Adjustable Torque Hinges: Five Key Industrial Uses

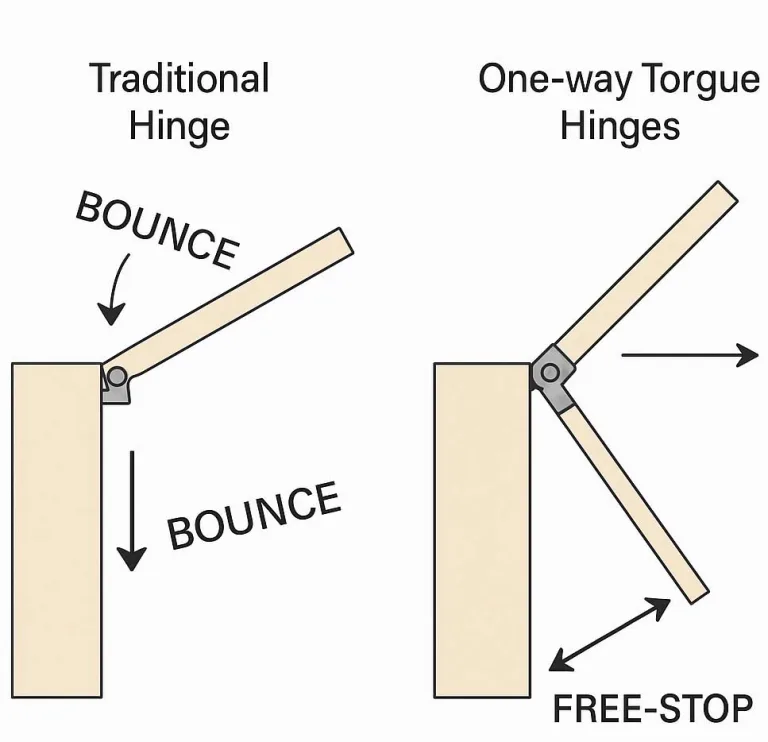

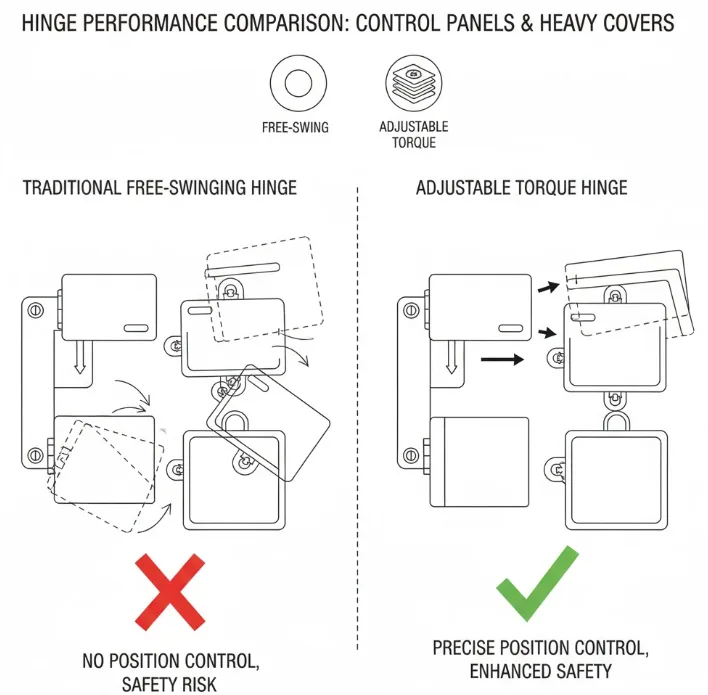

In modern industrial equipment design, component connections and motion control form the foundation for ensuring functionality, safety, and user experience. Traditional free-swinging hinges provide only basic rotational axes, failing to meet the demands of many complex devices. For instance, control panels must remain at specific angles for visibility, or heavy maintenance covers require safe opening and secure positioning—not sudden gravitational drops.

See more on Position Control

Addressing these challenges, the Adjustable Torque Hinge emerged. This precision-engineered component integrates an internal friction mechanism that delivers consistent rotational resistance. Its “adjustable” feature allows users or installers to precisely set the torque level via methods like adjusting screws.

The core functions are achieving “Free Stop” and “Position Control.” This article will delve into five specific application scenarios of adjustable torque hinges in industrial equipment, analyze their ability to solve engineering challenges, and provide relevant international standards for reference.

Adjustable Torque Hinge: Working Principle and Core Advantages

Clear Definition

An adjustable torque hinge, also known as an adjustable friction hinge or positioning hinge, is a hinge with an integrated internal friction mechanism. Its friction force remains relatively stable throughout the entire rotation range. By adjusting the preload of internal friction components, the output torque can be altered to match panels of varying weights or sizes.

Basic Working Principle

Torque Source

Common internal structures include:

- Disk Structure: Multiple fixed friction plates interleaved with a movable friction plate

- Curl Structure: Rolled spring steel strip tightly wrapped around a central shaft

- Pipe Structure: Shaft with a high-pressure-fit plastic tube or sintered bushing

All designs generate resistance through controllable preloaded friction.

