Adjustable Torque Hinges vs. Standard Hinges: Key Pros, Cons, and Cost Comparison

Introduction: Why Hinge Selection is Critical

Hinge selection is a critical design decision affecting performance, safety, user experience, and total cost of ownership (TCO). While small, the wrong hinge choice leads to serious consequences:

- Performance: Lids failing to stay in position.

- Safety: Heavy lids slamming shut, causing injury or equipment damage.

- Experience: Loose lids creating noise and vibration, conveying a “cheap feel.”

- Cost: Downtime and repairs far exceeding the hinge’s initial price.

This article compares standard hinges and adjustable torque hinges, providing a clear guide for engineers, designers, and purchasing managers based on pros, cons, cost analysis (BOM vs. TCO), and technical factors.

What is a Standard Hinge?

A standard hinge provides free rotation (usually 180° or 270°) around a fixed axis. Its sole function is connection and rotation, offering no motion control, damping, or position-holding capabilities. It typically consists of two leaves and a central pin.

It works on a “free motion” principle; any force (like gravity) will cause it to move freely until it hits a mechanical stop.

Common Types: Butt Hinges, Continuous (Piano) Hinges, and Concealed (Euro) Hinges.

Typical Applications: Residential doors, furniture, and lightweight boxes where there is no safety risk, no need for position holding, and cost is the primary driver.

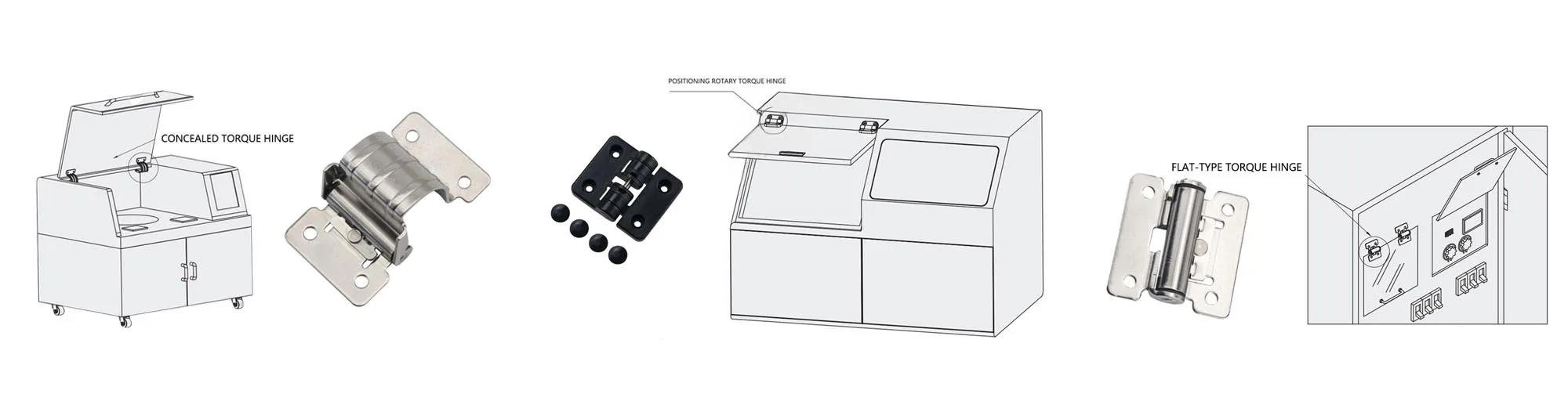

In-Depth Introduction: What is an Adjustable Torque Hinge?

An adjustable torque hinge provides constant, user-adjustable resistance (torque) during rotation. This resistance, created by internal friction plates and spring mechanisms, controls motion and balances forces like gravity.

Its key functions are:

- Position Holding: Allows a lid or panel to hold stable at any angle without drifting or sagging.

- Motion Control: Provides smooth, damped opening and closing, preventing slamming and enhancing safety.

The “adjustable” feature is a key engineering advantage. It allows users to fine-tune the torque in the field (typically with a screw) to compensate for different loads (e.g., added accessories) or natural wear, greatly extending the product’s safe service life.

Analysis of Standard Hinge Advantages and Disadvantages

Advantages of Standard Hinges

- Extremely Low Procurement Cost (BOM): Its most significant advantage.

- Structural Simplicity: Simple (leaves + pin), mature production, and simple failure modes (wear, corrosion).

- Easy Installation: Requires simple screw fastening with no calibration.

- Broad Versatility: Highly standardized dimensions make replacement easy.

Disadvantages of Standard Hinges

- Singular Function: No position control or damping.

