Industrial Hinge Cycle-Life Testing: Reliability & ROI Guide

In the design of industrial equipment, rail transit, and medical devices, the hinge is often mistaken for a simple connection component. However, real-world data indicates that hinge failure is one of the leading causes of unplanned downtime and increased maintenance costs.

For heavy machinery or specialty vehicles, a broken hinge means more than just replacing a part. It can render expensive equipment unusable, cause doors to detach, or even lead to serious safety incidents.

Industrial hinge cycle-life testing, often referred to as fatigue testing, is the only scientific method to transform reliability from empirical judgment into auditable data. This test is not merely a simple open-and-close action; it is a simulation of the stress, wear, impact, and environmental corrosion a hinge endures throughout its entire lifecycle.

This article will analyze why rigorous cycle testing is an indispensable standard for industrial hardware from three dimensions: engineering, safety compliance, and Total Cost of Ownership (TCO), referencing international standards like ANSI/BHMA and EN.

What is Industrial Hinge Cycle-Life Testing?

Cycle-Life Testing is a controlled engineering process. It uses Automated Testing Rigs, combined with specialized fixtures, drive mechanisms, and sensors, to simulate the repetitive motion of a hinge in actual applications.

The Automated Testing Process

In professional laboratories, testing follows strict parameter settings rather than random operation:

- Motion Range: The hinge rotates repeatedly between 0° to 90° or 0° to 180°, depending on the actual installation stroke.

- Speed Control: The Cycles Per Minute (CPM) must remain constant to prevent heat generated by friction from affecting the test results.

- Duration: Tests typically last from several days to weeks to achieve 20,000, 100,000, or even 1,000,000 cycles.

Beyond Simple Movement: Load and Environment

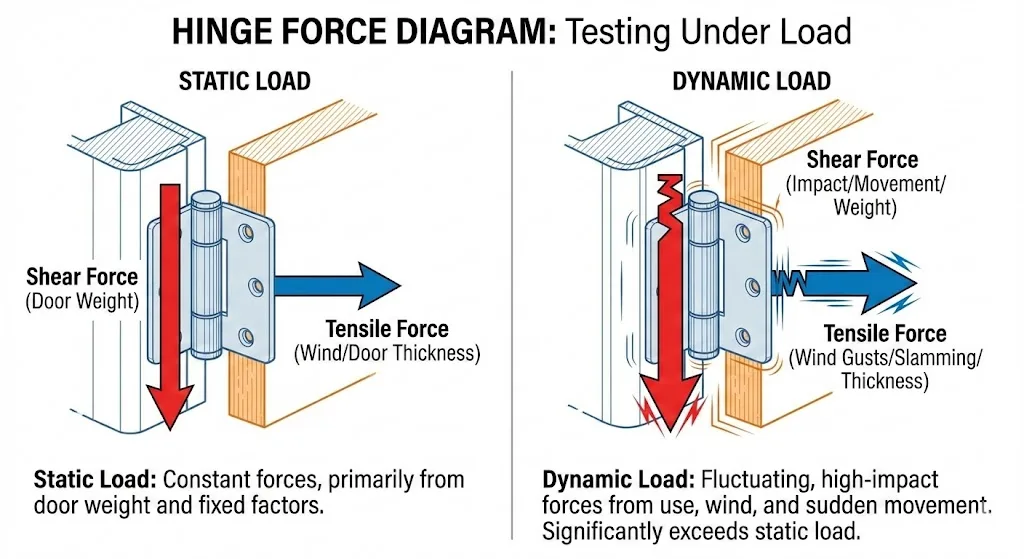

Simply letting a hinge rotate without resistance is insufficient to reflect reality. Effective engineering verification must include the following variables:

- Testing Under Load: The testing machine applies additional weight to the hinge to simulate the Shear Force and Tensile Force generated by the door panel. This ensures the structural integrity of the hinge under load and verifies whether the Load-bearing capacity decreases after cycling.

- Environmental Coupling: For outdoor or harsh environment applications, cycle testing is often combined with environmental testing.

- Extreme Temperatures: Operating under conditions from -40°C to +80°C to observe material dimensional changes and grease performance.

