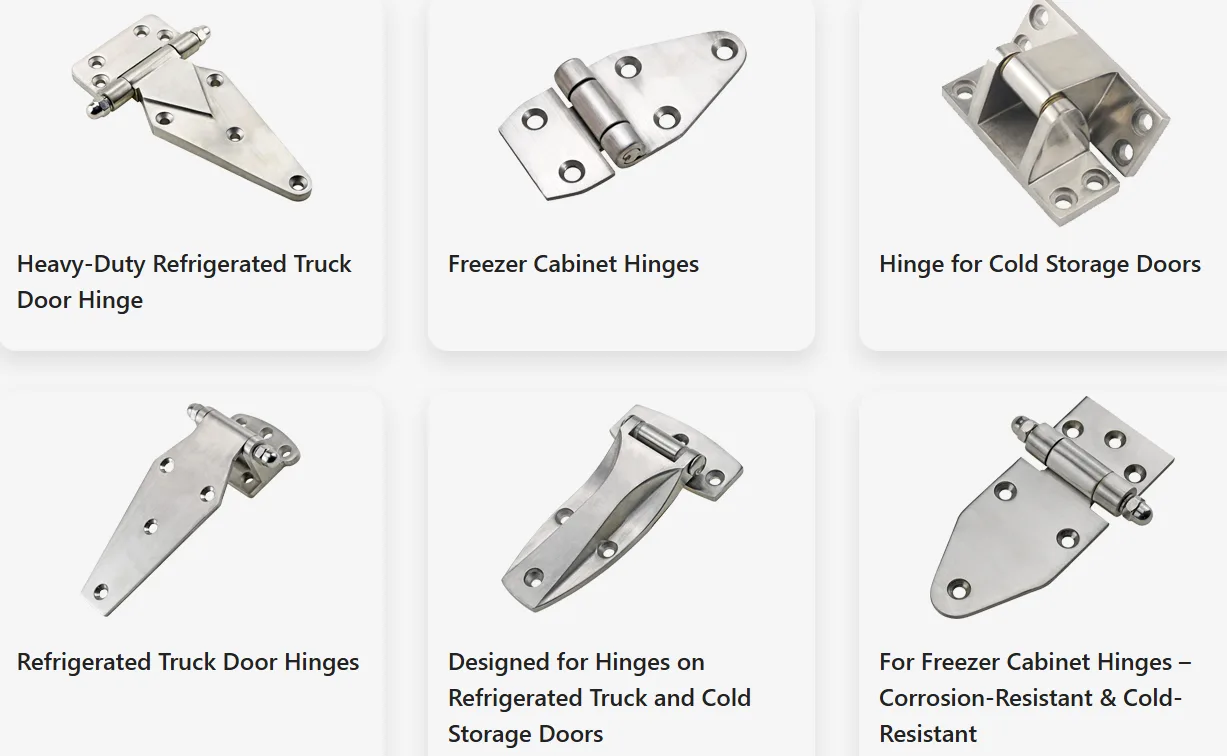

Durable Cold Storage Hinge Solutions for Beverage Warehouses

Various Cold Storage Hinges Displayed Together

Cold Storage Hinge are critical components of cold storage doors, essential for maintaining interior temperatures and reducing energy consumption.

This article addresses challenges in beverage cold storage—high humidity, frequent use, heavy door weight, and hygiene requirements—by outlining core hinge demands for durability and sealing. It provides systematic solutions through material selection (e.g., stainless steel), structural innovations (e.g., adjustable and self-closing designs), and precision manufacturing.

Full-cycle management from selection to installation and maintenance ensures cold storage operational efficiency and product quality.

Introduction

The rapid growth of the beverage industry drives increasing demand for modern cold chain storage.

Because beverages have high water content and stringent quality requirements, reliable cold storage facilities are crucial for extending shelf life and ensuring food safety.

As the primary thermal barrier, cold storage door performance directly impacts temperature control effectiveness and energy consumption. Under conditions of frequent opening/closing and low-temperature humidity, hinges must exhibit wear resistance and corrosion resistance while ensuring tight door-to-gasket contact to prevent cold air leakage.

This article explores hinge durability and sealing performance, proposing corresponding solutions.

