Industrial Concealed Hinges: Types & Design Guide

Introduction: Why “Concealment” Is Critical for Modern Industrial Equipment

In harsh industrial environments, a protruding hinge is not only an aesthetic flaw but also a potential safety hazard and failure point.

The core definition of an industrial-grade concealed hinge lies in this principle: when the door is closed, all hinge components—leaves, pins, and fasteners—are hidden, forming a flush interface between the door and frame.

Beyond this definition, the true value of a concealed design extends far beyond visual appeal—it delivers critical functional benefits for industrial environments.

- Enhanced Safety: Helps designs comply with OSHA 1910.212, which requires the elimination of pinch and snag hazards caused by protruding parts, and ensures the highest level of physical tamper resistance.

- Improved Environmental Sealing: Allows gasket seals to form a continuous, unbroken loop—essential for electrical enclosures to achieve IP65 or even IP67 protection levels.

- Optimized Space Utilization: A flush surface allows equipment to be installed edge-to-edge without gaps.

This guide systematically deconstructs concealed hinges used in heavy machinery, electrical enclosures, and special vehicles—covering structural classifications, materials science, torque calculations, and compliance with international standards (IP, NEMA, ATEX).

Beyond Aesthetics: The Core Advantages Concealed Hinges Bring to Industrial Manufacturing

Industrial equipment demands far greater functionality, durability, and compliance from hardware components than residential or consumer products.

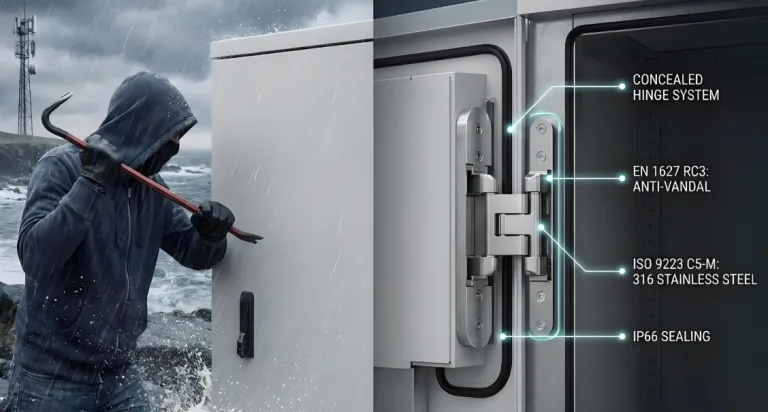

Exceptional Safety and Tamper Resistance

Concealed hinges provide dual-layer protection:

Tamper Resistance (Asset Security)

The hinge pin and mounting screws are completely enclosed within the door and frame. From the outside, there are no accessible points (such as pry gaps or removable pins) for forced entry. This is critical for protecting high-value assets like ATMs, data center servers, and critical infrastructure control panels.

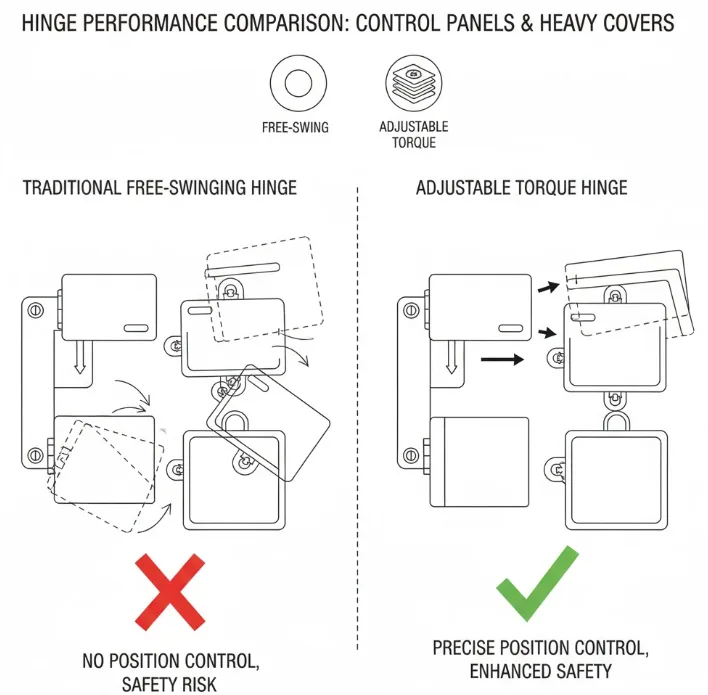

Operational Safety (Occupational Safety)

