0.5 Nm Torque Hinges: Engineering Principles, Failure Modes, and Application Guidelines

Figure 1: Close-up application of a 0.5 Nm torque hinge on a rugged industrial handheld device, showing the pivot mechanism for screen positioning.

Why Focus on the 0.5 Nm Specification?

In the realm of industrial hardware and electronic structural design, 0.5 Nm (approximately 5.1 kgf-cm or 4.4 lb-in) is a critical yet frequently misunderstood specification. Based on my observation of numerous hinge failure cases over the years, 0.5 Nm represents the definitive “tipping point” between lightweight handheld devices and desktop instrumentation.

For mechanical engineers, understanding this value isn’t just about selecting a part number; it is about achieving the perfect balance between “one-handed operation” and “position holding” for devices with 7-inch to 10-inch screens.

Specification Positioning: The Sweet Spot for Lightweight Devices

We typically define 0.5 Nm as the standard resistance value for small clamshell devices. If your design goal involves a flip-up assembly with a total weight between 300g and 600g, 0.5 Nm is generally the first value you should test.

In this range, the hinge must perform a dual task:

- Support Gravity: Prevent the screen from automatically closing or falling open within a 30° to 120° range.

- Provide Damping: Allow the user to adjust the angle with one hand without needing to hold the base down with the other.

The Cost of Errors: Consequences of Incorrect Selection

I frequently see engineers choose the wrong torque value based on “gut feeling” rather than precise evaluation, leading to significant design flaws:

- Choosing 0.8 Nm (Too Heavy): This forces you to add artificial weight to the device base; otherwise, the base lifts up when the user tries to open the lid. This is a fatal flaw for handheld devices where portability is key.

- Choosing 0.3 Nm (Too Light): While easy to open, it lacks sufficient static friction. The screen will drift or shake when the device is in a vibrating environment (like a vehicle mount) or during touchscreen operations.

Objective

As an experienced industry consultant, I will guide you through verifying the applicability of 0.5 Nm using a simple look-up table, evaluating environmental endurance via ASTM standards, and accepting shipments using data-driven checklists.

Deep Dive into 3 Core Application Scenarios for 0.5 Nm Hinges

Based on market data and engineering experience, the following three scenarios utilize 0.5 Nm torque hinges most frequently—and are also where selection errors occur most often.

Scenario 1: Portable Medical Diagnostics

Application Description: Handheld ultrasound scanners, portable blood analyzers, and vital signs monitors used in EMS scenarios. These devices usually feature a protective flip cover with an embedded display.

Technical Pain Points:

Medical environments require stability during movement. Doctors often hold the device in one hand while operating a probe with the other. Additionally, the device must withstand regular wiping with alcohol.

Why 0.5 Nm Works:

We find that the flip cover weight for such devices is usually controlled under 600g.

- Balance: 0.5 Nm perfectly counteracts the gravitational moment of the cover, preventing it from snapping shut while the doctor is walking or turning.

- Touch Resistance: Crucially, when a doctor taps the touchscreen to set parameters, the hinge must provide reaction force. If the torque is below 0.4 Nm, the force of a finger tap (typically 1-3 Newtons) will cause the screen to bounce back, severely degrading the user experience.

Industrial HMI & Handheld Terminals

Application Description: Wireless inventory scanners for warehousing, small add-on control screens for CNC machines, and teach pendants for industrial robots.

Technical Pain Points:

Industrial environments are full of low-frequency vibrations. If the hinge holding force is insufficient, the screen will exhibit “nodding” (slow downward drift) while the machine is running.

Why 0.5 Nm Works:

Here, the role of 0.5 Nm is not just support, but vibration resistance.

- Static Friction Advantage: Compared to lighter 0.3 Nm hinges, the internal interference fit (usually steel clips on a shaft) of a 0.5 Nm hinge provides a higher coefficient of static friction.

