One-Way Torque Hinge Design and Applications

Introduction

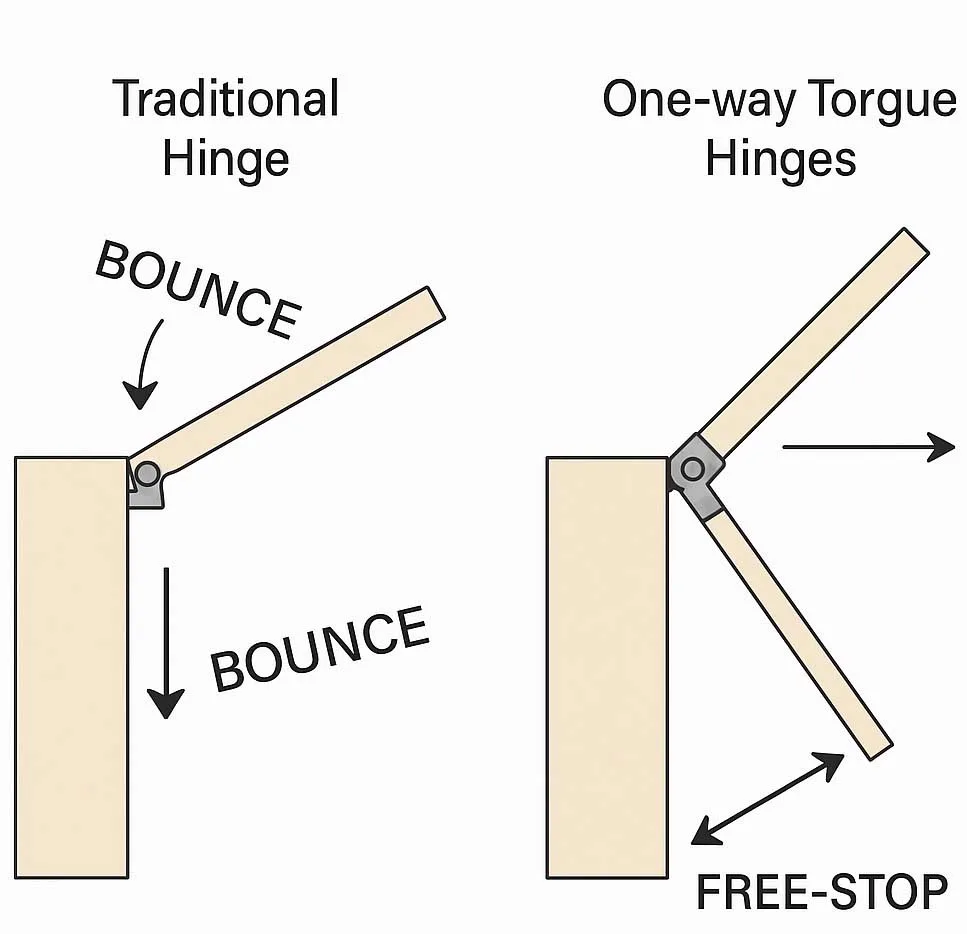

Traditional hinges often fail in high-end cabinets, medical devices, and lab cabinets. Problems include insufficient rigidity control. Doors can suddenly fall or bounce back due to gravity or inertia. This causes noise, safety risks, and user inconvenience.

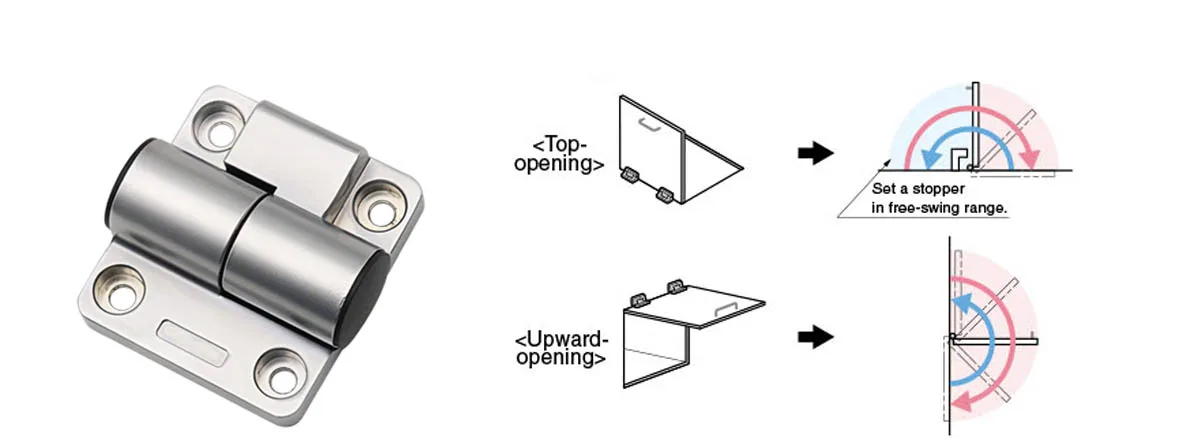

In contrast, one-way torque hinges provide controlled resistance only in the opening direction. The closing direction has near-zero friction. This allows the door to “free-stop” at any angle. These hinges integrate special torque mechanisms — they lock position in one direction but move freely in the other.

