360-Degree Friction Hinges: An Engineering Guide for Electronics and Kiosks

In modern hardware design projects, a clear trend has emerged: user demands for device flexibility have surpassed the limits of single-function capability. Whether for a doctor in a medical environment or an operator on a factory floor, equipment is required to adapt to complex physical environments.

Simple open-and-close connections are no longer sufficient. As an industry consultant focused on mechanical structures, I believe the 360-Degree Friction Hinge (Constant Torque Hinge) is currently the most effective solution for human-machine interaction flexibility. It is not just a connector; it is a core component that allows an object to hold its position at any point within a 0 to 360-degree range.

In this article, I will skip basic theory and directly analyze how this component creates value in three core sectors—portable devices, professional monitors, and self-service terminals—and provide selection advice based on specific technical standards.

Electronic Devices and Convertible Laptops

In the consumer electronics sector, the evolution of laptops into “Convertible Laptops” is the primary driver of hinge technology development.

Structural Support for Four Modes

360-degree hinges enable devices to support four distinct forms: Laptop Mode, Tablet Mode, Tent Mode, and Display Mode.

- The Technical Challenge: The greatest difficulty lies in “Tent Mode.” In this state, the device relies solely on the rigidity of the hinge to stand. If the torque is insufficient, the device will slide flat.

- The Solution: We determine the minimum holding torque by calculating the moment arm of the screen’s center of gravity. Typically, for a 13-inch screen, each hinge must provide at least 4.5 kgf-cm of torque to ensure the device does not collapse during touch operations.

Solving “Screen Bounce”

When users interact with a touchscreen, any wobbling of the screen severely degrades the user experience.

- My Recommendation: Increase the rigidity of the hinge rather than simply increasing friction. Using high-strength alloy steel (such as SUS420J2 or 17-4PH) to manufacture the shaft can reduce material deformation.

- Testing Standard: We usually reference touch panel pressure testing, requiring that the screen displacement angle remains less than 1 degree when subjected to a finger tap force of approximately 200g.

Balancing Thinness with Torque Density

To accommodate ultra-thin chassis (thickness less than 10mm), manufacturers must increase torque density. I recommend using Metal Injection Molding (MIM) technology to manufacture internal components. This allows for more complex geometric shapes and higher strength within a smaller volume.

Professional Monitors and Medical Mounts

In the professional sector, the demand shifts from “portability” to “stability” and “load-bearing capacity.”

Ergonomics and VESA Standards

Professional monitors are often heavy. Here, we must reference the VESA FDMI (Flat Display Mounting Interface) standard.

- Pivot Rotation: Programmers and radiologists often need to rotate screens 90 degrees to portrait mode. 360-degree friction hinges provide damping at the connection point, preventing the screen from rotating automatically under gravity.

- Application Case: In a dental monitor arm project, we used a friction hinge with a rated torque of 50 kgf-cm. This ensured that after the doctor pulled the screen with one hand, the screen remained stable in any position.

Eliminating Gravity “Drifting”

“Drifting” is a major failure in monitor stand design. This occurs when a screen is set to a position but slowly lowers over an hour due to gravity.

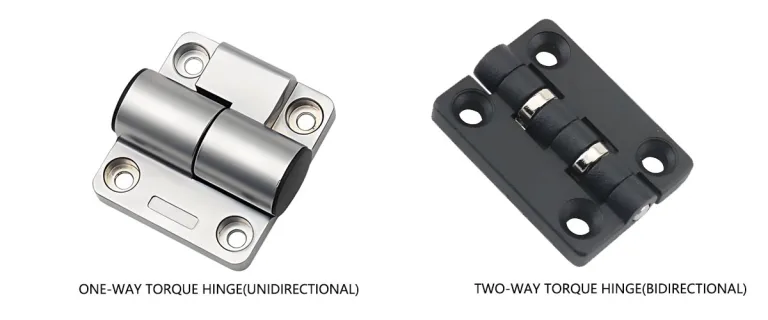

- Technical Countermeasure: I recommend using hinges with an “Asymmetric Torque” design. This means the opening torque (upward) is lower than the closing torque (downward). Users can lift the screen easily, while gravity faces greater resistance when pulling the screen down.

Specific Requirements for Medical Environments

For operating room equipment, compliance with IEC 60601-1 (Medical electrical equipment safety) is mandatory.

