Industrial Hinge Selection Guide: Concealed vs Traditional Hinges

In million-dollar industrial equipment design, hinges are far from insignificant accessories.

They directly influence door-closing reliability, enclosure protection ratings (IP/NEMA), and long-term maintenance costs.

When selecting hinges, engineers often need to balance two fundamentally different design philosophies:

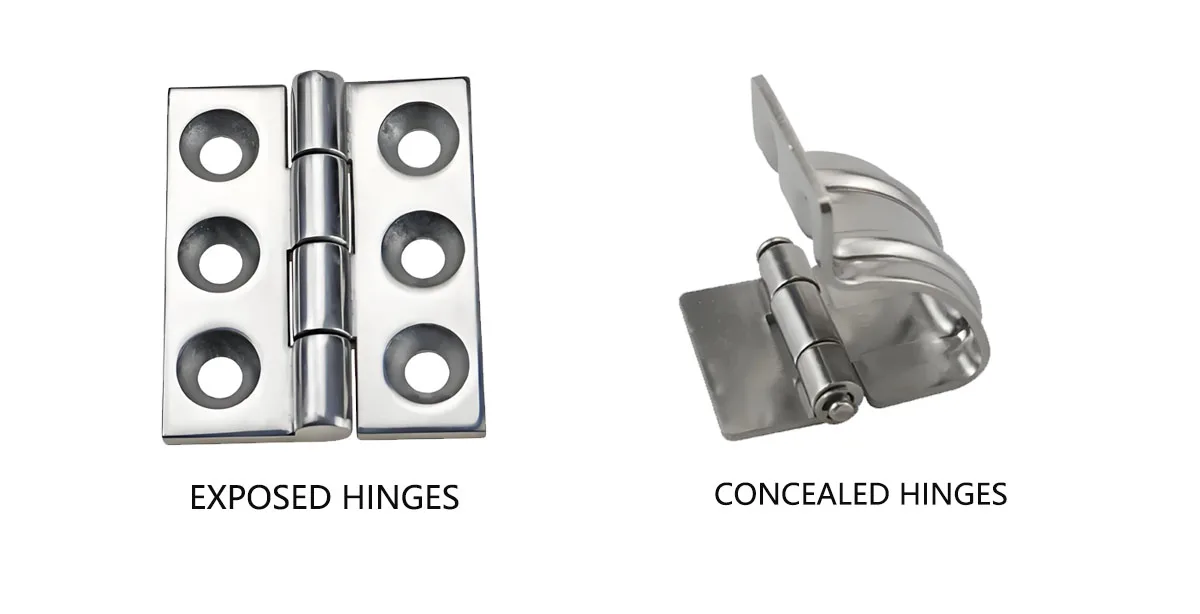

- Concealed hinges – emphasizing smooth appearance and tamper resistance;

- Exposed hinges – focusing on structural simplicity and high load-bearing capacity.

This article systematically compares their engineering characteristics, key performance indicators, and total cost of ownership (TCO),

providing an analytical framework that can be directly applied in design reviews and technical decision-making.

Core Definition of Industrial Hinges

Industrial Concealed Hinge

Definition: Mounted inside the door and frame, completely hidden when the door is closed.

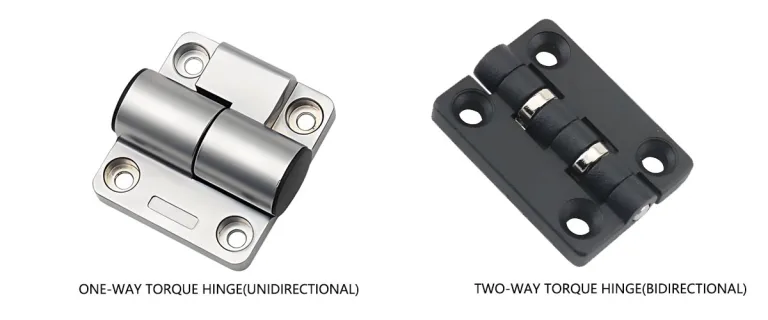

Structural Features: Uses multi-link or internal-shaft mechanisms, typically made from 304/316 stainless steel or high-strength zinc alloy.

