Torque Hinges: Applications, Selection, Installation & Maintenance Guide

Reliable Torque Hinge for Cabinets & Server Doors

You might know them as friction hinges or constant torque hinges. These torque hinges are special hardware parts. They give you controlled rotation and hold positions tight, no extra locks needed. These clever gadgets use internal friction. They keep lids, screens, and panels right where you want them. That’s why they’re super handy everywhere, from laptops to medical gear. People want more adjustable torque hinge solutions these days. It shows how key they are for making products work well and feel good to use, especially when you need smooth, dependable movement. Regular hinges just let things swing. But torque hinges are different. They’re precision-made to give just the right resistance. You can tweak them for different weights and how you’ll use them.Here’s what we’ll cover

Fundamentals of Torque Hinge Technology

What Are Torque Hinges and How Do They Work?

Torque hinges work by creating friction between their internal parts, usually with spring-loaded mechanisms or viscous fluid. Their core mechanism has a shaft that goes through specially designed friction

plates, giving you steady rotational resistance the whole time you’re moving it. Because the torque output is constant, these hinges can handle weights from just a few ounces up to more than 100 pounds, all while keeping things smooth.

Manufacturers can precisely calibrate how much resistance you get, so you can order custom torque hinges for special jobs where regular ones just won’t cut it.

From working with industrial designers, I’ve seen firsthand that how these friction hinges are built inside really makes a big difference in how well they perform.

The toughest models use multiple friction points instead of just one, which spreads out the wear and keeps them working consistently through thousands of uses.

This smart engineering is why high-quality constant torque hinges keep their holding power much longer than cheap ones that often wear out in just a few months.

Key Technical Specifications and Performance Metrics

When you’re picking out torque hinges, you’ll want to pay attention to a few key specs: torque value (in Newton-meters or Inch-Pounds), how far they rotate (usually 0-180 degrees), how much weight they can hold, and how many cycles they’ll last.

The torque rating tells you how much force you need to move the hinge and what weight it can reliably hold in place. Engineers also need to think about the environment – like temperature ranges, chemical exposure, and vibration – since these can all affect how the hinge’s friction works over time.

What the hinge is made of really matters for performance. Stainless steel torque hinges resist corrosion better, great for medical or marine use, while zinc alloy ones are more budget-friendly for consumer electronics.

The surface finish and lubrication type affect performance too. You need food-grade lubricants for pharmaceutical or food service gear, while special dry lubricants work better in extreme temperatures where regular ones might break down.

Precision Torque Hinge XG11-124 with 0°/180° Detent – SUS304 Steel

Types and Variations of Torque Hinges

Standard Torque Hinges Versus Adjustable Models

Standard torque hinges have their resistance set at the factory. You can’t change it after installing them. That’s why they’re great for mass production where you need things to stay consistent.

These preset friction hinges are usually cheaper and more reliable. They work best when you know exactly what you need. But adjustable torque hinges let you change the resistance on the spot. They use set screws or tensioning mechanisms.

So you can fine-tune them during installation or if your needs change later. This adjustability is super helpful when you’re prototyping or dealing with weights that aren’t always the same.

In a recent project, we ran into some surprise weight distribution problems. Without adjustable models, we would’ve had to replace all the hinges. Being able to bump up the resistance bit by bit saved us time and money on tooling.

Just keep in mind, adjustable versions don’t last quite as long. They have more moving parts in the adjustment mechanism, so their cycle life is a bit shorter than fixed hinges.

Specialized Hinge Designs for Unique Applications

Besides the standard models, there are also specialized torque hinge designs. These handle special operating needs. Dual-axis hinges let you move smoothly on two planes at once. They’re perfect for tricky positioning systems in planes or cars.

Detent hinges have specific stopping points at common angles, like 90 or 135 degrees. They still give you friction control between those stops. Then there are zero-profile hidden hinges.

They do the positioning job but stay completely hidden after installation. These are awesome for high-end gadgets and minimalist furniture.

For tough environments, hermetically sealed torque hinges keep out contaminants in medical cleanrooms or drug factories. Corrosion-resistant models can handle harsh marine conditions. I remember one case where a client needed hinges for MRI gear.

They couldn’t have any iron in them. So we had to use non-magnetic stuff like brass or certain aluminum alloys. And they still had to keep their precise torque through the product’s entire life.

Positioning Hinges – 4-Stop or Free-Swinging Zinc Alloy

Picking the right torque hinge for your project

Figuring out weight capacity and torque needs

First, you need to calculate the moment load to size torque hinges right. This means looking at the object’s weight and how far its center of gravity is from the hinge. Just multiply the weight by the distance to get the torque value you need.

