2 Nm Torque Hinge Procurement Guide

In the supply chain management of mechanical structural components, 2 Nm (Newton-meters) is often regarded as the key turning point in measuring project complexity.

Applications below 2 Nm typically belong to handheld devices (such as mobile phones and PDAs), where procurement focuses mostly on “unit price” and “appearance.” However, once the design requirement reaches or exceeds 2 Nm, the application scenario shifts from simple consumer electronics to medical workstations, industrial control panels, or heavy-duty rugged terminals.

At this level, if the procurement strategy focuses solely on price while ignoring “Position Holding” and “Vibration Resistance,” it can easily lead to the severe consequence of mass returns.

This article aims to strip away obscure physics formulas and analyze how to correctly understand and procure 2 Nm torque hinges directly from the perspectives of supply chain management and engineering application, ensuring components can successfully pass ASTM or MIL-STD standard tests.

Technical Overview: Positioning and Applicable Devices for 2 Nm Torque

Specification Definition: The Sweet Spot for Load Bearing

In the general spectrum of mechanical hinges, 2 Nm (approximately 20.4 kgf-cm or 17.7 lb-in) occupies a very special ecological niche.

According to industry observations, 2 Nm acts as a watershed between two categories of devices:

- Lightweight Handheld Devices: Typically use 0.3 Nm to 0.8 Nm (e.g., Nintendo Switch kickstands).

- Desktop/Vehicle-Mounted Devices: Typically start at 1.5 Nm and reach peak mainstream application at 2.0 Nm.

Procurement Quick Check: If your project involves a panel equipped with a 12-inch to 17-inch display, and the total weight of the panel assembly is between 1.2 kg and 2.5 kg, then “2 Nm” is the benchmark value you should enter on your Request for Quotation (RFQ).

Functional Goals: More Than Just “Staying Put”

Many junior procurement officers believe that a hinge is qualified as long as it holds the screen up without falling. However, in an industrial environment, this understanding is dangerous.

We define the functionality of a premium 2 Nm hinge across three dimensions:

- Static Holding Force: The screen remains suspended at any angle without slowly sliding down, without the need for locking mechanisms.

- Dynamic Stability: The screen does not experience “nodding” or dropping when the device is subjected to shock (such as a medical cart crossing an elevator threshold).

- Touch Bounce Reduction: When a user taps the touchscreen with a finger, the screen does not retreat due to the force, providing a solid sense of support.

Compared to lower torque hinges, 2 Nm hinges require a higher degree of design redundancy. We are not just buying a connector; we are purchasing “peace of mind.”

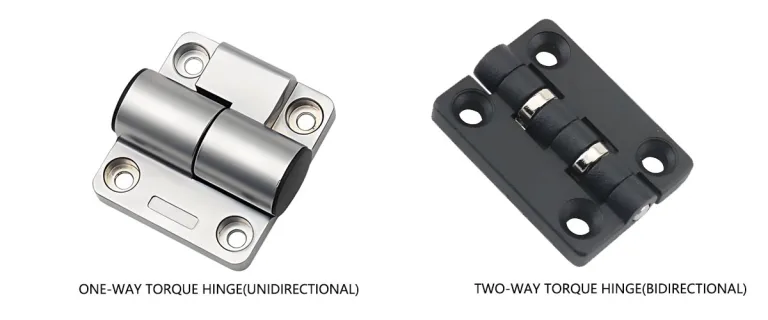

Structural Perspective: How Internal Construction Determines Product Life

There are two main structures for friction hinges on the market. As a procurement professional, understanding their essential differences helps you identify whether a supplier is cutting corners.

Structure Type Comparison: Why I Recommend Disk Stack Structures

Wrapped Clip Structure

This structure generates friction by stamping a steel band to directly wrap around the shaft.

- Characteristics: Looks simple, like a metal clip gripping a rod.

- Cost: Extremely low, suitable for high-volume production.

