Weld-On vs Bolt-On Hinges: How to Choose

Though often overlooked, hinges directly impact the reliability and lifespan of doors, windows, or equipment.Choosing between weld-on hinges and bolt-on hinges requires weighing installation methods, load requirements, durability, maintenance difficulty, and cost. Weld-on hinges are better suited for permanent, integrated connections; bolt-on hinges are more suitable for quick installation and future maintenance. This article provides an in-depth comparison across key dimensions, offering a selection checklist and clear conclusions based on specific scenarios to help you make a quick decision.

What Are Weld-On Hinges?

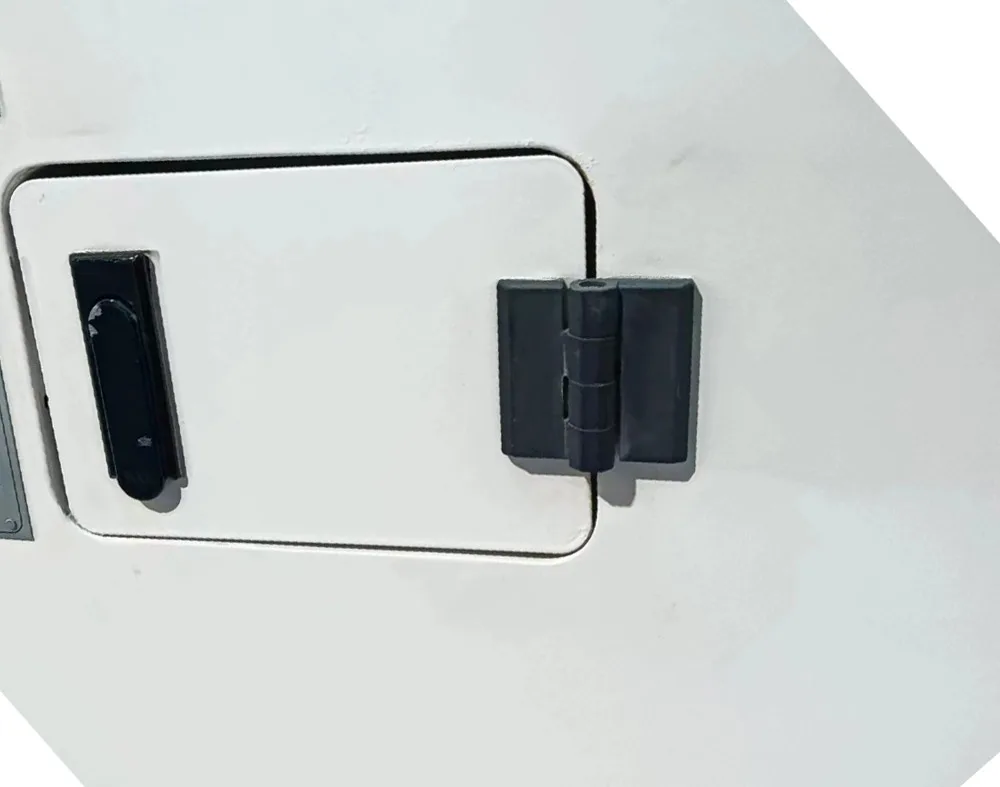

Weld-on hinges lack bolt holes. During installation, the hinge leaf is directly welded to the metal door frame or door body, creating a robust, non-removable connection. Common configurations include cylindrical or track-style designs, with materials ranging from carbon steel to 304/316 stainless steel and aluminum alloy. They are frequently used in heavy-duty industrial doors, steel gates, trailer tailgates, equipment hatches, and other applications requiring high strength and security.

Advantages

- Exceptionally high load capacity, effortlessly supporting tens of kilograms of heavy door panels

- No exposed bolts for a cleaner appearance and superior anti-pry resistance

- Stable weld points requiring minimal maintenance, with lifespans reaching decades

Disadvantages

- Installation requires professional welding equipment and expertise

- Once welded, disassembly or fine-tuning is virtually impossible, leading to high repair costs

- Welded areas require grinding and rust-proof coating due to high temperatures, otherwise corrosion is likely

Overall, Weld-on hinges suit one-time installation for long-term, stable heavy-duty applications.