These hinges are designed to handle combined axial and radial loads and require tight manufacturing and assembly tolerances.

Typical Types: Multi-joint concealed hinges, industrial-grade HTAN hinges.

Practical Case: In a rail-transit inspection panel project, switching to 316 stainless concealed hinges improved the overall IP rating from IP54 to IP66 and reduced door vibration displacement by 18%.

Industrial Traditional (Exposed) Hinge

Definition: Installed on the outer surface of the door or frame, visible both when open and closed.

Structural Features: Simple design with few components; easy to manufacture and replace. Suitable for welding, bolting, or riveting.

Typical Types: Welded hinges, continuous (piano) hinges, heavy-duty bearing hinges.

Advantages and Limitations of Concealed Hinges

Security and Tamper Resistance

Concealed hinges have no exposed pins or fasteners, eliminating common attack points by design.

They are ideal for applications requiring high intrusion protection—such as electrical control cabinets, data-center racks, ATMs, and inspection panels.

Aesthetics and Space Optimization

They support “zero-gap” door seam designs, delivering a cleaner appearance.

The recessed structure minimizes surface protrusions, making cleaning easier and meeting the appearance and hygiene requirements

of medical, laboratory, and high-end testing equipment.

Sealing and Environmental Protection

Internal mounting helps create a continuous sealing surface, improving protection ratings.

According to IEC 60529, IP66 means “completely dust-tight and protected against powerful water jets.”

This makes concealed hinges a key design element for achieving IP or NEMA compliance in outdoor enclosures.

Limitations:

- Load capacity is slightly lower than that of welded or continuous hinges of similar size.

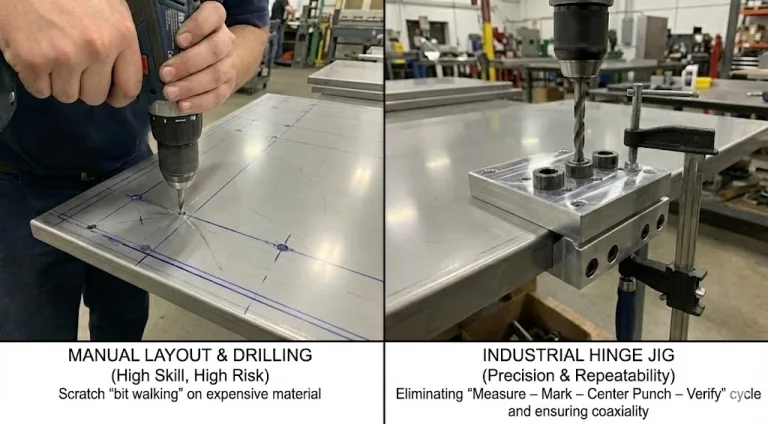

- Complex installation requiring CNC slotting or precision machining.

- Difficult maintenance—hard to lubricate or replace without shutting down equipment.

Advantages and Limitations of Traditional Hinges

High Load-Bearing Capacity and Reliability

Welded or continuous hinges with pin-and-bearing structures can withstand extremely high static and dynamic loads,

making them ideal for heavy machinery, warehouse doors, and mining vehicles.

Easy Installation and Maintenance

Welding or bolting provides quick, reliable installation. Replacement can be done on site with minimal downtime.

Cost Efficiency

Simple structure, mature fabrication, and high material utilization make traditional hinges highly cost-effective

for budget-sensitive or high-frequency usage environments.

Limitations:

- Lower security: exposed pins can be removed unless reinforced with anti-tamper features.

- Poor aesthetics and hygiene: prone to dust or fluid accumulation, unsuitable for food or pharmaceutical industries.

- Limited corrosion resistance: exposed parts require surface treatment or must pass ASTM B117 / ISO 9227 salt-spray testing.

