Carbon Steel vs. Stainless Steel Hinges: A Guide to Material Selection & TCO

Engineering Overview

Hinges may be small, but they have an outsized impact on enclosure uptime and user experience—smooth operation, long-term durability, and maintenance frequency, especially in outdoor, humid, or salt-spray environments. This document presents a clear Carbon steel vs stainless steel hinges comparison, highlighting the practical differences in strength, corrosion resistance, surface treatments, and total cost of ownership (TCO). The analysis is grounded in international engineering standards and supported by laboratory test data to help engineers and buyers optimize their industrial hinge material selection.

Material Definition in Industrial Environments

Industrial hinge applications typically involve harsh physical and chemical conditions. Major application areas include:

- Heavy Machinery: Requires tolerance for high loads and vibration.

- Outdoor Cabinets: Exposed to UV radiation, rain, and temperature fluctuations.

- HVAC (Heating, Ventilation, and Air Conditioning): Subject to long-term high humidity environments.

Engineers must prioritize the evaluation of the following core physical metrics during selection:

- Yield Strength: The maximum stress before permanent deformation occurs.

- Tensile Strength: The maximum load the material can withstand before fracturing.

- Corrosion Resistance Class: The oxidation resistance capability derived from standard environmental testing.

Impact on Total Cost of Ownership

Incorrect material selection leads to irreversible hardware failure. This significantly increases the Total Cost of Ownership (TCO) of the equipment. Major failure modes include:

- Structural Fracture: Leads to door detachment, triggering safety accidents.

- Corrosion Seizure: Prevents equipment access, increasing maintenance labor hours.

- Seal Failure: Hinge corrosion compromises door compression, leading to failure of protection ratings (e.g., IP65).

Technical Characteristics of Carbon Steel Hinges

Carbon steel (typically low carbon steel, such as Q235 or AISI 1020) is the most basic material option for industrial hinges. It achieves mechanical properties through the alloying of iron and carbon.

Basic Physical Properties of Carbon Steel

Mechanical Strength and Load Capacity

Carbon steel exhibits excellent structural strength. According to ASTM A1008 (Standard for Cold-Rolled Steel Sheet) or ASTM A36 (Standard for Structural Steel), industrial-grade carbon steel possesses the following typical mechanical properties:

- Yield Strength: Approximately 250 MPa to 350 MPa.

- Tensile Strength: Approximately 400 MPa to 550 MPa.

- Elastic Modulus: Approximately 200 GPa.

In high-load applications, carbon steel hinges can withstand significant radial and axial loads. Its hardness characteristics ensure stable performance in heavy cabinet door applications (single door weight > 50kg). Compared to aluminum alloys of the same volume, carbon steel is less prone to fatigue fracture.

Weldability and Machinability

Low carbon steel possesses excellent weldability. A carbon content below 0.25% ensures the weld zone is resistant to cracking. In industrial manufacturing, carbon steel is suitable for the following processing techniques:

- Weld-on Hinges: Can be welded directly to the cabinet frame without drilling holes.

- Cold Heading and Stamping: Easy to process into complex geometric shapes with low tool wear rates.

Corrosion Risk Management for Carbon Steel

Untreated carbon steel lacks inherent hinge corrosion resistance. In standard atmospheric environments, iron rapidly reacts with oxygen to form iron oxide (red rust).

Oxidation Characteristics

- The oxide layer of carbon steel is loose and porous.

- The oxide layer cannot prevent oxygen from further penetrating the substrate.

- Once corrosion begins, the effective cross-sectional area of the material decreases, leading to reduced load-bearing capacity.

