Torque Hinges in Industrial Monitor Arms

Why Torque Hinges Dominate Industrial Displays

Industrial environments demand displays that adjust smoothly and hold position reliably. Torque hinges (friction hinges) deliver controlled resistance, enabling operators to position touchscreens or HMIs at any angle. This capability proves essential in manufacturing, medical settings, and logistics centers. Unlike gas springs or mechanical locks, these hinges achieve free-stop positioning through internal friction, slashing costs and simplifying designs.

Industrial Tip: Free-stop torque hinges outperform traditional supports by eliminating external components.

Torque Hinges Explained: Friction at Work

Torque hinges provide rotational resistance via internal mechanisms like stacked discs, coil springs, or compression tubes. As an industrial monitor rotates, friction builds progressively, locking the screen securely. This friction-based free-stop function ensures smooth, vibration-free adjustments and prevents unexpected movement.

Core Definition

A torque hinge is a mechanical pivot generating friction-based resistance. It locks lids, panels, or industrial monitors at any position without secondary hardware.

How Torque Hinges Deliver Precision

Internal friction elements engage during rotation. Discs compress or springs tension, converting kinetic energy into holding force. The torque hinge automatically counteracts gravitational torque to maintain set angles.

Engineering Insight: Friction mechanisms self-compensate for wear, extending service life.

Torque Hinge Types for Industrial Needs

- Constant Torque Hinges: Uniform resistance throughout 0-180° motion. Ideal for predictable, smooth adjustments.

- Adjustable Torque Hinges: Feature set screws to modify resistance. Critical when monitor weight changes or environments evolve.

- One-Way Torque Hinges: Resist motion in one direction only. Use where easy closure with secure holding matters.

- Detent Torque Hinges: Incorporate a positive “click” lock at 0°. Prevents rebound in safety-critical closures.

Why Torque Hinges Outperform

- Precision Positioning: Achieve exact viewing angles without detents or locks.

- Vibration Resistance: Friction maintains position despite machinery-induced shocks.

- Extended Lifespan: Quality torque hinges withstand 20,000+ cycles.

- Environmental Toughness: Stainless steel or engineered polymers resist corrosion, chemicals, and extreme temperatures (-20°C to +85°C).

Industrial Monitor Arms: Non-Negotiable Requirements

Critical Applications

- Factory Floors: Adjustable HMIs for CNC or robotic control.

- Medical Devices: Sterile-field displays requiring single-handed positioning.

- Logistics Hubs: Multi-screen monitoring stations in space-constrained rooms.

Performance Demands

- Absolute Positional Stability: Zero drift at set angles.

- Heavy-Duty Support: Capacity for 10-50kg displays.

- Vibration Immunity: MIL-STD-810 compliance for high-shock environments.

- Safety Assurance: Eliminate accidental drops.

- VESA Compatibility: Standard 75x75mm or 100x100mm mounting.

Environmental Challenges

- Temperature Extremes: Hinges must operate from -30°C to +70°C.

- Contaminant Ingress: IP65+ sealing blocks dust, moisture, and oils.

- Constant Vibration: Friction-based torque hinges dampen oscillations better than mechanical locks.

Durability Note: Properly specified torque hinges increase system lifespan by 40% in harsh settings.

Torque Hinges: The Precision Positioning Engine

Torque hinges enable stepless adjustment through calibrated friction. Key advantages:

- Smooth, Effortless Adjustment: Move monitors fingertip-light yet lock solidly.

- Automatic Locking: No latches or knobs – set position hands-free.

- Enhanced Productivity: Operators focus on tasks, not display positioning.

