The Engineer’s Guide to Cold Storage Hinges: Sizing, Selection, and Failure Prevention

In facility management, a hinge is rarely just a hinge. It is the primary mechanical component ensuring the thermal integrity of your cold chain.

When a procurement officer selects a hinge based solely on price, they often unintentionally trigger a costly maintenance cycle. A failing hinge does not simply break; it degrades the entire cold storage system.

The “Domino Effect” of Freezer Door Hinge Failure:

- Mechanical Wear: The hinge pin wears down, creating play (slop).

- Door Sag: The door drops by millimeters, causing the gasket to misalign.

- Seal Failure: Warm, humid air infiltrates the cold room.

- Ice Buildup: Condensation freezes on the door frame, forcing the door further open.

- Energy Spike: Refrigeration units work overtime to compensate for leaks. This inefficiency not only inflates operational costs by 20% or more but also jeopardizes compliance with sustainability benchmarks like the GCCA Energy Excellence Program.

Selection Criteria for Cold Storage Hinges (The 3 Critical Factors)

Before browsing a catalog, you must quantify the demands of your specific application. “Standard Duty” is a marketing term; engineering data is what prevents failure.

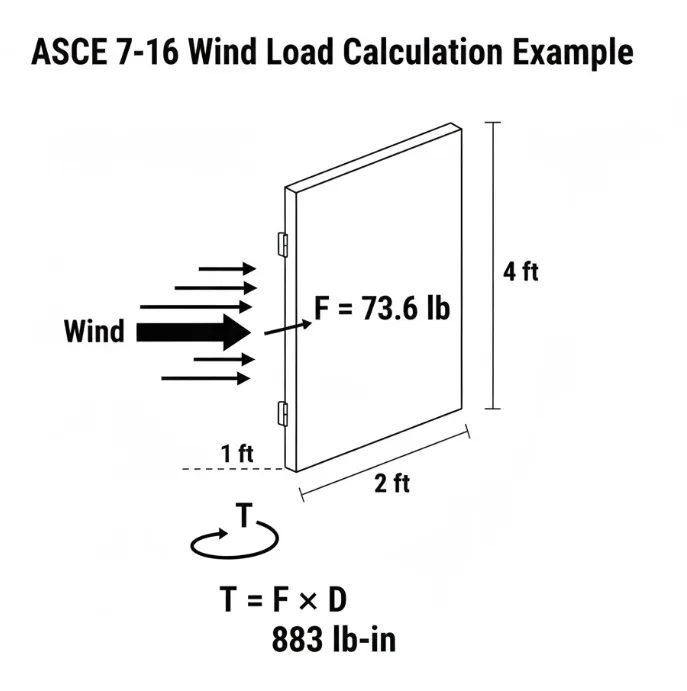

Door Weight & Dimensions (The Moment Load)

Most buyers know the weight of their door. Fewer consider the width.

A hinge supports vertical load (weight), but it also resists Moment Load (torque). A 100kg door that is 1.5 meters wide exerts significantly more stress on the top hinge than a 100kg door that is only 0.8 meters wide.

- Engineering Rule: As the door gets wider, the stress on the top hinge increases disproportionately.

- Recommendation: Always provide your supplier with both weight and width data. For doors wider than 1200mm, consider adding a third hinge to stabilize the door, not just to support weight.

Traffic Volume (Cycles Per Day)

Hardware fatigue life is measured in cycles.

- Low Traffic (<50 cycles/day): Typical for restaurant walk-in coolers or long-term storage. Standard friction-bearing hinges are sufficient.

- High Traffic (>200 cycles/day): Distribution centers (DCs) or cross-docking facilities. Here, hinges must withstand constant use.

- Recommendation: For high-traffic zones, specify hinges tested to EN 1935 Grade 13 or 14 (Severe Duty), which validates performance over 200,000 cycles.

The Environment (Thermal Shock)

Is your facility a dry warehouse or a blast freezer?

- The Trap: A hinge that works at 0°C may seize at -40°C.

- Thermal Shock: If a door connects a warm loading dock (+25°C) to a freezer (-20°C), the hinge acts as a thermal bridge. Rapid temperature changes can cause condensation to form inside the hinge mechanism, freezing the pin.

