SS304 vs. SS316 vs. Hardened Steel: The Ultimate Torque Hinge Material Guide

Introduction: Material Mismatch is the Invisible Killer of Hinge Failure

In my engineering career, I have analyzed hundreds of torque hinges that failed in the field.

We usually tend to blame “structural design,” but the data reveals a different truth.

According to common engineering-reference sources, fatigue has been estimated to contribute up to about 90% of metallic failures (see e.g., [textbook reference])

These are not geometric issues, but mismatches in Material Selection.

We use torque hinges to “control” motion. However, if the base material cannot withstand environmental stress, this control is quickly lost.

- A well-designed outdoor cabinet hinge, if mistakenly made of ordinary carbon steel, will rust and seize the door panel after three months.

- A high-frequency medical device bracket, if made of unhardened soft stainless steel, will lose its positioning function within weeks due to wear.

This article discusses no empty theory. We will directly compare the three core industrial materials based on real laboratory test data: SS304 Stainless Steel, SS316 Stainless Steel, and Hardened Steel.

Contender 1: SS304 Stainless Steel — The Industrial Standard “Workhorse”

(The Industrial Standard: SS304)

In our production data, SS304 accounts for the vast majority of the industrial-grade torque hinge market. For most non-extreme environments, it is the most cost-effective choice.

Chemical Composition Verification: The First Line of Defense Against Rust

We do not simply purchase raw materials labeled “304.” In our spectroscopy analysis, we strictly follow the ASTM A240 standard.

This standard strictly requires a Chromium content between 17.5% and 19.5%.

What does this mean for you?

It is precisely this ratio of chromium that forms a dense chromium oxide passivation film on the steel surface. According to my observations, once the chromium content falls below the lower limit specified by ASTM A240, this “protective shield” becomes extremely thin and unstable, causing the hinge to quickly lose its luster in humid environments.

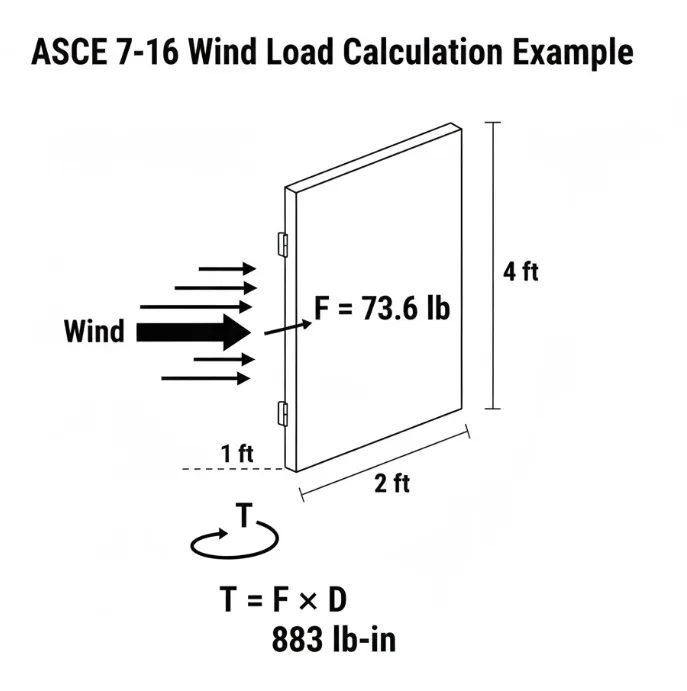

Tensile Test: Can It Withstand Heavy Door Panels?

To ensure the heavy-duty torque hinge does not deform under heavy loads, we conduct tensile testing according to ASTM A370.

Test data shows that the Yield Strength of qualified SS304 consistently remains above 205 MPa (30 ksi).

For a 4mm thick hinge, this means it can fully support a heavy industrial cabinet door without permanent deformation.

Limitations: The Limit of Salt Spray Testing

However, SS304 is not invincible.