Motion Process

- When applied external torque exceeds internal frictional torque, the hinge rotates.

- Upon removal of external force, frictional torque balances gravity or other torques, stabilizing the panel.

- High-quality industrial hinges minimize springback and backlash to ensure positioning accuracy and smooth operation.

Adjustment Mechanism

Modify the normal force N on friction elements via hex screws or similar devices.

Friction force formula: F = μN, where μ is the coefficient of friction, N is the normal force. Increasing N enhances torque output.

Note: Friction force may vary by ±5–10% in actual use; torque values require a safety margin.

Advantages over Traditional Hinges and Gas Springs

| Feature | Adjustable Torque Hinge | Gas Spring |

|---|---|---|

| Position Control | 0°–180° Any angle | Limited to fully open position |

| Space Occupancy | Low | High |

| Maintenance Requirements | Minimal | Moderate (prone to leakage) |

| Cycle Life | High (30,000+ cycles) | Moderate |

| Environmental Tolerance | Excellent (oil, dust, high temperature resistant) | Poor (seals prone to failure) |

Core Advantages:

- Precise Position Control

- Enhanced Operational Safety: Prevents sudden lid drop or spring-back

- Simplified Structure & Space Savings

- Long Service Life & Maintainability: High reliability friction mechanism, independent of airtightness

Cycle Life & Torque Performance Reference:

- BHMA A156.17 Cycle Life: Grade 1: 1,000,000 cycles; Grade 2: 500,000 cycles; Grade 3: 250,000 cycles

- IEC 60068-2 Torque Life: <15% torque decay after 20,000 cycles

- ASTM F1574 Torque-Angle: Starting torque ≤ 1.2 × operating torque.See authoritative standards & verification

Five Typical Application Scenarios

Scenario 1: Protective Covers and Access Doors for Heavy Machinery

Challenge: Heavy panels are difficult to operate with one hand, and gas springs are prone to failure.

Solution: Utilize high-torque adjustable hinges to precisely balance panel weight with torque, enabling “zero-gravity” operation.

Advantages:

- Frees both hands, enhancing maintenance efficiency

- Improves safety by allowing panels to remain at any angle

- High mechanical reliability, unaffected by oil contamination or high temperatures

Scenario 2: Industrial Control Cabinets and Electrical Enclosure Doors

Challenge: Confined spaces and high-frequency operation cause doors to auto-close or vibrate.

Solution: Employ medium-light torque hinges for free-angle positioning.

Benefits:

- Optimized workflow

- Prevents accidental closure

- Minimizes micro-motion wear while maintaining IP/NEMA ratings

Scenario 3: Medical and Laboratory Equipment Displays and Flip Covers

Challenge: Precision positioning, high smoothness, and easy-to-clean requirements.

Solution: High-precision torque hinges provide uniform damping and minimal rebound.

Advantages:

- Precise positioning for enhanced operational reliability

- Smooth and quiet operation reduces noise

- Simplified design facilitates sterilization

Scenario 4: HMI Displays and Adjustable Control Panels

Challenge: Multi-user adaptability with high stability requirements for touch operation.

Solution: Zero-backlash torque hinge with adjustable torque for balanced stability and operability.

Advantages:

- Customizable angle adjustment

- Enhanced operational precision

- Flexible adaptation to equipment upgrades

Scenario 5: Specialized Vehicles and Mobile Equipment

Challenge: High-intensity vibration and impact causing component loosening or cracking.

Solution: High-torque hinge acting as passive vibration damping to absorb micro-vibrations.

Advantages:

- Vibration resistance and noise reduction

- Ensures safety by preventing unintended panel movement

- Enhanced durability and extended service life

Key Selection Considerations

Torque Calculation

- m = Cover plate weight (kg)

- L = Horizontal distance from center of gravity to rotation axis (m)

- Add 20% safety margin to account for tolerances and wear

Material and Environment

| Material | ISO 15510 Reference | Salt Spray Test ASTM B117 | Corrosion Resistance |

|---|---|---|---|

| Zinc Alloy Zamak 3/5 | 96–200h | General | |

| 304 Stainless Steel | X5CrNi18-10 | 200–500h | Good |

| 316L Stainless Steel | X2CrNiMo17-12-2 | >500h | Excellent |

Note: 316L is optimal in highly corrosive environments, but 304 can be used in low-corrosion environments with surface treatment.

Cycle Life and Adjustment Range

- Reference ANSI/BHMA A156.17, QB/T 4595.1-2013, or QB/T 4063-2010

- Ensure calculated torque falls within 50–70% of the hinge’s adjustment range to allow for future adjustments

Summary

Adjustable torque hinges transcend traditional fasteners by integrating safety, ergonomics, reliability, and vibration management. Five key application scenarios demonstrate their capability to solve complex engineering challenges in industrial design. As industrial automation advances, high-performance torque hinges will become increasingly prevalent, serving as a critical indicator of equipment design sophistication.