- ** eliminating Lock Mechanisms:** Using a qualified 0.5 Nm constant torque hinge allows designers to eliminate extra mechanical locking knobs, simplifying the structure and lowering BOM costs.

Pro AV & Security Equipment

Application Description: Sunshades for professional camera monitors, folding antennas for drone ground stations, and camera flip-ups on portable video conferencing units.

Technical Pain Points:

This is a specific “Light Load, Long Lever Arm” scenario. For example, a folding antenna may weigh only 150g, but its length could reach 300mm.

Why 0.5 Nm Works:

Although the weight is low, the torque generated by the long lever arm is significant.

- Torque Amplification Effect: We recommend 0.5 Nm hinges for such long, slender components specifically to counteract the leverage effect. This ensures the antenna or sunshade remains suspended at any angle without shifting due to wind or minor bumps.

Engineering Practice: How to Quickly Determine if 0.5 Nm is Right

Many clients ask, “Do I have to perform complex physics calculations to select a hinge?” My answer is: Not during the preliminary selection phase.

Based on our analysis of hundreds of handheld device projects, we have summarized a simple “Rule of Thumb.” If your device fits the following characteristics, 0.5 Nm is usually the correct starting point.

Core Metric Quick-Check Table

Don’t be intimidated by physics formulas. You only need to focus on two core data points: Panel Weight and Screen Size.

| Device Screen Size (Ref) | Panel Weight Range (Ref) | Recommended Torque | Is 0.5 Nm Suitable? |

| 5.0 – 6.0 Inches | 150g – 250g | 0.25 – 0.35 Nm | Too Heavy (Opening feel will be stiff) |

| 7.0 – 8.0 Inches | 300g – 450g | 0.45 – 0.60 Nm | Perfect Match (The Sweet Spot) |

| 10.0 Inches + | > 600g | > 0.80 Nm | Too Weak (Panel will not hold position) |

Consultant’s Note:

If your device is a ~7-inch medical handheld or industrial tablet, and the flip section weighs around 350g, then 0.5 Nm is almost certainly your standard answer. You don’t need to recalculate; request samples of this spec directly.

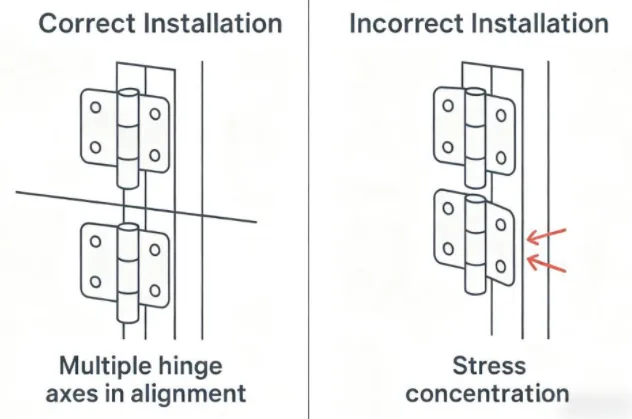

The “Invisible Force” You Must Consider: Leverage

Figure 2:Because the right side is farther from the pivot, identical 300 g creates larger torque

Why does a 0.5 Nm hinge sometimes fail to hold a 300g object? Usually, it is due to the Leverage Effect.

- Situation A (Safe): 300g weight is concentrated near the pivot (e.g., a thick, blocky base).

- Situation B (Risk): The same 300g is distributed in a long, thin sunshade where the center of gravity is far from the pivot.

Rule of Thumb:

If your flip component is long and slender (length > 15cm), even if the weight is light, please upgrade directly to 0.5 Nm or higher rather than 0.3 Nm. It is better to have a slightly stiffer feel than a device that “droops.”

The “Finger Press” Test: Specific Advice for Touchscreens

For touchscreens, gravity isn’t the biggest enemy—the user’s finger is.

