Zinc Die-Cast vs. Stainless Steel Concealed Hinges: A Sourcing Guide to Cost & Performance

In the realm of industrial hardware design, Concealed Hinges are not merely passive connectors; rather, they are critical components that define overall equipment reliability. Consequently, selecting the correct material is a strategic decision. This guide compares the two dominant material systems used in manufacturing Concealed Hinges: Zinc Die-Cast Alloy (Zamak) and Austenitic Stainless Steel.

Core Conclusion: On one hand, Zinc alloys, utilizing high-efficiency hot chamber die casting, offer unbeatable Total Cost of Ownership (TCO) for indoor controlled environments and high-volume consumer applications. Conversely, Stainless Steel (particularly Grade 316) remains the only compliant choice for heavy-duty anti-creep applications, hygienic requirements, and harsh outdoor environments meeting standards like NEMA 4X.

Material Science & Properties

Zinc Alloy Materials for Concealed Hinges (The Zamak Series)

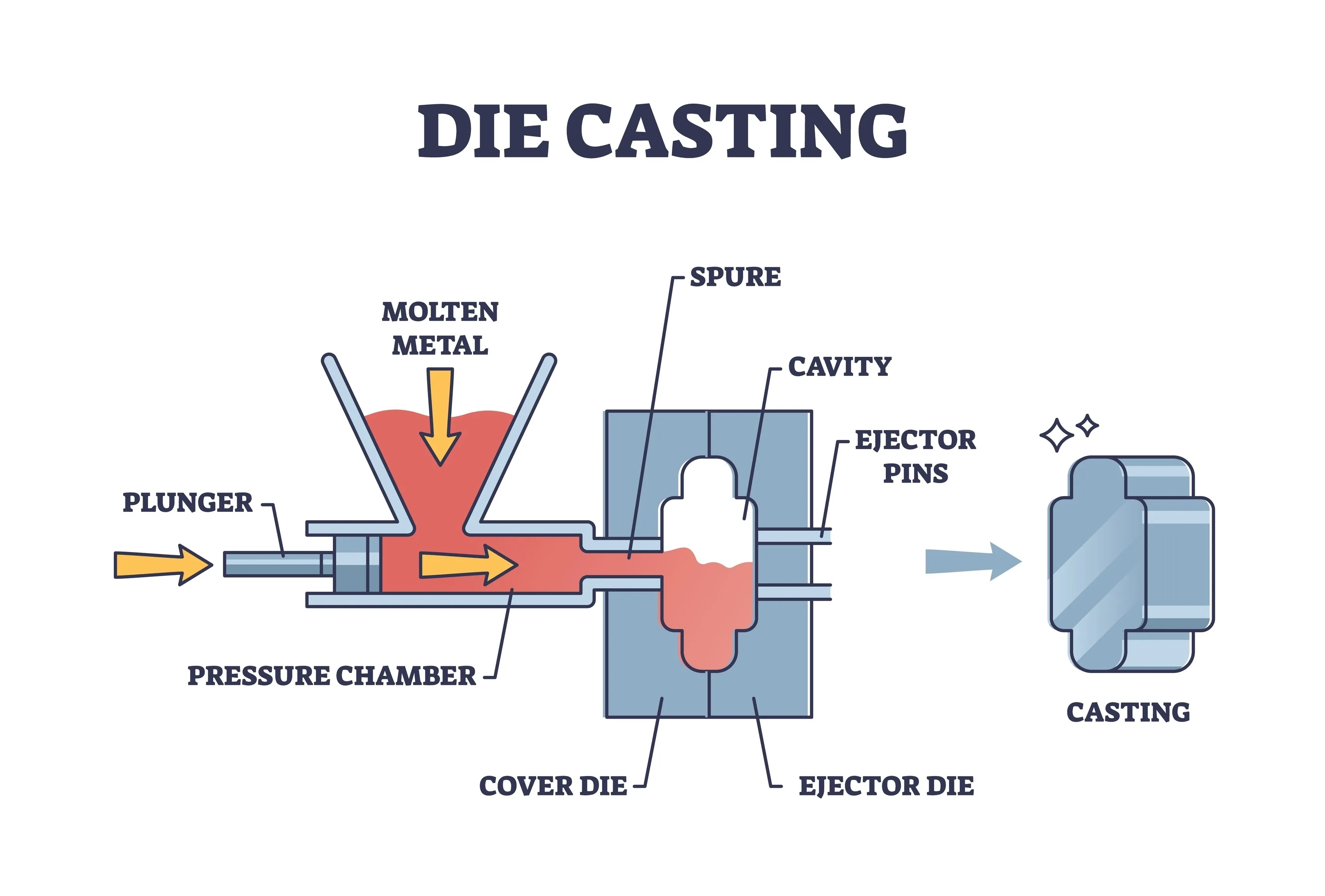

Zinc alloys are formed via hot chamber die casting. Because of this process, they offer excellent fluidity and dimensional stability, thus making them a popular choice for mass-produced Concealed Hinges.

