Torque Hinges Installation Guide: 7 Steps for Precision and Durability

Addressing Pain Points: More Than Just “Open” and “Close”

Hinge selection and installation directly impact equipment safety and reliability. Common issues include:

- Unexpected rapid closure of covers posing a falling hazard risk;

- Displays or door panels unable to hold any angle, requiring additional support;

- Requiring gas springs or support rods, increasing costs and structural complexity.

The Solution: Torque hinges (also known as friction hinges) utilize constant friction to hold doors or covers securely at any angle. Their built-in friction mechanism generates resistance during rotation, preventing unnecessary movement. However, even the highest-quality torque hinge will fail if improperly installed. This guide therefore provides comprehensive coverage from torque calculation and hinge selection to installation details, offering engineers a one-stop technical reference.

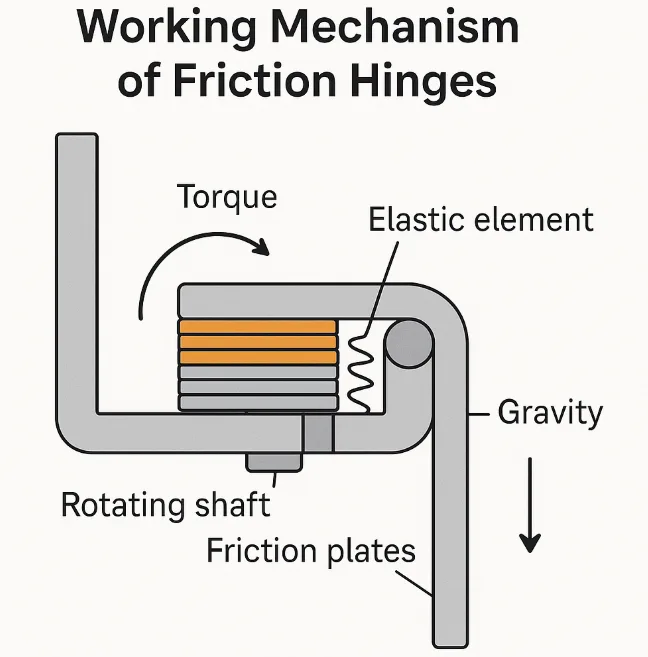

What is a Torque Hinge? Controlled Friction Principle

A torque hinge is an arbitrary stop hinge that secures doors or covers at any angle. Its internal structure typically includes friction pads, spring clips, grease, and other components. Resistance is generated through the friction mechanism on the shaft, thereby controlling movement. Torque is the rotational force around a pivot point, expressed as M = F × d,where M is torque (N·m), F is applied force (N), and d is the perpendicular distance from the axis (m). In torque hinge applications, this torque represents the force required to maintain the cover at a specific angle.

Distinguishing Torque Hinge Types

Diagram of one-way vs dual-torque vs adjustable torque hinges

- Constant Torque vs. Brake Torque: Constant torque hinges provide continuous resistance, while brake torque hinges incorporate a mechanical brake at the closing point to eliminate bounce and ensure complete door closure.

- Unidirectional vs. Bidirectional: Unidirectional torque hinges generate torque in only one direction (typically the lift direction); friction in the opposite direction is minimal, making door closure easier. Bidirectional torque hinges provide torque in both opening and closing directions, with torque values typically similar in both directions (some products differ by approximately 30%).

- Fixed Torque vs. Adjustable Torque: Fixed torque hinges have a factory-set torque value that cannot be altered; adjustable torque hinges incorporate an internal adjustment screw, allowing fine-tuning of the required torque with a hex wrench to adapt flexibly to different door panel weights or usage habits.

The Foundation Before Installation: How to Accurately Calculate Required Torque

Why “Weight” is Misleading, and “Torque” is Key

Hinges bear the torque required to hold the door panel at a specific angle, not merely its weight. Torque (M) = F × d (N·m),where F is the applied force (including gravity) and d is the lever arm distance from the hinge axis. For example, greater door panel weight or a center of gravity farther from the hinge axis increases the required torque. If the rated torque of the selected hinge is lower than the actual torque of the door panel, the door will not stay open and will “swing open” or fall off during use.

Detailed Steps for Calculating Torque

Determine the Door Panel Weight (F)

First, calculate the gravitational force exerted by the panel. Multiply the mass (in kg) by the standard gravitational acceleration (g ≈ 9.8 m/s²).

Formula: F = mass × g

- F = Force (Newtons, N)

- mass = Mass (Kilograms, kg)

- g = Gravitational Acceleration (9.8 m/s²)

Determine Center of Gravity & Lever Arm (d)

Locate the Center of Gravity of the door or cover panel. Measure the horizontal distance from the Hinge Pivot Axis to the panel’s center of gravity. This distance is your Lever Arm.