Unique Challenges for Hinges in Beverage Storage Environments

Applications of Cold Storage Hinges

High Humidity and Condensation Erosion

| Issue | Cause | Effect | Solution / Material |

|---|---|---|---|

| High Humidity & Condensation Erosion | Extremely high humidity with alternating hot and cold air | Moisture infiltrates hinge gaps, accelerating metal corrosion | Use 316 stainless steel hinges to maintain integrity in humid environments |

| Frozen Water Accumulation | Low temperatures causing water to freeze | Hinges can jam, increasing resistance | 316 stainless steel hinges resist corrosion and maintain performance |

Rigorous Testing from High-Frequency Operation

| Issue | Cause | Effect | Solution / Material |

|---|---|---|---|

| High-Frequency Operation | Cold storage doors open/close hundreds of times daily | Hinges experience repeated stress, potential wear | Use heavy-duty hinges with sealed bearings for durability |

| Durability under Load | Frequent operation with heavy doors | Increased wear and risk of failure | High-strength materials and wear-resistant designs are essential |

Significant Loads from Heavy Door Panels

- Doors often weigh 100+ kilograms, supported by few hinges.

- Heavy-duty hinges prevent door sagging.

- Essentra: Reinforced designs resist deformation.

- Insufficient load-bearing causes sagging → seal failure → higher energy use.

Strict Hygiene and Cleaning Requirements

Cold storage requires exceptional hygiene. Hinges must:

- Eliminate sanitation blind spots

- Resist cleaning agent corrosion

- Use smooth surfaces to reduce dirt adhesion

Food-grade stainless steel minimizes gaps, meeting food safety standards.

Core Functionality Analysis: Durability and Sealing

Cold Storage Hinges Used on Cold Room Doors

Durability: The Foundation of Stable Operation

Defined as the ability to maintain performance under high loads & frequent use.

Includes: load-bearing, fatigue resistance, wear resistance, corrosion resistance.

- Heavy-duty designs minimize maintenance needs.

- Insufficient durability → repairs, downtime, safety hazards.

Sealing: The Key to Energy Efficiency

Sealing ensures precise door closure & gasket compression.

- Hinges prevent temperature fluctuations.

- High-quality hinges enable tight closure.

- Poor sealing = frequent cycling of refrigeration system → high energy use.

The Dialectical Relationship Between Durability and Sealing

- Contradiction: ruggedness vs. closing precision.

- Poor durability → door sagging → seal failure.

- Poor sealing → extra hinge stress → wear.

- Optimal solution: balance both durability and sealing under tough conditions.

Key Elements for Developing High-Performance Hinge Solutions

Application of Materials Science

| Material | Features | Advantages | Limitations |

|---|---|---|---|

| 304/316 Stainless Steel | High corrosion resistance, easy to clean | Meets hygiene standards, durable in humid environments | Higher cost compared to alloys or composites |

| High-Strength Zinc Alloy | Corrosion-resistant with plating | Cost-effective, good for moderate loads | Weaker than stainless steel under heavy loads |

| Engineering Composites (e.g., reinforced nylon, PTFE) | Lightweight, moisture-resistant | Reduces weight, resists moisture | Limited load-bearing capacity |

| Bushings & Gasket Materials (PTFE, copper-based alloys) | Reduce friction | Extend hinge life, improve performance | May require replacement over long-term heavy use |

