Five Common Issues with Weld-On Hinges and Quick Solutions

Weld-on hinges are critical components for industrial doors, metal gates, and equipment cabinets. They securely connect door panels to frames via welding, providing strong support and safety. Proper hinge installation ensures stability and smooth operation. However, despite their reputation for durability, poor installation or low-quality products can still cause major issues. For example, welding misalignment during installation may lead to sticking doors, premature hinge wear, or other complications. Before exploring quick fixes, let’s examine the most common challenges faced by weld-on hinge users.

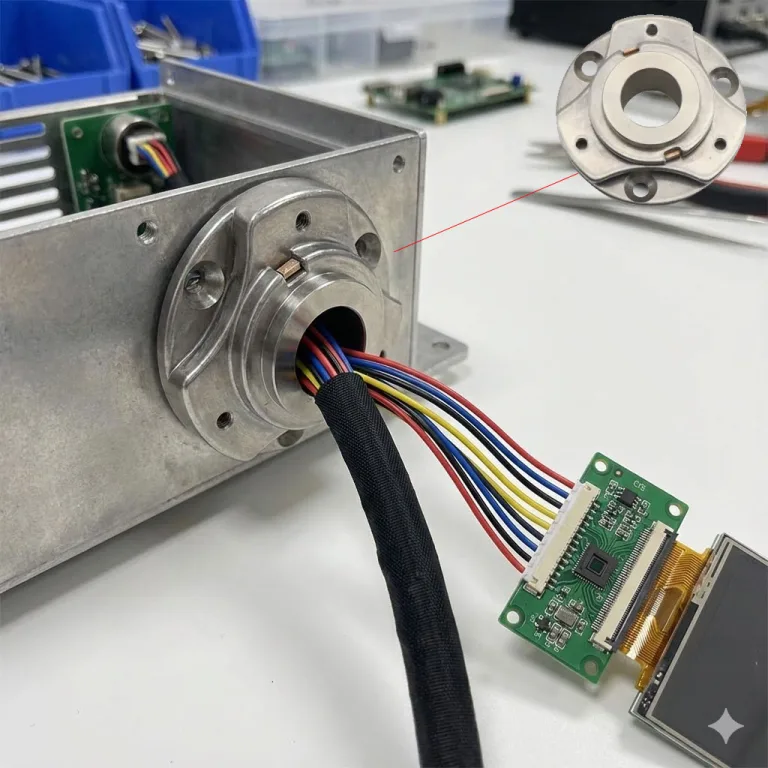

Weld-on hinge welding scenario

Issue 1: Poor Hinge Alignment

Symptoms: Newly installed doors fail to open and close smoothly, sometimes jamming or rubbing against the frame. The door may sag unevenly or resist operation.

