The Science of Smoothness: A Guide to Friction Hinge Haptics & Mechanics

Designers want sleek aesthetics. Engineers demand constant torque. To bridge this gap, the friction hinge is the critical solution. It delivers reliable, infinite positioning control without compromising the product’s clean visual lines

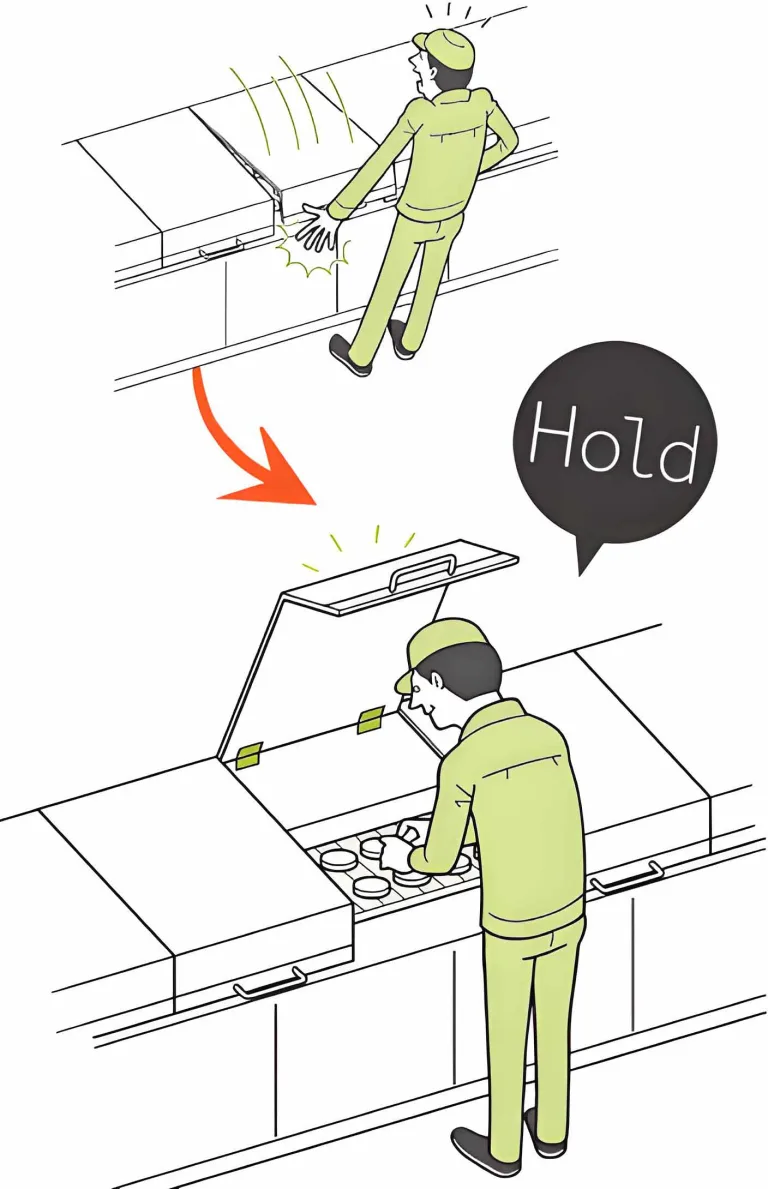

- The Engineers ask: “Does the hinge hold the weight? Does it pass the drop test?”

- The Designers ask: “Why does it feel ‘cheap’ when I open it?”

This disconnect highlights a critical nuance in hardware design: Engineering is about “Holding,” but Design is about “Moving.”

While you must ensure the hinge supports the load (if you haven’t calculated that yet, please refer to our [Torque Calculation Guide] to ensure the hinge holds the weight), the “feel” of that movement is often what sells the product.

Market observations suggest that the haptic quality of user interaction—much like the damped resistance of a premium audio volume knob—subconsciously signals robustness and reliability to the user. A screen that lifts with a consistent, velvet-like resistance conveys “precision engineering,” while a screen that jerks or rattles conveys “low cost.”

💡 Executive Summary for Buyers:

- Premium Feel = Brand Value: Users judge the quality of your entire device by the first touch. A smooth hinge justifies a higher price point.

- Risk of Going Cheap: Poorly designed friction mechanisms degrade quickly, leading to “floppy” screens and damaged brand reputation within months.