- Cleanliness: The damping grease inside the hinge must not leak. We recommend using a fully enclosed design and specifying medical-grade lubricants that are heat-resistant and will not contaminate sterile environments.

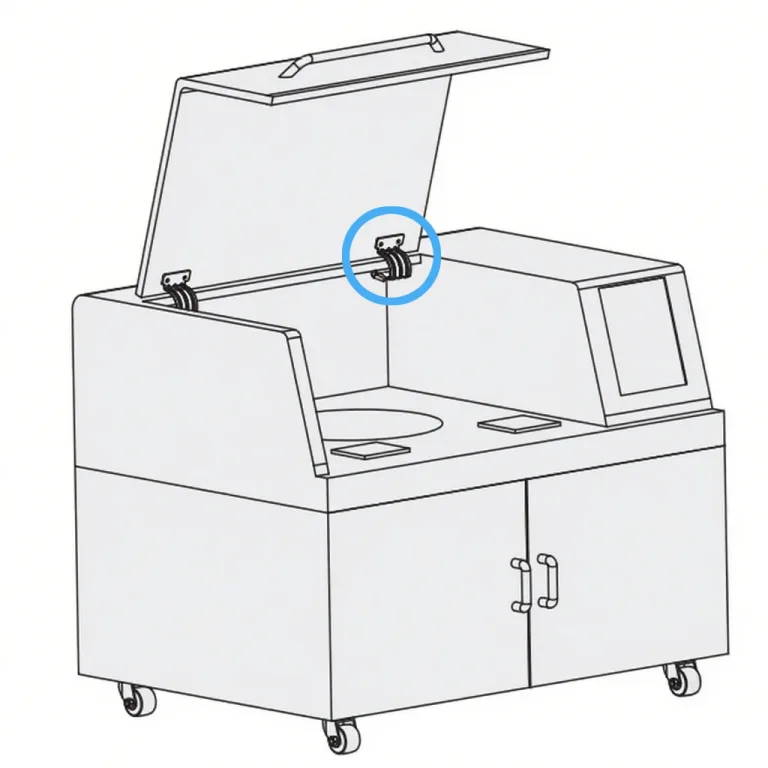

Self-Service Terminals and Kiosks

Self-service terminals (such as Bank VTMs and airport check-in counters) demand “extreme durability” from hinges.

Durability for High-Frequency Use

Unlike personal devices, a restaurant ordering kiosk may be adjusted hundreds of times a day.

- Data Support: During selection, we require passing a life cycle test of over 50,000 cycles.

- Material Selection: Hardened steel or nitrided surfaces must be used to resist wear.

Accessibility and ADA Compliance

In the US market, self-service terminals must comply with the ADA (Americans with Disabilities Act).

- Operational Range: The equipment must be adjustable to accommodate both standing users and wheelchair users (eye level approximately 48 inches).

- Practical Advice: Use 360-degree or large-angle friction hinges to allow the screen to flip down to 15 degrees or lower, ensuring wheelchair users can easily touch the screen.

Adaptability to Outdoor Environments

Outdoor Kiosks face drastic temperature changes.

- Environmental Testing: Manufacturers must conduct high and low-temperature testing based on MIL-STD-810G (-20°C to +60°C).

- Problem Solving: Standard damping grease becomes viscous at low temperatures (causing the hinge to seize) and thin at high temperatures (causing torque loss). I strongly recommend specifying wide-temperature range synthetic damping grease.

Why Do Manufacturers Prefer 360-Degree Friction Hinges?

As a consultant, I am often asked: “Why not use a simple locking nut?” Here is my business analysis:

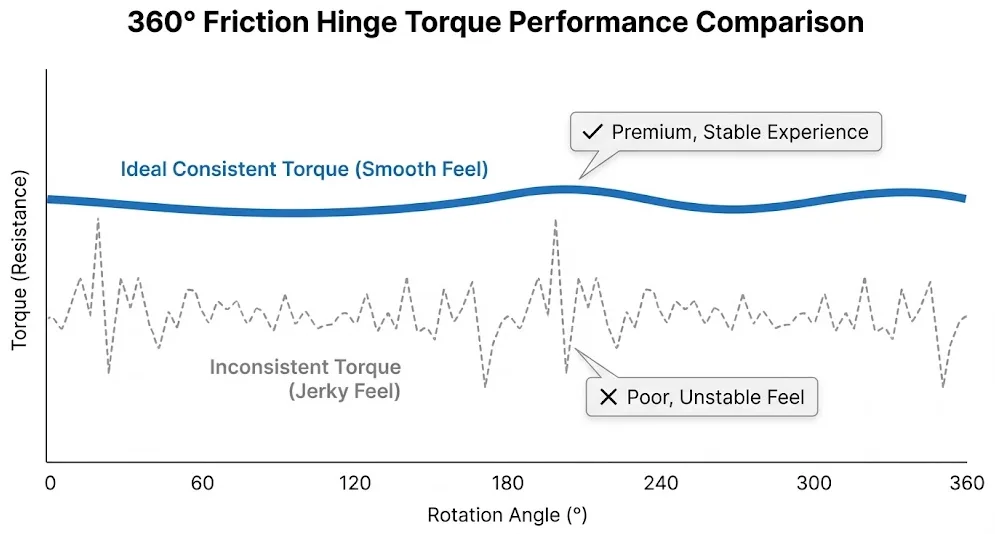

Premium Feel:The smooth, continuous damping sensation is perceived by users as a direct indicator of “high precision” and “quality.” This tactile feedback directly supports a higher market price point.

Simplified BOM and Structure:Friction hinges possess an inherent “free-stop” function. This means you can eliminate mechanical latches, gas springs, or support rods. Reducing the part count lowers assembly costs and minimizes failure points.

Supply Chain Maturity: This technology is now highly standardized. Manufacturers can directly procure off-the-shelf modules that comply with RoHS (Restriction of Hazardous Substances) and REACH standards, significantly shortening the R&D cycle.

Selection Key Indicators and Testing Standards Checklist

Before you decide to purchase, ensure your engineering team executes the following checklist. These indicators directly determine the final user experience:

Key Performance Indicators (KPIs)

- Torque Value: Determines the holding force required. You must calculate the Peak Torque (at the position of maximum stress, usually horizontal). Use this formula:T = (L / 2) × W × 1.2

T: Target Torque (kgf-cm)

L: Screen Height (cm)

W: Screen Weight (kg)

1.2: Includes a 20% safety margin.

- Cycle Life: According to ASTM E2444 (fatigue testing reference), industrial standards typically require that torque decay does not exceed 20% after 20,000 cycles.

- Springback: Quality hinges must achieve “zero springback” or extremely low springback. This means when the user stops applying force, the screen must stop immediately without oscillating.

- Static vs. Dynamic Torque Ratio: The ideal ratio should be close to 1:1 to ensure a smooth start without a “stuck” feeling.

Environmental and Material Testing

- Salt Spray Test: Outdoor equipment must pass the ASTM B117 standard 96-hour neutral salt spray test to ensure no corrosion.

- Hardness Test: The shaft core hardness should reach HRC 40-45 (Rockwell Hardness) to ensure wear resistance.

Conclusion

The 360-degree friction hinge is not just a rotating part; it is a critical technology for achieving ergonomics, durability, and a premium feel in modern electronic hardware. By providing precise position control and optimized space utilization, it solves engineering challenges ranging from convertible laptops to medical monitors.

Looking ahead, as flexible screens and dual-screen devices become widespread, we will see hinge solutions that are smaller and possess higher torque density. If you are developing next-generation hardware, incorporating international standard friction hinges into your design early is a key step toward product success.

FAQ

Q: What is a 360-degree friction hinge?

A: It is a mechanical device that allows an object to rotate 360 degrees and hold its position statically at any point in the travel range using internal friction, without the need for extra latches.

Q: What is the industrial life standard for friction hinges?

A: High-quality industrial-grade hinges typically guarantee a failure-free operation cycle of over 20,000 to 30,000 times, with torque decay controlled within 20%.

Q: How do I prevent a monitor from drooping or drifting during use?

A: You must calculate the torque generated by the screen’s gravity and select a hinge with a rated torque higher than that value. For heavy equipment, I recommend using an asymmetric torque design that increases resistance in the closing direction.

Q: What should I consider when selecting hinges for outdoor equipment?

A: Focus on two main points: First, corrosion resistance compliant with ASTM B117 (salt spray test); second, the stability of the damping grease under extreme temperatures (reference MIL-STD-810 standards).