Comparison Chart Traditional Hinges vs. One-Way Torque Hinges

This article systematically explores one-way torque hinges. We cover their definition, classification, working principles, key design parameters, manufacturing, and applications. We analyze their value for high-end storage and industrial design.

Definition and Classification of One-Way Torque Hinges

Core Definition

An one-way torque hinge generates torque resistance only when opening or lifting the door. Closing (or the opposite direction) has minimal resistance. The door moves freely. This one-directional force keeps the door stable at any open angle. Gravity or reverse motion won’t move it.

Unlike common two-way damped hinges, one-way torque hinges provide resistance only when the user lifts or pushes the door. Upon release, they automatically “free-stop”, significantly improving operational smoothness.

Classification

Torque Generation Mechanism:

- Spiral Spring Type: Uses coiled springs to create torque (similar to “curl friction”). Common in small torque hinges.

- Friction Disc Type: Uses angled discs and springs. Resistance comes from disc compression. Compact and adjustable.

- Magnetic Hysteresis Type: Uses permanent magnets or magnetic damping. Offers wear-free operation and long life.

- Hydraulic Check Valve Type: Contains silicone or high-viscosity oil with a one-way valve. Opening closes the valve, creating damping. Closing opens it for free flow.

Adjustment Method:

- External Knob: Users directly turn a knob to change preload torque.

- Hex Socket Screw: Adjust with a hex key. “Just tighten one screw with an Allen key” often fine-tunes the torque.

- Infinite Dial: Dial with markings for continuous adjustment and locking.

Mounting Style:

- Full Overlay (Concealed): For doors fully covering the cabinet frame.

- Half Overlay: Common on wooden cabinet doors.

- Inset: Hidden inside the cabinet and door for aesthetics.

- 180-Degree Folding: Opens fully; ideal for flip-up/folding doors.

- Aluminum Frame Glass Door Specific: Reinforced for glass in aluminum frames.

Key Differences

| Hinge Type | Resistance Direction | Special Feature |

|---|---|---|

| Two-Way Damped Hinges | Both directions | Prevent wobbling |

| One-Way Torque Hinges | One direction only | Free-stop + directional control |

| Free-Stop Hinges | Both directions | Locks at any angle |

Unique Feature: One-way torque hinges resist only in one direction. Opening requires torque; closing is nearly frictionless.

Working Principles Explained

Mechanical One-Way Systems:

Use needle clutches or ratchets with torsion springs. Clutch engages in one direction, creating resistance. In reverse, it disengages, enabling free rotation — like a car clutch. Torsion springs provide torque.

Friction Disc Systems:

Use angled cam discs and Belleville springs. Friction is generated during compression in one direction. In reverse, springs relax, reducing friction. High-strength bearings ensure torque stability.

Fluid Damping Systems:

Contain silicone/oil and a one-way valve. Opening = valve closes = damping. Closing = valve opens = free flow. Optional solid lubricants (e.g., MoS₂) make them maintenance-free.

Torque Adjustment Mechanisms:

- Preload Thread with Dial: Axial nut/screw alters preload. Each dial mark ~0.1 N·m torque change.

- Eccentric Cam: Varies lever arm length for continuous torque tuning.