- Corrosion Testing: Combined with ASTM B117 or ISO 9227 salt spray test standards to verify if the hinge experiences seizing or a sharp increase in friction after corrosion occurs.

The Engineering “Why”: Predicting Failure Before It Happens

Industrial hinge failure is usually not sudden but the result of accumulated material fatigue. The core value of cycle testing lies in identifying potential failure points before the product hits the market.

Understanding Metal Fatigue

The leaves and pins of a hinge undergo microscopic elastic and plastic deformation during every operation.

- Stress Accumulation: According to the S-N curve (Stress-Life curve), metal will undergo fatigue failure when subjected to repetitive loading, even if the stress is below the yield strength.

- Micro-crack Detection: Without high-cycle testing, engineers cannot detect micro-cracks inside the material. These cracks often originate in stress concentration areas, such as hole edges or pin roots, eventually leading to catastrophic fracture.

Wear and Debris Generation

Friction is the enemy of mechanical life. There is continuous contact between the hinge pin and the bushings or bearings.

- Debris: Testing can reveal whether friction pairs generate metal powder or debris. This debris can accumulate inside the hinge, causing operation stutter, increased noise, or mechanical seizing.

- Increased Play: Excessive wear leads to increased radial or axial play, resulting in Door Sag, which in turn causes door locks to misalign or seals to fail.