Flat, flush surfaces without protrusions are a fundamental principle of industrial safety design. OSHA (specifically section 1910.212) explicitly requires that machine guards eliminate pinch or snag hazards caused by protruding parts.

Traditional exposed hinges are a classic snag hazard, likely to catch on operators’ clothing or PPE. Concealed hinges eliminate these protrusions entirely, significantly reducing the risk of tripping or entanglement.

Superior Environmental Protection and Sealing

This is the most dominant technical advantage of concealed hinges in industrial applications—it directly determines whether an electrical enclosure can meet environmental protection certifications. High protection ratings (such as IP67) require uniform, continuous gasket compression.

Traditional exposed hinges must penetrate or interrupt the gasket seal, creating inevitable leakage points. Concealed hinges, mounted inside the gasket boundary, allow the gasket to form a complete closed loop around the door frame, ensuring perfect face sealing.

IP Rating (IEC 60529)

- IP65: Protection level “5” indicates resistance to low-pressure water jets.

- IP67: Protection level “7” indicates temporary immersion at 1 meter for 30 minutes.

Under water pressure, any gasket discontinuity is catastrophic. Concealed hinges mounted internally are essential to achieving IP67.

NEMA Ratings (NEMA 250)

The North American standard extends beyond IP ratings by adding requirements for corrosion, icing, and environmental resilience.

Note that IP and NEMA ratings are not directly interchangeable—NEMA includes additional criteria such as mechanical impact and corrosion resistance.

- NEMA 4 / 4X: Protection against rain, snow, and hose-directed water (≈ IP66). NEMA 4X adds corrosion resistance, typically requiring 316 stainless steel hinges.

- NEMA 6P: Protection against prolonged immersion (beyond IP67)—structural design is key.

IP vs. NEMA Rating Comparison for Industrial Hinge Selection

| Protection Rating | IP Definition (IEC 60529) | NEMA Definition (NEMA 250) | Key Hinge Design Points |

|---|---|---|---|

| IP65 | 6: Dust-tight; 5: Low-pressure water jets | ≈ NEMA 3 | Continuous gasket sealing required |

| IP67 | 6: Dust-tight; 7: Temporary immersion | ≈ NEMA 6 | Hinge must be inside gasket loop |

| NEMA 4 | ≈ IP66 | Rain, snow, high-pressure water | Must withstand freezing stress |

| NEMA 4X | ≈ IP66 | Adds corrosion resistance | Use SUS304 / SUS316 |

| NEMA 6P | ≈ IP68 | Prolonged immersion | Must endure continuous water pressure |

| NEMA 12 | ≈ IP54 | Indoor dust & drip protection | Zinc alloy or steel recommended |

Optimized Space Efficiency and Hygienic Design

Space Efficiency

Concealed hinges eliminate external protrusions, allowing enclosures to be placed side by side with zero clearance, maximizing layout density.

Hygienic Design

In food (NSF/ANSI) and pharmaceutical (EHEDG) industries, exposed hinges often trap contaminants. Concealed hinges provide smooth, flush surfaces, but certification (EHEDG/NSF) is required to verify full cleanability.

Enhanced Durability and Structural Integrity

External Protection

Hinge bodies are protected within the door and frame, shielded from physical impacts, corrosion, and environmental wear.

Structural Integration

Mortise-mounted hinges distribute loads internally, improving rigidity, load capacity, and anti-sag performance.

Core Classifications of Industrial Concealed Hinges: By Structure and Function

Multi-Link Heavy-Duty Concealed Hinges

- Structure: Multiple precision links and pins forming a complex system.

- Motion: Translation then rotation; check CAD motion files.

- Applications: 180° doors, thick panels.