When executing the ASTM B117 Salt Spray Test, we typically begin to observe signs of “Red Rust” around 96 to 120 hours.

This indicates that under continuous salt spray or high-humidity erosion, the protective capability of SS304 has an upper limit.

Contender 2: SS316 Stainless Steel — The “Guardian” of Extreme Environments

(The Premium Defense: SS316)

When customers tell me their equipment will be deployed on offshore drilling platforms, chemical plants, or seaside charging stations, I mandatorily recommend upgrading to SS316 torque hinges.

The Role of Molybdenum: Why is it Essential for Marine Grade?

The essential difference between SS316 and SS304 lies in their chemical composition. When we test SS316 bars according to the ASTM A276 standard, we must confirm a Molybdenum content of 2.0% to 3.0%.

Molybdenum is not just a simple additive. It changes the lattice structure of the steel at the atomic level.

Core Function: It greatly enhances the material’s resistance to Chloride Pitting. If it does not reach this ASTM standard range, such material is defined by us as “Pseudo 316” and absolutely cannot be used in marine environments.

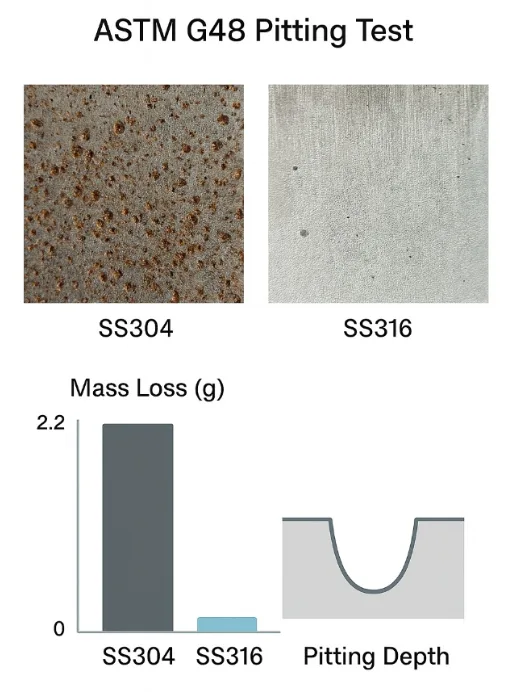

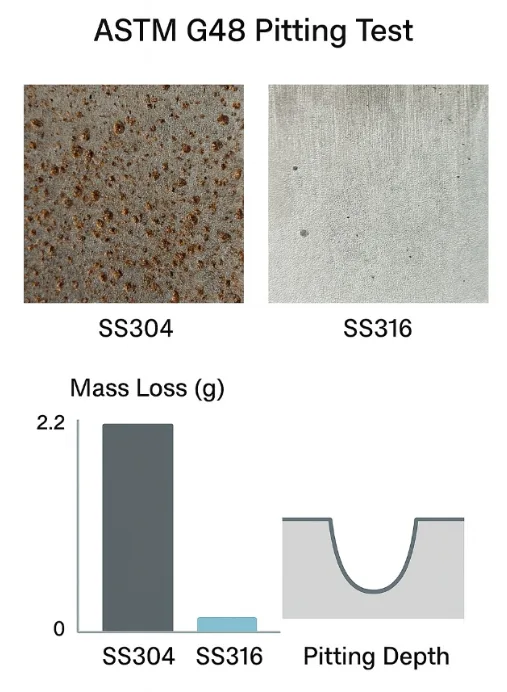

Decisive Corrosion Test (Pitting Experiment)

To quantify this difference, we conducted the ASTM G48 Method A (Ferric Chloride Pitting Test), which is more severe than ordinary salt spray.

The results are shocking:

Figure: Visual and quantitative results of the ASTM G48 pitting test. Note the severe pitting and significant mass loss (>2.0g) on the SS304 sample, while the SS316 sample remains largely unaffected due to its molybdenum content.