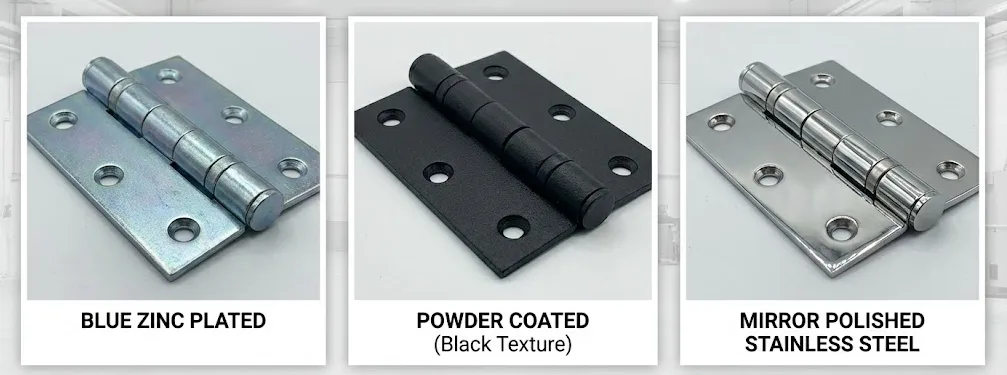

Necessary Surface Protection

According to DIN EN 1670 (Building hardware – Corrosion resistance requirements), untreated carbon steel is classified as Grade 0 (No defined corrosion resistance). For use in industrial environments, carbon steel hinges must undergo surface treatment (such as zinc plating, E-coating, or powder coating).

- Indoor Environments: Must achieve DIN EN 1670 Grade 2 or higher.

- Outdoor Environments: Must achieve DIN EN 1670 Grade 4 or higher.

Material Science of Stainless Steel Hinges

Stainless steel is not a single material, but a general term for a class of corrosion-resistant alloy steels. In the industrial hardware sector, Austenitic Stainless Steel is the most widely used. Its core characteristics stem from its Chromium content (typically greater than 10.5%).

Austenitic Grades: 304 vs 316 Stainless Steel Hinges

Engineers must select between AISI 304 or AISI 316 grades based on specific operating conditions.

Application Scenarios for AISI 304

AISI 304 (corresponding to EN 1.4301) is the general-purpose “18/8” stainless steel (containing 18% Chromium, 8% Nickel).

- Performance Characteristics: Excellent corrosion resistance in standard atmospheric environments. Good formability and weldability.

- Limitations: Sensitive to Chloride ions. In marine or high-salinity environments, it is prone to Pitting Corrosion.

- Typical Applications: Indoor cabinets, non-contact zones of food processing equipment, general outdoor facilities.

Marine and Chemical Resistance of AISI 316

AISI 316 (corresponding to EN 1.4401) adds 2% to 3% Molybdenum (Mo) to the 304 base.

- Chemical Mechanism: Molybdenum significantly enhances resistance to chlorides.

- Performance Data: In salt spray tests, the endurance time of 316 is typically more than double that of 304.

- Typical Applications: Offshore engineering, chemical plants, medical equipment, outdoor facilities within 5 km of the coast.

Self-Healing Mechanism

The corrosion resistance of stainless steel does not come from a coating, but from a Passive Film on its surface.

- Formation Principle: Chromium reacts with oxygen to generate an extremely thin (approx. 1-5 nm) and dense chromium oxide layer.

- Self-Healing: When the hinge surface suffers mechanical scratches, exposed chromium in the substrate rapidly reacts with oxygen in the air to regenerate the passive film.

- Contrast with Carbon Steel: Once a carbon steel coating is breached, the substrate begins irreversible rusting; stainless steel possesses chemical self-healing capabilities.

Core Performance Comparative Analysis

This section compares carbon steel vs stainless steel hinge durability and key performance indicators based on laboratory test standards.

Mechanical Life and Durability Testing

Cycle testing is performed according to EN 1935 (Building hardware – Single-axis hinges) or ANSI/BHMA A156.1.

- Carbon Steel Performance:

- Higher hardness, good wear resistance.

- Under well-lubricated conditions, it can withstand high-frequency cycling (> 200,000 cycles).

- Stainless Steel Performance:

- Material texture is relatively softer and exhibits stickiness.

- Risk Point: Stainless steel pins and bushings of the same material are prone to Galling or cold welding.

