Outdoor Torque Hinges: Why Stainless Fails in EVSE

When designing EVSE charging stations or outdoor 5G base stations, I see many engineering teams fall into a common trap. They believe that simply changing the material in the Bill of Materials (BOM) from “Carbon Steel” to “Stainless Steel” solves all outdoor adaptability issues.

The reality is far more complex.

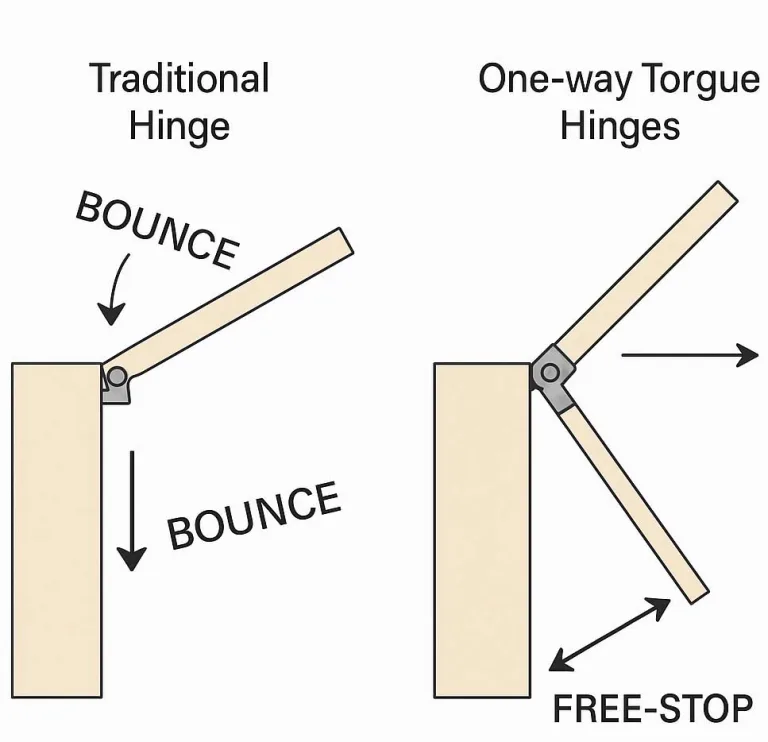

For high-performance outdoor torque hinges, ‘not rusting’ is merely the baseline requirement. From our extensive field experience, the predominant failure mode regarding these critical components is rarely catastrophic structural breakage, but rather ‘Torque Failure.’

When ambient temperatures swing violently from -20°C to 60°C, or when salt mist infiltrates the internal mechanism, the damping value of the hinge can spiral out of control. This results in equipment doors that refuse to open in winter (torque spike) or refuse to hold position in summer (torque loss).

This article does not cover basic definitions. Instead, I will share a set of selection logic derived from engineering field experience. These guidelines will help you ensure your equipment maintains “Torque Consistency” in extreme environments.

Redefining Acceptance Criteria for Outdoor Torque Hinges: Three Core Metrics

When auditing supplier specifications, I do not look solely at “Max Static Load.” For outdoor applications, I strictly require suppliers to benchmark against three key performance indicators. Experience has taught me that ignoring any one of these will exponentially increase future field maintenance costs (Truck Roll Costs).

First, Torque Tolerance vs. Temperature.