The Enemy of Smoothness: Understanding “Stiction”

If you have ever tried to open a laptop and the base lifted up off the desk before the screen moved, or if you felt a sudden “snap” when adjusting a monitor, you have encountered Stiction.

Defining the Physics

Stiction is a portmanteau of “Static Friction.” In the world of hinges, we must distinguish between two forces:

- Static Torque (Breakaway Torque): The force required to start the movement.

- Dynamic Torque (Running Torque): The resistance felt during the movement.

The “Stick-Slip” Phenomenon

In a poorly designed system, the static torque is significantly higher than the dynamic torque.

This creates a “Stick-Slip” phenomenon. The user applies force, nothing happens (Stick), and then suddenly the bond breaks and the device accelerates too fast (Slip). This results in a jerky, uncontrolled tactile experience that feels unrefined.

The Golden Ratio (Torque Ratio)

For high-end applications, such as medical displays or premium tablets, we strive for a Torque Ratio as close to 1:1 as possible.

Ideally, the difference between static and dynamic torque should not exceed 10%–15%. When these two values are nearly identical, the user experiences a “Velvet Feel”—motion that starts instantly and smoothly without an initial jolt. This consistency is the hallmark of advanced friction engineering.

Anatomy of Friction: Three Core Mechanisms Explained

Not all friction is created equal. The internal architecture of the hinge dictates the quality of the motion. Below, we dissect the three most common industrial solutions.

💡 Executive Summary for Buyers:

- Wrap-Around/Clip: Best for laptops and high-consistency needs. Medium cost, low risk.

- Disc Stack: Best for heavy monitors. High cost, extremely durable.

- Interference Fit (Knuckle): Lowest cost. High risk of wearing out quickly. Avoid for premium products.

The Wrap-Around Clip (The Smooth Operator)

The Mechanism:

Also known as the “Curl Structure,” this design features a spring steel band (C-clip) that is stamped and wrapped tightly around a central shaft.

Why Designers Love It:

- Velvet Consistency: Because the clip wraps 360 degrees around the shaft, it maintains a large, constant contact area. This physical characteristic inherently reduces the stick-slip effect.

- Self-Cleaning: The wrapping action has a mild self-cleaning effect on the shaft, making it more resistant to dust ingress compared to disk stacks.

- High Consistency: This structure offers excellent batch-to-batch torque consistency, which is why it is the standard for laptops.

Best For: Laptops, Convertibles, Handheld Medical Terminals.

The Axial Disc Stack (The Heavy Lifter)

The Mechanism:

Think of this as a miniature automotive clutch. It consists of alternating layers of fixed friction plates and rotating plates, compressed axially by a Belleville washer (spring washer).

Tactile Character:

- High Torque Density: By stacking more plates, we can generate immense torque in a small diameter.

- Solid Feel: It provides a very “solid” holding force. However, because it relies on high axial pressure, it is more prone to high static friction if the lubrication is not perfectly calibrated.

- Adjustability: This structure often allows for a tightening nut, making it an “Adjustable Torque Hinge“.