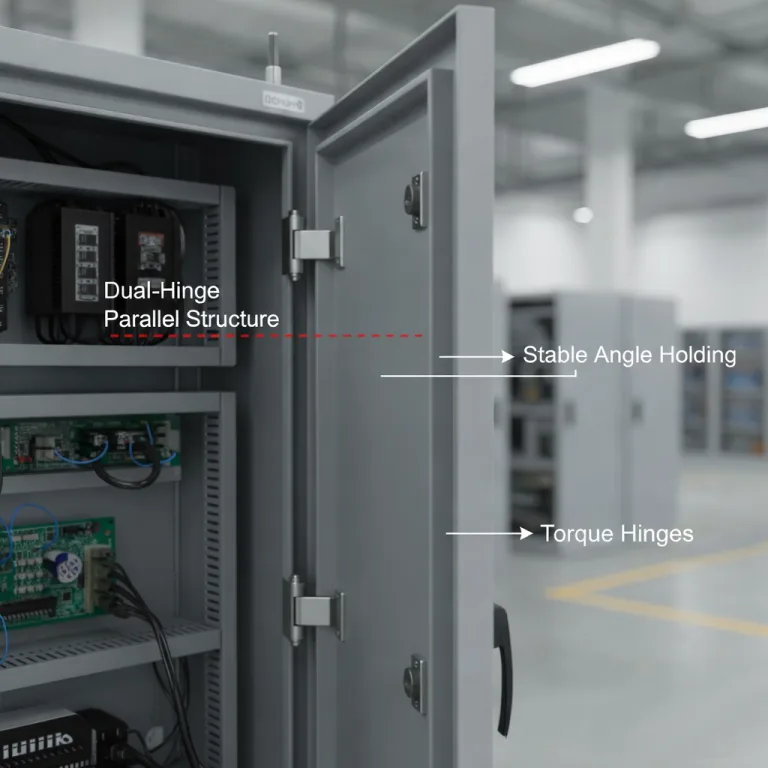

Structural Design Innovations

- Adjustable design: Compensates frame settlement, keeps seal intact.

- Angled lift hinges: Raise door slightly on opening, compress gasket on closing.

- Self-closing function: Prevents doors left open, cushions impact.

- Cold Bridge Prevention: Insulating spacers reduce heat transfer & condensation.

Precision Manufacturing Processes

- Forging/Casting: Improves density & strength.

- CNC Machining: Ensures dimensional accuracy, smooth rotation.

- Surface Treatment: Polishing, plating, brushing → better corrosion resistance & hygiene.

Installation, Maintenance, and Future Outlook

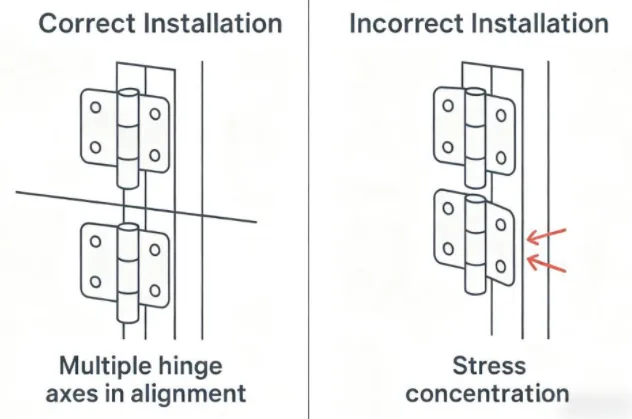

Professional Installation

- Requires precise measurement & alignment.

- Improper installation → misalignment → seal failure.

Preventive Maintenance Plan

- Regular Inspections: Check screw tightness, corrosion, wear.

- Cleaning & Lubrication: Use food-grade, low-temp grease.

- Adjustment & Calibration: Re-align doors, check gasket compression.

Conclusion

Hinge selection for beverage cold storage is a systemic decision impacting efficiency.

- Durability + Sealing are equally critical.

- Achieved through: proper materials, innovative designs, precision manufacturing.

- Premium hinges = higher upfront cost but lower long-term costs & energy use.

- Enterprises should adopt full-cycle management (selection → installation → maintenance).

FAQs

Q1: Why emphasize “sealing” in beverage cold storage hinges?

A1: Poor sealing causes leakage, temperature fluctuations, and shorter shelf life. Premium hinges ensure tight gasket contact, stabilizing temperature.

Q2: Difference between 304 and 316 stainless steel hinges?

A2: 304 = standard environments; 316 = better for salt, chemicals, humidity. Recommended for beverage cold storage.

Q3: Why use reinforced hinges for heavy-duty doors?

A3: Doors often weigh 100+ kg. Without reinforced hinges → sagging, seal failure, higher energy costs.

Q4: Do cold storage hinges require maintenance?

A4: Yes. Over 80% of failures = poor maintenance. Regular inspection, cleaning, lubrication essential.

Q5: Can hinge design reduce energy consumption?

A5: Yes. Lift-up hinges compress gaskets, self-closing prevents energy loss, cold-bridge prevention reduces leakage.