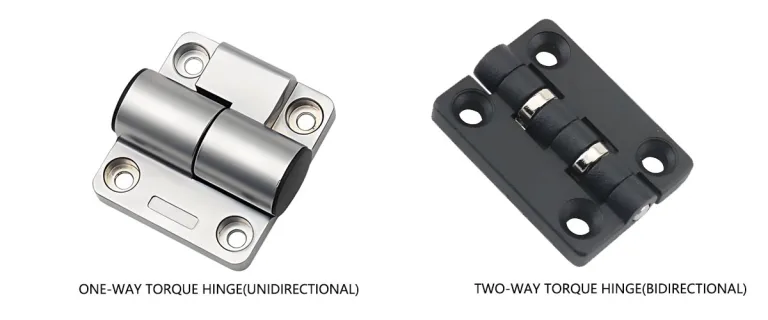

Beyond Golden Samples: 3 Advanced QC Protocols for Custom Hinge Procurement

A simple hinge failure in a medical device or EV charger can lead to disastrous recalls, yet many companies still rely on ‘Golden Samples’ to approve suppliers. This approach is flawed because a perfect sample does not guarantee a stable production process. To prevent inconsistent quality, procurement must go beyond simple measurements. This article outlines three key QC standards—Statistical Consistency, Durability, and Environmental Testing—to help you filter out risky suppliers before mass production begins

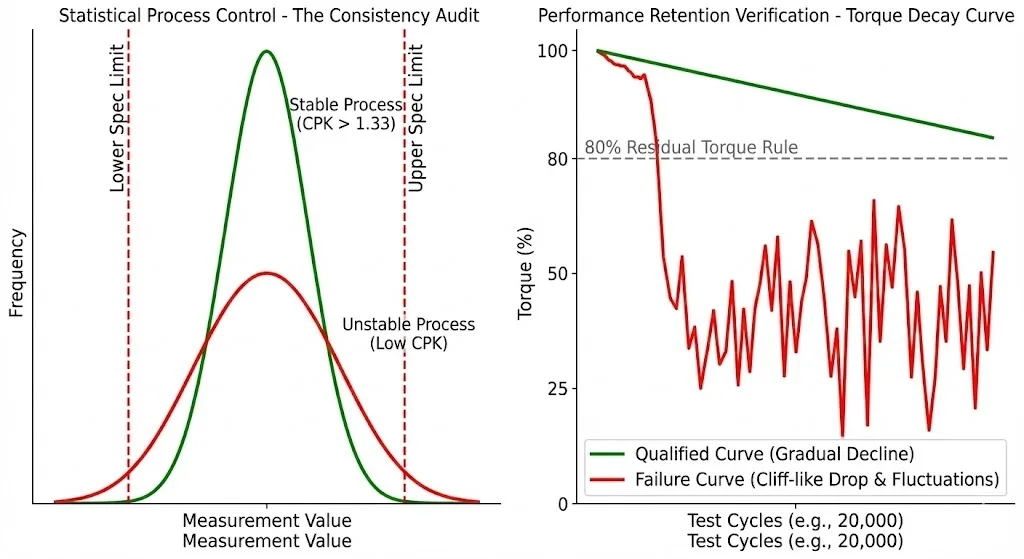

Statistical Process Control – The Consistency Audit

In industrial applications, unstable batch quality is more destructive than simply low performance. Standard inspections often accept any product within a ±20% tolerance range. However, in high-end applications, if batch variance is excessive—even if all units are within tolerance—it indicates an unstable manufacturing process.

Implement CPK (Process Capability Index) Requirements

Procurement teams should reject inspection reports that only contain “Pass/Fail” judgments. Suppliers must be required to provide CPK reports for critical torque parameters.

- Execution Standard: A qualified supplier must demonstrate a CPK value greater than 1.33.

- Data Significance: CPK > 1.33 proves that the production process is under statistical control, meaning product consistency stems from process capability rather than luck or sorting.

- Actionable Advice: Write CPK requirements directly into the technical annex of the procurement contract.

