Industrial Control Cabinet Safety: Technical Guide for Positioning Hinges to Prevent Door Fall Injuries

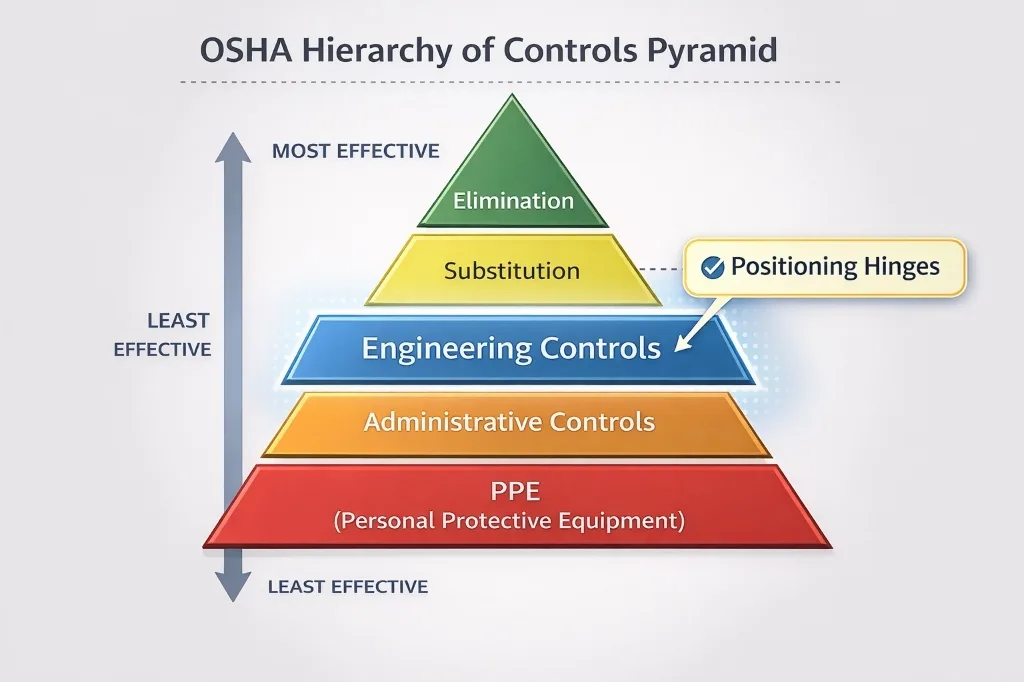

Deploying Positioning Hinges (also known as Constant Torque Hinges) in industrial automation production lines and power distribution facilities is crucial to mitigate the significant physical risk posed by the accidental movement of heavy control cabinet doors, such as falling, rapid closing, or sudden release. According to the risk assessment and risk reduction principles of ISO 12100 (Safety of machinery — General principles for design), uncontrolled door movement is a typical mechanical hazard. Risk reduction should prioritize engineering control measures rather than relying solely on warning signs or operating procedures.

This guide introduces how to implement stable, controlled movement and “free-stop” functionality for cabinet doors by deploying Positioning Hinges (also known as Constant Torque Hinges), thereby reducing the risk of door-fall injuries at the source.

Core Technical Definitions

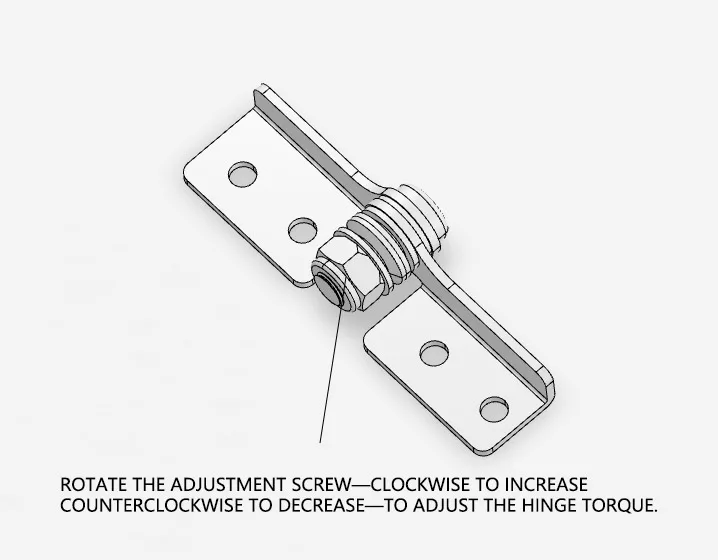

- Positioning Hinge: A hinge integrated with a friction damping or torque control mechanism. It uses internal resistance to counteract or partially counteract the load’s gravity, ensuring the door remains controlled during opening.