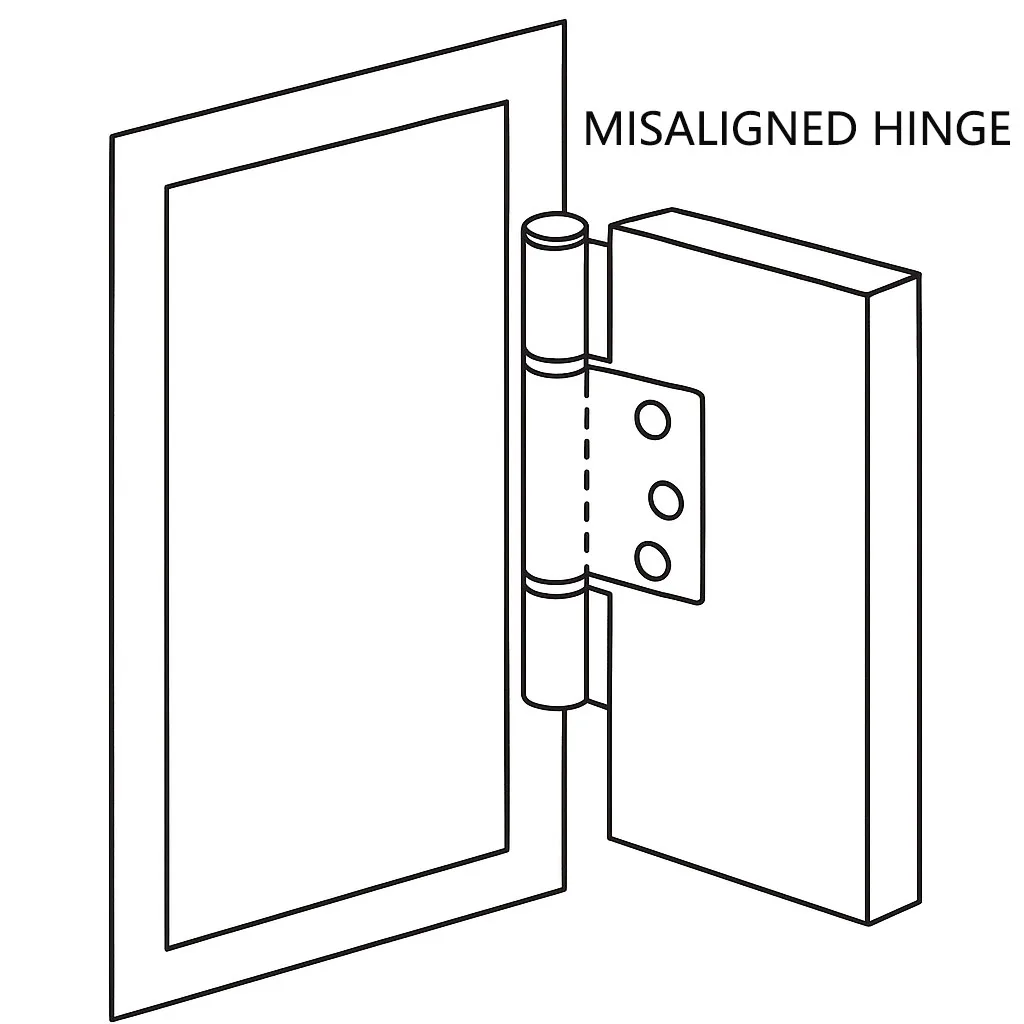

misaligned weld-on hinge installation

Causes: Misalignment during welding is usually the culprit. Common reasons include inaccurate marking or measurement, not using a level or clamps, or an uneven/warped door frame or panel. These factors cause hinge height or angle deviations.

Impact: Misalignment puts uneven loads on hinges, increasing friction and stress. This accelerates wear, shortens hinge lifespan, and can even lead to sagging or detachment.

Solutions:

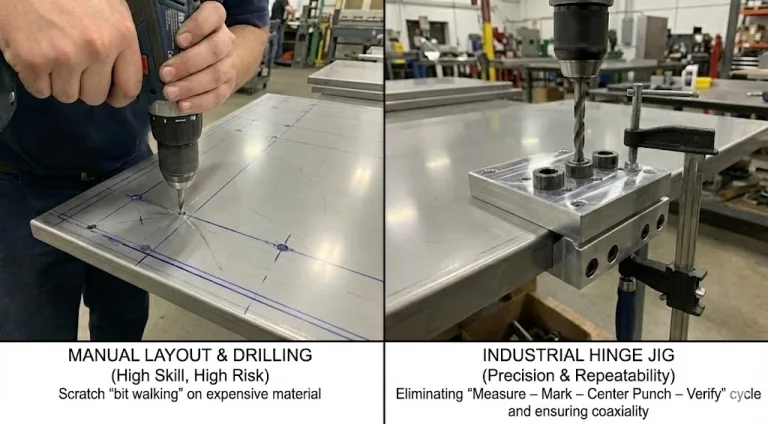

- Use a laser level or spirit level with clamps to secure hinge positions and mark points precisely.(AWS Welding Handbook, Vol.1, Welding Technology, PDFCoffee)

- Perform a spot-weld trial assembly before final welding: secure the hinge with small tack welds, test the door’s movement, and adjust if needed.

- Check the flatness of both door frame and panel, keeping them level during installation to minimize shear forces.

Once alignment is corrected, focus on weld quality.

Issue 2: Insufficient or Uneven Weld Strength

Symptoms: Hinges loosen during use, cracks appear at weld points, or hinges fail to support expected loads.

Illustration of cracked or defective weld joints

Causes: Weak welds result from:

- Choosing the wrong welding method.

- Inadequate surface preparation (oil, rust, or paint left on the surface).

- Poor control of welding parameters or inexperience.

Impact: Weak welds are serious safety hazards. Hinges may loosen or fracture, risking door collapse.

Solutions:

- Select the proper welding method (e.g., MIG for thick steel, TIG for stainless steel or thin materials).For reference, see the following materials:AWS-WELDING HANDBOOK VOL 1

- Clean surfaces thoroughly by removing oil, rust, and coatings before welding.

- For heavy doors, use multi-pass welding to reduce stress and improve strength.

- Rely on skilled welders, controlling current, voltage, and speed carefully. Inspect welds visually or with non-destructive testing.

Even with solid welds, environmental exposure introduces another issue—corrosion.

Issue 3: Corrosion and Rust Accumulation

Symptoms: Rust spots form, hinges operate stiffly, squeak, and lose visual appeal and functionality.

Causes: Outdoor exposure accelerates oxidation if hinges lack protective coatings. Ordinary carbon steel corrodes quickly, while welding heat zones or small cracks at seams become rust initiation points. Neglecting cleaning and lubrication worsens corrosion.