Materials

- Carbon steel (high strength, low cost)

- 304/316 stainless steel (corrosion-resistant)

- Aluminum alloy (lightweight)

Types

- Tubular (cylindrical), pin-type

- Wide-throw hinges provide greater opening angles

Applications

Heavy-duty industrial doors, steel gates, trailer tailgates, container doors, and other scenarios emphasizing durability and security.

Limitations

- Requires professional welding; irreversible after welding

- Welds require grinding and rustproofing

- Demanding installation environment

What are Bolt-On Hinges?

Applications of Bolt-On Hinges

Bolt-on hinges secure the hinge leaf to the door panel and frame using bolts or screws. Materials include steel, stainless steel, or aluminum alloy, suitable for wood, metal, or composite doors. Common types include T-plate hinges, continuous strip hinges, and adjustable hinges. Compared to Weld-on hinges, bolt-on hinges offer faster installation, easier disassembly, and greater suitability for applications requiring periodic maintenance, adjustments, or rapid construction. On-site installation requires only positioning, drilling, and bolting—no welding needed—making them preferable when construction conditions are constrained.

Advantages

- Rapid installation without welding equipment

- Post-installation micro-adjustment of door panel position via nuts or slot holes

- Easy maintenance—simply tighten or replace loose bolts

- Greater flexibility for removable structures like wooden doors, lightweight doors, trailers, and mobile display cabinets

Limitations

- Load capacity constrained by bolt strength and substrate

- Bolts may loosen under heavy loads or intense vibration, requiring periodic inspection

- Exposed fasteners present lower security, necessitating anti-tamper measures

- Visible screws compromise aesthetic neatness compared to welding

Structure

Bolt/screw fastening, suitable for removable and on-site adjustable applications.

Materials

- Steel, stainless steel, aluminum alloy

- Commonly galvanized or coated; stainless steel preferred for outdoor use

Advantages

- Simple installation, fast construction

- Precise on-site alignment adjustments

- Easy disassembly for maintenance or replacement during failures

Limitations

- Load capacity depends on bolt grade and door frame strength

- Requires anti-loosening measures

- Periodic tightening and lubrication needed for long-term use

Core Performance Metrics: Which is more stable, economical, and durable?