- Engineering Countermeasure: For high-frequency stainless steel hinges, it is recommended to pair with engineering plastic (e.g., POM) bushings or lubricated bearings to isolate metal contact.

Corrosion Resistance Testing in Extreme Environments

Neutral Salt Spray (NSS) testing is performed according to ASTM B117 or ISO 9227. The following represents typical test data (time to red rust appearance):

| Material Type | Surface Treatment | Salt Spray Hours | Applicable Environment (ISO 9223) |

|---|---|---|---|

| Carbon Steel | Zinc Plated (Blue/White) | 24 – 96 Hours | C1 – C2 (Indoor/Dry) |

| Carbon Steel | Powder Coated | 200 – 500 Hours | C3 (General Outdoor) |

| Stainless Steel (AISI 304) | Vibration/Electropolished | > 500 Hours | C3 – C4 (Industrial/Humid) |

| Stainless Steel (AISI 316) | Vibration/Electropolished | > 1000 Hours | C5-M (Marine/High Corrosion) |

Shock and Vibration Resistance

Shock testing is performed according to IEC 60068-2-27.

- Carbon Steel: High yield strength, strong resistance to deformation. However, at extremely low temperatures (below -20°C), some low carbon steels may exhibit cold brittleness.

- Austenitic Stainless Steel: Possesses excellent Toughness. In cryogenic temperatures, it maintains high impact resistance and is not prone to brittle fracture.

Surface Treatment Engineering

The material itself determines the performance ceiling, while surface treatment determines performance stability.

Essential Protection Systems for Carbon Steel

Zinc Plating

This is the most economical protection method for carbon steel.

- Process Parameters: The plating thickness for industrial-grade hinges should be controlled at 8 – 12 micrometers (µm).

- Passivation: Passivation (blue-white or yellow chromate) must be performed after zinc plating to seal micro-pores in the zinc layer.

- Limitation: The zinc layer acts as a sacrificial anode. Once the zinc is depleted, the substrate will rust.

E-coating and Powder Coating

- E-coating: Provides a uniform primer layer with corrosion resistance superior to zinc plating. Suitable for protecting internal cavities of complex structures.

- Powder Coating: Provides a thicker polymer coating (60 – 80 micrometers). Primarily used outdoors, offering excellent UV resistance to prevent fading and chalking.

Surface Treatment for Stainless Steel

Although stainless steel has an inherent passive layer, appropriate treatment can further enhance performance.

Vibration Grinding and Mirror Polishing

- Physical Principle: The smoother the surface, the harder it is for corrosive media (water, salt, dust) to adhere.

- Mirror Polishing: Reduces surface roughness (Ra) to below 0.05 µm, significantly improving corrosion resistance in marine environments.

Electropolishing

This is an electrochemical process used to remove microscopic peaks on the surface.

- Advantage: Preferentially dissolves iron ions from the surface, enriching the chromium content.

- Application: Preferred for medical and food industries. This process not only prevents corrosion but also inhibits bacterial growth and facilitates cleaning.

Selection Decision Matrix

Engineers should formulate the final material solution based on IP Ratings and cost budget.

Material Recommendation Based on IP Ratings

- IP40 – IP54 (Indoor/Dry/Dust-protected):

- Recommended Material: Carbon Steel (Zinc Plated or Powder Coated).

- Reason: No liquid water intrusion in the environment; carbon steel offers high strength and low cost.

- IP65 – IP66 (Outdoor/Water Jet-protected):

- Recommended Material: AISI 304 Stainless Steel or High-Quality Powder Coated Carbon Steel.

- Reason: Must resist rain washout and condensation. According to IEC 60529, sealing is critical; stainless steel prevents seal failure caused by rust.

- NEMA 4X (High Corrosion/Washdown):

- Recommended Material: AISI 316 Stainless Steel.

- Reason: NEMA 250 Type 4X explicitly requires equipment enclosures and accessories to be corrosion-resistant. In food plant washdown or chemical environments, 316 is the only compliant choice.