In our test labs, we often see hinges that support the screen’s weight perfectly but retract when the user taps an icon. This gives the user a perception of “loose, poor quality.”

Practical Advice for Procurement:

If your device is a touchscreen, follow the “+20% Rule”:

Check the table above for the recommended torque based on weight.

Add a 20% torque margin on top of that.This extra force is specifically reserved to resist finger tapping.

Conclusion: For 7-8 inch touch devices, 0.5 Nm provides that “rock-solid” premium feel that lower torque hinges cannot achieve.

Key Variables Affecting 0.5 Nm Performance

After confirming the theoretical value, we need to address real-world manufacturing variables. In small torque specifications like 0.5 Nm, minor deviations are keenly felt by the user.

Tolerance Stack-up

This is the root cause of most procurement failures.

- Industry Reality: Standard torque tolerance for industrial hinges is typically ±15% to ±20%.

- Data Analysis: If you buy a nominal 0.5 Nm (±20%) hinge:

- Upper Limit: 0.6 Nm (User might find it too hard to open).

- Lower Limit: 0.4 Nm (Might fail the touch stability test).

Recommendation:

For critical designs, you must specify a symmetric tolerance range on the 2D drawing. For example: 0.5 Nm +0.05/-0.05 Nm. This increases cost but guarantees consistency.

Temperature Effects on Damping Grease

Most constant torque hinges rely on a combination of viscous grease and mechanical friction.

- Low-Temp Risk (-20°C): Grease viscosity spikes. We have tested standard grease where torque jumped from 0.5 Nm to over 0.8 Nm at -20°C. This can crack plastic housings at the mounting root.

- High-Temp Risk (+60°C): Grease thins out, causing torque drop. This leads to slow panel “creep” (drooping) in hot environments.

Standard Protocol:

Explicitly state the operating temperature range in your spec sheet and ask the supplier if they use wide-temperature range specialty damping grease.

Springback

In light torque hinges (like 0.5 Nm), the energy storage effect of the metal clips causes “Springback.”

- The Phenomenon: The user stops the screen at 45°, and when they let go, it automatically bounces back to 43°.

- Strategy: While hard to eliminate entirely, it can be minimized by selecting high-rigidity shaft structures. You must check for this during the Design Verification Test (DVT) phase, as excessive springback feels “cheap” and imprecise.

Material Selection and Life Cycle Testing Standards

As a buyer, you must understand how different materials affect the stability of 0.5 Nm performance and accept goods based on international standards.

Shaft and Housing Material Matching

- Powder Metallurgy (PM):

- Pros: Low cost, good for high volume.

- Cons: Uneven density can lead to poor torque consistency.

- Advice: Only use for consumer electronics with low precision requirements.

- Stainless Steel + Hardened Steel:

- Pros: Wear-resistant, corrosion-resistant.

- Advantage: Highest torque stability.

- Advice: The only choice for medical devices and outdoor instruments.

- Engineering Plastic (POM/Nylon):

- Warning: While all-plastic friction hinges exist, plastic’s “creep” characteristics cause torque to decay rapidly within six months at the 0.5 Nm level. I strongly advise avoiding pure plastic friction structures for 0.5 Nm applications.

Life Cycle Testing

Do not accept a supplier’s verbal promise of “long life.” You need the test report.

Standard Test Protocol Recommendation:

- Stroke: 0° to 180° reciprocating motion.

- Frequency: 10-15 cycles per minute.

- Pass Criteria: After 20,000 cycles, torque decay must not exceed 20% of the initial value.

- Translation: A hinge starting at 0.5 Nm must not drop below 0.4 Nm after years of use (approx. 20k cycles).

Salt Spray Test (Corrosion)

For medical (chemical wipes) and outdoor devices, corrosion resistance is non-negotiable.

- Reference Standard: ASTM B117

- Indoor Devices: Require 24-hour salt spray with no red rust.