Note: Ensure you convert millimeters to meters for this calculation. (e.g., 200 mm = 0.2 m)

Calculate Required Torque (M)

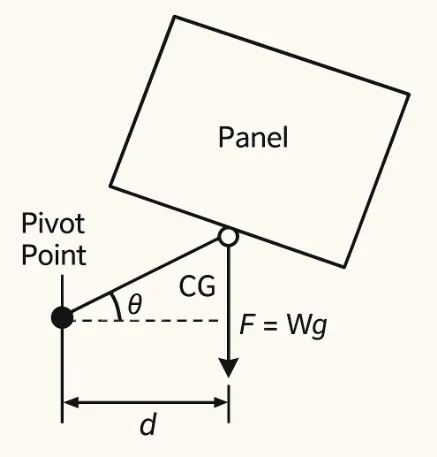

For top-opening covers (horizontal hinge axis), the required torque changes depending on the opening angle (θ).

General Formula: M = F × d × cos(θ)

Maximum Torque (M_max): The maximum torque required typically occurs when the cover is in a horizontal position (angle is 0°, where cos(0°) = 1).

M_max = F × d

Calculated Example

Scenario: A top-opening maintenance cover has a mass of 5 kg. The distance (d) from the hinge axis to the center of gravity is 0.2 m (200 mm).

1. Calculate Force (F): F = 5 kg × 9.8 m/s² = 49 N

2. Verify Lever Arm (d): d = 0.2 m

3. Calculate Maximum Torque (M_max): M_max = 49 N × 0.2 m = 9.8 N·m

4. Apply Safety Margin (+25%): We recommend adding a safety margin to account for potential friction variance or external vibration.

M_final = 9.8 N·m × 1.25 ≈ 12.25 N·m

Therefore, the total rated torque of the selected hinges (sum of all hinges used) should be approximately 12.25 N·m or higher.

Torque calculation diagram of a top-opening lid

For a side-opening door (with a vertical hinge axis):gravity acts parallel to the rotation axis and produces no torque. In this configuration, the torque hinge’s function is to provide frictional resistance, not to counterbalance the door’s weight. The required torque depends on the desired holding or damping effect rather than on the panel’s mass.

Note:

Always consider torque tolerance during selection. Some hinges have torque tolerances as high as ±20%, meaning a hinge rated at 3 N·m may only deliver 2.4 N·m. If the required torque for the door panel approaches this lower limit, reliable hold-open performance cannot be guaranteed.

Relevant Technical Standards Reference

Following industry practice, design and testing processes should reference relevant standards. International standards such as ISO 4769:2012 (Strength and durability of hinges) and EN 1935:2002 (Building hardware – Single-axis hinges) specify hinge performance requirements; These standards can be used for verification and testing to ensure selected hinges meet design requirements.

Select Hinges Based on Application Environment

Material Selection: Corrosion Resistance, Temperature Tolerance, and Cleanliness Requirements

Different environments impose distinct material demands on hinges. Common materials and their characteristics are as follows:

| Material | Characteristics and Applications |

|---|---|

| Stainless Steel (316/304) | Offers excellent corrosion resistance and strength. 316 (especially 316L) is significantly superior to 304 in resisting chloride corrosion (like salt spray), making it the top choice for marine, food processing, medical equipment, and harsh outdoor environments. |

| Zinc Alloy | Moderate cost, relatively high strength; suitable for general indoor cabinets, distribution boxes, etc. Surface can be powder-coated or electroplated to enhance corrosion resistance. |

| Engineering Plastics | Excellent insulation properties, lightweight; used for light loads or applications requiring electrical insulation, such as electronic equipment housings or medical diagnostic instruments. Note temperature resistance and long-term load capacity limitations. |