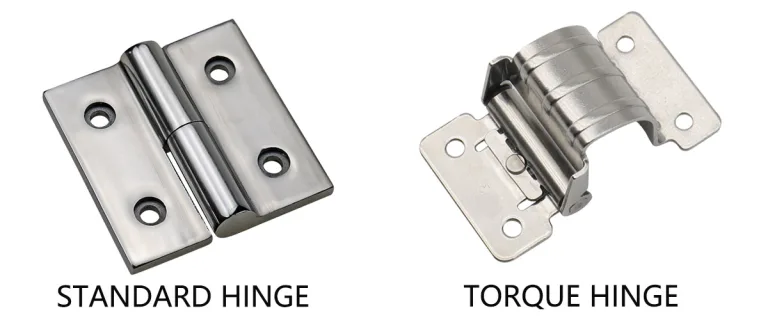

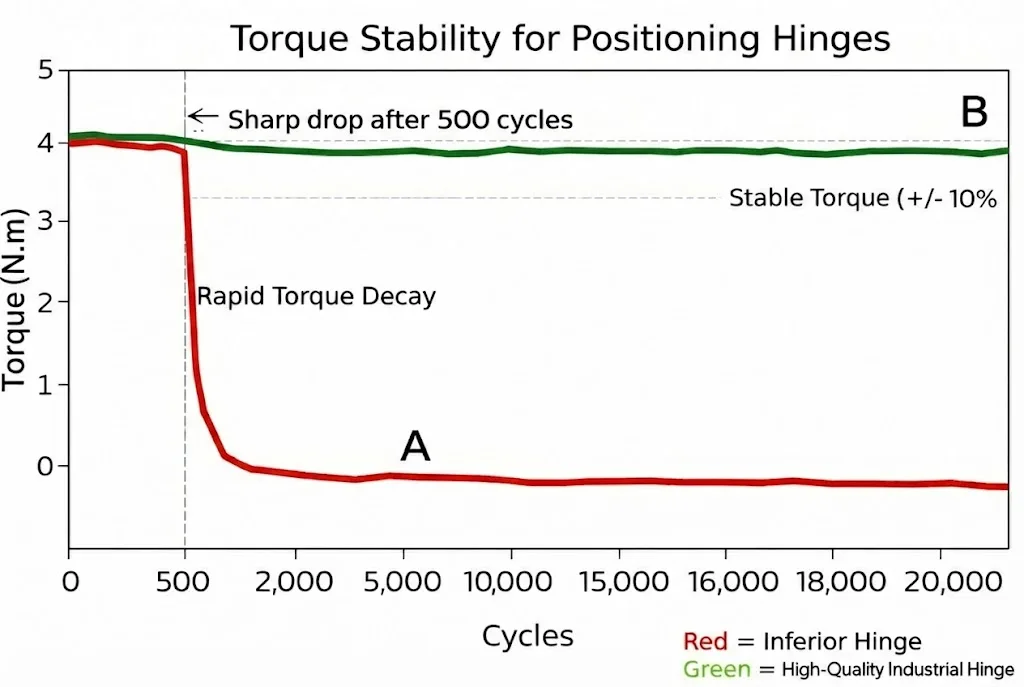

Torque Stability for Positioning Hinges

For Torque Hinges or Friction Hinges, the focus of testing is not fracture, but Torque Decay.

- Functional Failure Risk: These hinges rely on friction to hold the cover in a fixed position. An untested hinge may lose over 30% of its holding force after just 500 cycles, causing display screens or covers to slide down unexpectedly.

- Consistency Requirements: A qualified torque hinge must maintain its torque within +/- 10% to 20% of the initial value after 20,000 cycles. This must be proven by data, not just material datasheets.

The Safety & Compliance “Why”: Protecting People and Equipment

In many industries, using hardware verified by cycle testing is a legal or regulatory requirement and a necessary means for manufacturers to mitigate liability risks.

Preventing Catastrophic Failure

In dynamic applications, such as train doors or specialty vehicle compartments, hinges endure a combination of vibration and shock. If a hinge breaks, a heavy door panel may detach. This can cause physical injury to operators and damage expensive surrounding equipment. Using certified components helps manufacturers demonstrate they have performed Due Diligence.

Industry Standards and Reference Numbers

When sourcing industrial hinges, reference should be made to the following internationally recognized testing standard systems:

- ANSI/BHMA A156.1 (North American Standard):This is the authoritative standard for architectural hardware.

- Grade 1: Requires passing 2,500,000 cycles (for high-frequency public buildings).

- Grade 2: Requires passing 1,500,000 cycles.

- Grade 3: Requires passing 350,000 cycles.

- EN 1935 (European Standard):This is the European standard for single-axis hinges, containing 14 classification grades.

- Grade 12: For very heavy-duty doors, requiring passing 200,000 load cycles.

- Grade 7: For medium frequency use, requiring passing 200,000 cycles.

- Specific Industry Compliance:For medical devices (FDA related) or aerospace interiors (FAA related), cycle-life test reports issued by third-party laboratories are typically part of the compliance documentation package.

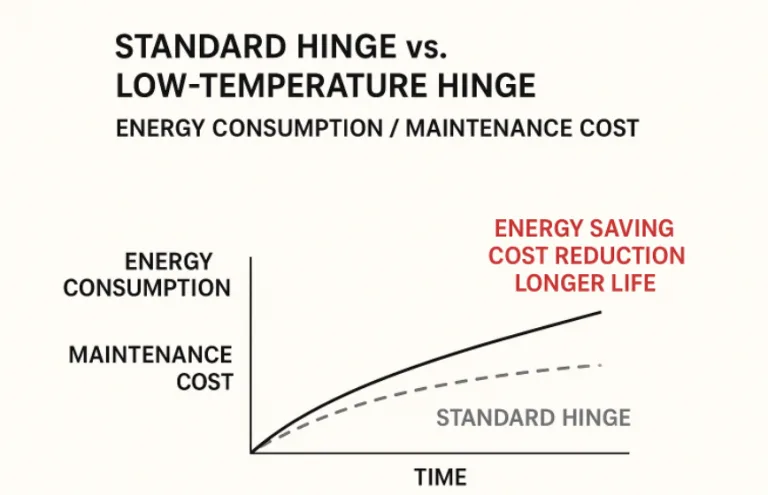

The Economic “Why”: Lowering Total Cost of Ownership

Procurement departments often face pressure to lower Bill of Materials (BOM) costs. However, choosing untested cheap hinges usually leads to a higher Total Cost of Ownership (TCO).

Initial Cost vs. Long-Term Reliability

- Scenario A: A generic hinge costs $5.00 and fails after 2,000 cycles.

- Scenario B: An industrial hinge verified for 20,000 cycles costs $15.00 and covers the equipment’s entire lifecycle.

