Friction vs. Torque Hinges: Achieving Free-Stop Functionality

Laptop lid with free-stop functionality

In everyday product design—whether laptop screens, kitchen cabinet doors, or industrial equipment covers—a common challenge arises: how can lids or panels stay at any angle during movement, instead of slamming shut or opening fully?

This highlights the limitations of traditional hinges.

Common Pain Points

Limitations of Traditional Hinges:

Conventional designs allow only two states—fully open or fully closed.

Safety Hazards:

Sudden closure of heavy lids risks pinching fingers or damaging equipment.

Usability Issues:

Users cannot secure lids at the optimal angle for operation or viewing.

Core Requirement: “Free-Stop”

Achieving “free-angle holding capability” (or “free-stop” functionality) is a critical design goal in many professional fields (e.g., medical, industrial), not merely a matter of convenience.

To achieve this, designers typically rely on two key components: friction hinges and torque hinges.

This article explores the working principles, types, advantages, and disadvantages of both, providing a detailed selection guide to help you choose the ideal “support” for your product.

What Is a Friction Hinge?

The friction hinge offers the most straightforward solution. As the name suggests, its functionality revolves entirely around friction.

How Friction Hinges Work: Mastering the Art of Friction Control

A friction hinge generates a constant resisting force through its internal components—spring plates, friction washers, or tight interference between the shaft and sleeve.

When the lid rotates, this resistance converts into damping torque, counteracting the lid’s weight (or gravitational components at various angles) and allowing it to hold position at any angle.

The torque it provides remains relatively constant throughout its range of motion.

Primary Types of Friction Hinges

Leaf-type friction:

A curved metal leaf clamps around the shaft to create friction.

Washer-type friction:

Friction arises by compressing a set of (metal or non-metal) washers.

Sleeve-type friction:

A sleeve tightly encircles the rotating shaft, producing controlled resistance.

Advantages and Disadvantages of Friction Hinges

Advantages:

- Simple structure and easy manufacturing

- Low initial cost

- Compact design, ideal for space-constrained applications

Disadvantages:

- Wear and Lifespan: Friction surfaces wear over time, causing torque decay—commonly known as “loosening.”

- Torque Consistency: Manufacturing tolerances affect torque output, leading to poor unit-to-unit consistency.

- Handling Feel: May show a “stick-slip effect”—high initial resistance followed by sudden easing—creating uneven motion or noise.

- Environmental Sensitivity: Open design allows dust or moisture intrusion. Temperature shifts can change friction coefficients, altering torque.

Durability testing can refer to standards such as DIN EN 1935 (Building Hardware – Single-axis Hinges), which covers cyclic and corrosion testing.

What Is a Torque Hinge?

Next, let’s explore a more precise and engineered solution—the torque hinge.

Clarifying Key Concepts: Torque Hinges vs. Friction Hinges

This is a common point of confusion. Broadly speaking, most torque hinges generate torque through friction.

However, for selection purposes in this article, we distinguish them as follows:

Friction Hinge:

A simple hinge relying on basic friction surfaces.

Torque Hinge (Precision or Constant Torque Hinge):

A precision-engineered hinge delivering rated, predictable, and long-lasting torque performance—an advanced evolution of the friction hinge.

Core Technologies of Precision Torque Hinges

- Precision Friction Mechanism: Utilizes advanced materials, multi-disc friction assemblies (similar to automotive clutches), or encapsulated spring systems.

- Patented Design: Many feature proprietary designs ensuring smooth torque output and long service life.

- Sealed Structure: Often filled with specialized grease to prevent noise, wear, and contamination by dust or moisture.

Advantages and Disadvantages of Torque Hinges

Advantages:

- Exceptional Durability: Withstands tens or hundreds of thousands of cycles with minimal torque decay (e.g., <15% after 20,000 cycles).

- Consistent Torque: Factory-calibrated torque ensures uniform performance across units.

- Premium Feel: Smooth, quiet, and uniform motion with no stick-slip effect.

- Environmental Resilience: Sealed construction enables reliable operation in harsh environments.

