ltimate Guide to Choosing Industrial Concealed Hinges

In modern industrial equipment design, functionality, safety, and aesthetics are all indispensable. Concealed hinges (also known as “invisible hinges”) have become a key component for elevating equipment quality and security due to their characteristic of being completely hidden when the door panel is closed.

However, the demands of industrial environments on hinges far exceed those for ordinary hardware. This article is an exhaustive selection guide that will take you deep into the seven key technical parameters—from load capacity and opening angle to material corrosion resistance—and combine them with specific industrial application scenarios to help you precisely select the concealed hinge that best suits your needs.

What is an Industrial-Grade Concealed Hinge?

An industrial-grade concealed hinge is a hardware system where, when the door panel is closed, its mechanical structure is completely installed and hidden within the door panel and cabinet body. This is in sharp contrast to traditional hinges (like flag or piano hinges) that are clearly visible externally.

Its core is a complex multi-link mechanism (such as a four-bar or six-bar) with a precisely defined movement path. This design doesn’t just solve “rotation”; it provides a complex kinematic solution for “how to move from a closed point to an open point without collision in a restricted space.” For example, some designs allow the door panel to first “translate” away from the frame before rotating, avoiding collisions in extremely small installation gaps.

Core Advantages in Industrial Applications:

- Ultimate Aesthetics and Ergonomics: Achieves a “seamless” flat design that is easy to clean and eliminates external protrusions, preventing accidental snagging of personnel clothing or cables. Learn more about how concealed hinges improve OSHA compliance and industrial safety.

- Superior Security and Tamper-Resistance: All fasteners and the hinge body are installed inside the cabinet, making it an ideal choice for outdoor electrical boxes and public facilities.

- Optimized Space and Sealing (IP/NEMA Ratings): Enables even gasket compression, crucial for achieving IP65 or NEMA 4/12 protection ratings.

- Reduced Maintenance and Increased Durability: Installed inside the cabinet and shielded from external erosion (dust, moisture, chemicals).

Seven Key Technical Parameters Explained

Load Capacity

- Torque (N·m) > Torque = Door mass (kg) × 9.81 × Distance (m); maintain ≥1.25× safety factor.

- Dynamic Load and Cycle Life (ANSI/BHMA): Grade 1 hinges must pass 2.5 million cycles per ANSI/BHMA A156.1.

- Load Distribution: Top hinge bears pull (radial force); bottom hinge bears axial weight.

- Engineering Misconception: Adding a third hinge does not proportionally increase the total load capacity. In multi-hinge systems, load distribution is inherently nonlinear—the top hinge primarily absorbs radial tension, while the bottom hinge carries most of the axial weight. The middle hinge provides limited additional support and primarily helps reduce door deflection and vibration rather than significantly boosting total capacity.

- Safety Margin: A minimum safety factor of about 1.25× is generally applied under stable conditions. For vibration or impact environments, engineers often use 1.5–2.0× to ensure durability and reliability.This follows standard engineering practice as outlined in Wikipedia’s “Factor of Safety”and Roy Mech’s guidelines.

Opening Angle

| Angle | Application | Note |

|---|---|---|

| 90° | Standard small access panels | Basic clearance |

| 120° | Most industrial cabinets | Best balance of access and space |

| 180° | Data centers, heavy access doors | Maximum opening; avoid collisions |

Engineering Warning: Forcing a hinge beyond its design limit causes permanent damage.

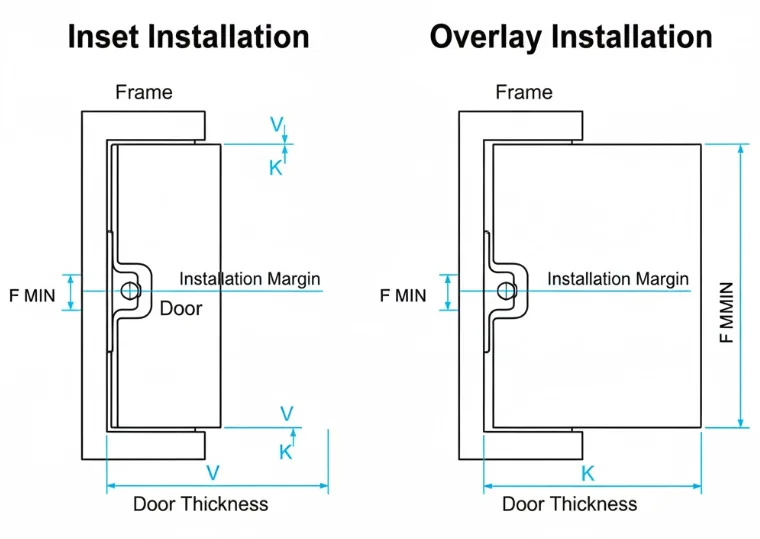

Door and Frame Geometry

- Installation Type: Depends on whether the door is Inset or Overlay.