- After soaking in the same corrosive solution for 72 hours, the mass loss of the SS304 sample exceeded 2.0g, and the surface was covered with deep pits.

- The SS316 sample that met standards had minimal mass loss, and the surface remained almost intact.

Real Case: Florida EV Charging Station

We once handled a typical failure case. An Electric Vehicle Supply Equipment (EVSE) station located on the Florida coast initially used SS304 hinges.

After only 8 months of operation, we discovered obvious Tea Staining on the torque hinge surface. Although this did not temporarily affect structural strength, it severely damaged the brand’s high-end image.

We replaced them all with SS316 hinges during later maintenance, and after two years of exposure to sea breeze, the surfaces remained shiny as new.(Not sure if your location requires SS316? [Contact us] for a free environmental assessment.)

Contender 3: Hardened Steel — The “Tough Guy” of Strength and Wear Resistance

(The Strength Specialist: Hardened Steel)

This is a common misconception: many engineers believe that “high-end” hinges must be all stainless steel. In fact, to achieve extremely high torque density and ultra-long service life, Hardened Steel is irreplaceable in the internal structure.

Hardness Test: Not Just Being Hard

The core principle of a torque hinge is friction. The material surface must be hard enough to maintain dimensional stability over countless friction cycles.

We use the ASTM E18 standard for Rockwell Hardness testing. For our high-performance friction shafts, we require the material to reach a hardness value of HRC 45-50 after heat treatment.

The significance behind the data:

Figure: The advantage of hardness. The chart demonstrates that hardened steel (HRC 45-50) maintains consistent friction torque over long lifecycles, whereas soft steel fails prematurely due to wear.

- If you use unhardened ordinary steel (hardness only around HRC 20), our wear tests show that torque values drop by more than 40% after 2,000 cycles.

- Whereas shafts meeting the ASTM E18 high hardness standard keep the torque decay rate within 15% after 20,000 cycles.

Fatal Weakness and Hybrid Material Solutions

The only downside of hardened steel is: it rusts upon contact with water.

Therefore, for high-performance torque hinge designs, we typically adopt a Bi-material Design:

- Housing: Use SS304 or SS316 to provide external rust protection.

- Internal Core: Use Hardened Steel, sealed inside special grease.

Deep Parameter Comparison (Technical Comparison Matrix)

Figure: Material Performance Radar. Note how Hardened Steel sacrifices corrosion resistance for ultimate strength, while SS316 offers the balanced maximum protection.

To help you decide quickly, I have compiled the following key parameter comparison table:

| Feature | SS304 Stainless Steel | SS316 Stainless Steel | Hardened Steel |

| Best Application | Indoor Industrial, General Outdoor | Marine, Chemical, Medical | Heavy Machinery Internal, High Frequency Use |

| Corrosion Resistance | Good | Excellent | Poor – Requires Plating |

| Pitting Resistance | Weak | Strong | None |

| Surface Hardness | RB 80-90 (Medium) | RB 80-90 (Medium) | HRC 45+ (Very High) |

| Wear Cycle Life | Medium (<5,000 cycles) | Medium (<5,000 cycles) | Excellent (>20,000 cycles) |

| Reference Standard | ASTM A240 / B117 | ASTM A276 / G48 | ASTM E18 |

Technical Trap to Watch Out For: Stainless Steel Galling

This is an invisible killer often ignored by design engineers.