Most makers say to add a 25-30% safety buffer. This covers dynamic loads, wear and tear, and extra weight from cables or add-ons.

From experience, lots of engineers don’t account enough for off-center loads. That leads to hinges that are too small and fail early. A smarter move is to make a detailed CAD model to find the real center of gravity.

This is key for odd-shaped stuff like medical monitors or industrial panels. If things move a lot, go for hinges with at least 50% more torque than you calculated. That’ll make them last longer.

Thinking about the environment and picking materials

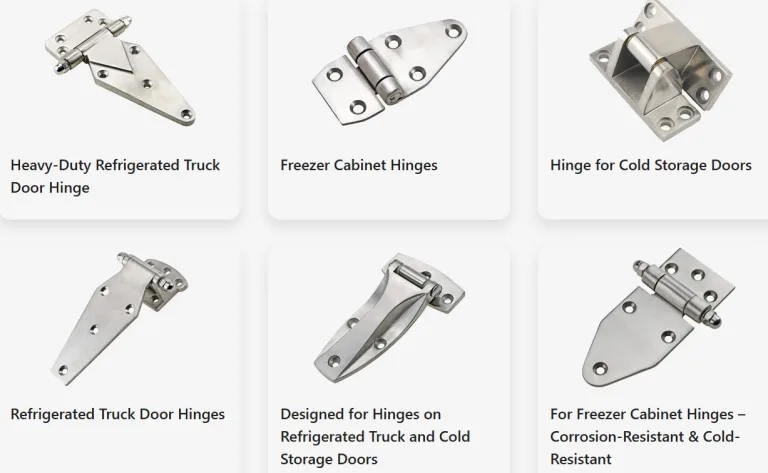

Where you use the hinge really affects your choice. Things like crazy temperatures, moisture, chemicals, and how clean it needs to be decide what materials and finishes work best. For outdoors, stainless steel hinges with good seals fight off rust.

In medical or food spots, electropolished finishes make cleaning easier. In really hot places over 200°F, you need special lube and materials to keep working right. Regular hinges would just give up.

For tough environments, don’t forget about how easy it is to maintain them. Sealed, forever-lubed hinges are great for spots you can’t reach. But some industrial jobs do better with hinges made for occasional re-greasing.

Once in a food plant, we picked hinges with zerk fittings. You could lube them without taking them apart. This made them last way longer in a high-pressure washdown area that would kill normal hinges in months.

XG11 Straight Dual-Axis Torque Hinge for Medical & Electronics

Installation Techniques and Best Practices

Proper Mounting Methods for Optimal Performance

If you install torque hinges correctly, they’ll work just like they’re supposed to for their whole life. Make sure the surfaces you mount them on are flat, stiff, and lined up right to avoid sticking or wearing down unevenly.

When installing cabinet hinges, it’s best to use precision jigs. They help get multiple hinge points perfectly aligned. Even a tiny misalignment, just half a degree, can cause a lot more wear and weaken the holding force.

Picking the right fasteners is just as key. Always use the screws that are recommended, the right types and sizes. And if things might vibrate, think about using some thread-locker.

From my time watching production lines, I’ve seen it a lot – people often screw things in too tight. This can bend the hinge housing and mess up how consistent the torque is. You can avoid this by using a torque-limiting driver.

This is super helpful for small hinges, where you might only need 5 to 10 inch-pounds of force. For really important jobs, double-check after installing. Have a process to verify the torque is still within spec.

Alignment and Adjustment Procedures

Getting the alignment spot-on is what makes a pro installation stand out from a DIY try. Start by marking your guide lines with precise measuring tools – don’t just eyeball it.

If you’re installing several hinges, hold the panel in place temporarily first. Check that everything lines up before you fix it permanently. For adjustable torque hinges, don’t try to set the perfect

resistance before you put them on. Instead, make small tweaks while testing them with the actual load.

Once they’re installed, test them through their full movement. Watch out for any changes in resistance – that could mean something’s misaligned. With lid support hinges, check that they hold the lid steady at different angles.

It shouldn’t droop or jump around. Write down your final settings for later. This is really useful for adjustable models, since you might need to recalibrate them during maintenance.

Adjustable Torque Hinge | 180° Free-Stop | SK7 Steel, Nickel-Plated

Maintenance and Troubleshooting

Routine Maintenance Procedures for Longevity

Doing regular maintenance really helps your torque hinges last longer, but what you need to do depends on the hinge type and where you use it. If you have sealed torque hinges, you usually just check them now and then for wear or rust.

But the unsealed ones might need oiling every so often. Plan your maintenance based on how much you use them, not just the calendar. Hinges used every day need more care than those you only move once in a while.

When you maintain them, look for rust, wear, and any loose screws. Test them to make sure the torque feels the same when moving, and clean out any dirt that could cause problems.