Key Design Parameters & Calculation

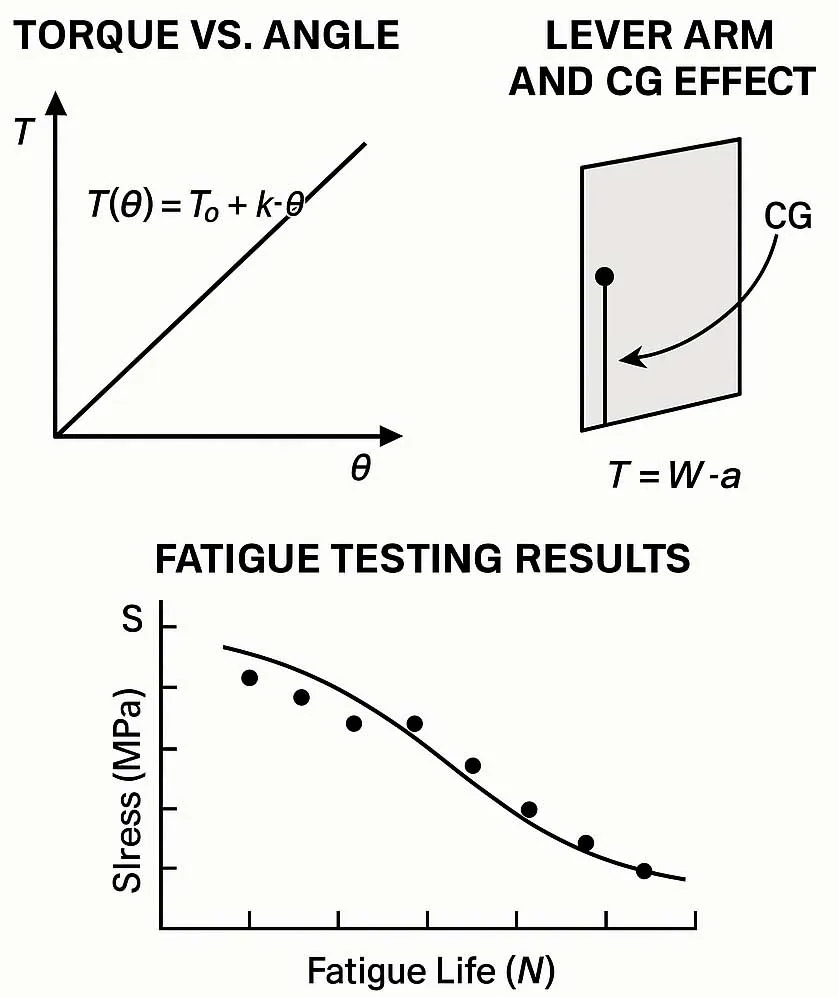

- Torque Curve:

Near-linear:T(θ) = T₀ + k·θ.

T₀ = preload torque; k = stiffness.

Closing torque ≈ 0. - Torque Requirement:

τ = F × d(F = door weight, d = CG distance from hinge).

Multiple hinges share the load. Each hinge must handle its share. - Life Model:

Use Miner’s Rule + S-N curves. High-quality designs reach 100,000+ cycles. - Material Selection: ComponentMaterialFeaturesSpringAlloy steelHigh fatigue resistance, surface-treatedHousingZinc alloy or 316L SSZinc = cost-effective; 316L = corrosion resistant

- Tolerances & NVH:

Tight fits (±0.05mm) reduce noise. Solid lubricants lower friction and wear.

Shown in the figure are the torque-angle relationship, CG-induced moment, and fatigue life

Manufacturing & Quality Control

- Spring Winding: CNC coiling + laser force measurement.

- Housing Casting: Die-casting + CNC machining for critical areas.

- Clutch Assembly: Cleanroom assembly; shaft perpendicularity ≤ 0.02mm.

- Torque Testing: 100% calibration. Torque-angle curve checked via servo testers.

- Environmental Testing:

- 48-hour salt spray

- 50,000+ open/close cycles

- Accelerated aging

Ergonomics & User Experience of Adjustment

- Knob Resistance Profile: Non-linear for safety. Prevents accidental changes.

- Scale Visibility: High-contrast, luminous dials. Hidden viewports.

- Tool-Free Adjustment: Some models use dials with audible clicks.

Applications and Case Studies of One-Way Torque Hinges

Premium Kitchen Cabinets

Tall flip-up doors (e.g., 1.8m) need one-handed lift. One-way torque hinges support smooth open/stay and free-close.

Medical Sterile Cabinets

Prevents door rebound in sterile environments. Quiet, stable, antibacterial stainless/brass.

RV/Boat Cabin Doors

Locks doors during travel in one direction. Free in the other. Withstands -40°C to +80°C. Ideal for moving vehicles.

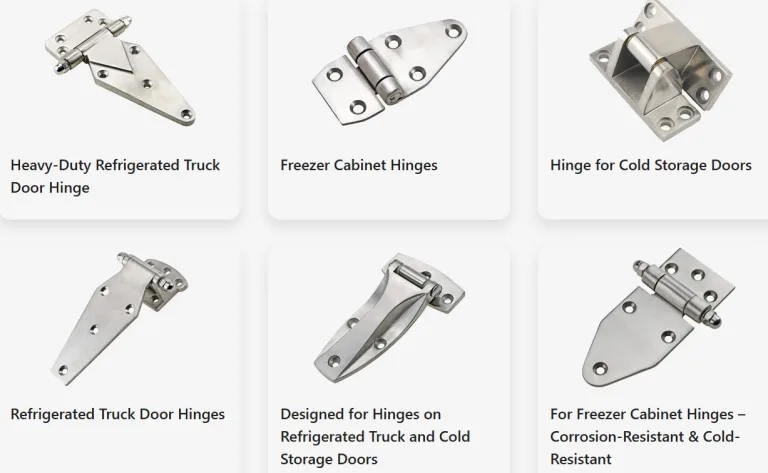

Commercial Freezers

Works at -20°C. PTFE coatings ensure torque stability (±10%). Safe and consistent in cold environments.