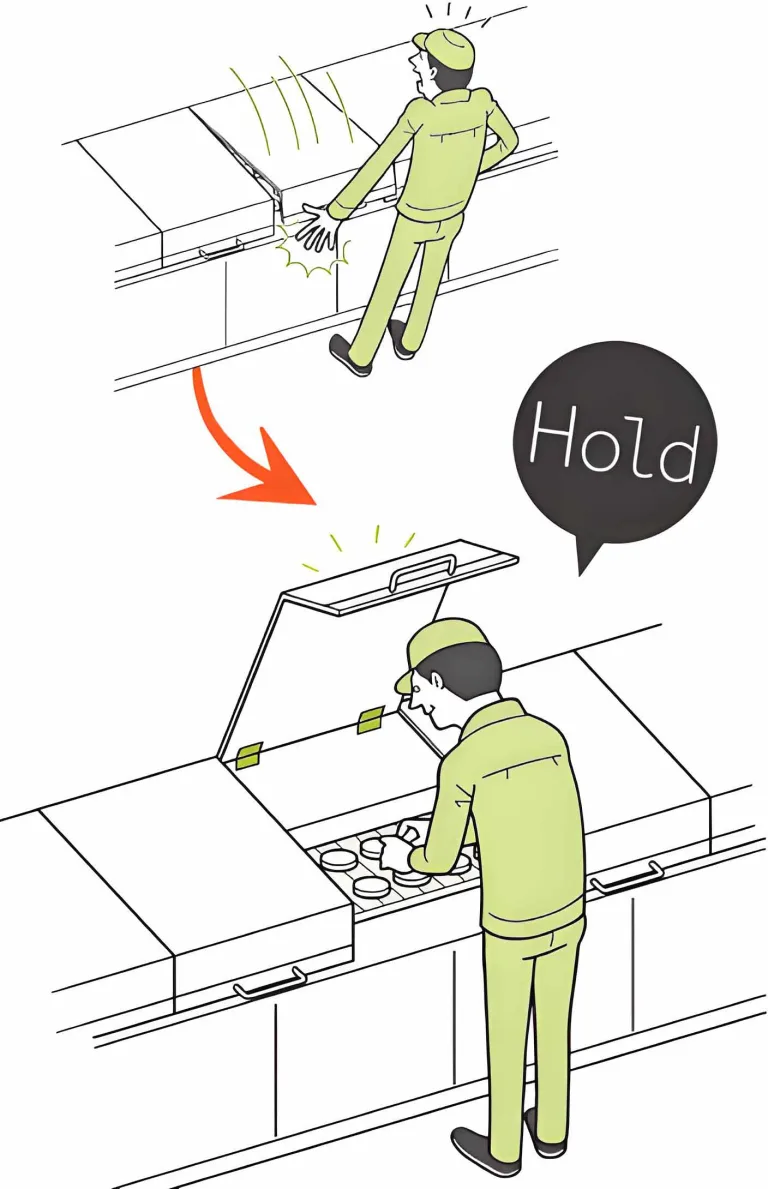

Haptic Consistency Check (Static vs. Dynamic Ratio)

Torque hinges must not only hold a position but also provide a premium operational feel. It is essential to measure the difference between “Breakaway Torque” (start) and “Running Torque” (move).

- Risk Indicator: If the Breakaway Torque is more than 30% higher than the Running Torque, a “stiction” effect occurs. Users will feel a noticeable jerkiness during operation.

- Root Cause: High ratio differences usually indicate improper control of internal friction materials or failed lubrication management.

- Acceptance Standard: For premium custom hinges, the difference between static and dynamic torque should be controlled between 10% and 15%.

Stratified Sampling Strategy

Specific gravity of grease and tool wear can lead to quality stratification within the same batch.

- Sampling Method: Reject sampling solely from the top layer of the shipping box. A random sampling protocol must be implemented to draw samples from the bottom, middle, and top of the shipment.

- Objective: To detect inconsistencies caused by grease separation during transport or die wear at the end of the assembly line.

Performance Retention Verification – The Life Cycle Stress Test

Cycle counting (e.g., 20,000 cycles) is meaningless in isolation. If a hinge survives structurally but loses 50% of its torque, it has functionally failed. The standard for “durability” must be redefined.

The 80% Residual Torque Rule

Acceptance standards must be established based on performance, not just structure.

- Reference Standard: ASTM F1578 (Standard Practice for Contact Closure Cycling of a Notebook Computer Hinge) provides a reference framework for testing methods.

- Execution Standard: After completing the rated cycle test (e.g., 20,000 cycles), the Residual Torque must remain above 80% of the initial value.