- Risk: Under the high pressure of 2 Nm, the steel band is prone to loosening (metal fatigue/stress relaxation).

- Consultant’s Advice: If your product is a fast-moving consumer good (FMCG) or a disposable medical device, this is acceptable. If it is a durable industrial product, proceed with caution.

Disk Stack Structure (Multi-disk)

This generates friction by alternating layers of friction plates and spring washers (Belleville washers), compressed axially like a “sandwich.”

- Characteristics: Compact structure with a large friction surface area.

- Advantage: Extremely smooth output and exceptionally long lifespan.

- Data Support: Based on accelerated life cycle testing (often referenced against IEC 60068-2-38 for composite temperature/humidity cycling)

- Consultant’s Advice: For industrial-grade 2 Nm applications, the disk stack structure is the only reliable choice.

The Critical Role of Damping Grease

Under the high pressure of 2 Nm, there must be damping grease between metal surfaces.

- Common Issue: Cheap grease thins out after prolonged friction, causing resistance to drop suddenly.

- Procurement Strategy: When auditing the BOM (Bill of Materials), confirm that the supplier uses Synthetic Fluorinated Grease. This type of grease has the most stable performance within the range of -20°C to 120°C and will not migrate or dry out.

Pain Point Solutions for Medical and Industrial Scenarios

To give you a more intuitive understanding, I have selected three typical 2 Nm application scenarios. These are summarized based on pain points from real-world projects.

Medical Carts and Diagnostic Workstations

Scenario Description: A mobile ultrasound diagnostic unit equipped with a 15-inch touchscreen. Doctors need to adjust the angle frequently and push the cart between hospital wards.

Pain Point: Vibration-Induced Drooping When the cart passes over bumps on the floor, it generates instantaneous impact force. If the hinge strength is merely “just enough,” the screen will droop instantly during vibration. This is unacceptable in a medical setting.

The 2 Nm Solution: We adopted the “Safety Margin” principle.

- Although theoretically, 1.3 Nm could hold the screen.

- We directly procured a 2.0 Nm hinge.

- Result: The extra torque provided sufficient reserve, ensuring the screen remained motionless even during the vibration phase of IEC 60601-1 mechanical testing.

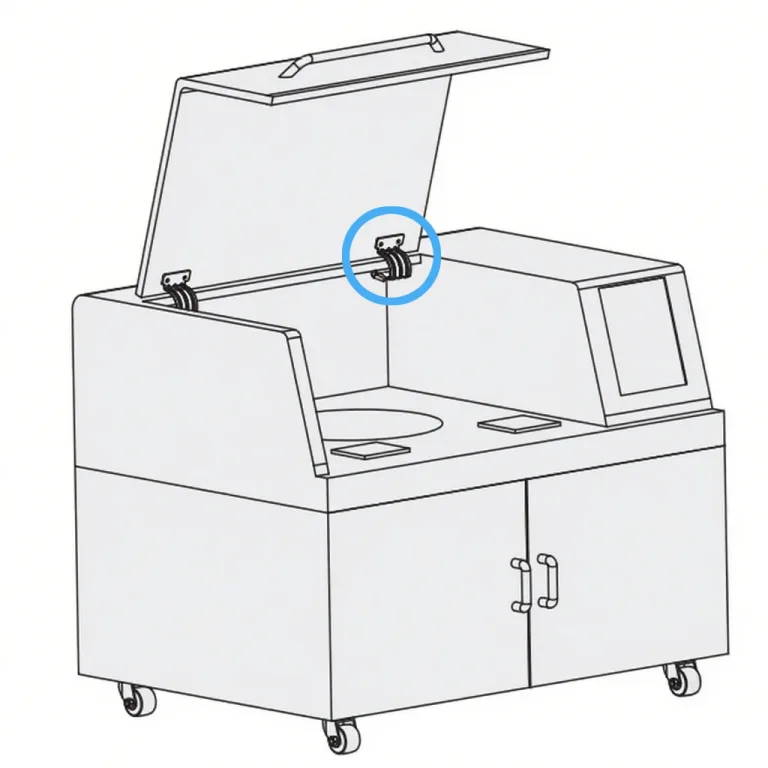

Industrial HMI and CNC Machine Panels

Scenario Description: A control panel suspended on the side of a CNC machine, in an environment with continuous high-frequency micro-vibrations.