Disadvantages:

- Higher initial cost due to precision manufacturing

- Slightly larger size for equivalent torque output

Core Showdown: Friction Hinge vs. Torque Hinge

| Comparison Dimension | Simple Friction Hinge | Precision Torque Hinge |

|---|---|---|

| Torque Accuracy | Low, wide tolerance range | High, precisely calibrated |

| Torque Consistency | Poor, varies by unit | Excellent, consistent batch-to-batch |

| Service Life | Short (thousands of cycles) | Long (tens to hundreds of thousands) |

| Torque Decay | Rapid and unpredictable | Slow and predictable |

| Operating Feel | May stick or generate noise | Smooth, uniform, and quiet |

| Environmental Resistance | Poor | Excellent, sealed construction |

| Maintenance | May need cleaning or adjustment | Maintenance-free |

| Initial Cost | Low | High |

| Total Cost of Ownership (TCO) | High (replacement/maintenance) | Low (long lifespan) |

Beyond Cost: The True Value of Selection

User Experience:

In electronics and premium appliances, smooth operation enhances perceived quality.

Reliability:

In medical, aviation, or defense fields, hinge failure is unacceptable—reliability is critical.

Total Cost of Ownership (TCO):

A durable, maintenance-free torque hinge often results in lower lifetime cost than a cheaper friction hinge requiring replacements.

How to Select the Right Hinge

Step 1: Calculate Required Torque

Torque is defined as Force × Lever Arm.

Simplified formula:

Where:

T = Torque per hinge (N·m)

W = Lid weight (N)

D = Horizontal distance from lid’s center of gravity to hinge axis (maximum when lid is horizontal)

N = Number of hinges (usually 2)

Add a 20–30% safety margin to the calculated torque, considering the most unfavorable angle.

Step 2: Define Your Core Requirements

- Usage Frequency: Daily cycles? (industrial vs. household)

- Feel and Quality: Is tactile experience critical?

- Environment: Dust, humidity, vibration, temperature?

- Budget: Initial cost vs. lifecycle cost?

- Space Constraints: Available installation space?

Selection Guidelines

Choose Friction Hinges When:

- Low-cost product with infrequent operation

- Examples: Toolboxes, makeup mirrors, storage bins, toy chests

- Suitable when performance degradation over time is acceptable

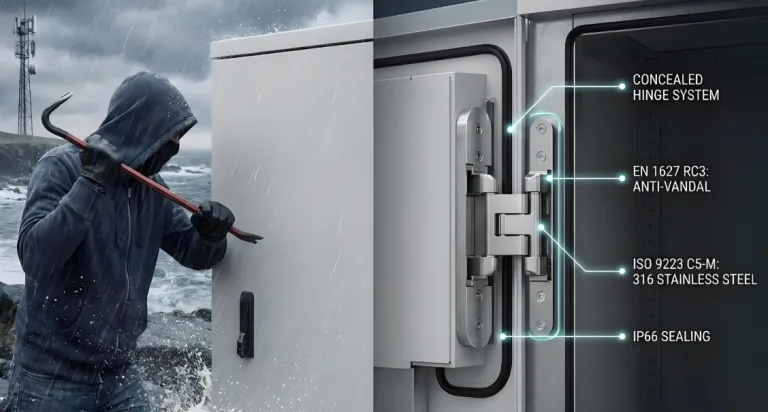

Choose Precision Torque Hinges When:

- High Usage Frequency & Premium Feel:

Laptops, premium appliances, luxury automotive compartments - High Reliability & Harsh Environments:

Medical monitors, industrial control panels, outdoor enclosures, marine devices - Heavy-Duty Covers & Safety Requirements:

Machinery guards, copier lids, large access panels

Application Examples

How Torque Hinges Are Used in Various Industries

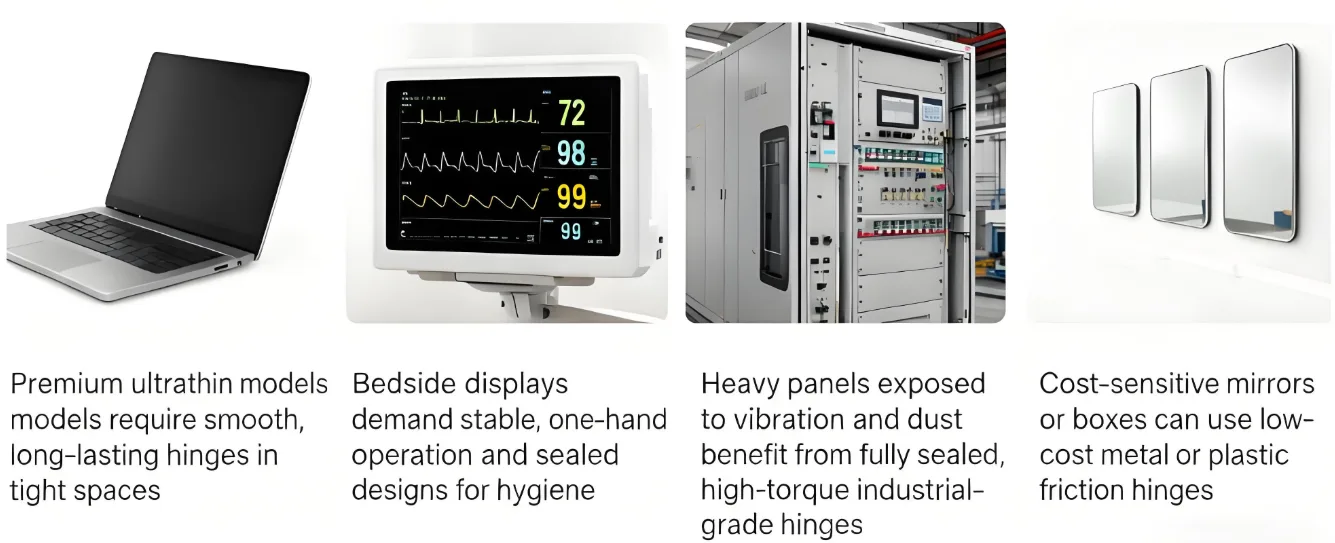

Case 1: Laptop

Premium ultrathin models require smooth, long-lasting hinges within tight spaces. Dual-axis torque hinges provide precise, silent motion—hallmarks of modern laptop design.

Case 2: Medical Monitor

Bedside displays demand stable, one-hand operation and sealed designs for hygiene. Medium-torque sealed hinges deliver reliability and ease of use.

Case 3: Industrial Control Cabinets

Heavy panels exposed to vibration and dust benefit from fully sealed, high-torque industrial-grade hinges—maintenance-free for years.

Case 4: Home Appliances

Cost-sensitive mirrors or boxes can use low-cost metal or plastic friction hinges—adequate for their limited lifecycle.

Installation and Maintenance

Best Practices:

- Coaxial Alignment: Hinge axes must be strictly collinear to prevent uneven torque or premature wear. Refer to ISO 1101 geometric tolerance for “coaxiality.”

- Even Load Distribution: Ensure lid weight is shared across all hinges.

- Proper Fastening: Use correct screws and torque for secure installation.

Maintenance:

Torque Hinges:

Typically maintenance-free—do not disassemble or lubricate.

Friction Hinges:

Keep friction surfaces clean; adjust compression if possible, though this is only a temporary fix.

Conclusion

Friction and torque hinges are not competing technologies but complementary solutions.

- Friction Hinges solve the fundamental “hold at any angle” problem economically.

- Torque Hinges deliver superior precision, feel, and longevity—ideal for demanding, high-end applications.

Designers’ Takeaway:

- Never compromise on hinge quality. A failing hinge can undermine an otherwise premium product.

- Clearly define your torque needs, lifespan expectations (refer to JIS S 1032 furniture hinge testing), and quality goals.

- With the right hinge, your lid will stay precisely where you want it—smoothly, reliably, and for years to come.