Impact: Rust hinders hinge rotation, damages welds, and may weaken the surrounding structure.

Solutions:

- Use corrosion-resistant materials like stainless steel (304, 316) or galvanized hinges for outdoor or humid environments.For example, HTAN provides stainless steel (304/316) and galvanized weld-on hinges designed specifically for outdoor and humid environments.(ASM International – Corrosion Resistance of Stainless Steels)

- Apply protective coatings such as rust-proof paint, epoxy, or powder coating after welding.

- Perform regular cleaning and lubrication with oil or graphite every 3–6 months. Remove rust spots promptly to prevent spread.

Corrosion isn’t the only cause of hinge failure—incorrect load capacity also leads to problems.

Issue 4: Mismatched Load Capacity

Symptoms: Large or heavy doors sag, open with difficulty, or cause hinge failure.

Causes: Using undersized hinges, miscalculating door weight, or installing too few hinges. Two hinges are often insufficient for tall or heavy doors, resulting in uneven stress distribution.

Impact: Excessive stress causes hinge cracks, weld failure, and unsafe door sagging.

Solutions:

- Calculate door weight and select hinges that meet load-bearing specs. Use at least one hinge per 30 inches (approx. 75 cm) of door height.

- Increase hinge count for heavy or tall doors. Adding a third or fourth hinge distributes weight evenly.

- Consult hinge suppliers or engineers for accurate selection based on material, size, and frequency of use.

Even with the right hinges, performance will decline without proper upkeep.

Issue 5: Lack of Regular Maintenance

Symptoms: Hinges become noisy, sluggish, or even seize up after long use.

Causes:

- Lack of lubrication, causing metal-to-metal wear.

- Loose fasteners or weld points.

- Dust and moisture buildup in outdoor environments.

Impact: Neglect accelerates wear, corrosion, and fatigue, shortening lifespan and creating safety hazards.

Solutions:

- Inspect and lubricate hinges quarterly or semi-annually (every 3–6 months in industrial settings). Increase frequency in humid or high-use conditions.

- Clean hinge surfaces with a cloth or brush before lubrication to ensure protection.

- Regularly check bolts, welds, and pins, tightening or replacing as needed to prevent loosening or shifting.

Consistent maintenance significantly reduces hinge failures.

Key Tips for Preventing Hinge Issues

Comparison Chart of Stainless Steel Welded Hinges vs

- Choose Quality Materials: Prioritize stainless steel (304, 316) or hot-dip galvanized hinges for strength and weather resistance.

- Measure and Test Before Welding: Use precise tools, perform trial assemblies, and confirm smooth door movement before final welding.

- Apply Protective Coatings and Maintain Regularly: Use epoxy paint, powder coating, or galvanization for long-term durability. Clean and lubricate hinges regularly, repairing coatings when needed.

- Work with Professional Suppliers: Reliable suppliers provide expert advice and customized solutions, reducing risks from poor hinge choices.

Conclusion

The five issues above—misalignment, weak welds, corrosion, inadequate load capacity, and lack of maintenance—represent the most common risks in weld-on hinge use. Solutions include precise installation, correct welding techniques, corrosion-resistant materials and coatings, and scheduled inspections. In short: Proper installation + regular maintenance = long-term reliable hinge performance.

When sourcing hinges, choose reputable suppliers to ensure product quality and technical support. Consult professionals for guidance whenever necessary.By partnering with HTAN, users gain access to reliable products and expert consultation for long-term hinge performance.

FAQ

Q1: Where are weld-on hinges most suitable?

A: They are ideal for heavy-duty applications requiring permanent welded connections, such as industrial plant doors, iron gates, equipment cabinets, trailers, and cold storage doors. Compared to bolt-on hinges, they offer greater strength and tamper-resistance.

Q2: How can I check hinge alignment?

A: If a door sticks, sags, or resists movement, alignment may be off. Release the door and see if it stays vertical, or gently push it to check for tilting. Use a level to measure parallelism between hinge and frame.

Q3: Can weld-on hinges be used outdoors?

A: Yes, if corrosion protection is applied. Choose stainless steel (304/316) or apply coatings such as galvanizing, epoxy paint, or powder coating. Regular cleaning and lubrication are essential.

Q4: How often should weld-on hinges be lubricated?

A: Every 3–6 months depending on conditions. Use industrial grease or dry-film lubricant on hinge pins and contact areas. Shorten intervals for humid or high-use environments.

Q5: What is the difference between weld-on and bolt-on hinges?

A: Weld-on hinges are permanently attached, offering superior strength and pry resistance. Bolt-on hinges can be removed or replaced easily but may loosen under heavy loads. Weld-on hinges suit heavy-duty doors, while bolt-on hinges are better for lightweight or frequently serviced doors.