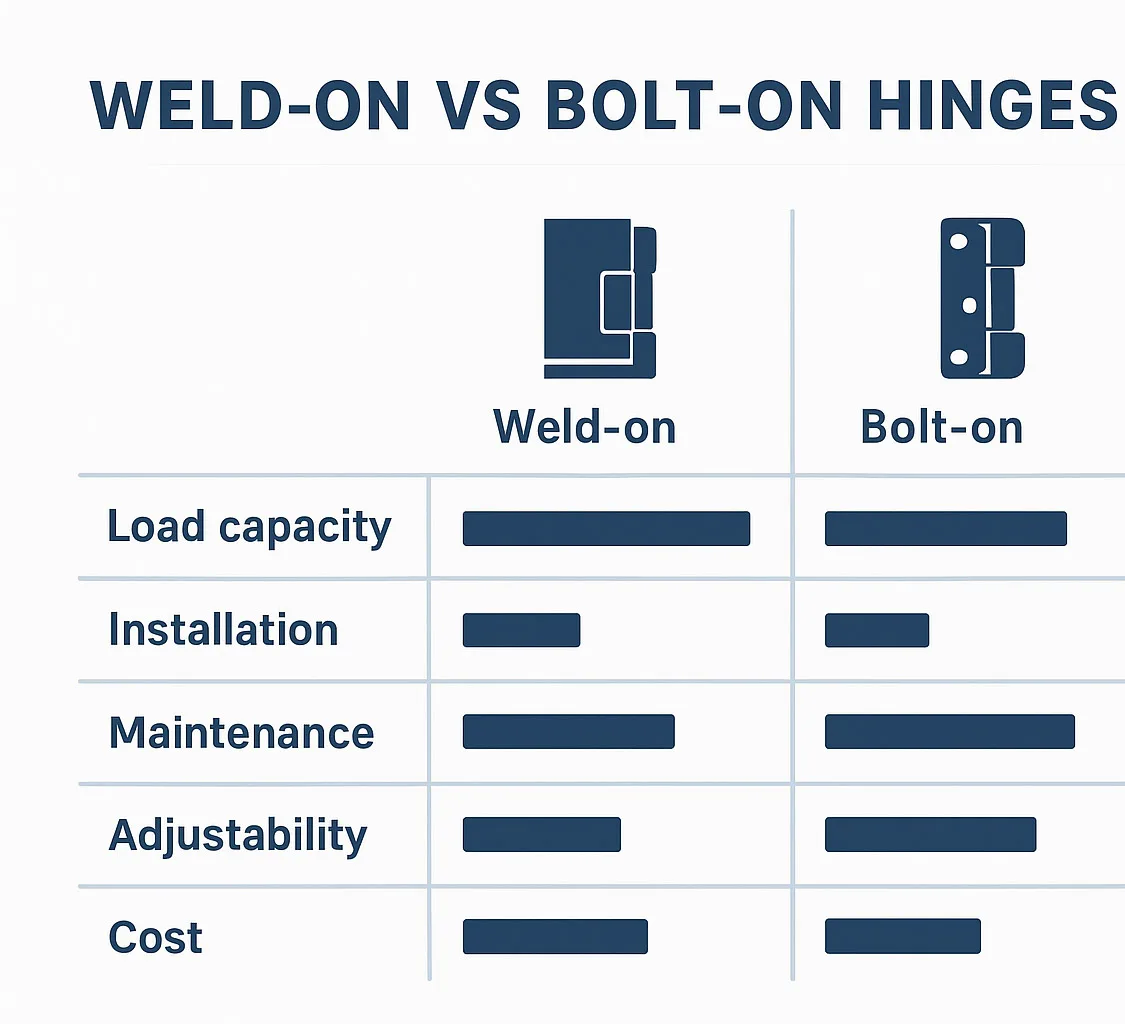

Infographic: Differences Between Weld-On and Bolt-On Hinges

Load-bearing & Strength

Weld-on hinges transmit forces directly to the door frame via welds, offering high structural integrity and withstanding extreme torque and shear loads. Bolted hinges distribute loads across bolts, with load capacity determined by bolt quantity, grade, and substrate hardness; bolts may pull out and fail under high loads. Prioritize Weld-on hinges for doors exceeding 100 kg.

Alignment Tolerance

Bolted hinges typically feature adjustment slots or nuts, allowing on-site fine-tuning for greater flexibility. Weld-on hinges require precise initial positioning and are difficult to adjust after welding.