Pain Point: Micro-motion Wear (Fretting) Long-term micro-vibrations cause internal wear in the hinge, leading to slow drifting of the screen position.

Procurement Strategy: Asymmetric Torque For this case, we customized an “asymmetric” specification from the supplier:

- Opening (Upward): 2.0 Nm — Allows the operator to lift the screen easily.

- Closing (Downward): 3.0 Nm — Provides greater resistance to counteract gravity and vibration. This configuration ensures ease of operation while solving the vibration issue.

Military and Rugged Vehicle Terminals

Scenario Description: A rugged laptop installed in a field command vehicle, required to work in extreme cold (-40°C).

Pain Point: Low-Temperature Seizure Ordinary carbon steel becomes brittle at low temperatures, and standard grease solidifies. This causes the starting torque to skyrocket, directly snapping the plastic housing.

Material Requirements: We mandated the use of 17-4PH Stainless Steel for the shaft material.

- Reason: This material has extremely high yield strength and low-temperature toughness.

- Pairing: Use of wide-temperature range aerospace-grade damping grease.

- Verification: Ensured passing of MIL-STD-810H (Low-Temperature Operation) testing.

Procurement Guide: Selection and Tolerance Control Without Calculation

As a procurement professional, you do not need to master complex physics formulas, but you do need to master the following “Rules of Thumb” to judge whether the engineering department’s selection is reasonable.

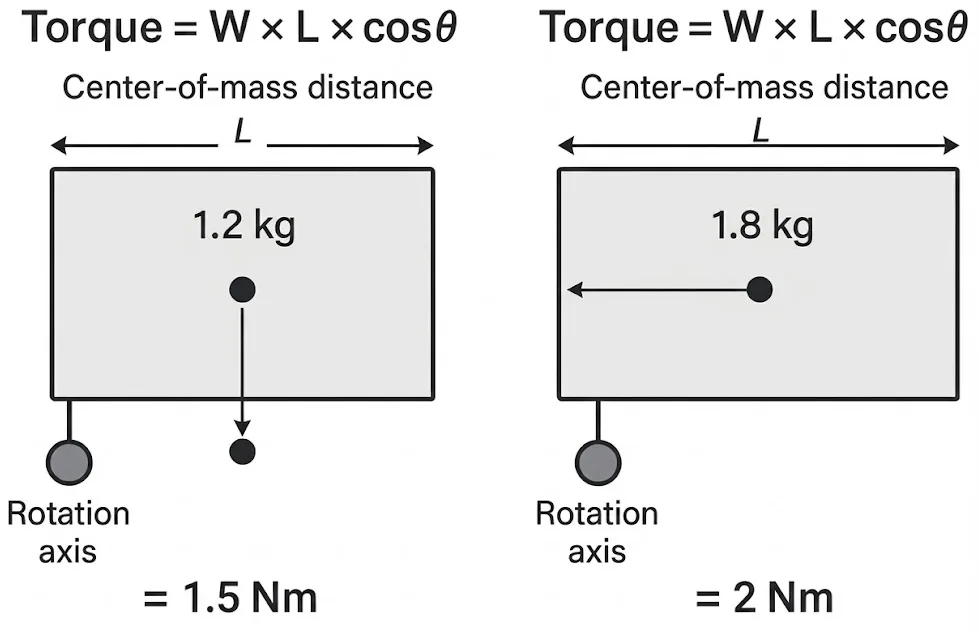

The Simple Weight and Distance Rule

To determine if 2 Nm is needed, look at two data points: Panel Weight and Center of Mass Distance.

