Lift-Off Hinges: A Design Solution for Modern Applications

Lift-off hinges play a critical role in modern design by making doors, lids, and panels easily removable. These lift-off hinges – also called detachable or take-apart hinges – allow a leaf of a door to slide off its pin without unscrewing the hardware.

This simple change in hinge design transforms how components are assembled and maintained. Because one leaf contains a fixed pin and the other a matching socket, lifting the door at a certain angle frees it from the frame, enabling quick, tool-free removal.

In practice, lift-off hinges instantly detach doors from cabinets, machine guards, and enclosures. This ease of use captures designers’ and users’ attention from the start. By highlighting their unique benefits – especially compared to traditional fixed hinges – we can see why lift-off hinges are gaining traction in today’s efficient, modular designs.

Background of Lift-Off Hinges

Hinges have evolved over millennia, but the lift-off hinge concept emerged in the early 20th century to meet industrial needs. Early hinge designs simply let doors swing open, but lift-off hinges were engineered so panels could be separated without tools.

The mechanism is ingenious yet simple:

- One “fixed” leaf is attached to a frame

- One “removable” leaf is on the moving panel

- When the door is fully opened, the removable leaf lifts vertically out of the fixed leaf

No screws or pins need removal – a quick upward motion frees the panel.

This innovation was originally driven by factories and equipment makers who needed fast access for maintenance or part replacement.

Industry Adoption of Lift-Off Hinges

Over time, engineers adopted lift-off hinges in many fields:

- Industrial machinery doors

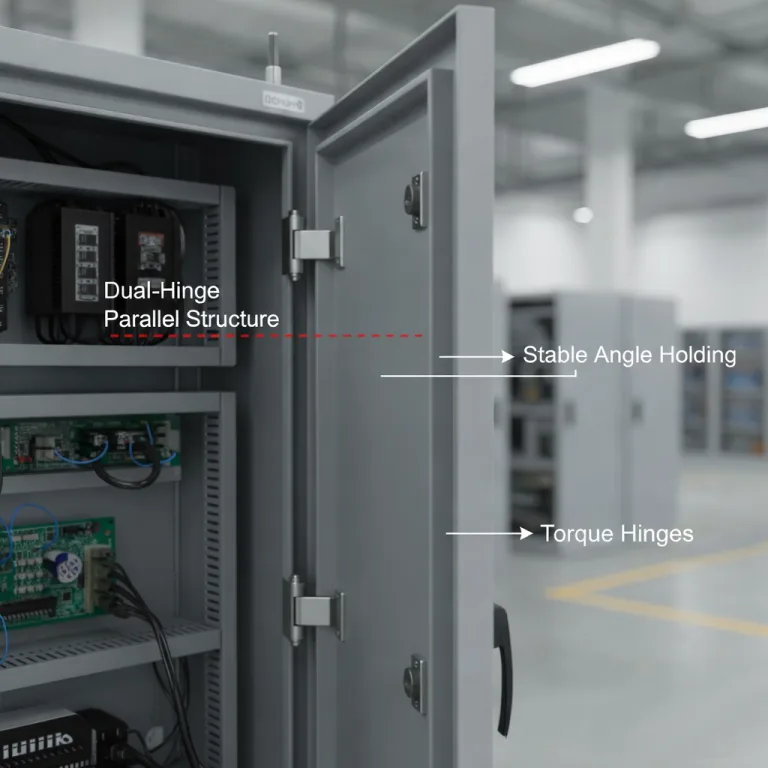

- Electrical and control cabinets

- HVAC panels

- Large access hatches

- Automotive and aerospace assemblies

- Furniture and cabinetry

In all these areas, they help designers build products that balance functionality and convenience.

Working Principle of Lift-Off Hinges

The working principle of lift-off hinges is straightforward:

- One leaf has a fixed pin

- The other has a socket or tube

- The pin slides into the socket and holds the parts together

- When opened, the panel lifts off — no tools required

This makes lift-off hinges invaluable in scenarios requiring frequent removal.