- Constant Torque: The hinge provides an approximately constant resistive torque within a specific angular range (e.g., 0° to 180°), ensuring uniform movement of the door.

- Free-stop: The door remains stationary at any angle relying solely on hinge resistance, without the need for external supports such as gas springs or mechanical struts.

- Safety by Design (Inherently Safe Design): A design approach that limits dangerous movement or reduces hazardous energy through structural design and engineering controls to prevent accidents.

Industry Benchmarks

When evaluating the reliability of positioning hinges as safety hardware, it is recommended to use manufacturer test reports and common industrial test methods as a basis. Common target indicators are as follows:

| Performance Category | Recommended Target Indicator | Reference Method/Standard |

| Fatigue Life | Higher than 20,000 cycles (Torque attenuation within 20%) | Supplier Cycle Life Test Report |

| Corrosion Resistance | Neutral Salt Spray (NSS) 96–480 hours | ASTM B117 |

| Torque Tolerance | Within +/- 15% of the rated torque value | Supplier Torque Calibration Report |

| Material Strength | Fastener strength grade higher than 8.8 | ISO 898-1 |

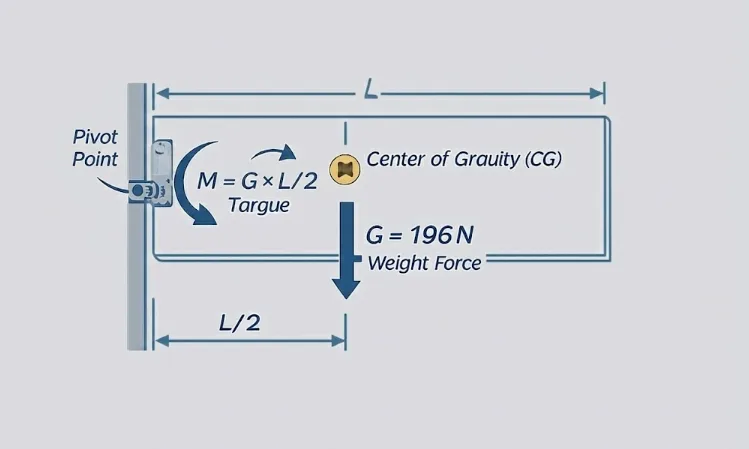

Practical Case: Torque Calculation for Fall Prevention

To ensure that positioning hinges effectively prevent falling, a mechanical verification should be performed based on the door’s physical parameters, combined with a safety factor to determine the hinge selection.

Determine Known Parameters

- Door Mass (W): 20 kg

- Gravitational Acceleration (g): 9.8 N/kg

- Door Width (L): 0.6 m (assuming the hinge is on the side and the center of gravity is at L/2)

Calculate Door Weight (G)

- G = W * g = 20 kg * 9.8 N/kg = 196 N

Calculate Maximum Gravitational Torque (M_max)

The torque is at its maximum when the door is opened to a near-horizontal position:

- M_max = G * (L / 2) = 196 N * 0.3 m = 58.8 N-m

Selection Decision (Safety Factor of 1.2)

Total Required Torque (T_total) = M_max * 1.2 = 58.8 * 1.2 = 70.56 N-m

If using 2 hinges installed symmetrically:

- Rated Torque per hinge = 70.56 / 2 = 35.28 N-m

Engineering Selection Points:

- The torque should aim to “counteract gravity and achieve hovering.” Excessive torque will result in difficult opening, accelerated wear, and potential long-term deformation or loosening of the mounting points due to stress.

- After selection, perform hover verification and operational “feel” validation to ensure the door can stay stable and open/close smoothly.