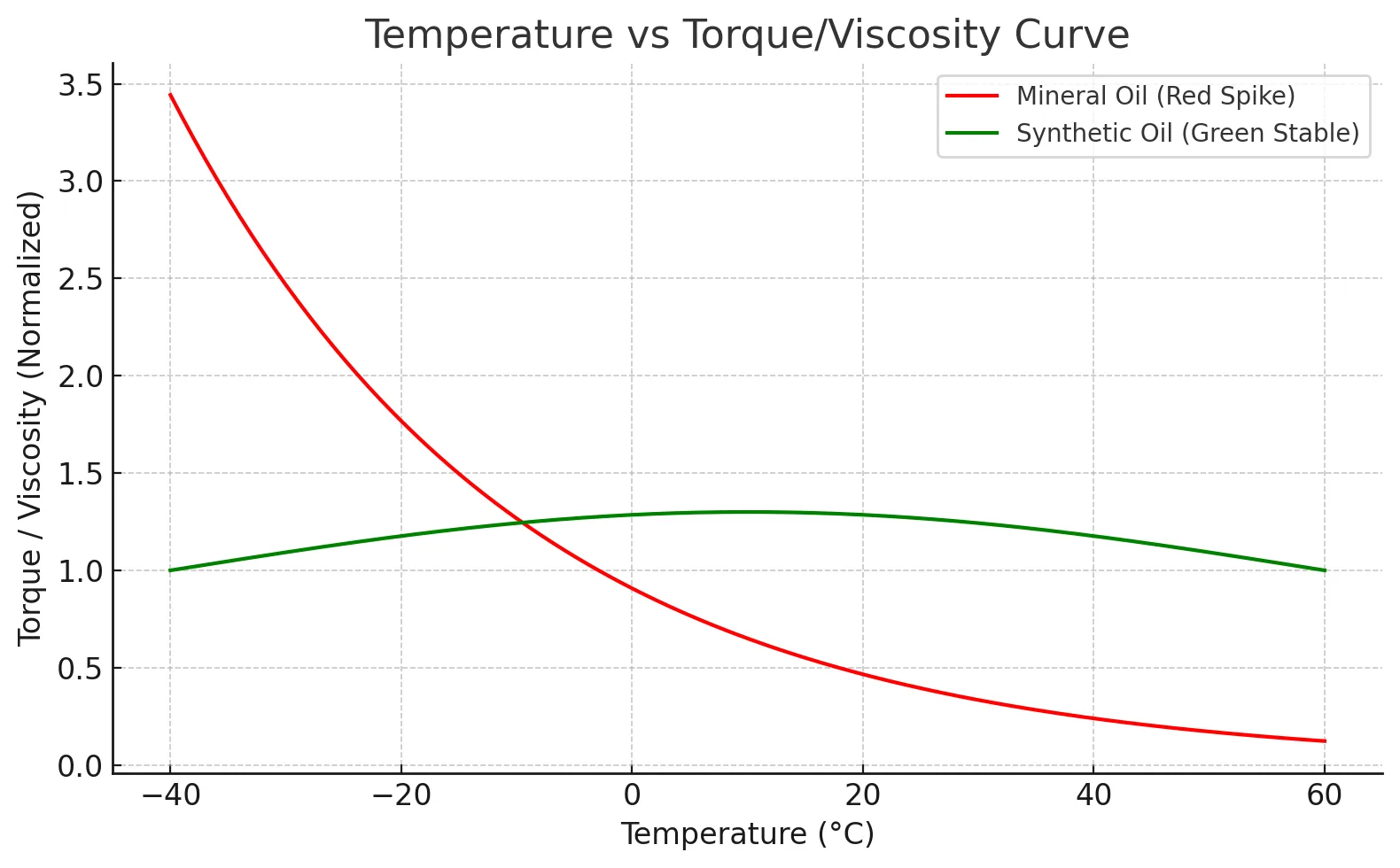

Within the operating range of -40°C to 60°C, we require the dynamic torque variation rate to be controlled within ±30%. This specification is critical because the viscosity of standard mineral-based damping greases is not linear. At -40°C, these greases inherently thicken, often causing torque values to spike by up to 300% compared to room temperature. Such a dramatic increase generates reaction forces that can easily exceed the structural limits of plastic enclosures.

Second, Internal Component Corrosion Protection.

Do not be misled by a SUS316L housing. We must confirm whether the internal high-hardness friction disks and springs have equivalent protection. These components usually cannot be manufactured from 316L due to hardness requirements.

Third, Cycle Life Stability in Harsh Conditions.

In simulated sand and dust testing, after 20,000 cycles, the allowable torque decay limit must be less than 20%.

Combatting Low-Temperature Lockout: Engineering Grease Rheology

We frequently receive customer complaints that outdoor torque hinges ‘freeze’ in cold regions during winter. Users may even break handles by applying excessive force. This is typically not a mechanical jam, but a problem with the Viscosity characteristics of the damping grease.