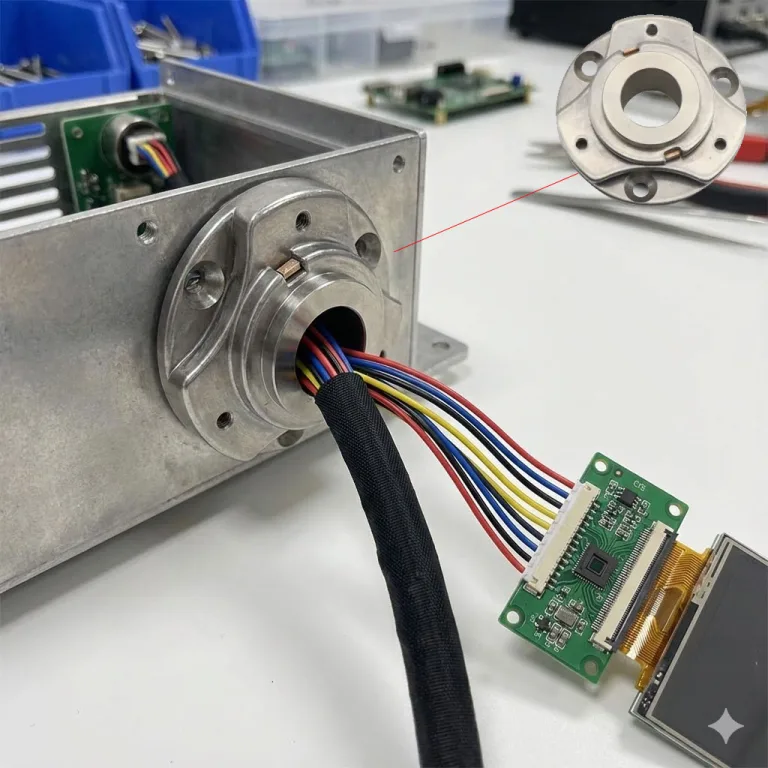

Galling Risk Test: When Metal Undergoes “Cold Welding”

If you blindly insert a stainless steel shaft into a stainless steel hole, you may trigger a disaster.

According to ASTM G98 (Standard Test Method for Galling Resistance of Materials), austenitic stainless steels (such as 304 paired with 304) have a very high tendency to adhere.

The phenomenon we observe in the lab is:

Under high pressure without special lubrication, the two contact surfaces do not just rub; micro-level “Cold Welding” occurs. This causes the torque hinge to experience severe stuttering during operation, or even lock up directly.

My Advice:

- Avoid all-stainless friction structures.

- If you must use all-stainless (e.g., MRI non-magnetic environments), one of the contact surfaces must undergo Nitriding or be coated with Molybdenum Disulfide (MoS2).

Selection Decision Framework

Based on the data above, I suggest you lock in your final torque hinge material choice through the following three scenarios.

High Salt Spray, Marine, or Chemical Environment

- Typical Application: Yacht hatches, seaside charging piles, pool equipment.

- My Recommendation: Must choose SS316.

- Reason: Do not choose SS304 to save 20% on material costs. In a C5 corrosion environment defined by ISO 9223, the cost of later rust maintenance for SS304 will be enormous.

Controlled Indoor Industrial Environment

- Typical Application: Server racks, automation equipment safety doors, folding workbenches.

- My Recommendation: SS304 is the first choice.

- Reason: There is no salt spray risk here. SS304 offers perfect mechanical strength and aesthetics at the most reasonable cost.

