Why Engineers Abandon Gas Springs for Heavy-Duty Torque Hinges: TCO & Reliability

In precision equipment maintenance logs, gas spring seal failure frequently stands out as the leading cause of unplanned downtime. For too long, engineers have had to tolerate the wasted internal space and potential leakage risks inherent in pneumatic cylinders just to achieve lift assistance.

However, that compromise is no longer necessary. As Bill of Materials (BOM) optimization becomes more rigorous, heavy-duty torque hinges are rapidly replacing pneumatic solutions, driven by their “zero-maintenance” characteristics and the stability of pure mechanical structures. This article bypasses standard functional descriptions to argue the engineering necessity of this technical upgrade directly through Failure Mode and Effects Analysis (FMEA) and Total Cost of Ownership (TCO) data.

Space Efficiency and Aesthetic Engineering: From “Compromise” to “Integration”

In modern compact device design, every cubic centimeter of internal volume is directly correlated with product performance density. The most significant flaw of gas springs lies in their “invasive” nature regarding spatial requirements.

Quantifying Internal Volume Efficiency

The working principle of a gas spring relies on the linear extension and retraction of a piston rod within a cylinder. This means engineers must reserve two non-negotiable zones during the CAD design phase:

The space for the cylinder body itself.

The stroke space required when the piston rod is fully extended.

Case Study: Industrial Control Cabinet Design

In a recent outdoor base station control cabinet project, we compared two design scenarios:

- Scenario A (Gas Springs): To support a 15kg door panel, two gas springs with a 200mm stroke were required. To ensure proper clearance and avoid mechanical interference, the installation layout had to comply with IEC 61439 thermal management guidelines. The result showed the gas spring’s motion path occupied approximately 1.2 liters of effective volume on the cabinet sidewall. This forced a rerouting of the heat dissipation airflow, potentially risking non-compliance with the standard’s temperature rise limits.

- Scenario B (Torque Hinges): We adopted two heavy-duty torque hinges. The hinge mechanism is coaxial with the rotation axis and fits completely flush against the cabinet edge. The effective internal volume occupied was virtually zero.

Data Conclusion:

By switching to the torque hinge solution, we increased the cabling space for core electronic components by 15%. For semiconductor equipment or medical carts pursuing high-density integration, this space saving is decisive.

Design Continuity and “Invisible” Installation

In the design of high-end medical equipment (such as ultrasound diagnostic machines), exposed linkage mechanisms are often viewed as design flaws.

- Gas Springs: No matter how they are optimized, a gas spring remains an external linkage component. It disrupts the visual continuity of the device profile and creates traps for dust that are difficult to clean.

- Torque Hinges: Modern torque hinges support Flush Mount or fully Concealed Mount options.

Technical Recommendation:

For cleanroom equipment compliant with ISO 14644, I strongly recommend using concealed torque hinges. This eliminates the risk of lubricant particle contamination from gas spring piston rods and removes hard-to-clean dead zones.

Engineering Advantages in Cable Management

A frequent challenge we encounter involves running cables through the hinge area for components mounted on the lid (e.g., touchscreens).

- Gas spring solutions cannot provide a cabling path; engineers typically must add drag chains or spiral tubing, increasing part count.

- Hollow Torque Hinges allow cables to pass directly through the center of the axis. This design not only protects cables from shear forces but also significantly simplifies the assembly process.

Maintainability and Reliability: A Comparison Based on Failure Modes

This is the core reason I advise clients to move away from gas springs. From a maintenance engineering perspective, gas springs and torque hinges represent two completely different lifecycle models.

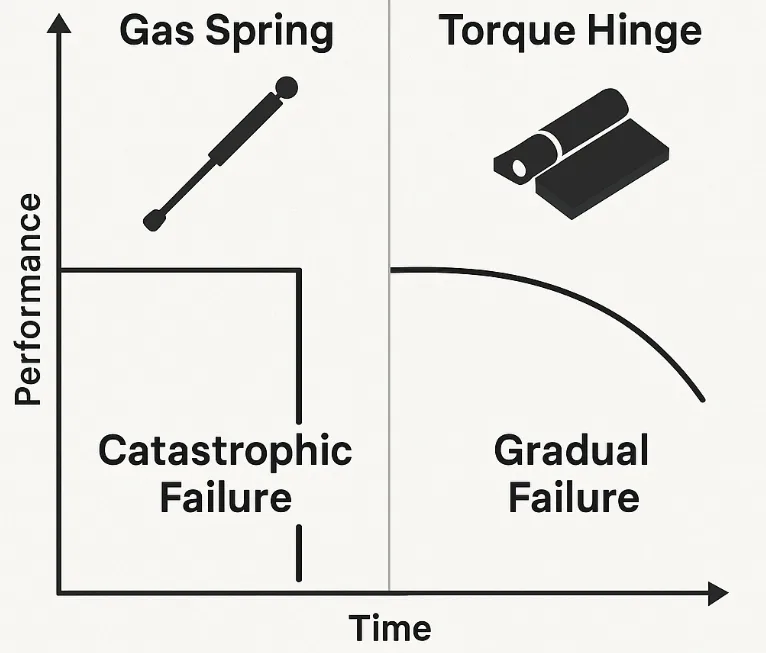

Gas Spring Failure Mode: Catastrophic Risk

A gas spring is essentially a high-pressure vessel filled with nitrogen. Its sealing performance relies entirely on rubber O-rings or lip seals.