If you use them a lot, think about checking the torque with a gauge every now and then. This way, you can spot issues before they mess with how well the hinge works. Keep good notes on your maintenance.

Tracking how they perform over time helps you guess when to replace them before they actually break.

Common Problems and Effective Solutions

The most common problems with torque hinges are: they lose their grip, the resistance feels uneven when you move them, or they just won’t stay in place at all. Losing torque usually happens because the parts inside wear down or the lubricant goes bad.

Often, this means you’ll need to get a new hinge. If the resistance is uneven, it’s often a sign things are out of line, stuck, or dirty. Sometimes, just cleaning them up and putting them back straight fixes it.

If one suddenly fails, check for broken pieces or stripped screws. You might be able to just swap those out instead of replacing the whole hinge. On big industrial jobs, I’ve fixed pricey torque hinges

by taking them apart, cleaning them, and putting in new friction plates instead of buying whole new units. But you gotta get the manufacturer’s okay and know what you’re doing.

Always check the maker’s guide before trying to fix anything. Taking them apart the wrong way can void your warranty and even be dangerous.

304 Stainless Steel Torque Hinge for Vents – 360° Adjustable Hold

Innovations and Future Trends in Torque Hinge Technology

Smart Hinges with Integrated Sensing Capabilities

Torque hinge tech is getting smarter. Now they’re adding electronic sensors and feedback systems. This turns basic hinges into active parts of your system. These smart hinges come with built-in angle sensors.

They send position data to control systems. That means connected gear can adjust automatically as the hinge moves. Some fancy models even have force sensors. They sense external loads and tweak resistance on the fly. You get adaptive systems that handle different conditions.

In cars and planes, these smart hinges talk to central computers. They give real-time status updates and can even warn you before maintenance is needed. I just worked on surgical gear with smart torque hinges.

They didn’t just position monitors – they also gave feedback for sterilization checks and tracked usage for maintenance timing. Mixing mechanical function with digital smarts – that’s where hinge technology is heading.

Advanced Materials and Manufacturing Techniques

New materials are making torque hinges even better. Composites give great strength without weight for aerospace. Special polymers keep friction consistent without needing lube. 3D printing lets us make complex internal shapes we couldn’t before.

Now hydraulic damping hinges have better fluid channels, and we can create custom mounts for special jobs.

Surface treatments like PVD coatings make super hard, low-friction surfaces. These really extend hinge life in high-use situations. Better sealing with multiple backup seals keeps hinges working reliably everywhere – from deep ocean to outer space.

All these improvements mean torque hinges can now handle jobs where reliability and precision absolutely can’t fail.

Torque hinges sit right where mechanical engineering meets real-world use. They give you controlled motion in tons of industries. From basic laptop screens to high-tech medical gear, these hinges keep things running smoothly.

Most people don’t notice them until they break. If designers understand how they work, pick the right hinge for the job, and maintain them properly, they can build products that last.

When choosing torque hinges for your project, don’t just go cheap. The cheapest option often costs more later when it fails early and needs replacing. Instead, talk to experienced engineers and good manufacturers.

They’ll help you find the best solution for what you need. For more help, check ASME or SAE engineering handbooks about hinge design. Or just call application engineers at top hinge makers – they’ll give recommendations for your specific project.

Frequently Asked Questions About Torque Hinges

What is the typical lifespan of torque hinges?

Good torque hinges usually last 10,000 to 25,000 cycles if you use them right, and the fancy ones can go over 50,000 cycles. How long they last really depends on how heavy the load is, where you’re using them, and how well you take care of them.

If you’re constantly moving them or putting heavy stuff on them, you might need to replace them more often or get heavier-duty torque hinges.

Can torque hinges be repaired or recalibrated?

Most sealed torque hinges can’t be fixed or adjusted – when they start wearing out, you just have to swap them out for new ones. But some types let you tweak them right where they’re installed, using set screws or adjusting the tension.

For really pricey industrial hinges, a few companies might fix them up, but for regular hinges, it’s usually cheaper to just buy new ones.

How temperature affects torque hinge performance?

Temperature really affects how torque hinges work, especially the ones that use fluid inside. When it’s cold, they get stiffer, but when it’s hot, they loosen up.

If you’re using them in really hot or cold places, make sure to get torque hinges made with special materials and lubricants that work consistently in those temperatures.

Are torque hinges suitable for outdoor applications?

Yep! Outdoor torque hinges are made differently – they use stuff like stainless steel that won’t rust, have protective coatings, and are sealed up tight.

But don’t ever use regular indoor hinges outside – they’ll break down fast from rain, sun, and weather. Always check the specs to make sure the hinges are meant for outdoor use before you buy them.