8. Installation, Tuning & Maintenance Guide

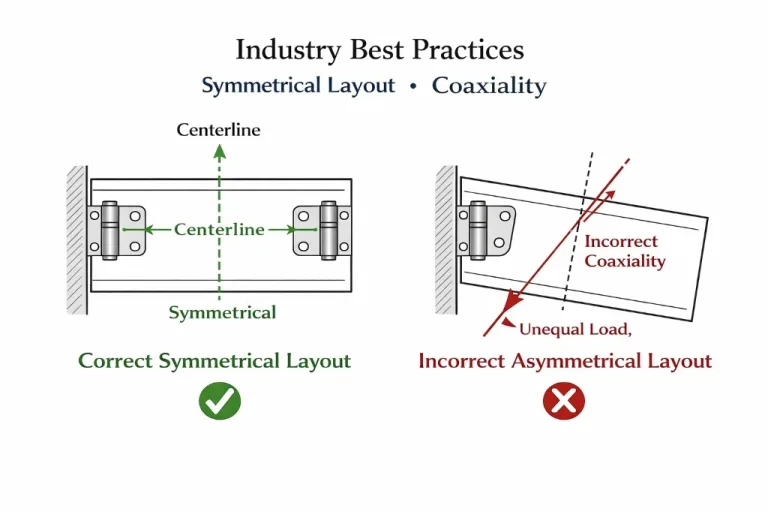

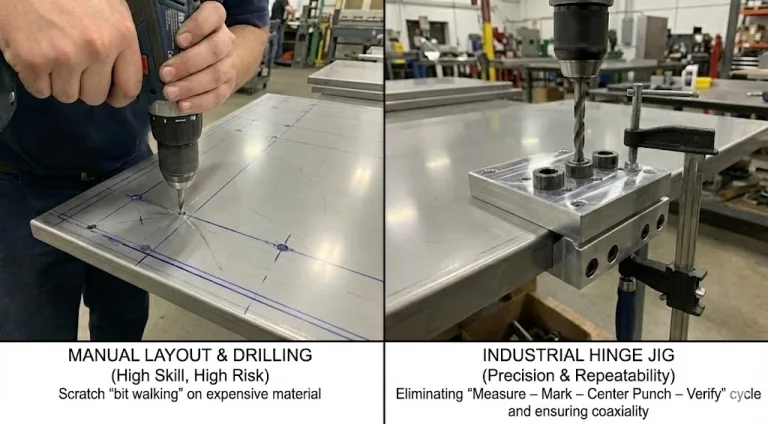

Template Positioning

Use laser levels and 3D jigs. Ensure hinge symmetry and vertical alignment.

Three-Step Torque Tuning

- Empty

- Half-Load

- Full-Load

Fine-tune torque based on weight + contents.

Troubleshooting:

| Problem | Cause | Fix |

|---|---|---|

| Torque Fade | Spring fatigue | Re-tension or replace |

| Noise | Debris or dry parts | Clean + re-lubricate |

| Misalignment | Loose parts | Tighten lock pins/nuts |

Maintenance-Free Lubrication:

Solid lubricants (e.g., MoS₂) ensure 5+ years of use without oiling. Lower maintenance costs.

Conclusion

one-way torque hinges offer vital value for premium cabinets and professional equipment. They deliver directional control and stable support, enabling smooth, precise motion with minimal user effort.

Success depends on holistic integration — combining materials science, mechanical design, and user ergonomics. This innovation loop ensures these hinges meet the demands of high-end industrial and consumer use globally.

FAQ

Q: What is an One-Way Torque Hinge?

A: A hinge that provides torque resistance in one direction (usually opening), and nearly zero in the reverse. Enables doors to free-stop at any angle.

Q: How is it different from Two-Way Torque Hinges or Gas Springs?

A:

- Two-Way: Resists both opening and closing

- Gas Spring: Bulky, nonlinear

- One-Way Torque: Compact, resists one direction, ideal for premium designs

Q: How is adjustment implemented?

A: Mechanical (spring preload, knob/hex screw) or electronic (e.g., magnetic fluid + PWM). Torque is fine-tuned per door weight.

Q: Common failure modes?

A:

- Torque fade: Spring fatigue

- Noise: Lack of lubrication

Fix: Clean, re-lube, adjust or replace components.

Q: Maintenance tips?

A: Use high-quality hinges with built-in solid lubricants. Typically maintenance-free for 5+ years. For harsh environments, inspect coatings periodically.