- Outdoor/Medical: We strongly recommend requiring 48-hour or 96-hour ASTM B117 compliance. This ensures the internal shaft does not seize due to rust accumulation.

Procurement and Inspection Checklist

To ensure stable quality for bulk purchases of 0.5 Nm hinges, I have compiled a practical inspection checklist. Please incorporate this into your Incoming Quality Control (IQC) process.

Sample Evaluation Points

Before approving mass production (PPAP), check these two points:

- Static vs. Dynamic Torque:Use a torque tester to rotate the hinge. Observe the peak value at the moment of start.

- Red Flag: If the starting (static) torque is 0.7 Nm but the running (dynamic) torque is only 0.4 Nm, the user will feel a distinct “stiction” or jerkiness. In a premium 0.5 Nm hinge, the difference between these two values should be within 10%.

- Tactile Consistency:Randomly select 10 samples. Rotate them by hand.

- Subjective Check: Even if they are within tolerance, if one feels very loose and another very tight, the supplier has poor Process Control.

Key Items for the Supplier Spec Sheet (RFQ)

When requesting a quote, strictly include these parameters:

- Nominal Torque: 0.5 Nm ±15% (Recommended to tighten tolerance).

- Life Cycle: >20,000 Cycles (Decay <20%).

- Static Holding: No rebound or drift at any angle.

- Operating Temp: -20°C to +60°C.

- Mounting: Specify breaking torque for mounting holes (to prevent self-tapping screws from stripping).

- Compliance: RoHS and REACH compliant.

Conclusion

Summary

The 0.5 Nm torque hinge is the bridge between lightweight display technology and user experience. While it is small in volume and cost, its performance dictates the reliability and “premium feel” of a handheld device. It is highly susceptible to tolerance stack-up, temperature changes, and material quality.

Actionable Advice

As a closing note, here is a practical tip for engineers currently running a project:

Do not cut molds immediately.

Before finalizing the 0.5 Nm specification, use SLA (3D printing) or CNC to build a prototype with the real weight and center of gravity. Purchase samples of 0.4 Nm, 0.5 Nm, and 0.6 Nm to install and test.

In my experience, only through physical touching and shaking of a prototype can you find the perfect value that holds the screen steady while feeling smooth to the user. Always reserve at least a 20% torque safety margin in your design to account for future wear.

FAQ

Q1: What is the typical weight range for a 0.5 Nm hinge?

A: Generally, a single 0.5 Nm hinge (or a pair totaling 1.0 Nm) is ideal for device panels weighing between 300g and 600g (approx. 0.6 to 1.3 lbs), common in 7-inch to 10-inch tablets or medical handhelds.

Q2: Why does my device screen bounce back when I tap it?

A: This is usually due to insufficient torque to resist the “finger force.” For touchscreen devices, we recommend the “+20% Rule”: calculate the torque needed to hold gravity, then add 20% extra resistance to ensure a solid tapping experience.

Q3: How much torque tolerance should I expect?

A: The industry standard is ±15% to ±20%. For precision applications, you should request a tighter tolerance (e.g., ±10%) from your supplier to ensure consistent feel across all units, though this may increase cost.

Q4: Can 0.5 Nm hinges work in freezing temperatures?

A: Standard damping grease stiffens in the cold, causing torque to spike (making the device hard to open). If your device is used below 0°C, you must specify wide-temperature range grease (effective from -20°C to +60°C) in your RFQ.

Q5: What is the standard lifespan of a friction hinge?

A: A high-quality industrial hinge should pass 20,000 open-close cycles with less than 20% torque decay. Always ask for a life-cycle test report before mass production.

Recommended Text:

Designing for a Heavier Application?

If your project involves a screen larger than 12 inches or a panel heavier than 1.0 kg, the 0.5 Nm specification discussed here will be insufficient.

To avoid vibration issues and screen drooping on larger devices, please read our heavy-duty guide: 👉 [2 Nm Torque Hinge Procurement Guide]