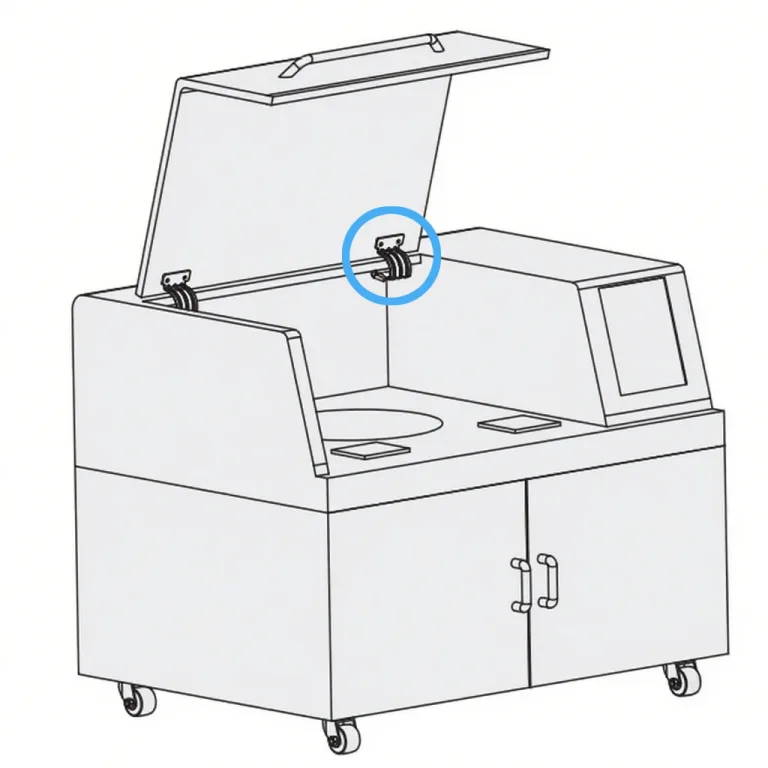

Best For: Heavy Industrial Monitors, Medical Support Arms, Heavy-Duty Machinery Access Panels.

Interference Fit / Knuckle Friction (The Budget Choice)

The Mechanism:

This is the simplest form, often called a “Sleeve-type” friction hinge. It relies on a shaft being press-fitted into a plastic or metal tube (knuckle) with a tight interference fit.

The Trade-off:

- Inconsistent Wear: While cost-effective, the friction relies heavily on the elasticity of the outer tube. As the material relaxes (creep) or wears, torque decays rapidly.

- Poor Haptics: It often suffers from uneven resistance throughout the rotation range.

Best For: Toys, Simple Access Hatches, Cost-sensitive applications where “feel” is secondary.

Material Science: The “Secret Sauce” of Feel

Even with the right mechanism, using the wrong materials will ruin the user experience.

💡 Executive Summary for Buyers:

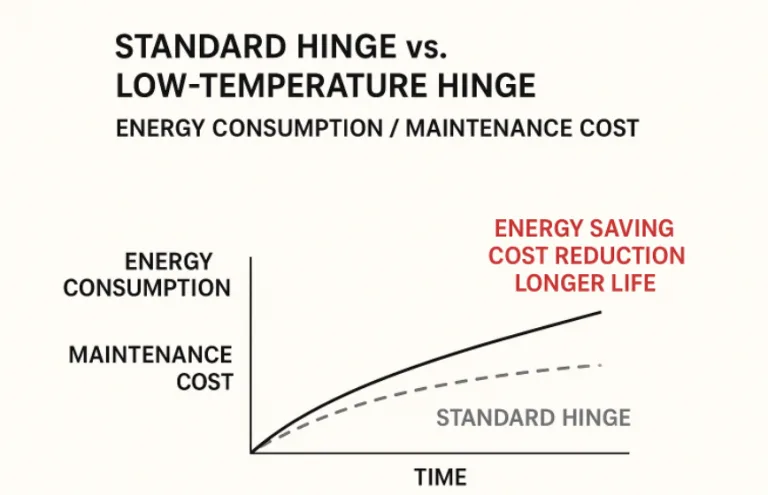

- Grease Matters: Standard oil freezes in winter. Ensure your supplier uses Synthetic Grease to prevent cracked housings in cold markets.

- Rust = Seizure: For outdoor use, specify 316 Stainless Steel. 304 Steel may look fine outside but seize inside.

Grease Rheology (Viscous Damping)

Grease in a friction hinge is not just for lubrication; it is a functional component that creates Viscous Damping.

- The Damper Effect: High-viscosity grease fills the microscopic imperfections in the metal, creating a fluid drag that smooths out the transition between static and dynamic friction.

- The Cold Start Problem: Standard mineral oils thicken in cold temperatures. At -20°C, a standard hinge might require 300% more force to open, potentially causing plastic housings to crack.

- The Solution: For outdoor or premium devices, specify Synthetic Fluorinated Grease or Synthetic Hydrocarbon based lubricants. They maintain stable viscosity from -40°C to +80°C.

Metal Pairing (Avoid Galling)

In the world of Tribology, “Like hates Like.”

- The Galling Risk: If you pair a stainless steel shaft with a stainless steel clip, under high pressure, they will undergo “Cold Welding” (Galling). This destroys the smooth surface and leads to seizure.

- The Ideal Pair: We recommend a Hardened Steel Shaft (HRC 45+) paired with a Phosphor Bronze or Spring Steel Clip. This “Hard + Soft” combination ensures that the clip wears predictably without damaging the shaft.

Design Integration: Preserving the Feel in Your Housing

You can select the perfect hinge, but poor integration can destroy the tactile experience.