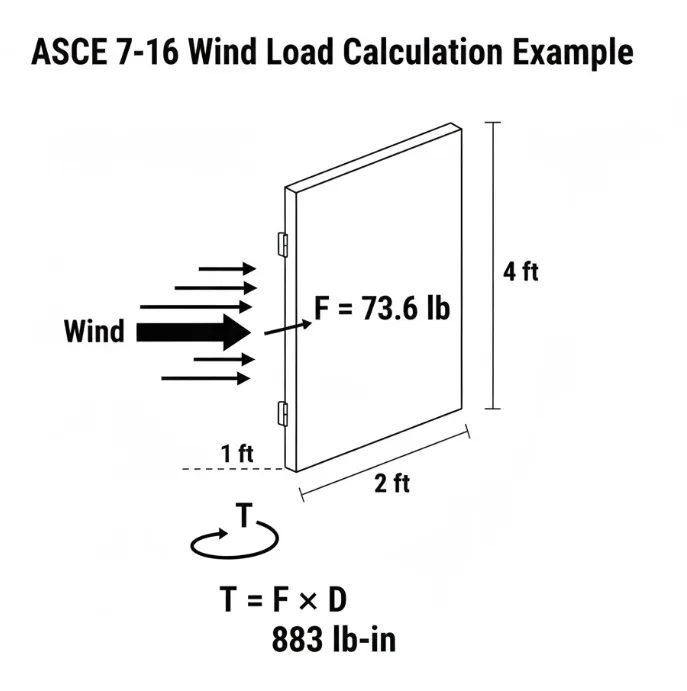

- Accurate Torque Calculation:

M = d × m × g

Whered= pivot-to-CG distance (m),m= mass (kg),g= 9.81 m/s².

Example: A 10kg monitor with 0.15m CG offset requires 14.7 N·m torque.

Pro Tip: Use manufacturer tools to calculate exact torque needs and select pre-validated torque hinge models.

Torque Hinges: Unyielding Support Under Load

- External Force Resistance: Maintains position during impacts or vibrations.

- High-Load Capacity: Heavy-duty torque hinges support up to 70 kgf·cm (e.g., HTAN XG series).

- Long-Term Reliability: 20,000-cycle test validation ensures decades of service.

- Cost Efficiency: Eliminates gas springs and reduces maintenance downtime.

Torque Hinges in Action

As shown in the image above: the application of torque hinges in industrial displays.

- Auto Manufacturing: A major plant eliminated screen drift on robotic lines using constant torque hinges, boosting assembly accuracy.

- Surgical Imaging: Medical displays stayed fixed during procedures after switching to medical-grade torque hinges.

- Warehouse Control Rooms: Torque hinge monitor arms enabled dense, adjustable multi-screen arrays in tight spaces.

Application Insight: Torque hinge reliability directly reduces operational downtime.

Selecting Industrial-Grade Torque Hinges

Load Capacity Rules

Calculate torque (M = d × m × g). Select a torque hinge with 20-40% higher rating than calculated value. For dual-hinge setups, divide total torque by two.

Torque Range Guide

- Light Displays (<5kg): 0.8–3.0 N·m

- Medium HMIs (5-15kg): 3.0–10.0 N·m

- Heavy Monitors (15kg+): 10.0–70 kgf·cm

Environmental Match

- Corrosive Areas: Specify 316L stainless steel torque hinges.

- High-Temperature Zones: Use heat-stabilized polymers.

- Cleanrooms: Opt for lubrication-free designs.

Selection Protocol

- Measure monitor weight, CG, and tilt angle.

- Calculate required torque. Apply safety factor.

- Choose hinge type (constant/adjustable, one-way/detent).

- Validate environmental specs (IP rating, temperature range).

Critical Notes:

- Account for ±20% torque tolerance during design.

- Avoid combining gas springs with torque hinges unless engineered for synergy.

Torque Hinge Installation & Maintenance

Mounting Best Practices

- Align hinge axes perfectly parallel.

- Use manufacturer-recommended fasteners.

- Torque adjustment screws evenly for balanced resistance.

Sustaining Peak Performance

- Quarterly Checks: Inspect fasteners for loosening.

- Contaminant Removal: Clean hinges with dry brushes or approved solvents.

- Recalibration: Adjust resistance on serviceable torque hinges annually.

Operational Warning: Never exceed rated load. Jerky motion accelerates wear.

Conclusion

Torque hinges solve core industrial challenges: precise positioning, vibration resistance, and heavy-load stability. Their friction-based mechanism outperforms complex alternatives while reducing costs. By mastering torque calculations and environmental specs, engineers deploy displays that withstand decades of harsh use. From operating rooms to factory floors, torque hinges are the definitive solution for industrial monitor arms requiring uncompromising reliability.