Load Distribution in Industrial Cabinets: Continuous vs. Butt Hinges

In the engineering of industrial enclosures—such as electrical control cabinets and server racks—the technical selection of Continuous Hinges vs. Butt Hinges determines the integrity of the primary load-bearing interface. These components must reliably manage static gravitational loads and dynamic operational stresses over thousands of cycles, making the choice between linear and point loading critical for long-term performance.

Improper hinge specification often leads to localized structural failure, compromising both the environmental seal and the enclosure’s safety. The core engineering challenge lies in the effective transfer of the door’s weight into the cabinet frame. This article analyzes the structural mechanics of Continuous Hinges (Piano Hinges) versus Butt Hinges to provide a data-driven basis for hardware selection.

Structural Definitions and Mechanical Loading Models

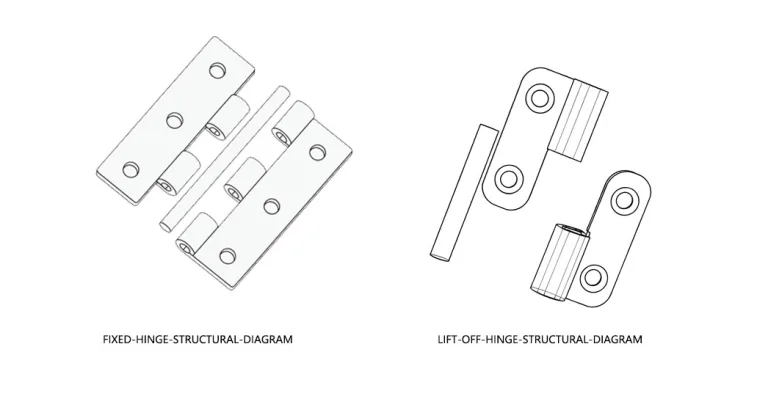

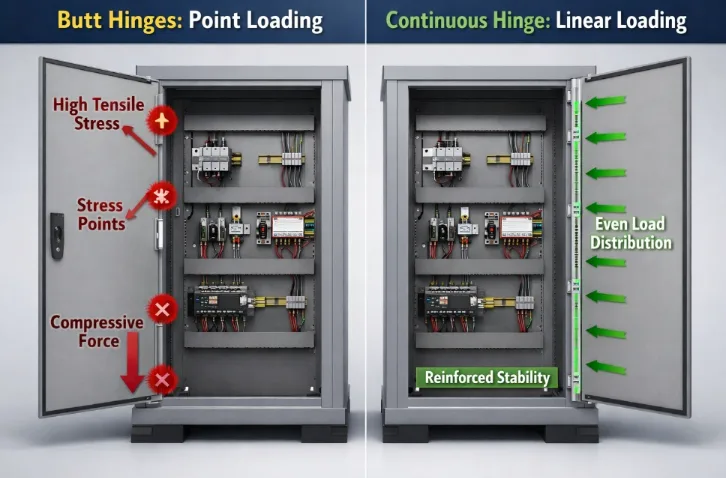

Butt Hinges: The Point Loading Model

Butt hinges are discrete mechanical components installed at specific intervals.

- The Mechanic: This arrangement creates Point Loading. Because the attachment points are separated, the door’s mass creates a moment arm that results in a high tensile load at the upper fasteners and a compressive load at the lower fasteners.

- The Engineering Risk: Stress is concentrated at the immediate perimeter of a few fastener holes. In enclosures with thin-gauge cabinet walls, this can lead to fastener hole elongation or localized yielding (permanent deformation) over time.

Continuous Hinges: The Linear Loading Model

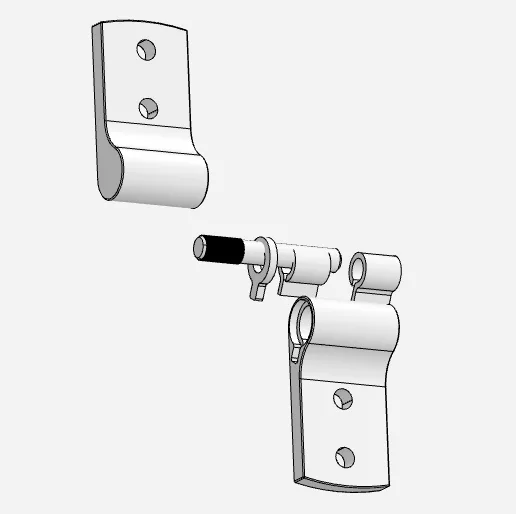

A continuous hinge runs the full height of the door, utilizing an integrated single-axis design.

- The Mechanic: While ANSI/BHMA A156.26 provides performance classifications and cycle testing criteria for these hinges, the inherent mechanical advantage lies in the linear fastener pattern. This allows the total weight to be shared across a significantly higher number of attachment points.

- The Stiffener Effect: Beyond load transfer, the hinge leaves act as a continuous reinforcement rib. This increases the vertical section modulus of the door edge, effectively enhancing the overall rigidity of the assembly.

Comparative Analysis of Load Distribution

Stress Concentration and Gauge Suitability

The interaction between hardware and sheet metal thickness (typically 1.5mm to 3.0mm in industrial applications) is a critical failure point.

- Butt Hinges: In higher door-weight ranges (e.g., tens of kilograms and above), concentrated stress can exceed the yield strength of the cabinet wall near the top hinge. This often necessitates the use of heavy-duty reinforcement plates.

- Continuous Hinges: By spacing fasteners at dense intervals (typically 50mm to 75mm), the shear force per individual screw is minimized. This configuration allows relatively heavy doors to be mounted securely even on thin-gauge panels, though final designs should always verify the required safety margin based on door geometry.