- Zamak 3 (Industry Benchmark): Known as ASTM AG40A, this alloy contains ~4% Aluminum and no Copper. Notably, its primary advantages are superior dimensional stability and relatively good impact strength. Therefore, it is the go-to material for general industrial Concealed Hinges.

- Zamak 5 (High Strength): Known as ASTM AC41A, this variant adds ~1% Copper. In contrast to Zamak 3, it offers higher hardness and tensile strength. However, this comes at the cost of reduced ductility (making it more prone to brittle fracture) and lower dimensional stability under heat.

- Engineering Warning: Furthermore, Zinc alloys are extremely sensitive to impurities such as Lead, Cadmium, and Tin.Consequently, strict adherence to ASTM B240 standards is mandatory; failure to do so leads to severe Intergranular Corrosion in the hinge body.

Stainless Steel Materials for Concealed Hinges (The Austenitic Series)

- AISI 304 (Standard Grade): UNS S30400 contains 18% Chromium and 8% Nickel. Generally, it is suitable for indoor or mildly humid environments. However, in chloride-rich environments like coastal areas, the passive film is easily penetrated, subsequently causing Pitting Corrosion on the Concealed Hinge surface.

- AISI 316 (Marine Grade): UNS S31600 adds 2-3% Molybdenum (Mo). Significantly, Molybdenum boosts resistance to pitting (resulting in a higher PREN value).Therefore, for outdoor ratings requiring NEMA 4X / IP66 compliance, 316 is the specified material for Concealed Hinges.

Physical Parameters Comparison of Hinge Materials

| Key Parameter | Zinc Alloy (Zamak 3) | Stainless Steel (304/316) | Engineering Implication for Concealed Hinges |

| Density | 6.6 g/cm³ | 8.0 g/cm³ | Since stainless Concealed Hinges are generally heavier, door load margins must be calculated accordingly. |

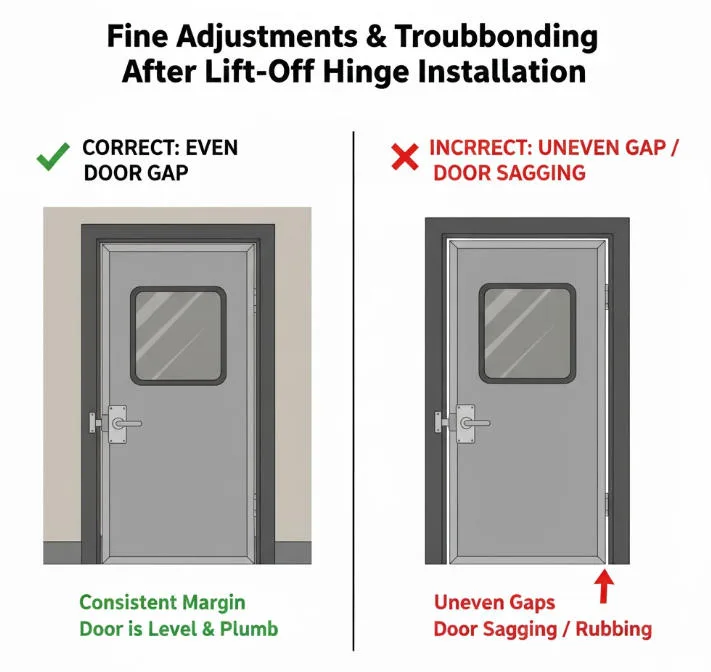

| Modulus of Elasticity | 85 GPa | 193 GPa | Rigidity: Under the same load, stainless steel exhibits half the deformation of zinc; thus, it is superior for precision gap control. |

| Melting Point | ~385°C | >1400°C | This determines process cost: Zinc allows efficient die casting, whereas Steel requires expensive investment casting. |

| CTE (Thermal Expansion) | 27.4 µm/m°C | 16.0 µm/m°C | Because Zinc Concealed Hinges expand/contract significantly in outdoor temp fluctuations, larger tolerances are required. |

| Conductivity | Good | Poor | Zinc aids EMI/RFI Shielding grounding in cabinets; meanwhile, Stainless usually requires dedicated grounding straps. |

Manufacturing Processes & Cost Logic for Concealed Hinges

Zinc Concealed Hinges: Hot Chamber Die Casting

- Process: First, molten metal is injected directly into the mold. As a result, cycle times are measured in seconds rather than minutes.