Design Advantages of Lift-Off Hinges

Lift-off hinges offer five key advantages in design:

- Easy Installation and Removal

- Space Saving

- Flexibility

- Safety

- Aesthetics

We explore each below:

Easy Installation and Removal of Detachable Hinges

Lift-off hinges simplify installation and maintenance:

- No screws or tools needed

- Dramatically cuts downtime in factories and field repairs

- Enables quick, tool-free panel replacement

Elesa Components notes that lift-off hinges enable “unparalleled convenience for situations where doors need to be frequently removed.”

Internal Link: This ease of assembly and service is a cornerstone of their appeal. See Industrial Equipment for examples.

How Lift-Off Hinges Help Save Space

Lift-off hinges are ideal for tight or confined spaces:

- No extra clearance is needed to swing open a door

- Panels lift straight up and out

ProtoSpace Mfg. describes them as “useful if there is limited space on your enclosure.”

Titan AV states their lift-off hinge “saves space by detaching the lid.”

Key Benefit: Reduces the swing arc, maximizing usable space in cramped designs like:

- Aircraft cabins

- Workshops

- Narrow cabinetry

Design Flexibility with Removable Hinges

Designers can reconfigure layouts without tools:

- Doors and panels can be removed and repositioned

- Many hinges are reversible (left/right orientation)

Lift-off hinges are ideal for:

- Modular furniture

- Exhibition booths

- Cleanroom partitions

Safety Benefits of Detachable Hinges

Lift-off hinges enhance safety in emergencies:

- Panels become instant exits or access paths

- No need to break down or unlock doors

Everyday Security:

- Welded or interior-mounted hinges prevent tampering

- Doors remain secure when closed and pinned

Engineers note that tool-free removal “reduces evacuation time and risk of damage.”

Aesthetic Advantages of Lift-Off Hinges

Lift-off hinges contribute to clean, modern design:

- Hidden hardware

- Flush finishes

- Color-matched coatings

ProtoSpace notes that hinges with hidden mounting holes “create a clean, uninterrupted appearance.”

They complement:

- Modern furniture

- Architectural paneling

- Industrial enclosures with a premium finish

Applications of Lift-Off Hinges

Lift-off hinges shine in many real-world settings. Below are key sectors that benefit from their five main advantages.

Industrial Equipment

Used on:

- Machine guards

- Control panels

- Enclosure doors

Advantages:

- Rapid maintenance access

- Reduced swing clearance

- Layout flexibility

- Emergency safety

- Clean industrial aesthetics

DB Roberts notes they “increase access in restricted spaces for easy maintenance.”

Furniture Design

Used in:

- Modular cabinetry

- Office furniture

- Home storage units

Advantages:

- Tool-free disassembly during moves

- Space-saving in small living areas

- Adjustable layouts

- Child safety and accessibility

- Hidden hinges for minimalism

Building and Architecture

Applied to:

- Fire exits

- Inspection panels

- Utility closets

Advantages:

- Emergency panel removal

- Easier access during building maintenance

- Cleaner transitions in minimalist interiors

Designers appreciate:

- Flush mounting

- Concealed hardware

- Fewer visual distractions

Transportation and Vehicles

Used in:

- Aircraft interior panels

- Bus and train emergency doors

- Car hoods and cargo compartments

Advantages:

- Fast maintenance

- Space-saving in compact interiors

- Emergency access

- Hidden mechanisms for sleek cabin design

Panels can be detached:

- For servicing

- To expand exits

- To remove bulk when loading/unloading

Conclusion

Lift-off hinges offer five essential benefits for modern design:

- Effortless Installation & Removal – Panels detach in seconds, no tools needed

- Space Saving – Slim profiles and vertical lift reduce swing clearance

- Design Flexibility – Doors become modular, allowing reconfiguration

- Safety – Panels can be removed in emergencies for rapid access

- Aesthetics – Hidden hinges preserve clean, minimal designs

From industrial machines to home furniture and transportation systems, lift-off hinges offer unmatched convenience and efficiency. As one supplier summarizes, they allow doors to be “quickly mounted or removed from frames” — a design solution that is as practical as it is elegant.