- Recommendation: For temperature differentials exceeding 30°C, specify hinges with thermal break pads and low-temperature synthetic lubrication.

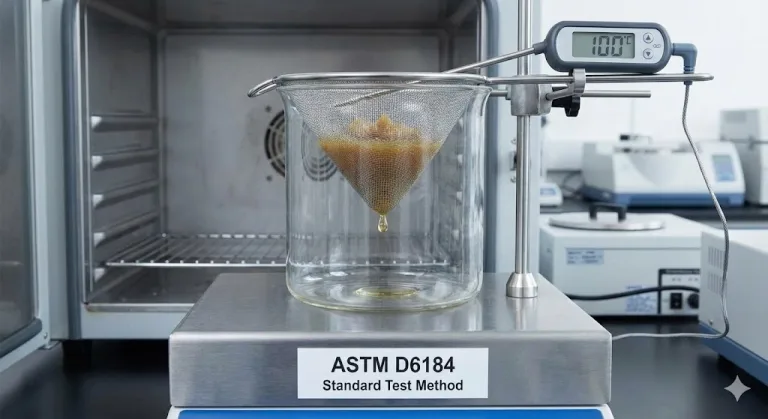

Material Guide for Cold Room Hardware: Balancing Cost and Corrosion

Material selection is a balance between upfront budget and long-term replacement costs. Below is a comparison of common materials used in cold storage hardware.

| Material | Cost | Corrosion Resistance | Best Application | Standard Reference |

|---|---|---|---|---|

| Zinc Die-Cast (Zamak) | Low | Low/Moderate | Dry storage, non-corrosive environments. | ASTM B86 |

| 304 Stainless Steel | High | High | Commercial kitchens, general cold storage. | ASTM A240 |

| 316 Stainless Steel | Very High | Extreme | Seafood processing, coastal facilities, salted roads. | ASTM A240 |

| High-Performance Polymer | Moderate | Immunity | Light to medium doors in high-humidity areas. | N/A |

Advice:

For any facility involving food processing (daily wash-downs with caustic chemicals) or coastal locations, 316 Stainless Steel is the only viable option. While it costs 30-40% more upfront, it eliminates the “tea staining” rust that plagues 304 steel in these environments, preventing potential health code violations.

Types of Commercial Refrigeration Hinges and Mechanisms

Selecting the right mechanism can solve operational headaches such as doors left ajar or uneven floor wear.

Rising (Lift-Off) Hinges

The Mechanism: The hinge barrel is cut at a spiral angle. As the door opens, the hinge physically lifts the door panel up by 10-20mm.

Why Choose This?

- Self-Closing: Gravity forces the door to slide back down the spiral to the closed position. This is the most reliable, energy-saving “automatic closer” available.

- Gasket Protection: By lifting the door, the bottom rubber sweep clears the floor immediately, reducing friction wear and tear.

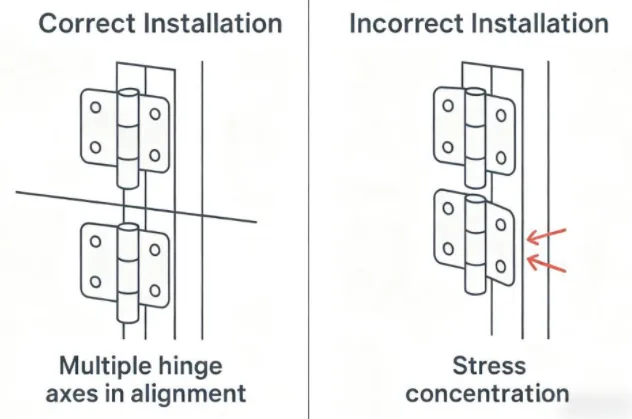

Adjustable Hinges

The Problem: Over time, concrete floors settle, and heavy doors sag. A standard fixed hinge requires you to remove the door, fill the old holes, and drill new ones to fix the alignment.

The Solution: Adjustable hinges feature 2D or 3D adjustment screws.

- Vertical Adjustment: Compresses the gasket to the correct height.

- Horizontal Adjustment: Fixes the seal gap on the lock side.

- Benefit: Maintenance teams can realign a sagging door in 5 minutes using a simple hex key, with zero downtime.