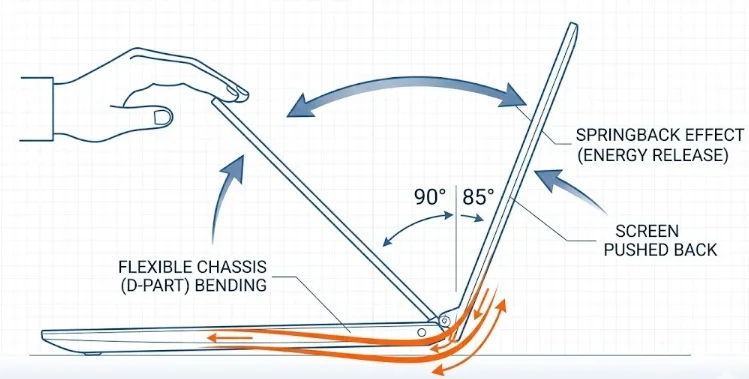

Rigidity Matters: The “Springback” Effect

One of the most common complaints I receive is “Springback”—where the user sets the screen at 90°, and it bounces back to 85°.

This is rarely the hinge’s fault. It is usually the housing flexing.

If your plastic chassis is too soft, it twists as you open the device. When you let go, the plastic releases that stored energy, forcing the hinge back.

- Advice: If using a high-torque hinge (>0.5 Nm), ensure the mounting area is reinforced with ribs or a metal backing plate.

Tolerance Stack-up

Misalignment is the silent killer of smoothness.

If two hinges are not perfectly coaxial (aligned), they fight each other. This creates internal binding forces that skyrocket the friction and create a “grinding” feel.

- Advice: Use installation jigs to align the axes before tightening screws. Refer to our guide on [Torque Hinge Installation & Alignment] for detailed protocols.

Selection Matrix: Matching Mechanism to User Intent

Use this decision matrix to align the mechanical choice with your UX goals and budget.

| Feature | Wrap-Around Clip | Axial Disc Stack | Interference Fit |

| Smoothness (Haptics) | ⭐⭐⭐⭐⭐ (Best) | ⭐⭐⭐⭐ | ⭐⭐ |

| Load Capacity | Medium (0.3 – 1.5 Nm) | High (2.0 – 10.0 Nm) | Low (<0.5 Nm) |

| Tactile Consistency | High (Consistent) | High (Solid) | Low (Variable) |

| Dust Resistance | High (Self-Cleaning) | Medium (Needs Sealing) | Low |

| Initial Cost | Medium | High | Low |

| Quality Risk (Long Term) | Low | Low | High (Loosens quickly) |

Conclusion: Engineering the Perfect Touch

A friction hinge is more than a fastener; it is the first physical handshake between your user and your product.

A jerky, stiff, or loose hinge signals poor quality before the device is even turned on. By selecting the right mechanism (Wrap-around vs. Disc), specifying the correct grease rheology, and ensuring structural rigidity, you can elevate the perceived value of your entire product line.

Next Steps for Your Design:

- Unsure which mechanism fits your UX goals? Request a [Sample Kit] to physically feel the difference between Wrap-around and Disc technologies.

- Need to verify load capacity? Once you have determined the desired friction feel, you must verify the load capacity using our [Torque Calculation Formula] to ensure safety.

FAQ for Procurement Managers

Q: Why is the Wrap-Around or Disc hinge more expensive than the “Interference Fit” option?

A: The “Interference Fit” is basically just a tube squeezed onto a shaft. It relies on the material deforming, which means it wears out very fast. You are paying more for Wrap-Around/Disc types to get consistent torque that lasts 20,000+ cycles, reducing your long-term warranty and replacement costs (TCO).

Q: How do I Quality Control (QC) “Smoothness” in a shipment?

A: Don’t just rely on “feeling it.” Require your supplier to provide a Torque Ratio report. Demand that the difference between Static Torque (start) and Dynamic Torque (run) is less than 15%. If the ratio is high (e.g., 30%), reject the batch.

Q: Can we use standard SS304 hinges for our outdoor/marine device?

A: Be careful. While the housing won’t rust, the internal mechanism might seize if it’s not designed correctly. For marine/outdoor use, we strongly recommend SS316 or a sealed internal mechanism to prevent “tea-staining” and seizure.