- Rule Explanation: The heavier the object, or the further the center of mass is from the pivot, the more torque is needed. It’s the lever principle: the further from the fulcrum, the more effort is required.

- Real-world Quick Check:

- Weight 1.0kg – 1.5kg: If the screen is wide (center of mass is far), select 2.0 Nm directly.

- Weight 1.5kg – 2.0kg: This is the core comfort zone for 2.0 Nm.

- Weight > 2.5kg: 2.0 Nm may not be enough; suggest considering 3.0 Nm or a dual-hinge solution.

- Conclusion: If you see a panel weighing 1.8kg, and the engineer has selected only a 1.5 Nm hinge, you must raise a query: This may not pass the vibration test.

Tactile Experience Evaluation

After determining the force, user operation experience must be evaluated. Too tight will make the device difficult to open, or even cause the base to tip over.

- Tactile Rule: The wider the screen, the longer the lever arm when the user grips the edge, making the hinge feel “lighter.” The narrower the screen, the “heavier” the hinge will feel.

- Evaluation Standard: For a 15-inch industrial screen using a 2 Nm hinge, the force required for single-handed operation is roughly equivalent to lifting an 800ml bottle of water. This is a “steady, firm, but effortless” premium damping feel, perfectly fitting the positioning of industrial equipment.

Tolerance and Pairing Strategy

The standard tolerance for industrial products is typically ±20%. This means the 2.0 Nm hinge you buy could actually fluctuate between 1.6 Nm and 2.4 Nm.

Risk: If you are unlucky and receive a product at the lower limit (1.6 Nm), and your screen is heavy, it may fail to hold.

Procurement Strategy:

- Dual Hinge Pairing: If the device has a hinge on both the left and right, require the supplier to perform “pairing” before shipment. I.e., match one on the high side with one on the low side, ensuring the total torque stabilizes around 4.0 Nm.

- Asymmetric Tolerance: Specify 2.0 Nm (+0.4 / -0.0) on the drawing. Explicitly tell the supplier that it can be stiffer, but never softer.

Quality Risk Control: Failure Mode Analysis (DFMEA) and Prevention

When auditing suppliers, asking the following three questions can quickly determine their level of professionalism.

Regarding Torque Decay

- Question: “How much will the torque drop after six months of use?”

- Qualified Answer: “After 25,000 cycle tests, the decay rate is controlled within 20%.”

- Pitfall Avoidance: Reject any supplier who only gives verbal promises but does not provide test reports.

Regarding Low-Temperature Failure

- Question: “Will this seize up at minus 20 degrees?”

- Qualified Answer: “We use wide-temperature grease; the starting torque at low temperatures will not exceed 1.5 times the room temperature torque.”

- Pitfall Avoidance: If the supplier says “no problem” but cannot name the grease brand, there is usually a hidden risk.

Regarding Springback

- Phenomenon: The user stops the screen at 45 degrees, releases their hand, and the screen automatically bounces back to 42 degrees.

- Reason: Insufficient shaft rigidity, twisting like a spring.

- Countermeasure: Require the supplier to use a thicker shaft or eliminate internal assembly clearance.

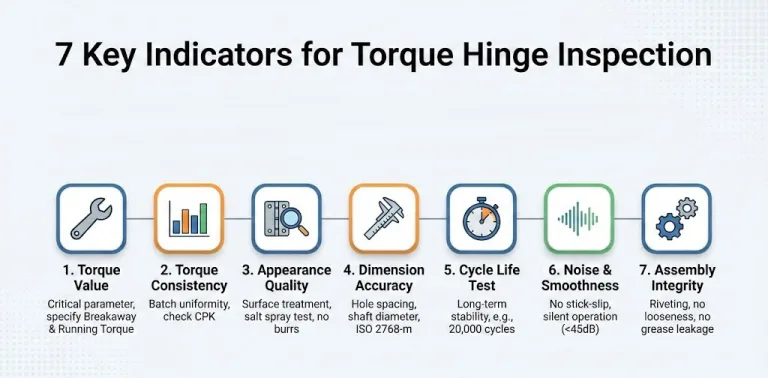

Acceptance Standards: Drafting the Perfect Specification Sheet

To avoid disputes upon receipt of goods, please copy the following parameters directly into your procurement contract or technical drawings.