Alignment and Operating Torque

- Coaxiality Requirements: Utilizing multiple butt hinges requires precise alignment of the centerlines across all units. Minor deviations in concentricity can lead to increased operating torque and accelerated pin wear due to internal friction.

- Single-Axis Integration: A continuous hinge features a factory-aligned, unbroken pin. This eliminates the accumulation of assembly tolerances, ensuring consistent rotational resistance and reducing maintenance requirements.

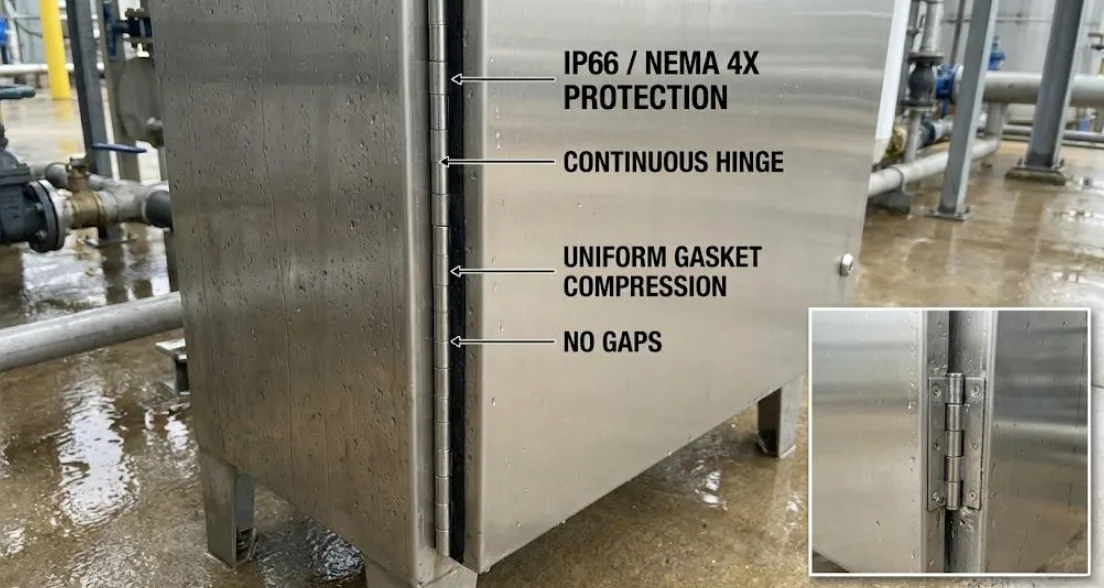

Protection Ratings and EMC Considerations

For enclosures requiring high ingress protection (IP66 / NEMA 4X):

- Gasket Compression: Continuous hinges provide uniform support along the entire length of the door. This prevents the “bowing” effect between hinges, ensuring that the environmental gasket is compressed evenly to maintain its seal.

- EMC Shielding Support: The continuous metal-to-metal contact can help maintain a more consistent bonding path, which may support Electromagnetic Compatibility (EMC) design goals. However, final performance must be verified against applicable EMC standards (e.g., IEC 61000 series) and should consider the enclosure’s specific bonding and grounding strategy.

Technical Performance Comparison Matrix

| Feature | Butt Hinges | Continuous Hinges |

| Loading Model | Concentrated Point Load | Uniform Linear Load |

| Sag Resistance | Moderate (Material Dependent) | Superior (Structural Reinforcement) |

| Fastener Stress | High Tension at upper points | Minimal per point (Distributed) |

| Alignment Sensitivity | Critical (Multi-axis Concentricity) | Low (Integrated Single Axis) |

| Vibration Robustness | Risk of localized loosening | Excellent (Multi-point Anchoring) |

| Security Level | Gaps allow for levering/prying | High (Seamless seam protection) |

Standards and Compliance Reference

For a rigorous specification process, engineers should consult the following international standards:

- ANSI/BHMA A156.26: Performance and cycle test classification for continuous hinges.

- ANSI/BHMA A156.1: Performance criteria for standard butt hinges.

- NEMA 250 / UL 50E: Requirements for enclosure structural integrity and environmental protection.

- IEC 60529 (IP Code): Classification of degrees of protection provided by enclosures.

- ASTM B117: Standard practice for salt spray testing (crucial for material/coating verification in corrosive environments).

FAQ: Engineering Inquiries

Q: Can a continuous hinge fix an existing enclosure with door sag?

A: Yes. In many retrofit scenarios, engineers replace failing butt hinges with a continuous hinge to redistribute the vertical load across the entire frame. This process reinforces the previously yielded frame material and restores the door’s original alignment and functional clearance.

Q: What safety factor (SF) should be used for hinge load calculations?

A: Engineers should apply a safety factor based on the enclosure’s risk class and internal design rules. While many organizations utilize factors between 1.5 and 2.0 for static load checks, the final value must align with the specific project’s design control plan and anticipated dynamic loads, such as seismic activity or transport vibration.

Q: How do you calculate the capacity of a continuous hinge?

A: Manufacturers typically rate capacity as a “load per linear inch” or “load per 100mm.” To calculate the total capacity, multiply this rating by the total hinge length, assuming a consistent fastener pattern and appropriate substrate thickness.

Conclusion

While butt hinges remain a viable, cost-effective solution for enclosures with rigid, reinforced frames and standard loads, continuous hinges offer a superior mechanical model for high-load or thin-walled applications. By distributing forces linearly, they mitigate localized stress, enhance frame rigidity, and support long-term environmental sealing.

Would you like me to develop a specific “Checklist for Enclosure Hardware Specification” based on these standards, or perhaps a more detailed look at the corrosion resistance of different stainless steel grades?