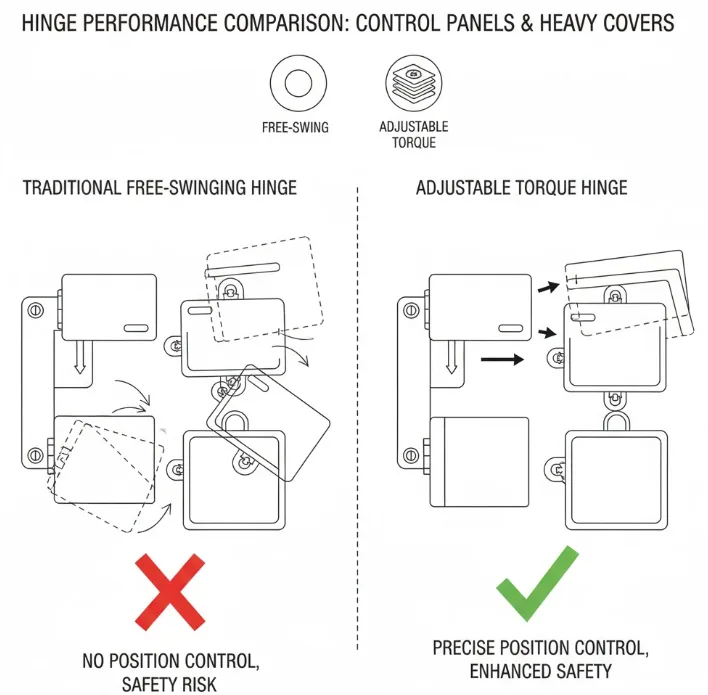

Asymmetric Torque and Damping Direction

“Symmetric torque” (bidirectional) is standard, but the value of “custom” lies in optimizing the experience. We find that for heavy covers exceeding 3kg, asymmetric design is mandatory.

Why Distinguish Direction?

If opening and closing require the same force, the user experience suffers:

- Opening: The user fights against hinge resistance + cover gravity (too heavy).

- Closing: Resistance offsets gravity, but if not tuned correctly, the cover may not stay down.

The Golden Ratio: 60/40 or 70/30

We recommend using One-way Damping or Asymmetric Torque.

- Reverse Installation: Reduce resistance in the direction where gravity aids opening (e.g., a downward-opening inspection hatch).

- Forward Installation: Increase resistance in the direction fighting gravity (e.g., an upward-lifting laptop lid).

Practical Case Study:

In a previous industrial tablet project, we specified an asymmetric design: 1.5 Nm Opening / 2.5 Nm Closing.

Result: Users felt they could lift the screen easily with one hand (low opening resistance), but when released, the strong closing resistance (2.5 Nm) locked the screen firmly in place with zero wobble.

Springback Effect — The Overlooked “Silent Killer”

This is rarely written in textbooks, but it is a major headache for senior engineers.

What is Springback?

When you rotate a hinge to a specific angle and let go, the hinge may “bounce back” a few degrees in the opposite direction due to the elastic memory of metal clips or plastic components.

- Phenomenon: You adjust a screen to 90°, and upon release, it automatically snaps back to 85°.

Why Procurement Needs to Care

For precision optical instruments or laser measurement devices, a deviation of a few degrees is unacceptable.

- Standard Hinges: Springback angle can be as high as 3° – 5°.

- Precision Hinges: Through special heat treatment processes, springback can be controlled to within 1°.

Procurement Action Guide:

If your application is sensitive to angular precision, you must ask the supplier:

“What is the average Springback Angle of your product? Do you have relevant test data?”

Life Cycle Testing and Performance Degradation Curves

The phrase “20,000 cycle life” is meaningless unless accompanied by specific test conditions.

Must-Cite Test Standards

Do not accept a supplier’s arbitrary internal standards. To mitigate risk, cite international standards:

- ASTM F1578: This is the standard for notebook computer hinges but is widely applicable to electronic devices. It specifies testing speeds (e.g., 180 degrees per minute).

Focus on “Residual Torque Percentage”

The critical data is not the number of cycles, but how much force remains after those cycles.

Inferior hinges may lose friction pad integrity after 5,000 cycles, dropping torque to 40% of the initial value, causing the cover to fail to hold.

Spec Sheet Example Clause:

“Require 20,000 full-stroke cycle tests. Upon completion, the torque degradation rate must not exceed 20% (i.e., Residual Torque must remain above 80% of the initial value).”

Salt Spray and Environment (ASTM B117)

If your equipment is used near the ocean, in ship cabins, or for outdoor EV charging stations:

- Mandatory Requirement: Material must be SUS304 or SUS316 Stainless Steel.

- Test Requirement: Pass at least 96 hours (Neutral Salt Spray) or 200 hours salt spray test with no functional corrosion.

- Note: Nickel-plated carbon steel only prevents minor rust and cannot withstand harsh environments.

Tolerance Control and Consistency

This is the hidden factor determining price.

Industry “Hidden Rules”

Friction hinge manufacturing involves complex stamping and heat treatment. Standard industry tolerance is typically +/- 10% to +/- 15%.

This means if you order a 1.0 Nm hinge, receiving a batch at 0.85 Nm (too loose) or 1.15 Nm (too tight) is considered “within spec.”

When Do You Need 100% Inspection?

If your product is high-end consumer electronics (e.g., foldable phones, premium earbud cases), this inconsistency is fatal.

You can specify CPK > 1.33 or require 100% Inspection/Screening in the contract.

- Cost Warning: This typically increases unit price by 20%-30%, but it eliminates massive rework and sorting time on your production line. In our observation, for high-value products, this investment is absolutely worth it.

Advanced Procurement Strategy: How to Analyze Supplier Quotes (Cost Breakdown)

When you receive quotes from three suppliers with vast price differences, how do you judge them? In my experience, the cost is usually hidden in these details:

| Cost Driver | Budget Option | Premium Option | Procurement Advice |

| Shaft Material | Free-cutting Steel | Hardened Steel or 17-4PH Stainless | Hardened steel is more wear-resistant with a longer life; recommended for heavy-duty equipment. |

| Grease | Generic Mineral Oil | High-Performance Damping Grease (e.g., Fluorocarbon Gel) | Premium grease won’t thin out or harden in extreme temperatures, ensuring smooth tactile feel. |

| Tolerance Screening | Sampling (AQL Level) | 100% Torque Testing | If consistency is critical, do not save money on tolerance screening. |

| Tooling Precision | Single Stage Die | Progressive Die | Progressive dies have high initial cost but offer extremely high consistency for mass production. |

Conclusion and Actionable Advice

Selecting a custom torque hinge is essentially balancing three elements: User Experience (Tactile Feel), Durability (Life Cycle), and Cost.

My Final Recommendation:

Do not wait until the molds are cut to look for hinges. During the ID (Industrial Design) phase, contact suppliers with this “Ultimate Checklist”:

- Load Profile: Provide the cover’s center of gravity and maximum weight.

- Motion Trajectory: How many degrees does it need to open? are there dead angles?

- Tactile Definition: Static/Dynamic torque ratio requirements; is asymmetric force needed?

- Environmental Definition: Salt spray test level, operating temperature range (-20°C to 60°C?).

- Validation Standards: Explicitly cite ASTM F1578 or equivalent standards.

Approaching communication with this checklist will not only demonstrate high professionalism but also help your company avoid 90% of potential rework risks.