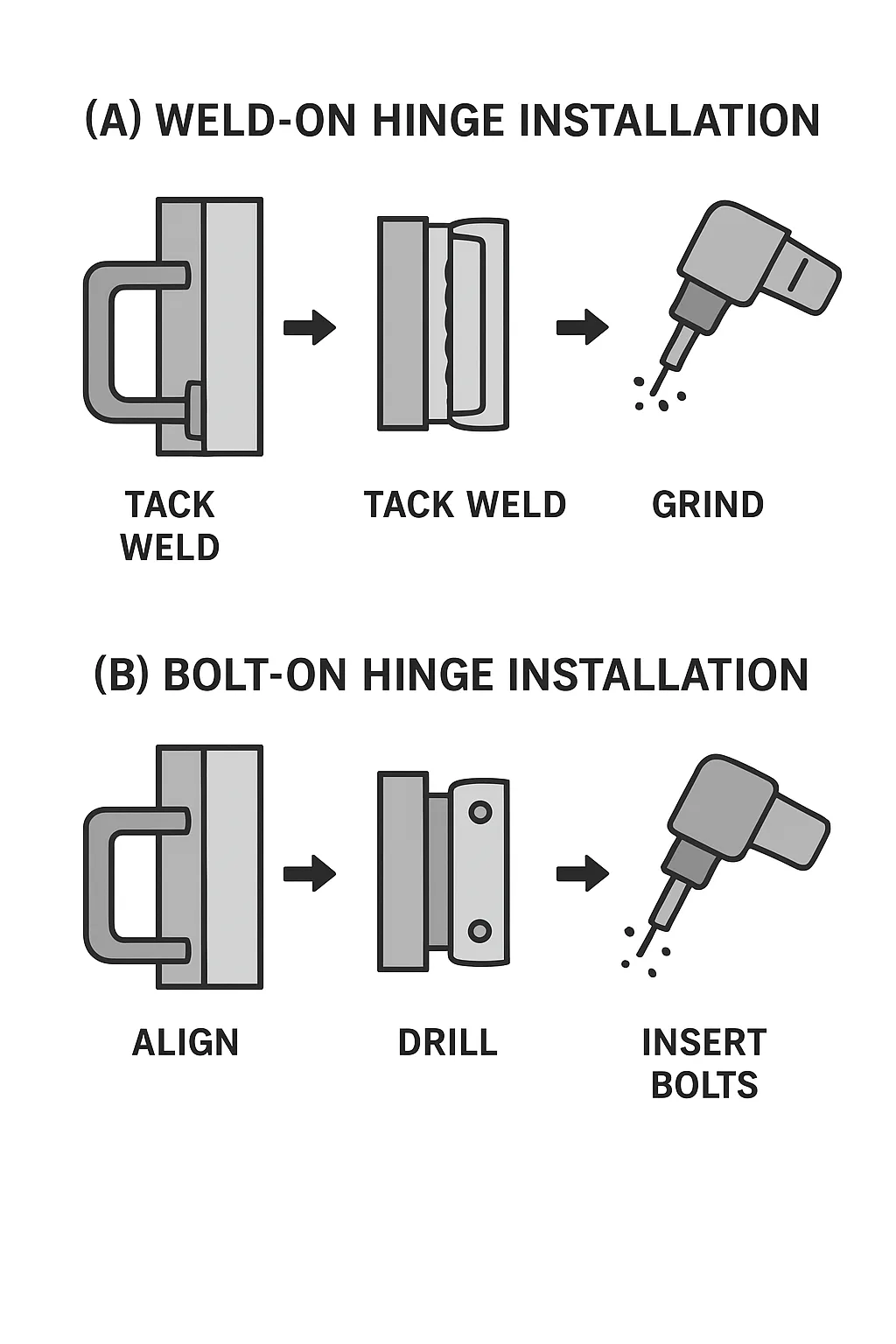

Installation Time & Tools

Weld-on hinges involve a more complex process: surface preparation, jig alignment, spot welding, filler application, and grinding. A professional welder may take 10–20 minutes or longer per hinge. Bolted hinges require marking, drilling, bolting, and torqueing—typically completed in 3–5 minutes. Bolting saves time but demands precise hole alignment.

Long-term maintenance

Weld-on hinges are virtually maintenance-free and won’t loosen. Bolted hinges require periodic tightening checks and lubrication of pins, with higher maintenance frequency in vibrating environments.

Corrosion Resistance

Both require protection. For outdoor or chemical environments, Weld-on hinges are recommended in 304/316L stainless steel or hot-dip galvanized steel; bolted hinges commonly use galvanized or coated steel plates. 316L stainless steel Weld-on hinges withstand over 1000 hours of salt spray testing without corrosion, far exceeding standard galvanized coatings (approx. 100–300 hours).

Aesthetics and Security

Weld-on hinges allow grinding of weld seams and painting for a seamless appearance. Hidden fasteners enhance tamper resistance. Bolt hinges expose screws; security caps or spot welding can be added for tamper resistance.

Smoothness and Noise

Both can use bearings or bushings and require periodic lubrication to reduce friction. Ball bearing hinges operate more quietly but cost more. For either type, keeping the pivot pin clean and oiled is crucial.

Total Cost of Ownership

Weld-on hinges have higher initial labor costs but lower maintenance expenses. Bolt hinges are cheaper initially but require ongoing maintenance. Choose bolt hinges for tight budgets; Weld-on hinges are often more cost-effective over their lifecycle.