Technical Comparison: Safety Advantages of Positioning Hinges

In industrial safety engineering, the OSHA Machine Guarding eTool emphasizes the “Hierarchy of Controls.” This framework prioritizes Engineering Controls—physical changes to equipment that eliminate hazards—over administrative warnings. Positioning hinges serve as a primary engineering control by physically arresting dangerous motion.

| Solution | Movement Performance | Potential Safety Risk | Core Flaw |

| Standard Hinge | Fully gravity-driven; fast opening or falling. | High risk of head injuries or crushed fingers. | Lacks control mechanism; relies on manual support. |

| Gas Spring | Automatic lifting; possesses initial pop-out force. | Sudden fall if pressure is lost. | Risk of sudden failure; requires frequent maintenance. |

| Mechanical Strut | Provides support only at specific locking positions. | Accidental release leads to unexpected falling. | Complex operation; high risk during one-handed use. |

| Positioning Hinge | Moves and stops at any position; stable and controlled. | Resistance is continuous; no sudden falling risk. | Integrated structure; no additional parts needed. |

Failure Mode and Effects Analysis (FMEA)

The risk control logic of positioning hinges for the specific failure of “door falling and injuring personnel” is as follows:

| Failure Mode | Potential Cause | Risk Level | Prevention and Design Strategy |

| Door sliding down slowly | Insufficient torque or increased load. | Medium | Implement 1.2x safety factor; recalculate if load changes. |

| Axis/Structure fracture | Material fatigue, shock loads, or corrosion. | Extremely High | Use high-strength stainless steel (e.g., SS304/SS316) and set inspection cycles. |

| Loss of positioning function | Wear of friction pairs or temperature drift. | High | Regular hover tests; replace if resistance weakens. Confirm temperature range suitability. |

| Mounting loosening | Vibration, insufficient preload, or lack of anti-loosening. | High | Use lock washers/threadlocker. Install per torque specs and include in inspections. |

Industry Best Practices and Operational Checklist

Industry Best Practices

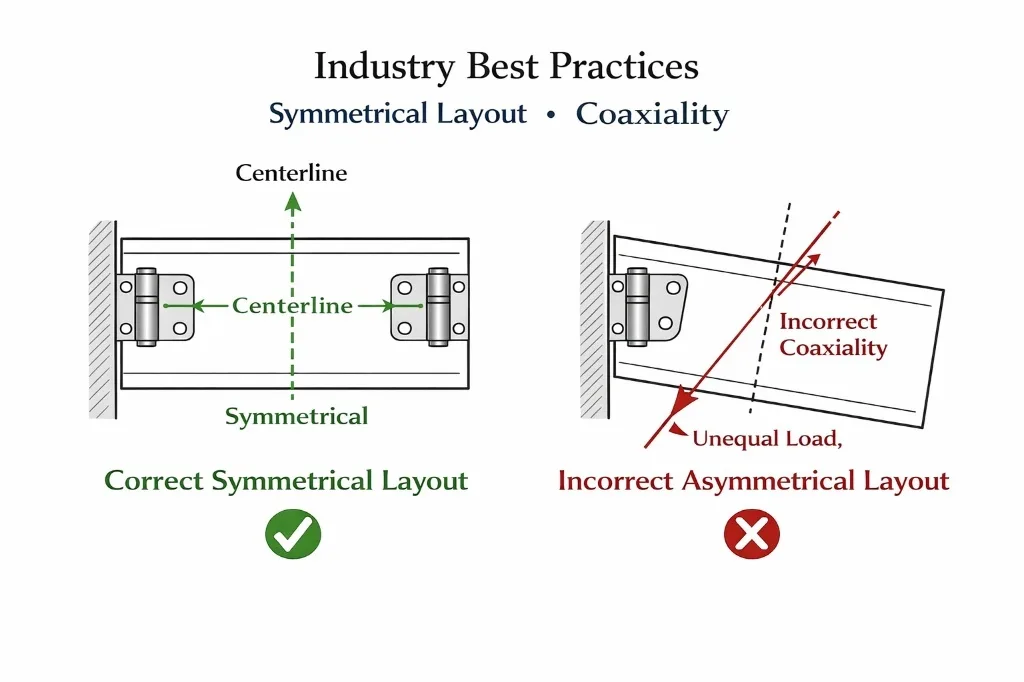

- Symmetrical Layout: Install positioning hinges symmetrically (top/bottom or left/right) to avoid offset loads that shorten lifespan or cause torque anomalies.