Although the initial cost of Scenario B is higher, the potential risk cost of Scenario A increases exponentially.

Calculating the Hidden Cost of Downtime

The true cost of replacing a failed hinge includes:

- Technician Fees: Labor hours plus travel expenses.

- Lost Production: Revenue loss caused by production line stoppage.

- Secondary Damage: Door sag may cause wire harness breakage or cabinet structural deformation.

- Brand Reputation: A door falling off at a customer site directly damages the OEM manufacturer’s brand image.

The average cost of a single on-site repair often exceeds $500. This renders the $10 price difference in hinges insignificant.

Key Factors Monitored During Cycle Testing

Professional laboratories monitor more than just the cycle count. We monitor the following Key Performance Indicators (KPIs) in real-time:

| Parameter | Acceptance Criteria | Impact of Failure |

| Torque Tolerance | Final torque remains within +/- 10% – 20% of the initial value. | Cover cannot hold position; accidental closing causes pinching or equipment damage. |

| Play/Slop | Radial or axial movement does not exceed specific micron values. | Door Sag occurs, leading to lock misalignment or seal failure. |

| Coating Integrity | No visible rust at friction points; no plating peeling. | Leads to early corrosion; metal dust contaminates clean environments. |

| Noise Level | Smooth operation without harsh metal grinding sounds. | Poor user experience indicating internal lubrication failure. |

How to Interpret Cycle-Life Data for Your Application

When reviewing a product specification sheet, how do you know if “20,000 cycles” is sufficient? You need to calculate the Service Life based on the actual application scenario.

Defining “Service Life”

The calculation formula is as follows:

$$Required Cycles = (Operations Per Day) \times (365 Days) \times (Expected Equipment Life in Years)$$

Application Examples

Data Center Server Cabinet:

- Frequency: Maintenance once a month.

- 10-Year Total: 1 × 12 × 10 = 120 Cycles.

- Conclusion: Standard hinges are sufficient; the focus is on static load bearing rather than cycle life.

Industrial Machine Guard / Public Transport Door:

- Frequency: Opens 4 times per hour, two shifts per day (16 hours).

- 5-Year Total: 4 × 16 × 365 × 5 = 116,800 Cycles.

- Conclusion: Must select heavy-duty hinges tested to ANSI Grade 1 or equivalent levels.

Conclusion

Cycle-Life Testing for industrial hinges is not a marketing gimmick; it is an engineering necessity. It serves as the bridge between design theory and real-world reliability.

By simulating tens of thousands of repetitive motions, loads, and environmental stresses, testing reveals weaknesses invisible to the naked eye. For engineers and procurement managers, selecting hinges verified by cycle testing means:

- Compliance with safety regulations (Meeting ANSI/BHMA and EN standards).

- Elimination of maintenance costs (Lower TCO).

- Assurance of lasting performance (Especially for the positioning function of torque hinges).

Looking for hinges that stand the test of time?

Do not let low-quality hardware become the weak link in your equipment. Contact our engineering team to obtain detailed Cycle-Life Test Reports for specific products or to consult on custom solutions for your high-frequency application scenarios.

Frequently Asked Questions (FAQ)

Q1: How many cycles does a standard industrial hinge last?

A: The life of a standard industrial hinge is typically between 2,000 and 5,000 cycles. However, specially designed high-performance hinges are usually tested for 20,000 to over 100,000 cycles, and can even reach the ANSI/BHMA Grade 1 standard of 2,500,000 cycles, depending on the design grade.

Q2: What is the difference between static load testing and cycle testing?

A: Static Load Testing measures the maximum weight a hinge can withstand before deformation or fracture. Cycle Testing measures the durability of the hinge under repetitive motion. A hinge may have high static load-bearing capacity but wear out quickly during cycling. Both are critical for industrial applications.

Q3: Do stainless steel hinges require cycle testing?

A: Yes. Although stainless steel has excellent corrosion resistance, it is a relatively soft metal prone to galling. Cycle testing is essential to verify the lubrication design and material compatibility of stainless steel hinges.