- Tooling Life: Additionally, quality tool steel (H13) can last up to 1 million shots.

- Cost Structure: While there is a moderate tooling investment, the single piece price is extremely low. Therefore, economic benefits become exponential at volumes >10,000 units for Concealed Hinges.

Stainless Steel Concealed Hinges: Investment Casting

- Process: This is also known as “Lost Wax” casting. Specifically, it involves wax pattern creation, shelling, dewaxing, and pouring. Consequently, cycle times are measured in days or weeks.

- Design Limits: Although complex shapes are possible, minimum wall thickness requirements are higher than zinc (>1.5mm). Thus, extreme lightweighting is difficult for Concealed Hinges.

- Limitation of Stamping: Furthermore, stamping is only viable for thin sheet metal. For instance, for Solid Body heavy-duty Concealed Hinges requiring complex 3D geometry, stamping is generally not a viable manufacturing option.

Mechanical Failure Modes

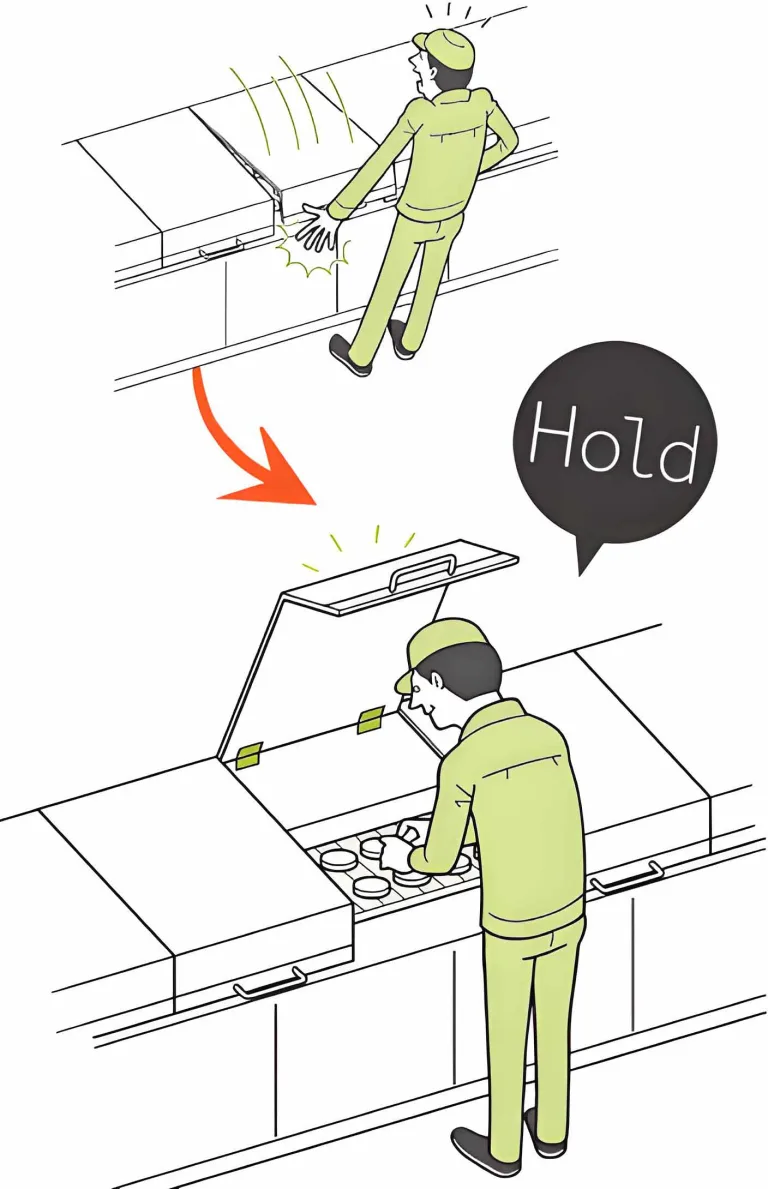

Creep Deformation in Zinc Concealed Hinges

- Phenomenon: Zinc alloys undergo slow plastic deformation under continuous load, even at room temperature. Moreover, if ambient temperature rises to 50°C+ (common in outdoor cabinets), the creep rate accelerates drastically.