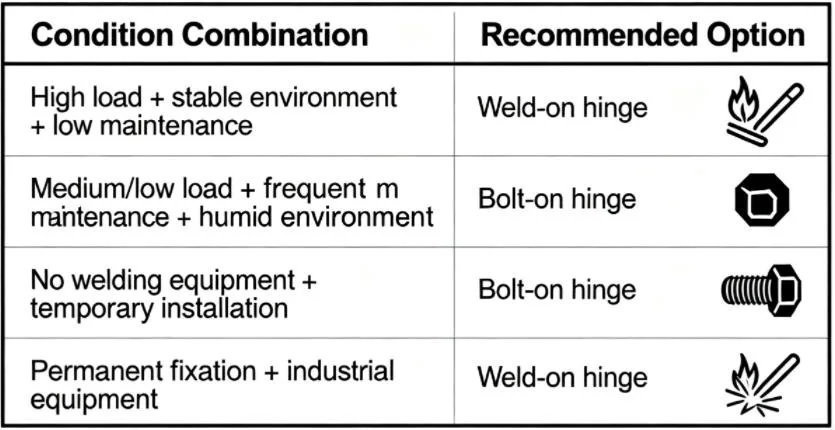

Selection Criteria for Different Scenarios

- Heavy-duty steel doors and industrial equipment: Prioritize Weld-on hinges for maximum strength and anti-pry performance due to high load-bearing and security requirements.

- Wooden or composite doors: When welding is impractical, use bolt hinges directly—e.g., interior wood doors, container conversions, lightweight fence gates.

- Movable/removable structures: Trailers, portable fences, exhibition equipment requiring frequent disassembly benefit from bolt hinges for efficiency.

- High-security/vandal-resistant settings: Banks, prisons, military facilities, etc., should use Weld-on hinges embedded within door panels or columns for enhanced tamper resistance.

- Outdoor or highly corrosive environments: Prioritize corrosion-resistant materials (e.g., 316L stainless steel), then select installation methods based on door material and maintenance plans. Extreme corrosion zones like coastal areas or chemical plants require heavy-duty protection.

- Frequent adjustments and maintenance: Bolt-on hinges are more convenient for furniture, cabinet doors, and other applications requiring repeated fine-tuning.

How Materials and Specifications Influence Your Decision

Material differences

- Carbon steel offers high strength at low cost but requires coating for rust prevention

- 304 stainless steel provides better corrosion resistance at a higher price

- 316 stainless steel performs best in marine and acidic environments

- Aluminum alloy is lighter and rust-resistant but has limited load capacity, suitable for medium to light loads

Plate Thickness and Pin Diameter

Load-bearing capacity directly correlates with plate thickness and pin size. Weld-on hinges typically use ≥6mm thick steel plates and thicker pins for higher shear strength. Bolted hinges often use 2–5mm plates and require high-grade bolts. Match material thickness to expected loads during installation.

Surface Treatment

Hot-dip galvanizing, electrophoretic coating, epoxy paint, and powder coating all enhance rust resistance. Cold galvanizing or phosphating suffices for standard environments; choose hot-dip galvanizing or fluorocarbon coating for heavy-duty corrosion protection. Construction quality determines lifespan—strict adherence to specifications is mandatory.

Fastener Grade

Use Grade 8.8 or 10.9 high-strength bolts. Grade 10.9 offers higher tensile strength for heavy-duty applications. Apply nylon lock washers, spring washers, or threadlocker for anti-loosening. Match fasteners to hinge material (e.g., stainless steel hinges with stainless steel bolts).

Installation Essentials & Best Practices

Installation Essentials & Best Practices

Weld-on hinges

- Clean the weld surface and precisely position using clamps

- Test open/close after tack welding to ensure no binding before completing the weld fill

- Alternate welding left and right to minimize distortion

- Grind weld slag and spatter post-weld, then apply rustproofing or galvanized coating

- Apply grease to bearing surfaces for enhanced smoothness

Bolt-Fastened Hinges

- Use a level and straightedge to determine hole positions; maintain verticality and precision when drilling pilot holes

- Install with metal washers or backing plates to distribute load and prevent wood splitting

- Tighten to recommended torque; recheck all fasteners for looseness post-installation

- Allow appropriate expansion gaps for thermal movement

General principles

- Maintain concentric hinge axes and ensure door panels remain flat without misalignment

- Conduct multiple opening/closing tests post-installation and perform simulated load verification for reliability

- Perform regular tightening and lubrication checks to extend service life

Common mistakes

- Neglecting door weight and dimensions: Insufficient hinge quantity or inaccurate load assessment leads to prolonged overload and sagging.

- Misalignment errors: Off-center drilling or welding causes door jamming and pulling.

- Inadequate corrosion protection: Failure to grind welds or apply rustproofing allows hinge joints to rust and seize, especially in humid environments.

- Inadequate fastening: Using low-strength screws or lacking anti-loosening measures (nylon washers, thread sealant) increases loosening under vibration or heavy loads.