Key Parameter Checklist

- Nominal Torque: 2.0 Nm ±15% (Note: Specify this refers to Dynamic/Running Torque).

- Life Cycle Requirement: 25,000 Cycles (one open-close counts as one cycle), speed 10-15 cycles per minute.

- Decay Limit: After completing the life cycle test, torque must not be lower than 80% of the initial value.

- Operating Temperature: -20°C to +60°C (Covers most industrial uses).

- Salt Spray Test: Compliant with ASTM B117 standard, 96 hours with no red rust (Suitable for medical/outdoor).

- Core Material: Shaft must be Hardened Stainless Steel.

Rapid Sample Verification Method (IQC)

When receiving goods at the warehouse, I recommend a rapid inspection method that does not require professional equipment:

- Rotate It: Slowly rotate the hinge by hand.

- Feel the Difference: Feel the difference between the force required “at the very start of rotation” and “during continuous rotation.”

- Judgment: For a high-quality hinge, the starting and running forces should feel almost the same. If the start feels particularly sticky (stiction/jerkiness), it indicates poor lubrication or an overly tight fit, which will result in a poor user experience.

Conclusion

The 2 Nm torque hinge is not just a connector; it is a core component that balances heavy loads, protects expensive screens, and provides a premium human-machine interaction experience.

As a procurement expert, your strategy should be:

- Leave a Margin: Do not buy specifications that are “just enough”; reserve a 20% safety margin to cope with vibration.

- Select the Structure: Prioritize Disk Stack Structures for industrial applications.

- Check the Data: Insist on requesting life cycle test and salt spray test reports.

If you are developing a medical workstation or industrial control terminal, correctly selecting a 2 Nm hinge will be the most cost-effective investment to enhance the “precision feel” and “reliability” of your product.

FAQ

Q1: Why did the force of my 2 Nm hinge decrease after testing it a few times? This is usually a “break-in” phenomenon. A drop within 10% is normal and represents the process of grease redistributing internally. If it drops too much, it is a quality issue.

Q2: Is 2 Nm torque too heavy for a 10-inch tablet? Very likely. A 10-inch tablet is usually quite light; using a 2 Nm hinge will make it very difficult to open, possibly requiring two hands. For such small devices, it is recommended to test a 1.2 Nm sample first.

Q3: Is it normal for the hinge to make a squeaking noise? Absolutely not. Noise means internal metal is experiencing dry friction, indicating the grease has failed or dried out. This will lead to rapid product wear and must be returned.

Q4: Why perform a 96-hour Salt Spray Test? For medical equipment (frequent contact with disinfectants) and outdoor equipment, rust prevention is crucial. While 48 hours is usually sufficient for ordinary office use, 96 hours represents a higher standard of stainless steel material.

Q5: How to choose between Dual Shaft and Single Shaft designs in the 2 Nm specification? If your screen only needs to open and close (like a laptop), choose Single Shaft; it is more stable and cheaper. Only choose Dual Shaft if you need the screen to flip 360 degrees.

Recommended Text:

Working on a Handheld Companion Device?

Many industrial projects also include a portable remote or a 7-inch tablet controller. For these lightweight devices (under 600g), a 2 Nm hinge will be too stiff for users to operate.

Discover the correct specification for portable gears in our dedicated analysis: 👉 [0.5 Nm Torque Hinges: Engineering Principles, Failure Modes, and Application Guidelines]