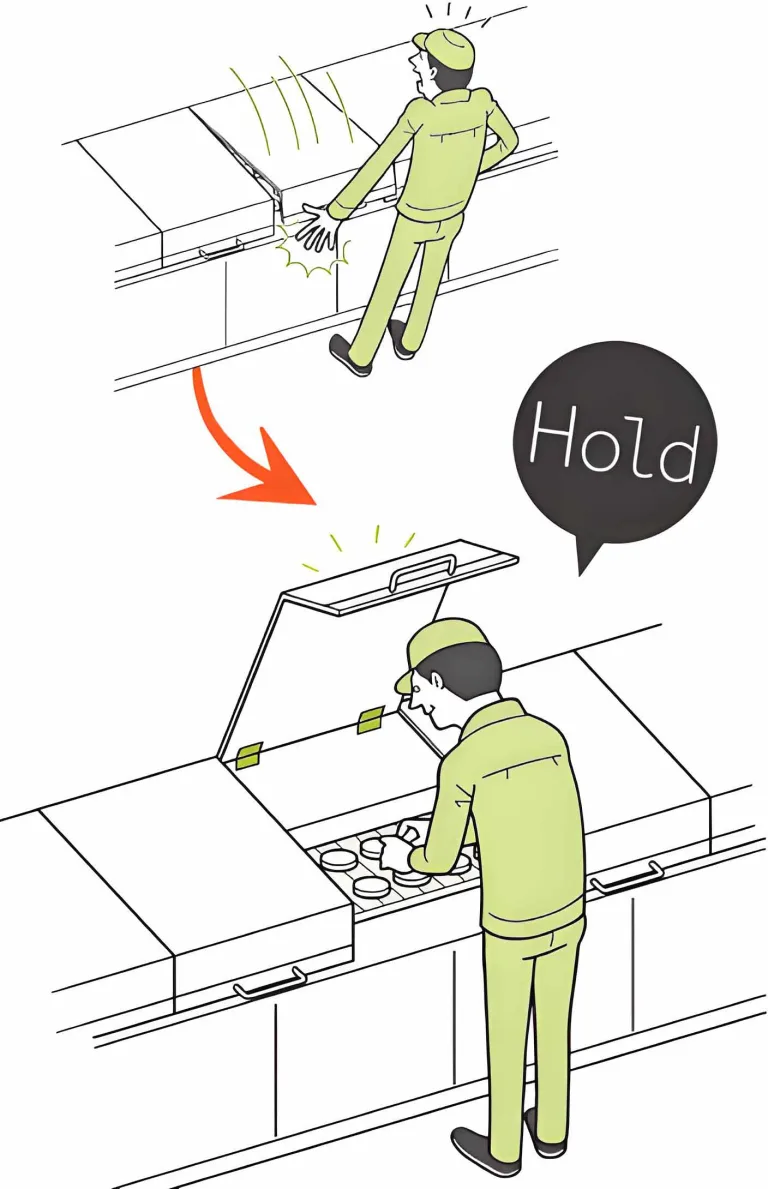

High Cycle Count and High Torque Stability Requirements

- Typical Application: Laptop hinges, heavy machinery access covers (requiring frequent opening).

- My Recommendation: Hardened Steel Core + Stainless Steel Housing.

- Reason: Only hardened steel can pass life tests of over 20,000 cycles. Stainless steel is too soft to maintain stable torque values over the long term.

Conclusion

There is no absolute “best” material, only the most “suitable” balance point for the working conditions.

- Pursuing Ultimate Rust Protection -> SS316

- Pursuing Cost-Effectiveness -> SS304

- Pursuing Ultra-Long Life Torque Hinges -> Hardened Steel Core

Next Step:

If your project is in the R&D stage and you are unsure of the specific environmental tolerance requirements, please contact our engineering team. We can arrange a 48-hour ASTM B117 Salt Spray Test for your existing hinge design and provide a material upgrade report based on real data.

FAQ

Q1: Can SS304 hinges really be used outdoors?

A: Yes, but with conditions. In general urban or rural outdoor environments, SS304 performs well. However, we recommend: If the installation site is within 5 km of the coastline, or located in a heavy industrial area with severe acid rain, please be sure to upgrade to SS316.

Q2: Why shouldn’t I use all hardened steel to get the highest strength?

A: Because the rust protection cost is too high. Hardened steel must rely on plating (such as zinc or nickel plating). During the friction movement of the hinge, the plating will be worn away. Once the plating is breached, the internal steel will rust. This is why we advocate the “Stainless Housing + Hardened Core” hybrid design.

Q3: Can I use a magnet to distinguish between SS304 and SS316?

A: No, this is a misconception. Although both are theoretically non-magnetic, after cold working (such as stamping or bending), their crystal structures undergo a slight martensitic transformation, thereby acquiring weak magnetism. The only reliable way to distinguish the two is to use an XRF Analyzer to detect the Molybdenum content.