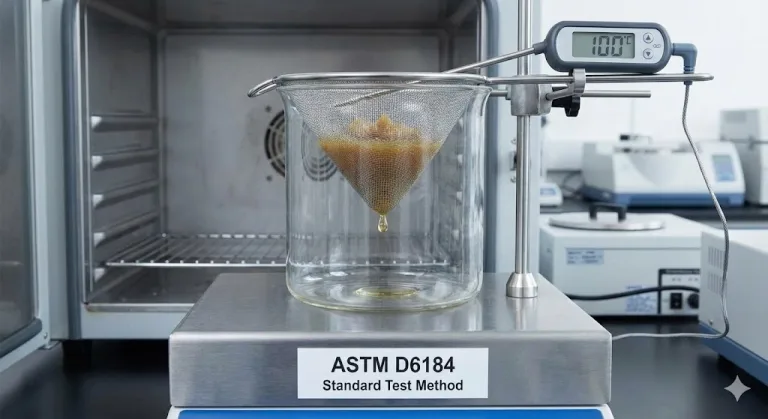

To solve this, I directly reject mineral oil-based standard grease during selection. I recommend explicitly specifying Fluorosilicone or Synthetic Hydrocarbon based lubricants on the drawing. Referring to ASTM D445, these greases exhibit minimal viscosity change at low temperatures.

Furthermore, we require suppliers to provide the “Temperature-Torque Curve” for the specific model. A qualified curve should be flat. This ensures that at -40°C, the torque value does not exceed 1.5 to 2.0 times the value at room temperature.

On the structural design side, we must also introduce a “Cold Start Factor.”

If a panel requires 2.0 N·m of torque to hold position, we design the mounting point strength to withstand at least 5.0 N·m. This accounts for the instantaneous high torque that may occur during extreme cold weather.

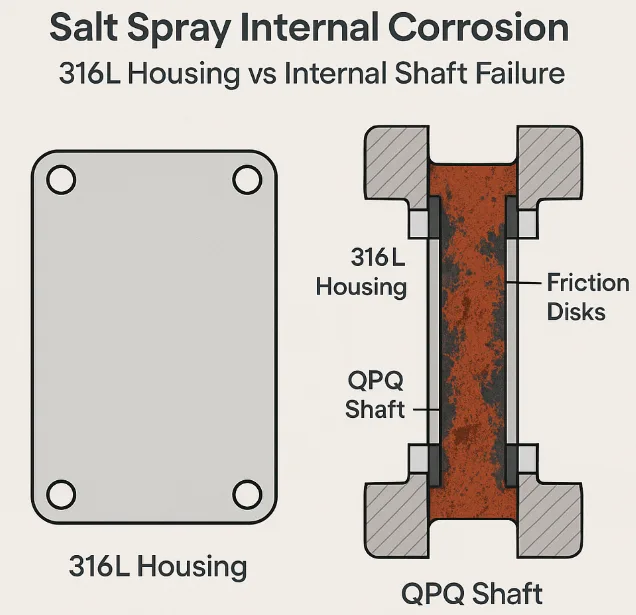

Defending Internal Corrosion: The Invisible Friction Engine

Many engineers believe that if the housing has no red rust, the part is qualified. However, in salt spray tests, we often find housings that look brand new, while the hinge is completely “seized.” Dissection reveals that the internal shaft has rusted and bonded to the friction disks, causing the friction coefficient ($\mu$) to spike.

To address this, we must distinguish between the housing and the internal core.

For the housing, specifying SUS316L with Passivation is standard practice for coastal applications.

However, for the internal shaft, which requires high wear resistance and hardness, we typically mandate QPQ (Quench-Polish-Quench) liquid nitriding or High-Phosphorus Nickel Plating.

Our acceptance standard is based on ASTM B117 testing. The focus is not on appearance, but on function: after 480 hours, the change in torque value must be less than 20%.

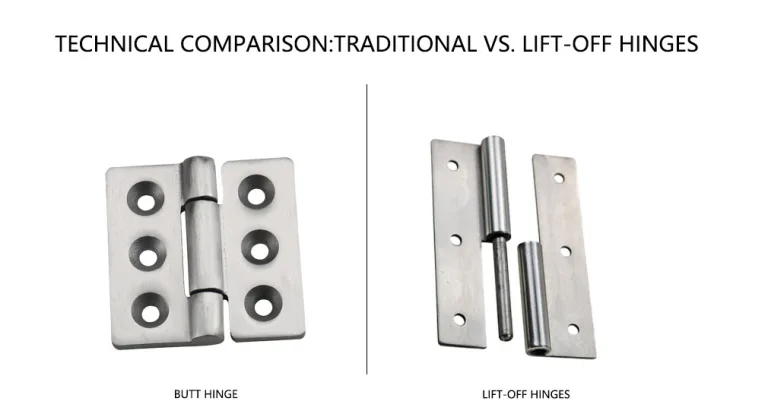

If the budget allows, I prioritize Encapsulated Barrel designs. These block salt mist from contacting the internal grease mixture through physical sealing rings.