Physical Facts:

Rubber materials undergo Aging and Creep over time. According to the Arrhenius equation (describing the relationship between chemical reaction rates and temperature), seal aging is irreversible.

Failure Consequences:

Once the seal fails and gas leaks, the gas spring’s support force drops from 100% to 0% in a very short time. This Catastrophic Failure is extremely dangerous.

- Safety Hazard: In accident reports I have reviewed, there have been instances where 20kg access panels fell unexpectedly due to gas spring failure, resulting in operator finger fractures. This is a direct violation of the “Inherently Safe Design” principles outlined in ISO 12100.

Torque Hinge Failure Mode: Progressive Decay

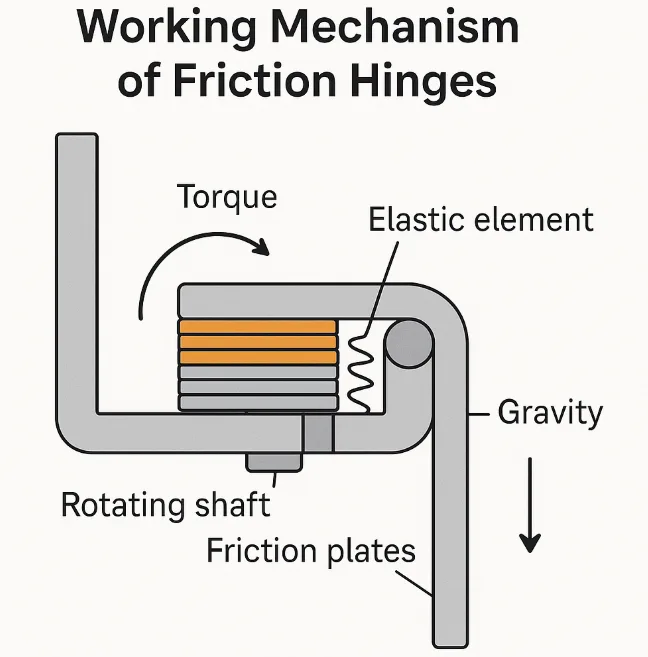

Heavy-duty torque hinges rely on physical friction between spring steel plates or powder metallurgy friction plates to generate resistance.

Failure Manifestation:

As wear increases (typically after 20,000 cycles), torque values exhibit a slow decay. This decay is linear and predictable.

- Safety Advantage: The lid will not fall suddenly; the “hold” feel simply becomes lighter. This Progressive Failure gives maintenance personnel a sufficient time window to detect the issue and intervene.

Environmental Adaptability Data

In harsh operating conditions, the performance difference is stark.

A. Temperature Sensitivity

- Gas Springs: Follow Charles’s Law (P1/T1 = P2/T2). Cylinder pressure is directly proportional to temperature.

- Low-Temp Risk: In -20°C outdoor environments, gas spring thrust may drop by 15%-20%, failing to support the lid.

- High-Temp Risk: Above 60°C, internal pressure surges, potentially causing seal blowout.

- Torque Hinges: The special damping grease we use typically covers a working range of -40°C to +80°C. At these extremes, torque fluctuation is controlled within ±10%, making the difference virtually imperceptible to the user.

B. Contamination Resistance

- Gas Springs: The piston rod must maintain a mirror finish. If contaminated by paint mist, dust, or weld spatter, these impurities will cut the seal when the piston retracts, causing immediate failure.

- Torque Hinges: Feature enclosed structural designs. For high-dust environments (like cement plants or mines), we recommend hinges with IP65 ratings, rendering internal friction components immune to external particulates.

Maintainability Operations

- Gas Springs: Non-repairable. Once leaking, they must be scrapped and replaced.

- Adjustable Torque Hinges: This is a feature I highly recommend to facility maintenance supervisors. After 3-5 years of use, if damping force decreases, technicians can simply rotate the adjustment screw with a hex key to restore initial torque. This significantly extends the lifespan of the single component.

Cost-Benefit Analysis: Reconstructing the TCO Perspective

Procurement managers often push back, noting, “The unit price of a gas spring is half that of a torque hinge; why switch?”

My response is standard: Please calculate the Total Cost of Ownership (TCO), not just the purchase price.

BOM and Assembly Costs

Hidden Costs of Gas Spring Solutions:

To install one gas spring, the BOM typically requires adding:

The gas spring body.