- Pros/Cons: High load & angle; costly; precision required.

Mortise-Mount Concealed Hinges

- Structure: Fully embedded into recesses.

- Applications: Common type for medium to heavy-duty enclosures.

- Pros/Cons: Excellent stability; requires precise machining.

Internal Surface-Mount Concealed Hinges

- Structure: Mounted on interior surfaces.

- Applications: Thin sheet-metal enclosures (1.5–2.5 mm).

- Pros/Cons: Easy install; limited load-bearing capacity.

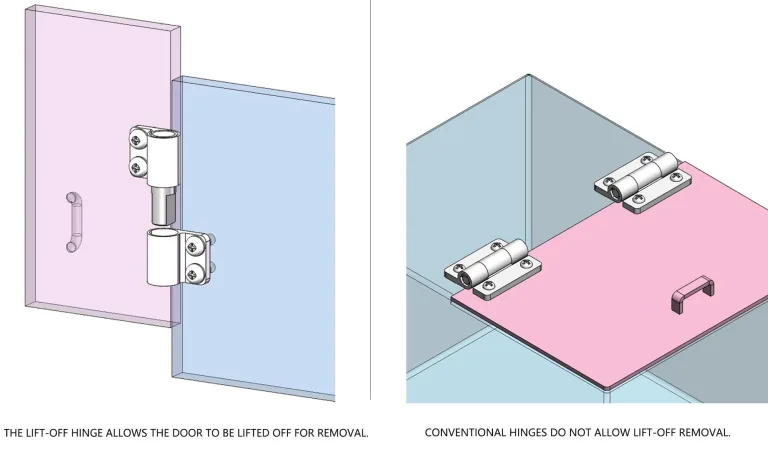

Removable Concealed Hinges

- Structure: Two-part flag design; doors lift off at angle.

- Applications: Server cabinets, frequent maintenance.

- Pros/Cons: Improves serviceability; lower tamper resistance.

Special Function Type (3D Adjustable)

- Feature: Fine-tuning on X, Y, Z axes (±2 mm typical).

- Importance: Critical for gasket sealing and alignment in large assemblies.

In-Depth Analysis of Typical Industrial Applications

| Application | Core Challenge | Key Selection Factors |

|---|---|---|

| Electrical Control Cabinets (NEMA & IP) | Environmental sealing (IP65/IP67), chemical resistance | Mortise or surface-mount; 3D adjustment; SUS316 for NEMA 4X |

| Large Machinery Guards | Heavy doors, vibration, OSHA compliance | Multi-link hinges; anti-loosening fasteners |

| Data Center Server Cabinets | Secure access, airflow, narrow aisles | 180° or removable hinges |

| Special Vehicles | Continuous vibration, temperature cycling | EN 61373 compliance; aluminum or SS hinges |

| Special Environments (ATEX / EHEDG) | Explosion or hygienic zones | EN ISO 80079-36 / EHEDG certified designs |

Ultimate Design and Selection Guide for Industrial Concealed Hinges

Accurately Calculate Load Requirements

A common mistake is selecting hinges solely by door weight.

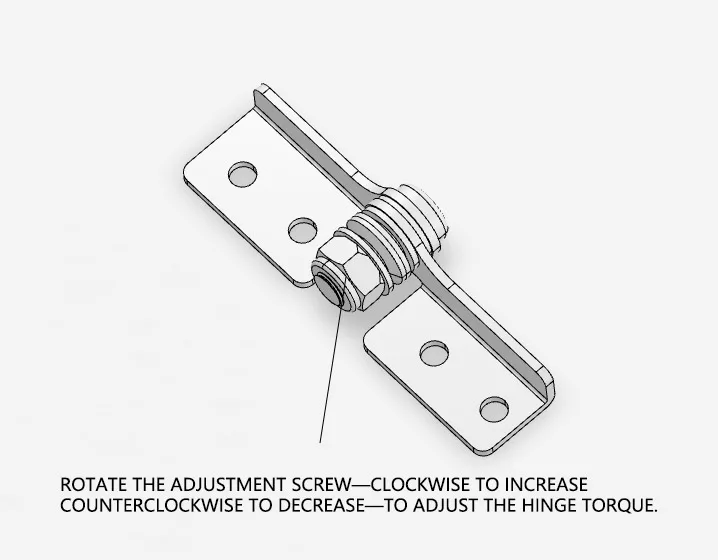

Torque Calculation

Torque Calculation Formula: M = F × D

Where:

- M = Torque (N·m)

- F = Force (Weight) of the door (N)

- D = Lever arm distance (m) (distance from hinge axis to door’s center of gravity, usually Door Width / 2)

To calculate the torque, you must first convert the door’s mass to force (weight).

Formula: Force (N) = Mass (kg) × g (m/s²) (Use g ≈ 9.8 m/s² for standard gravity)

Example (using Door B):

- Door Mass (m): 40 kg

- Door Width: 1.0 m

1. Calculate Lever Arm (D): D = 1.0 m / 2 = 0.5 m

2. Calculate Force (F): F = 40 kg × 9.8 m/s² = 392 N

3. Calculate Torque (M): M = 392 N × 0.5 m = 196 N·m

Steps:

- Calculate the door’s Force (F) in Newtons and Torque (M) in Newton-meters.

- Distribute loads among hinges.

- Apply safety factor ≥ 1.5.

- Verify rated thrust and radial load exceed calculated values.

Determine Motion Path and Opening Angle

- Define opening angle (90°, 120°, 180°)

- Check motion interference (adjacent enclosures)

- Use manufacturer’s CAD files to validate motion curve

Match Materials to Environment and Standards

Material Performance and Standard References

| Material | International Standard | Core Properties | Typical Application |

|---|---|---|---|

| 316/316L SS | ASTM A240 / EN 1.4401 | Superior corrosion resistance | NEMA 4X, marine, medical |

| 304 SS | ASTM A240 / EN 1.4301 | Good corrosion resistance | Food, humid, outdoor |

| Zinc Alloy (Zamak) | ASTM B86 | Cost-effective, easy casting | NEMA 1/12 indoor |

| Carbon Steel (Coated) | Steel + coating | High strength, needs coating | Dry machinery components |

Installation Method and Tolerance Compensation

- Manufacturing Capability:

Choose mortise-mount (CNC) or surface-mount (drill/punch). - Tolerance Compensation:

Large assemblies need 3D adjustable hinges to correct misalignment and ensure gasket uniformity.

Installation, Maintenance, and Common Issues

- Accurate Positioning:Use mounting templates or CNC drawings to ensure precise alignment and placement.

- Secure Fastening:Use a torque wrench to tighten fasteners to their specified torque value. Apply a thread-locking method (either chemical, such as Loctite, or a mechanical fastener like a lock washer) to prevent loosening from vibration.

Common Troubleshooting

Q: The door is sagging—what should I do?

- Recalculate Torque: Verify the required torque using the correct physical formula.

- Formula: M = (m × g) × (D / 2)

- Where:

- M = Torque (N·m)

- m = Door Mass (kg)

- g = Gravity (≈ 9.8 m/s²)

- D = Door Width (m)

- Check Hinge Rating: Confirm the hinge’s rated load (in N·m) is sufficient for your calculated torque.

- Recalibrate or Upgrade: Attempt to realign the hinge. If the load exceeds the hinge’s capacity, you must upgrade to a model with a higher load rating.

Q: Why is my IP rating failing (losing the seal)?

- Verify Gasket Compression:Check that the gasket is being compressed evenly and sufficiently around the entire perimeter.

- Adjust Alignment:If using 3D-adjustable hinges, use the X-axis (depth) adjustment to ensure the door seals flush against the frame.

- Ensure Gasket Integrity:Inspect the gasket itself for any breaks, tears, or gaps (especially at seams) that would compromise the seal.

Selection: Welded vs. Screw-Mounted

- Welded Hinges:Best for: Permanent installations and heavy-duty assemblies where no future adjustment or removal is needed.

- Screw-Mounted Hinges:Best for: Modular designs, adjustable enclosures, or applications where easy maintenance and serviceability are required.