- Potential Safety Hazards: Heavy vertical lids can slam shut, posing a significant risk of injury or damage.

- Poor User Experience: Lids can swing freely, rattle in vibrating environments, or require a separate prop rod.

- Increased Design Complexity: Forces designers to add extra components (gas springs, struts, latches) to achieve position holding, which increases BOM cost and adds failure points.

Analysis of Adjustable Torque Hinge Advantages and Disadvantages

Advantages of Adjustable Torque Hinges

- Precise Position Control: Its core value. Allows lids to hold at any angle, critical for medical displays or hands-free access panels.

- Significantly Improved Product Safety: Controlled motion prevents lids from slamming shut, crucial for OSHA compliance and operator safety.

- Superior User Experience: Provides a smooth, quiet, “high-quality feel” (Haptics) essential for premium products.

- Design Flexibility: The “adjustable” feature allows for fine-tuning torque late in the design phase or by the end-user.

- Integrated Design (System Cost Advantage): Replaces the complex “standard hinge + gas spring” combo. This simplifies the structure, reduces part count (SKU), and lowers installation complexity.

Disadvantages of Adjustable Torque Hinges

- Significantly Higher Procurement Cost: The initial BOM price is much higher due to complex mechanisms and materials.

- More Complex Internal Structure: More moving parts can mean more complex failure modes in extreme environments (dust, vibration).

- Installation Requires More Expertise: Requires calibration (sometimes with a torque wrench) to correctly balance the load.

- Greater Size and Weight: May be bulkier than standard hinges to accommodate the friction mechanism.

Core Comparison: Cost Analysis of Standard vs. Adjustable Torque Hinges

Standard hinges win on initial procurement cost (BOM), but adjustable torque hinges have an overwhelming advantage in total cost of ownership (TCO).

Purchasing and engineering must avoid the “BOM trap.”

Scenario A: Standard Hinge ($1) + Gas Spring ($15) + Bracket ($3) = $19

Scenario B: Adjustable Torque Hinge = $20

A BOM-based decision favors Scenario A. But TCO analysis reverses this conclusion.

Initial Procurement Cost (BOM Cost)

Torque hinges are more expensive due to:

- Materials: High-performance plastics, hardened steel friction plates, specialty damping grease.

- Processing: Precision machining, complex assembly, and 100% torque calibration.

- R&D Costs: Significant investment in friction and material science.

Installation and Commissioning Costs

- Standard Hinge: Low labor cost, no commissioning.

- Adjustable Torque Hinge: Higher labor cost; requires time for torque adjustment and calibration.

Long-Term Maintenance and Total Cost of Ownership (TCO) Analysis

$TCO = \text{Initial Cost} + \text{Operating Cost} + \text{Maintenance Cost} + \text{Risk Cost}$

- Standard Hinge TCO:

- High Maintenance: Gas springs (if used) will fail due to seal leaks, requiring replacement every 1-3 years.

- High Indirect Costs: Damage to the machine (frames, screens) from slamming lids.

- High Risk Costs: Downtime and potential liability from safety accidents.

- Adjustable Torque Hinge TCO:

- Extremely Low Maintenance: Durable purely mechanical structure with no gas or liquid to leak.

- Extended Machine Life: Smooth, controlled motion eliminates slamming and impact damage.

- Reduced Risk Costs: Fundamentally eliminates the safety hazard of falling lids.

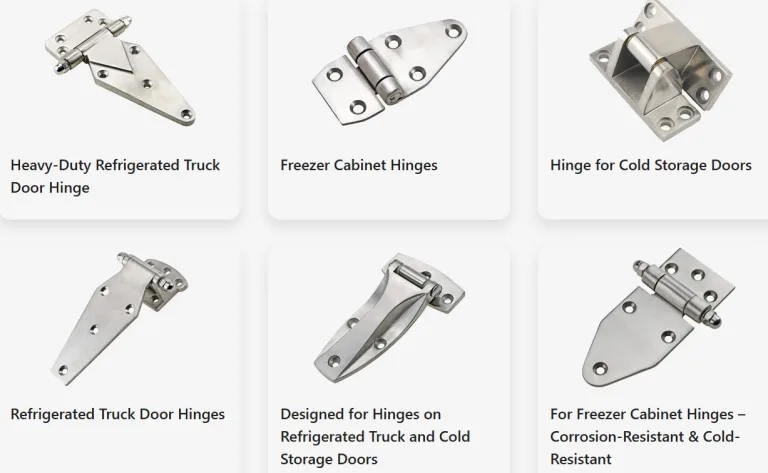

In harsh environments (marine, medical), corrosion resistance is also key. A cheap standard hinge that rusts and fails has an extremely high TCO due to frequent replacement.