- Business Value: This metric effectively filters out suppliers using inferior friction materials or unstable greases, as these low-quality materials degrade rapidly under heat and friction.

Torque Decay Curve Analysis

Require suppliers to provide data points throughout the testing process, not just the final result.

- Qualified Curve: Shows a linear, gradual downward trend.

- Failure Curve: Shows a cliff-like drop early in the test or exhibits violent fluctuations.

- Decision Basis: Sudden torque drops indicate catastrophic wear of the internal structure or grease failure.

Destructive Teardown Analysis

Samples must be disassembled and inspected after testing.

- Inspection Focus: Observe whether there is excessive black metal powder inside.

- Failure Mode: Excessive metal powder is direct evidence of abnormal wear, usually caused by improper heat treatment or incorrect metal material pairing.

Functional Environmental Validation – The Corrosion Trap

Standard salt spray tests often focus only on surface rust of the housing. However, the critical failure mode for torque hinges is internal seizure caused by corrosion of the internal shaft. A passing appearance does not equal a passing function.

Post-Salt Spray Functional Test

Do not clean samples or perform only visual inspections immediately after the salt spray test (referencing ASTM B117 standards).

- Mandatory Step: Immediately measure dynamic torque after exposure to the salt spray environment (24, 48, or 96 hours).

- Acceptance Standard: The torque variation rate after the salt spray test must be controlled within ±20% of the pre-test value.

- Data Interpretation:

- Significant Torque Spike: Indicates internal corrosive adhesion or seizure.

- Significant Torque Drop: Indicates compromised structural integrity.

Invisible Failure: Grease Demulsification Resistance

Inferior lubricating greases will emulsify in salt spray environments, leading to a loss of lubrication function.

- Inspection Method: Compare operational smoothness before and after the test.

- Risk: Emulsified grease leads to drastic changes in the friction coefficient, destroying the user experience.

Temperature-Viscosity Stability Verification

Validate the performance of damping grease across the entire operating temperature range (e.g., -20°C to +60°C).

- Low-Temperature Risk: Inferior mineral oil-based greases will harden in cold environments.

- Consequence: This causes a surge in breakaway torque; the resulting stress can cause plastic housings to crack.

- Requirement: Suppliers must provide a report on the torque variation curve across the full temperature range.

Implementation: Integrating QC into the Supply Chain

To ensure the effective execution of the above protocols, Standard Operating Procedures (SOPs) must be established.

Adopt International Sampling Standards

Adopt objective batch acceptance standards to avoid subjective judgment.

- Execution Standard: ISO 2859-1 or ANSI/ASQ Z1.4.

- Defect Classification:

- Critical Defects: Functional failure, Acceptance Quality Limit (AQL) is 0.

- Major Defects: Dimensions or torque out of specification, recommended AQL 2.5.

Supplier Laboratory Capability Assessment

During the supplier audit phase, evaluate the hardware capabilities of their internal laboratory. A qualified custom hinge partner must possess the following in-house equipment:

- Digital torque testers capable of generating data curves.

- Salt spray test chambers compliant with ASTM B117 standards.

- Programmable life cycle test rigs.

Conclusion

Effective procurement strategies for custom torque hinges must go beyond basic dimensional checks. By enforcing Statistical Consistency (CPK), defining Residual Torque limits, and validating Environmental Functionality, enterprises can significantly reduce Total Cost of Ownership (TCO). Quality assurance is not merely an expense; it is a strategic line of defense preventing supply chain disruption and maintaining brand reputation.

FAQ

Q: Will enforcing these strict QC standards increase the unit price?

A: Likely yes, but marginally. However, compared to the cost of a halted assembly line or a field recall, the “insurance premium” of validation is negligible. It significantly reduces the Total Cost of Ownership (TCO).

Q: What if a supplier refuses to provide CPK data or torque curves?

A: Treat this as a major red flag. A refusal often indicates a lack of process confidence or capability. For critical applications (medical/EV), such suppliers should be disqualified immediately during the sourcing phase.

Q: Are these protocols necessary for standard off-the-shelf hinges?

A: Not necessarily. These protocols are specifically designed for custom torque hinges in critical applications. For non-critical components (like standard cabinet hinges), generic ISO sampling is usually sufficient.