Resisting Abrasive Wear: Choosing the Right Technology

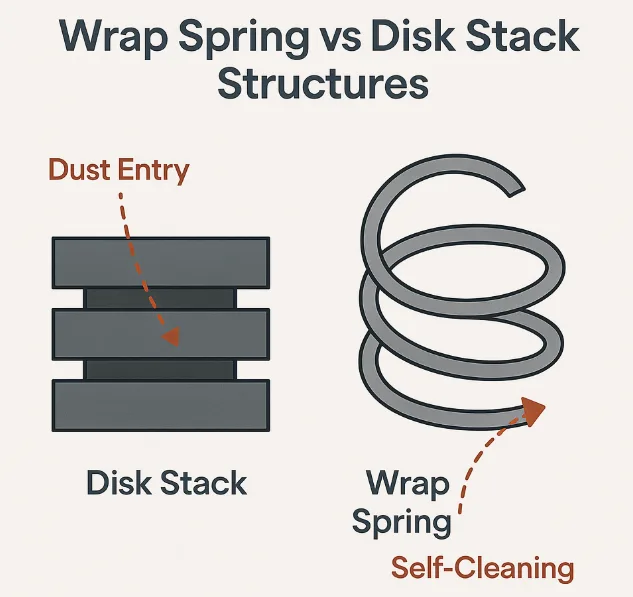

In environments with heavy sand and dust, such as mining areas or the Middle East, outdoor torque hinges often experience significant ‘sagging’ (or droop) after just six months. The root cause is particle ingress: fine dust penetrates the housing clearances, forming an abrasive paste that rapidly grinds down the friction surfaces.

In these conditions, I prefer Wrap Spring Technology over Disk Stack technology.

Based on my observations, if disk structures are not perfectly sealed, dust easily enters between the layers and destroys the torque. Wrap spring structures, which utilize a spring tightening around a shaft, have a self-cleaning effect. They also have a higher tolerance for diameter wear, demonstrating superior torque stability.

For extremely harsh scenarios, we may even adopt Hybrid Material Solutions. These utilize engineering plastics (like glass-filled POM) paired with metal shafts. This combination offers self-lubricating properties and does not rely on grease, fundamentally eliminating the issue of dust adhesion.

Optimizing the Installation Interface: Waterproofing and Stress Management

Torque hinges generate immense reaction forces. In low temperatures, plastics become brittle, leading to frequent tearing at mounting points. Simultaneously, through-holes on the panel are potential water ingress points.

To solve these two problems, I strongly advise against using through-hole screws on outdoor cabinet panels.

We recommend using hinges with Stud Mounts (welded studs) that fasten from the rear. This not only maintains the integrity of the exterior surface but also makes it easier to meet IP65/IP66 protection ratings.

For thin sheet metal or plastic enclosures, we add a metal Backing Plate (at least 2.0mm thick) behind the hinge mounting surface. This effectively distributes the stress generated by the torque over a larger area, preventing mounting hole failure.

Validation in the Field: Beyond the Datasheet

Before signing the PPAP (Production Part Approval Process), we do not rely solely on paper specifications. We execute two targeted destructive tests.

The first is the “Freezer Function Test.”

We freeze the sample in a -40°C environmental chamber for 4 hours. We then remove it and measure the dynamic torque within 30 seconds. If the data exceeds 3 times the room temperature value, we deem the grease selection a failure and require a rework.

The second is the “Salt Spray Functional Verification.”

We strictly execute ASTM B117 standards (typically set for 240 or 480 hours). After the test concludes, we do not clean the sample. We test the torque immediately.

This step is critical. We are not concerned with cosmetic rust, but functional impairment. The passing standard is that the torque value remains within ±20% of the initial value. A sudden increase implies internal seizing; a sudden decrease implies structural disintegration. Both are unacceptable.

Conclusion

In extreme environments, a torque hinge is not just a fastener; it is a precision Motion Control Subsystem.

By specifying the correct grease (synthetic), the correct surface treatment (QPQ/Passivation), and the correct installation method (Studs/Backing Plates), we can completely avoid the embarrassment of doors that “won’t open in winter” or “won’t stay put in summer.”

As engineers, our goal is to eliminate these hazards at the blueprint stage, rather than trying to solve them in the field.