- Lack of maintenance plan: Irregular tightening and lubrication leads to bolt loosening, pin wear, poor operation, and reduced lifespan.

Step-by-Step Selection Checklist for Quick Decisions

- Define load requirements: Determine load rating based on door weight and opening frequency.

- Base material and construction conditions: Confirm door frame material and on-site welding feasibility. Consider Weld-on hinges for weldable metal frames; choose bolted hinges for wood or non-weldable surfaces.

- Environmental assessment: Select materials and protection based on corrosion level. Prioritize 316 stainless steel for marine environments.

- Maintenance and adjustability needs: Choose bolted hinges for frequent disassembly or adjustments; opt for Weld-on hinges for long-term maintenance-free operation.

- Cost calculation: Compare material, processing, labor, and long-term maintenance expenses; conduct economic evaluation by weighing hinge price, labor hours, and future repairs.

- Prototype Testing: Conduct small-batch trial installations to measure load-bearing capacity and adjustment effectiveness; validate solutions through load and endurance opening/closing tests.

Clear Conclusions: When to Choose Welded vs. Bolted

A decision flowchart showing how to pick between weld-on and bolt-on hinges based on load, maintenance needs, and environment.

One-Sentence Decision: Select Weld-on hinges when extremely high load-bearing is required and welding is feasible during installation; choose bolted hinges when flexible adjustments, frequent maintenance, or installation constraints are present.

Select Weld-on hinges:

Suitable for heavy-duty loads, high-security, and concealed installations, such as steel gates, armored doors, and high-security facilities.

Select bolted hinges:

Suitable for applications requiring future adjustments/maintenance or substrates unsuitable for welding, such as wooden doors, equipment access panels, and demountable structures; also ideal for rapid installation or projects with potential future replacements.

FAQ

Can Weld-on hinges be used outdoors? How to prevent rust?

Yes. Select 316L stainless steel or hot-dip galvanizing, and apply post-weld protection (cold zinc spray, epoxy paint, hot-dip galvanizing). Remove weld slag, grind the surface smooth, and apply rust-proof coating to prevent weld oxidation. Regular inspection and reapplication of rust inhibitors extend service life.

How to estimate the maximum load capacity of bolt-mounted hinges?

Refer to the product manual or rated capacity. For example, a single hinge rated for 500 kg can theoretically support about 1000 kg when using two hinges. Actual calculations should include a safety factor. Ensure the bolt grade matches the substrate strength; for doors weighing 500 kg, use at least two hinges rated for 250 kg or more and select high-grade bolts.

What distinguishes adjustable hinges from standard hinges?

Adjustable hinges feature built-in adjustment bolts, allowing post-installation fine-tuning of door panel alignment (horizontal or vertical). Standard hinges lack internal adjustment mechanisms, requiring shims or repositioning for correction.

How to quickly correct sagging doors?

First, tighten all bolts. Then, address the specific issue:

- For bolt-on hinges: Add or replace the shims with higher-strength versions to enhance support points.

- For Weld-on hinges: Weld a reinforcement plate beneath the top hinge or install height-adjustment plates to restore levelness.

- For excessively tall doors: Install a third hinge to better distribute the weight.

Keep in mind that some hinges feature their own height-adjustment screws for quick corrections.

Is 316 stainless steel worth the premium cost near the coast?

Yes. Coastal salt spray corrosion is severe, and 316L significantly extends service life. Though 20–30% more expensive than 304 or carbon steel, it reduces replacement and maintenance costs, making it more economical long-term.

Does painting after welding affect hinge performance?

No. Proper painting or galvanizing enhances corrosion resistance. Ensure clearance around pivot pins to prevent paint film jamming; apply grease before and after installation for smooth operation. Use high-quality rust-proof paint with multiple thin coats and thorough drying for optimal results.

Conclusion

Selection must balance application, load capacity, and installation feasibility: prioritize Weld-on hinges for heavy-duty, high-security environments; choose bolted hinges when adjustability and maintenance ease are required. We recommend evaluating each item against the checklist above and confirming material and specifications with suppliers. Precise selection reduces future risks while enhancing durability and cost-effectiveness. Correct hinge selection is the foundation for long-term reliable operation of doors, windows, or equipment. Download the hinge selection checklist or contact technical support for further guidance and assistance.