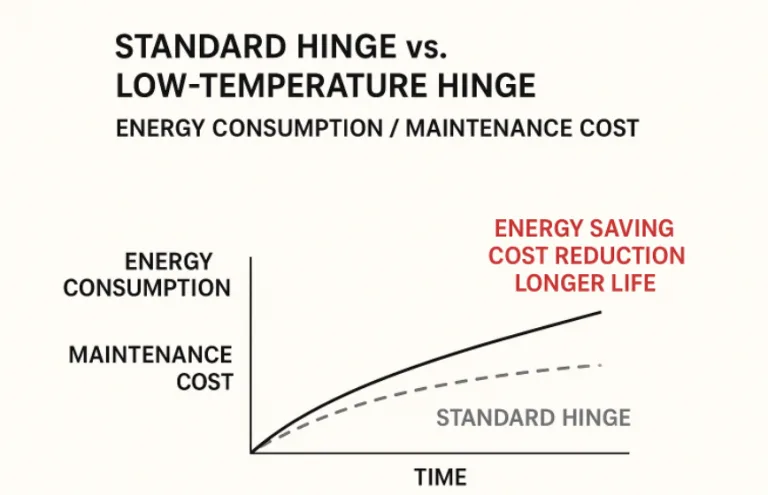

Cycle Life: Opening/Closing Frequency Requirements

A hinge’s cycle life denotes the number of sustained operations under standard opening/closing conditions. Each operation causes fatigue, so select products with high cycle life. Industry experience indicates that standard industrial hinges typically last around 20,000 cycles, while premium products can exceed 50,000 cycles. In high-frequency usage environments, torque hinges with extended lifespans are recommended to prevent reduced holding force due to fatigue failure.

5 Critical Installation Technical Details

Preparation of Mounting Surface

The hinge mounting surface must be sufficiently rigid and level. If the substrate is too soft or uneven, it can cause deformation of the hinge seat, shifting the relative position of friction components and leading to inaccurate torque values or even failure. Therefore, inspect and reinforce the mounting surface beforehand to ensure no significant deflection occurs after tightening the hinge. The area around the mounting holes must also remain straight.

Strict Axis Alignment

Correct vs Incorrect Torque Hinge Installation (Do / Don’t)

Alignment Key Points: The hinge axes must be strictly parallel and on the same horizontal plane. Any misalignment concentrates torque load on a single hinge or its edge, accelerating localized wear and causing uneven friction. As industry guidelines indicate, misaligned screw holes can lead to door panel skewing, poor sealing, rattling, or even water leakage.

Alignment Technique: Use a laser level or long straightedge to verify the reference line. Secure one side of the hinge first, then fine-tune the opposite side to ensure uniform gaps. Utilize the long slot design (if available) for minor adjustments during installation until all hinge axes align consistently. Proper alignment significantly extends hinge lifespan and maintains constant torque performance.

Use Correct Fasteners

Torque hinges endure continuous twisting forces, so fasteners must possess sufficient tensile strength and torque-bearing capacity. Use mechanical screws or hex socket high-strength bolts matching the hinge hole dimensions and installation thickness. In vibrating environments, pair with threadlocker or spring washers to prevent loosening. Avoid under-tightening during installation, as this may deform the hinge base; similarly, avoid over-tightening to prevent damage to the hinge body. Proper tightening ensures long-term stable operation.

Correct Adjustment Method for Adjustable Torque Hinges

For torque hinges with adjustment screws, calibration must be performed under actual load conditions:

- Adjust under load: Set the torque with the door panel or cover plate attached to accurately gauge friction changes. Adjusting without load yields inaccurate results.

- Adjust incrementally: Turn the adjustment screw 1/4 turn at a time, observing torque changes. Increase or decrease torque in the direction indicated by the arrow. If torque is adjusted on one hinge, make the corresponding adjustment on the other hinge to maintain force balance.

- Precautions: Never over-tighten or fully remove the adjustment screw, as this will cause the hinge to lose its friction-holding capability. After adjustment, re-test the door panel movement to ensure it holds at the desired angle under the intended torque.

Do Not Lubricate!

Torque hinges rely on friction to maintain position. Do not apply any lubricants (such as WD-40, grease, etc.) to the pivot point. This “no-lubrication” principle is a critical maintenance requirement for all friction-based mechanisms. Lubrication destroys the friction layer, rendering the hinge incapable of adjusting torque. Routine maintenance requires only keeping the hinge surface clean—dust may be wiped with a dry cloth. If rust or wear appears, replace the hinge instead of attempting to lubricate it. Proper surface treatments (e.g., powder coating, electroplating) enhance corrosion resistance and reduce maintenance requirements.

FAQ

Q1: Door panel won’t stay in any position?

A: Typically caused by insufficient or uneven torque selection. Verify torque calculations are accurate (considering weight and center-of-gravity distance); ensure hinges are perfectly aligned; if hinges are aged, friction pads may be worn out and should be replaced promptly.

Q2: Opening or closing the door panel requires excessive force?

A: This may result from selecting excessive torque or mismatched torque on a single hinge. Also check for installation misalignment, which can cause jamming. Appropriately loosen the adjustment screw to reduce torque, or realign the axis and retest.

Q3: Hinges become “loose” after several months?

A: Increased swing may indicate insufficient cycle life during selection, or fatigue damage to internal springs/friction pads from prolonged use. Installation deviations can accelerate wear. Additionally, severe environmental corrosion may intensify wear in torque hinges due to rust. Solutions include replacing with products offering longer cycle life, inspecting and correcting installation deviations, and selecting corrosion-resistant materials.