Spring-Loaded Hinges

Best For: Smaller reach-in doors or personnel doors where positive latching is required for security.

Caution: Springs fatigue over time. Ensure the spring cartridge is replaceable without discarding the entire hinge housing.

Specifying Heavy-Duty Hinges: Offset and Load Ratings

This is the technical stage where most ordering errors occur. Accurate measurement here prevents returns and project delays.

Understanding “Offset”

Cold storage doors are rarely flush with the frame. They usually overlay the frame to create a thermal seal.

Flush vs. Offse:

- Flush: The door surface is level with the frame surface.

- Offset: The door surface projects out from the frame.

How to Measure Offset:

Do not guess. Use a caliper or ruler to measure the distance from the mounting surface of the frame to the mounting surface of the door. Common industrial offsets are 1-1/8″ (28.5mm) to 2-3/4″ (70mm). Buying a hinge with the wrong offset will result in a door that either binds (won’t open) or has a massive air gap (won’t seal).

Load Rating Calculation

Manufacturers list “Max Load” ratings, but these are based on static, gentle testing.

The Consultant’s Rule of Thumb:

Calculate your required load rating using a Safety Factor of 2:1.

- Actual Door Weight: 80kg.

- Target Hinge Rating: 160kg.

Why? Staff will slam doors. They will lean on them. Carts will impact them. A 2:1 safety factor ensures the internal bearings can handle the abusive “shock loads” of a real-world warehouse environment.

Hygiene and Compliance ( NSF/FDA )

If your facility handles open food (meat processing, dairy, central kitchens), your hardware is subject to sanitation audits.

Sanitary Design Requirements:

- Clean-in-Place (CIP): The hinge must be cleanable without disassembly.

- Surface Finish: Surfaces must be polished (electropolished is best) to less than 0.8 µm roughness (Ra) to prevent bacterial biofilm adhesion, aligning with EHEDG Hygienic Design Guidelines (Doc. 8) for cleanability.

- No Traps: Avoid designs with exposed threads, open springs, or sharp internal corners where grease and blood can accumulate.

Relevant Standard:

Look for hardware certified to NSF/ANSI 2 (Food Equipment). This certification verifies that the materials are non-toxic and the design is easily cleanable. Using NSF-certified components simplifies your HACCP (Hazard Analysis Critical Control Point) compliance audits significantly.

Maintenance and Retrofitting for Cold Chain Hinges

For MRO (Maintenance, Repair, and Operations) buyers, the priority is compatibility.

Retrofit Considerations:

Before switching brands, check the Bolt Hole Pattern.

Many industry leaders (like Kason or Fermod) have established “de facto” standard hole patterns.

- Scenario: You have a failing Kason 1245 hinge.

- Strategy: Look for a replacement that matches the specific mounting centers (e.g., measuring 3 inches center-to-center).

- Benefit: Compatible replacement means no drilling, no patching, and no compromised insulation.

Serviceability:

Ask your supplier: “Do you sell replacement bushing kits?”

High-quality hinges allow you to replace the worn plastic bushings or the pin for a fraction of the cost of a new hinge. If the hinge is a sealed unit that must be thrown away when it squeaks, it is not an industrial-grade solution.

FAQ

Q: How do I measure the offset of my cold room door?

A: Close the door securely. Place a straight edge on the face of the door extending over the frame. Measure the gap between the straight edge and the face of the frame. That distance is your offset.

Q: Can I replace a Zinc hinge with a Stainless Steel one?

A: Yes, provided the Bolt Hole Pattern and the Offset are identical. This is a highly recommended upgrade for facilities experiencing corrosion issues.

Q: How often should I grease my cold storage hinges?

A: It depends on the model.

- Greaseable Hinges (with Zerk fittings): Every 3-6 months using low-temperature synthetic food-grade grease.

- Maintenance-Free Hinges: These use self-lubricating polymer bushings (like PTFE) and should never be greased, as grease attracts dust that accelerates wear.

Q: What is the difference between a “cam-lift” and a “spring-assist” hinge?

A: A cam-lift uses the door’s weight and a sloped cam to close the door (gravity). A spring-assist uses a coiled metal spring. Cam-lifts are generally more durable as they have no spring to break, but springs offer more forceful closing power for small gaskets.