- Key Constraints: Door thickness (V), installation margin (K), and side clearance (F MIN) have strict geometric relationships.

- Selection Requirement: Reference the manufacturer’s technical data sheets or CAD drawings.

Center of Rotation (Pivot Point)

The center of rotation is a “virtual point” defined by the multi-link mechanism. Incorrect modeling leads to collision between the door and frame during opening.

Material and Finish

| Material | Characteristics | Typical Use |

|---|---|---|

| Zinc Alloy | Precision die-cast; good aesthetics | Indoor cabinets, control consoles |

| Steel | Highest strength; needs anti-corrosion coating | Heavy machinery guards |

| 304 Stainless Steel | General corrosion resistance | Food, medical, outdoor (non-salt) |

| 316 Stainless Steel | Contains Mo; excellent chloride resistance | Marine, coastal, chemical environments |

| Aluminum | Lightweight (⅓ density of steel) | Vehicles, aviation, rail transit |

Mounting Style

- Screw-on / Bolt-on: Common and adjustable; ensure correct left/right orientation.

- Weld-on: Strongest, vibration-proof, and tamper-resistant; ideal for heavy-duty doors.

- Lift-Off: Allows quick door removal for transport or maintenance.

Additional Features

- 3D Adjustment: Enables fine-tuning in three directions; critical for maintaining gasket compression and IP/NEMA ratings.

- Detent Function: Holds doors open at preset angles—important for operator safety.

- Torque / Friction Hinge: Maintains position at any angle; ideal for vibration-prone vehicle panels.

Practical Analysis of Three Industrial Scenarios

Electrical Cabinets, Server Racks, and Control Boxes

- Characteristics: Indoor use; IP rating and tamper resistance prioritized.

- Selection Priority:

Heavy-Duty Machinery Guards and Equipment Access Doors

- Characteristics: Heavy doors, high vibration, frequent operation.

- Selection Priority:

- Calculate torque with safety margin.

- Use weld-on hinges for vibration resistance.

- Detent function recommended for safety.

- Verify ANSI/BHMA cycle life data.

Specialty Vehicles (RVs, Construction Vehicles), Outdoor Equipment

- Characteristics: Harsh environments with moisture, salt, and vibration.

- Selection Priority:

- Use 304 stainless steel for general outdoor.

- For coastal or salt zones, use 316 stainless steel (NEMA 4X).

- Consider friction hinges for vibration control.

Not to Be Overlooked: Correct Installation and Maintenance of Concealed Hinges

Installation Key: Alignment!

All hinges must align perfectly along the same axis. Misalignment causes uneven loading, torsion on the top hinge, and premature wear.

Maintenance Trap: Stainless Steel “Galling”

Stainless steel under friction can experience adhesion (“cold welding”).

- Solution: Periodically lubricate with anti-seize grease containing molybdenum or nickel—never use common grease.

Frequently Asked Questions (FAQ)

Q1: Why is my hinge sagging even if the load capacity is sufficient?

A: Common causes include misalignment, incorrect torque calculation, or loose fasteners.

Q2: Do 180-degree hinges always have a lower load capacity than 120-degree ones?

A: Not necessarily, but 180° designs are more complex and may have more stress points.

Q3: Do stainless steel hinges really not rust?

A: They can. Chlorides break the passive layer of 304 stainless; 316 (with Mo) resists this per ASTM B117 tests.

Q4: Which is better: universal (non-handed) hinges or dedicated left/right hinges?

A: Universal hinges reduce SKUs; dedicated types may be structurally stronger for special geometries.

Conclusion

Selecting a concealed hinge for an industrial application is far more than just “aesthetics.” It is a serious engineering decision concerning equipment safety, IP/NEMA protection ratings, durability, and ergonomics.

This decision begins with a precise calculation of load torque and door geometry, deepens with a profound understanding of the application environment (corrosion, vibration) and industry standards (ANSI, NEMA), and is finalized with strict control over material (316 vs. 304) and installation accuracy (alignment, anti-galling). Choosing the correct concealed hinge is the cornerstone of ensuring your equipment remains safe and reliable throughout its entire lifecycle.