Table 1: 5-Year Total Cost of Ownership (TCO) Comparison Estimate

| Cost Factor | Scenario A: Standard Hinge + Gas Spring | Scenario B: Adjustable Torque Hinge | Notes |

| Initial Procurement Cost (BOM) | $19 (Hinge $1 + Gas Spring $15 + Bracket $3) | $20 | Scenario B’s initial BOM is slightly higher. |

| Installation & Commissioning Labor Cost | $8 (Install 3 components) | $3 (Install 1 component & commission) | Scenario B reduces assembly time. |

| 5-Year Maintenance Cost | $38 (Replace gas spring 2x) | $0 | Scenario A has predictable maintenance costs. |

| 5-Year Expected Risk/Damage Cost | $10 (Estimate) | $1 | Scenario B greatly reduces impact damage. |

| 5-Year Total Cost of Ownership (TCO) | $75 | $24 | Conclusion: Scenario B’s long-term TCO is significantly lower. |

Key Application Scenario Comparison (Case Studies)

Industrial Machinery

- Standard: Lightweight electrical cabinet doors.

- Torque: Heavy safety guards, CNC machine windows.

- Problem Solved: Prevents heavy guards from slamming, allows “hold at any angle” for safe worker maintenance.

Medical Equipment

- Standard: Lightweight storage cart doors.

- Torque: Medical display arms, surgical lights, analytical instrument covers.

- Problem Solved: Enables precise positioning with no drift, smooth/quiet motion, and easy-to-clean sealed designs.

Electronics and High-End Appliances

- Standard: Low-cost printer covers.

- Torque: Laptop hinges, high-end oven doors, all-in-one computer tilts.

- Problem Solved: Provides a “premium feel” (haptics) and controlled motion for safety (oven) and brand value (laptop).

Transportation (Automotive, Aerospace)

- Standard: Simple glove boxes.

- Torque: Center console lids, overhead displays, aircraft overhead bins.

- Problem Solved: Resists vibration, prevents rattling and “nodding” of screens or lids in a mobile environment.

How to Choose the Right Hinge for Your Project?

The decision must be based on a quantitative assessment of application needs, not just BOM cost.

Key Factors to Evaluate

- Load: Weight, size, and center of gravity of the lid (to calculate torque).

- Motion: Is position holding required?

- Frequency: How often will it be used?

- Safety: Is there a risk of injury or damage from slamming?

- User Experience: Is a “premium feel” a key selling point?

- Environment: High/low temps, vibration, corrosion, or cleaning requirements?

- Budget: What is the weighting of BOM vs. TCO?

Table 2: Hinge Selection Decision Matrix

| Decision Factor | Scenario A: Standard Hinge | Scenario B: Standard Hinge + Gas Spring | Scenario C: Adjustable Torque Hinge |

| Initial BOM Cost | Very Low | High | High |

| Long-Term TCO | High (High risk/damage) | Very High (High maintenance) | Low |

| Position Holding (Stay-put) | None | Yes (But only fully open) | Excellent (Any angle) |

| Motion Control (Damping) | None | Yes | Excellent (Smooth) |

| Safety (Anti-slam) | Very Poor | Medium (Gas spring can fail) | Excellent (Mechanically reliable) |

| Installation Complexity | Low | High (3+ components) | Medium (1 component + commissioning) |

| Structural Reliability | High | Poor (Seals prone to failure) | Excellent (Purely mechanical) |

| User Experience | Poor | Medium | Excellent |

Durability Cycles vs. Torque Decay

This is a critical selection pitfall.

- Standard Hinge Durability: Tested for mechanical failure (e.g., millions of cycles). It asks: “Did it break?”

- Torque Hinge Durability: Tested for performance decay (e.g., 25,000 cycles). It asks: “Does the torque still hold within specification?”

A torque hinge’s true durability is its “torque retention.” A hinge that claims 1 million cycles but loses 50% of its torque after 1,000 cycles is useless. Always ask suppliers for the “Torque-Life-Decay Curve,” not just a single cycle count number.

Conclusion: Balancing Function, Cost, and Long-Term Value

The core difference is simple: standard hinges provide basic connection, while adjustable torque hinges provide controlled motion and position holding.

There is no “best” hinge, only the “most suitable” choice. The decision must be based on a comprehensive evaluation of application needs (safety, function) and the complete cost (initial procurement BOM + long-term TCO).