- Consequence: As a result, the arms of the Concealed Hinges elongate and sag, eventually causing door friction or lock failure.

- Countermeasure: Therefore, for heavy loads or constant stress, avoid standard zinc or increase the Design Safety Factor to 2.5x.

Galling & Cold Welding in Stainless Steel Concealed Hinges

- Phenomenon: Austenitic stainless is tough. However, when same-material surfaces rub under load, the oxide layer breaks. Subsequently, this causes atomic-level adhesion, also known as cold welding.

- Countermeasure:To prevent this, never pair a “304 Pin with a 304 Knuckle” in Concealed Hinges.

- Dissimilar Pairing: Instead, use a harder Martensitic Stainless (410/420) for the pin.

- Lubrication: Additionally, the application of Molybdenum Disulfide (MoS2) or PTFE grease is mandatory.

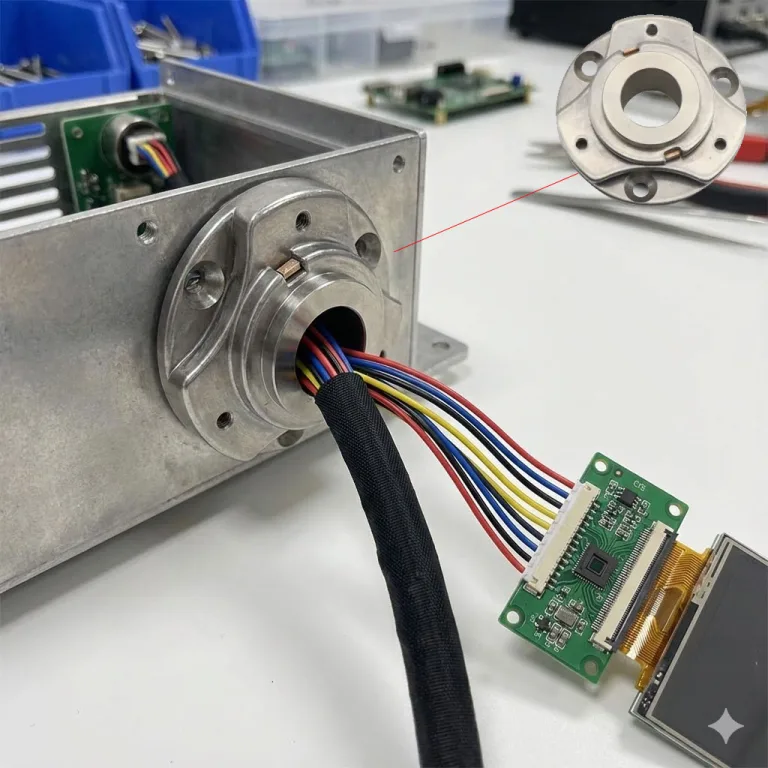

Hybrid Concealed Hinges: The Cost-Performance Compromise

- Concept: This design utilizes a Zinc Alloy Body + Stainless Steel Pin.

- Advantage: Effectively, it leverages zinc to lower body cost and molding complexity, while simultaneously using a stainless pin to provide wear resistance and shear strength. Hence, this is a common configuration for mid-range industrial Concealed Hinges.

Environmental Adaptability

Salt Spray Test Interpretation for Hinge Materials

- Zinc Alloy: Initially, bare zinc corrodes easily. Typically, standard zinc plating + passivation lasts 96-120 hours in ASTM B117 testing. Although high-end E-coating/Powder Coating can reach 500+ hours, it relies entirely on coating integrity. Once scratched, the substrate undergoes Sacrificial Anodic Corrosion, thereby creating voluminous white powder (White Rust) that can seize the Concealed Hinge mechanism.

- Stainless Steel 316: In comparison, this material can withstand 1000+ hours of salt spray without red rust and, importantly, produces no voluminous corrosion products.

Galvanic Corrosion Risks in Hinge Mounting

- Aluminum Cabinet + Stainless Concealed Hinge:

- Indoor/Dry: Generally, this presents a low risk.

- Outdoor/Salt: Conversely, this is a high-risk scenario.

Therefore, Isolation gaskets (EPDM/Nylon) and insulating bushings must be used. Otherwise, as detailed in the SSINA Galvanic Corrosion Guide, the aluminum cabinet (acting as the Anode) will suffer accelerated corrosion at the Concealed Hinge contact point.