Key Performance Comparison

| Characteristic | Industrial Concealed Hinge | Industrial Traditional (Heavy-Duty) Hinge |

|---|---|---|

| Safety / Tamper Resistance | ★★★★★ | ★★★ |

| Load Capacity | ★★★★ | ★★★★★ |

| IP Protection / Sealing | ★★★★★ | ★★★ |

| Appearance / Concealment | ★★★★★ | ★★★ |

| Installation Complexity | High (precision machining required) | Low (welding/bolting) |

| Maintenance Convenience | Low (hard to access) | High (easy to replace) |

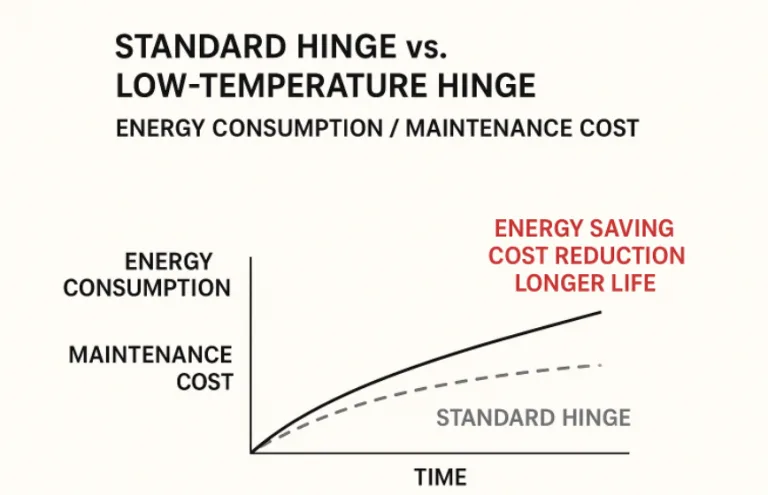

Total Cost of Ownership (TCO) Comparison

TCO includes not only the purchase price, but also installation effort, maintenance cost, downtime risk, and lifecycle value.

| Cost Category | Concealed Hinge | Traditional Hinge |

|---|---|---|

| Purchase Cost | High | Low |

| Installation Cost | High (precision machining) | Low (quick install) |

| Maintenance Cost | High (difficult to access) | Low (field-replaceable) |

| Risk & Lifecycle Value | Excellent in secure, sealed environments | Excellent for heavy-duty, long-life use |

Field Insight: In high-security environments requiring IP/NEMA compliance, concealed hinges offer greater lifecycle value.

In high-load or high-frequency applications, traditional hinges deliver superior cost-performance.

Typical Application Scenarios and Recommendations

| Application Scenario | Key Requirements | Recommended Solution |

|---|---|---|

| High-security / high-value equipment (data cabinets, instruments) | Tamper resistance, aesthetics, IP rating | Concealed hinge |

| Heavy machinery, mining equipment | Load-bearing, vibration resistance, easy maintenance | Welded or heavy-duty exposed hinge |

| Food / pharmaceutical equipment | Cleanability, corrosion resistance | 316 SS concealed hinge or salt-spray-tested exposed hinge |

| Outdoor electrical enclosures | Waterproof, dustproof, corrosion resistance | Concealed hinge meeting NEMA/IP standards |

Selection Self-Check List (Decision Support)

- Is safety or load capacity the top priority?

- Does the application require a high IP/NEMA rating?

- Does appearance affect perceived product value?

- Does manufacturing support precision machining?

- Which is more critical: downtime cost or initial purchase cost?

During design review, it is recommended to include DFMEA (Design Failure Mode and Effects Analysis)

and a TCO decision matrix to ensure that hinge selection is integrated into risk management early on.

Conclusion

Concealed and traditional hinges are not a matter of absolute superiority.

The optimal choice depends on application requirements, engineering constraints, and lifecycle-cost weighting.

- When safety, protection, and appearance are priorities → choose concealed hinges.

- When load-bearing, maintenance, and economy matter most → choose traditional hinges.

Design Recommendation:

Quantify hinge performance and cost impacts at the DFMEA stage.

Incorporating these parameters into the system risk matrix helps reduce rework, delays, and maintenance costs later in the project lifecycle.

Author

Author Bio

Zhifang Li, Mechanical Design Engineer with 10+ years of experience in industrial equipment and sheet-metal structure design.

Led multiple projects in rail-transit systems, electrical enclosures, and medical devices, with deep expertise in protection structures and lifecycle cost analysis.