Upper ball stud bracket.

Lower ball stud bracket.

Reinforcement backing plate (because the short lever arm of gas springs creates extreme local stress on sheet metal).

Streamlining with Torque Hinges:

- Single SKU: Just the torque hinge.

- Assembly Man-hours: We have measured that installing and calibrating a pair of gas springs takes an average of 180 seconds; installing a pair of positioning hinges takes only 45 seconds. On a production line producing 100,000 units annually, the labor savings are immense.

Logistics and Compliance Costs

This is an often-overlooked pain point.

- Dangerous Goods Transport: Gas springs are pressurized vessels. In international air freight, they must adhere to UN 3164 provisions under IATA DGR (Dangerous Goods Regulations). This requires special packaging, labeling, and declaration documentation, significantly increasing logistics fees and customs clearance time.

- Warehousing Limits: Due to natural gas permeation, gas springs have a “Shelf Life,” typically 12-18 months. Expired inventory must be scrapped.

- Torque Hinges: These are standard metal structural components. They have no shelf-life restrictions, no transport restrictions, and extremely low warehouse management costs.

After-Sales and Downtime Costs

According to our client feedback data, the average replacement cycle for gas springs in medical cart applications is 24 months. In contrast, high-quality friction hinges often require no replacement throughout the equipment’s lifecycle (typically 5-8 years).

Reference Calculation:

TCO = Purchase Cost + (Installation Hours x Rate) + Sum of Years [Failure Rate x (Spare Parts + Travel Expenses + Downtime Loss)]

Even if the initial purchase cost of a torque hinge is 3x that of a gas spring, by eliminating just one on-site service call, the TCO becomes lower than the gas spring solution.

Engineer’s Decision Guide and Recommendations

Based on the above analysis, we are not suggesting abandoning gas springs in all fields. As an advisor, my role is to help you apply the right technology to the right scenario.

Scenarios Strongly Recommended for Heavy-Duty Torque Hinges

If your project meets any of the following criteria, switch to a torque hinge solution immediately:

Need for “Free-Stop” Positioning: The user needs to keep the screen or lid at arbitrary angles like 20°, 45°, or 60°, not just fully open or closed.

High-Value Medical Equipment: Such as ventilators, anesthesia machines, or dental monitors. These cannot tolerate the contamination risk of leaking oil or the safety risk of failure.

Outdoor Harsh Environments: EV charging station access doors or outdoor base station cabinets involving drastic temperature changes. Refer to ASTM B117 standards for salt spray selection.

Extreme Space Constraints: Portable military computers or foldable consoles.

Scenarios to Retain Gas Springs

In the following situations, gas springs remain a cost-effective choice:

- Super-Heavy Loads Requiring Only Lift Assist: For example, vehicle hoods or large equipment access doors weighing over 50kg, where only “Open” and “Closed” states are needed, and no intermediate hovering is required.

- Cost-Sensitive Disposable Equipment: If the device itself has a short design life and no precision requirements.

Conclusion

The shift from gas springs to heavy-duty torque hinges is essentially a technological leap from “Energy Storage Assistance” to “Precision Friction Control.”

For modern industrial designers, the torque hinge is no longer just a connector; it is a functional component that elevates product quality, reduces lifecycle costs, and meets strict ISO and ASTM standards.

We recommend re-evaluating traditional support solutions during the design review phase of your next project. If your goal is to build a device that requires no maintenance for the next five years and offers a premium operational feel, then the pure mechanical torque control solution is undoubtedly the smarter engineering choice.

FAQ

Q1: Can torque hinges really support heavy lids like a car trunk?

Answer: We must distinguish between “supporting” and “lift assisting.”

Modern heavy-duty torque hinges can achieve single-unit torque of 20 N·m or higher. When installed in pairs, they can stably support industrial lids or medical arms weighing up to 25kg.

However, if your lid exceeds 50kg and requires easy one-handed operation, we recommend a Hybrid Solution: use torque hinges to control the position/angle, combined with a low-force gas spring to assist in counteracting gravity.

Q2: Can I retrofit torque hinges onto old equipment that already has gas spring mounting holes?

Answer: You cannot simply swap them out. Gas springs are typically mounted at the midpoint of the lid to gain leverage, whereas torque hinges must be installed on the Axis of Rotation.

Solution: You will need to use an Adapter Plate or redesign the sheet metal at the root of the lid. While this involves a one-time retrofit cost, it is worth the investment for the subsequent years of maintenance-free operation.

Q3: Will the lid vibrate loose or fall in high-vibration environments (e.g., vehicles/heavy machinery)?

Answer: No. This is a specific strength of torque hinges.

Relying on Static Friction, the hinge naturally resists displacement caused by vibration. In contrast, gas spring seals are prone to wear and leakage under vibration. For extreme conditions (referencing MIL-STD-810 vibration standards), we recommend selecting models filled with High-Damping Grease to further absorb micro-vibration energy.