- Material Matching: Prioritize stainless steel for humid, dusty, or corrosive environments, selecting based on salt spray rating requirements.

- Temperature Adaptation: In high-temperature environments, confirm that the hinge’s internal materials and lubrication system are suitable to avoid significant torque fluctuations.

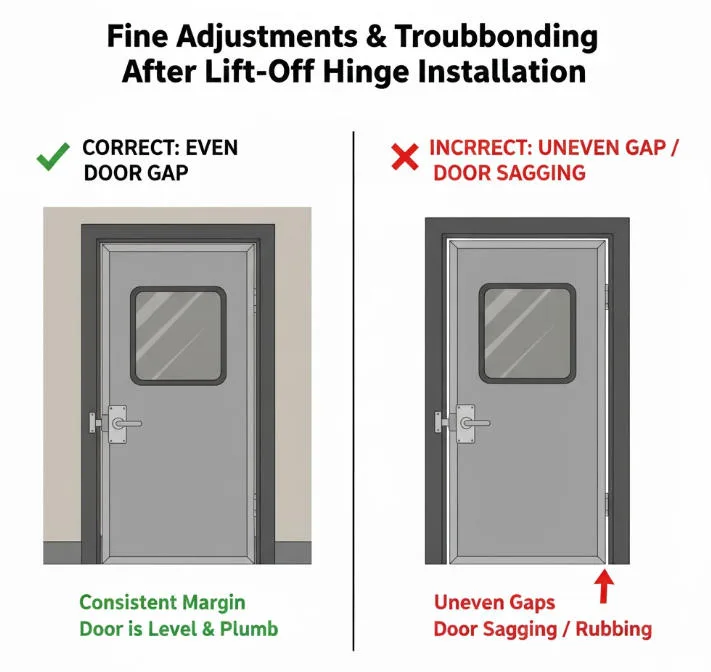

- Installation Precision: Ensure the coaxiality and parallelism of the hinge axis to avoid accelerated wear from additional lateral loads.

Field Safety Checklist

- Static Hover Test: Place the door at 30, 60, and 90 degrees; ensure no displacement within 15 seconds.

- Operation Feedback Check: Opening torque is uniform with no sudden jumps, sticking, or abnormal noise.

- Fastener Integrity: Bolts are not loose and show no cracks or corrosion.

- Load Verification: No extra displays, fans, or cooling units added to the door; if added, torque must be recalculated.

- Appearance Condition: No oil leakage, no metal shavings, and no abnormal wear powder.

FAQ

Q1: Are positioning hinges safer than gas springs?

A: Generally, yes, regarding the prevention of accidental falls. Gas springs rely on sealed pressure and can fail suddenly; positioning hinges typically exhibit gradual torque attenuation, allowing risks to be identified early through inspections.

Q2: Will it be difficult to open the cabinet door after installing positioning hinges?

A: Not if properly selected. The torque should be calibrated to counteract gravity. Both the operating force and the “hand-feel” must be validated to ensure the door is controllable yet smooth.

Q3: How do I handle a decline in torque after years of use?

A: Choose products with documented cycle life data and perform regular hover tests. If a downward trend in the door’s position is observed, replace the hinges promptly.

Q4: Can positioning hinges completely eliminate the risk of pinched fingers?

A: They cannot eliminate it entirely, but they significantly reduce the probability of crushing injuries caused by gravity-induced loss of control. They should still be used in conjunction with safe operating procedures.

Q5: Is stainless steel mandatory?

A: It depends on the environment. In humid, dusty, or corrosive gas environments, stainless steel significantly reduces the risk of structural failure caused by rust. Its use is highly recommended in such cases.

Conclusion

The falling of control cabinet doors is a typical mechanical hazard that can be mitigated through engineering controls. Implementing positioning hinges allows for stable, controlled movement and free-stop functionality at any angle, reducing the risk of sudden falls and improving maintenance safety and efficiency. It is recommended to perform torque calculations for heavy doors, select appropriate models, and implement verification and periodic inspections according to the checklist to ensure safe and reliable operation throughout the equipment’s lifecycle.