Cost-Benefit Analysis

- Initial Acquisition Cost (CAPEX): Carbon steel hinges cost approximately 20% to 40% of stainless steel hinges.

- Long-term Maintenance Cost (OPEX):

- Carbon steel requires periodic inspection, repainting, or replacement in harsh environments, leading to high labor and downtime costs.

- Stainless steel typically achieves “Fit and Forget” status, with lifecycle maintenance costs approaching zero.

Conclusion: Based on this hinge TCO comparison, for outdoor or harsh environment equipment with an expected service life exceeding 5 years, Stainless Steel offers the lowest TCO despite the higher initial cost. For controlled indoor environments, Carbon Steel is a highly cost-effective engineering choice.

FAQ

Carbon steel hinges can be used outdoors. When is it acceptable?

It is acceptable when the environment is not highly corrosive and the design can reliably maintain coating integrity. In practice, “acceptable” usually requires high-quality powder coating (edge coverage matters), controlled installation damage, and a maintenance plan. If long service life is required with limited maintenance access, stainless steel typically reduces risk.

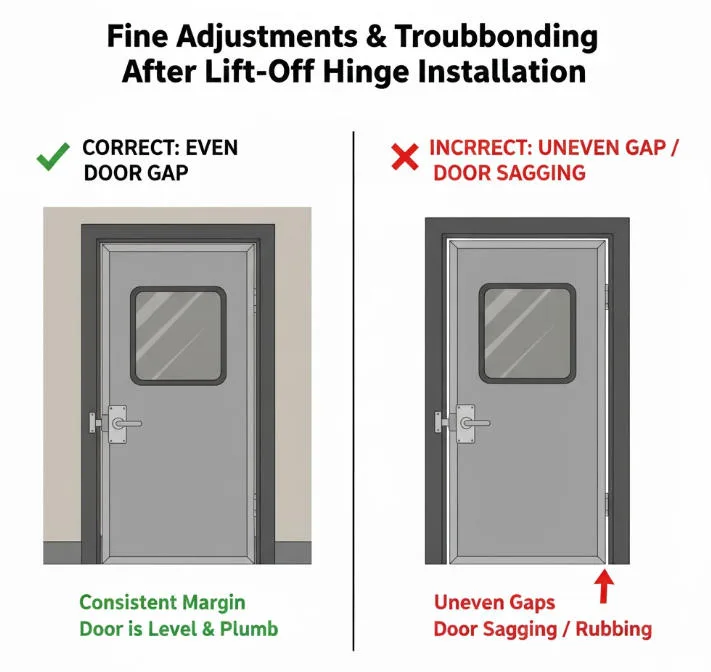

Why can hinge corrosion affect IP65 sealing?

Corrosion products can change hinge geometry and increase friction, which may compromise door compression and alignment. Once the sealing line loses stable compression, the enclosure can fail to maintain protection ratings (e.g., IP65).

304 vs 316: what is the simplest rule?

Use 304 for standard atmospheric exposure and general outdoor environments. Use 316 for chloride-bearing conditions (marine air, coastal zones, salt spray, certain chemicals), where pitting risk becomes a primary driver.

What is “galling” and how do I prevent it in stainless hinges?

Galling is adhesive wear that can lead to “cold welding” between similar stainless surfaces. Common countermeasures include using dissimilar materials at the interface (e.g., POM bushings), adding lubricated bearings, and ensuring proper lubrication and surface finish.

Is zinc plating enough for carbon steel hinges?

Zinc plating is cost-effective and commonly used, but it is sacrificial; once zinc is depleted, the substrate will rust. For more aggressive environments, E-coating and powder coating can provide more stable protection, especially for complex geometries and outdoor UV exposure.

What should I ask suppliers to provide?

Request coating thickness data (e.g., zinc 8–12 µm; powder 60–80 µm as referenced), surface treatment process notes, and corrosion test reports under relevant standards (e.g., ASTM B117 / ISO 9227), ideally on the same hinge geometry and finish you are buying.