Industry Compliance Guide

Hygiene & Food Grade Requirements

- Requirement: Equipment must withstand harsh acidic/alkaline washdowns, be non-porous, and have no risk of coating delamination (Per FDA/NSF guidelines).

- Verdict: Consequently, Stainless Steel (304/316) Concealed Hinges are the only option. Even if coated, Zinc alloys pose a risk of chips contaminating food; therefore, they are strictly prohibited in the direct Food Zone.

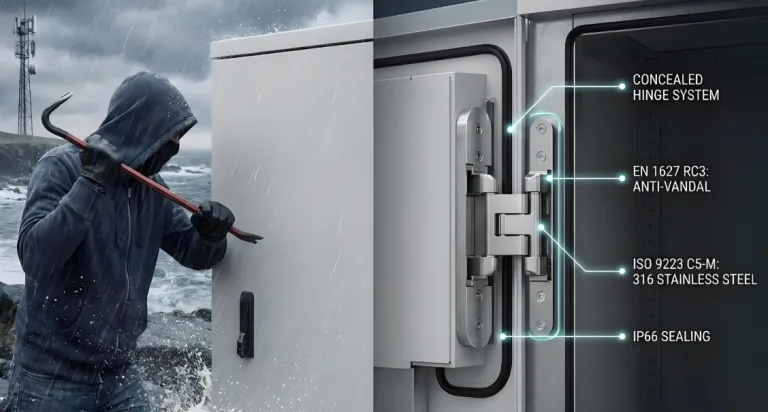

Outdoor Cabinet Standards & Hinge Selection

- Indoor Standards (NEMA 1 / 12): For these applications, Zinc Alloy Concealed Hinges (with surface treatment) are fully compliant.

- Outdoor Standards (NEMA 4 / 4X): However, for corrosive/outdoor environments, 316 Stainless Steel is strongly recommended. If Zinc Concealed Hinges are used, premium powder coating is required, and the user assumes the risk of failure due to coating aging.

Concealed Hinge Material Selection Matrix

| Application Scenario | Recommended Material | Core Rationale |

| Data Center / Server Racks | Zinc Alloy (Zamak 3) | Controlled environment, no high-temp creep risk; furthermore, offers optimal cost and good EMI grounding. |

| General Machinery (Indoor) | Zinc Alloy + Powder Coat | Meets oil/dust resistance needs; additionally, allows flexible aesthetic customization. |

| Outdoor Telecom / Power | Stainless Steel 304 | Balances weatherability and cost. However, if budget is tight, consider Hybrid Concealed Hinges. |

| Marine / Chemical | Stainless Steel 316 | Chloride/Acidic environment. Molybdenum content is mandatory. In contrast, Zinc lifespan is negligible here. |

| Heavy Doors / High Frequency | Stainless Steel (Cast) | Specifically avoids creep deformation and fatigue failure associated with zinc Concealed Hinges. |

| Food / Pharma Equipment | Stainless Steel 304/316 | Necessarily complies with FDA/HACCP washdown standards for Concealed Hinges. |

Conclusion

In the BOM selection for Concealed Hinges, there is no absolute “best,” but rather only “most suitable.”

- To summarize, for TCO (Total Cost of Ownership) and High-Volume Delivery, choose Zinc Alloy Concealed Hinges.

- Alternatively, for Extreme Environment Survival, Hygiene Compliance, and Long-Term Maintenance-Free operation, choose Stainless Steel Concealed Hinges.

FAQ

Q1: Can Zinc die-cast concealed hinges be used for outdoor NEMA 4X enclosures?

A: Generally, no. Zinc is prone to “white rust” and coating failure in harsh elements. For NEMA 4X/IP66 compliance and long-term corrosion resistance (especially in coastal areas), AISI 316 Stainless Steel is the required standard.

Q2: When is Zinc Alloy the better choice over Stainless Steel?

A: Zinc is superior for indoor, controlled environments (like data centers) and high-volume production (>10,000 units). Its fast hot-chamber die casting process offers the lowest unit price and excellent Total Cost of Ownership (TCO) for non-corrosive applications.

Q3: Are Zinc hinges safe for food processing equipment?

A: No. Zinc alloys risk chipping and contaminating food, making them prohibited in direct Food Zones. Stainless Steel (304/316) is the only option that meets FDA/NSF hygiene requirements for washdown and non-porous surfaces.