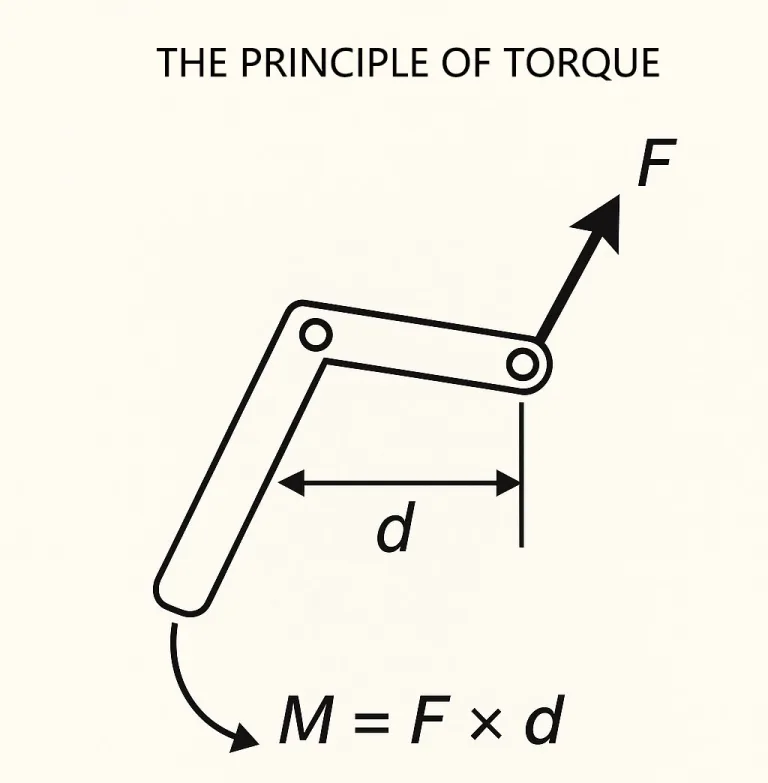

Cold Chain Hinges: Why Low-Temperature Hinges Are Essential for Cold Storage Efficiency

Cold Chain Supply Chain Process Flow Diagram

The Critical Role of the Cold Chain

In today’s world, many everyday items rely on continuous refrigeration. Fresh food, meat, and dairy products must be kept cold at every step of the supply chain (FAO). Otherwise, they spoil, threatening consumer health.

Similarly, crucial pharmaceuticals and vaccines require strict temperature control (CDC). As demonstrated by COVID-19 vaccine distribution, even a brief temperature rise can ruin an entire batch. In short, the cold chain is vital for food safety, public health, and business operations.

Distribution centers and cold storage warehouses are the hubs of this network. Their operations must be stable and reliable. However, a frequently overlooked component—the seemingly ordinary door hinge—plays a key role.

The Hidden Complexity of Cold Storage Doors

Heavy Cold Storage Door with Close-Up of Door Hinge

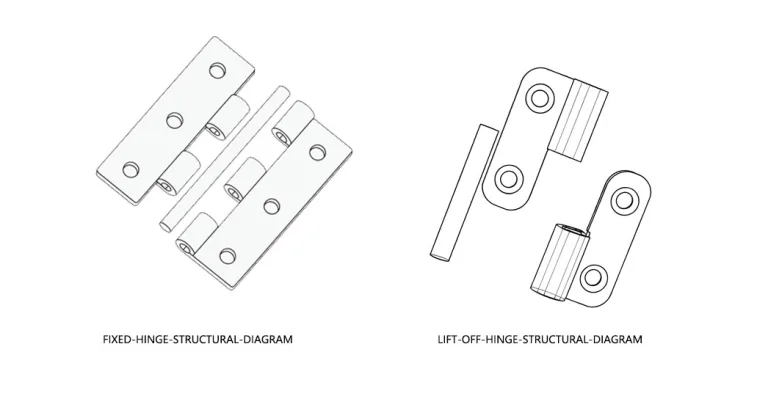

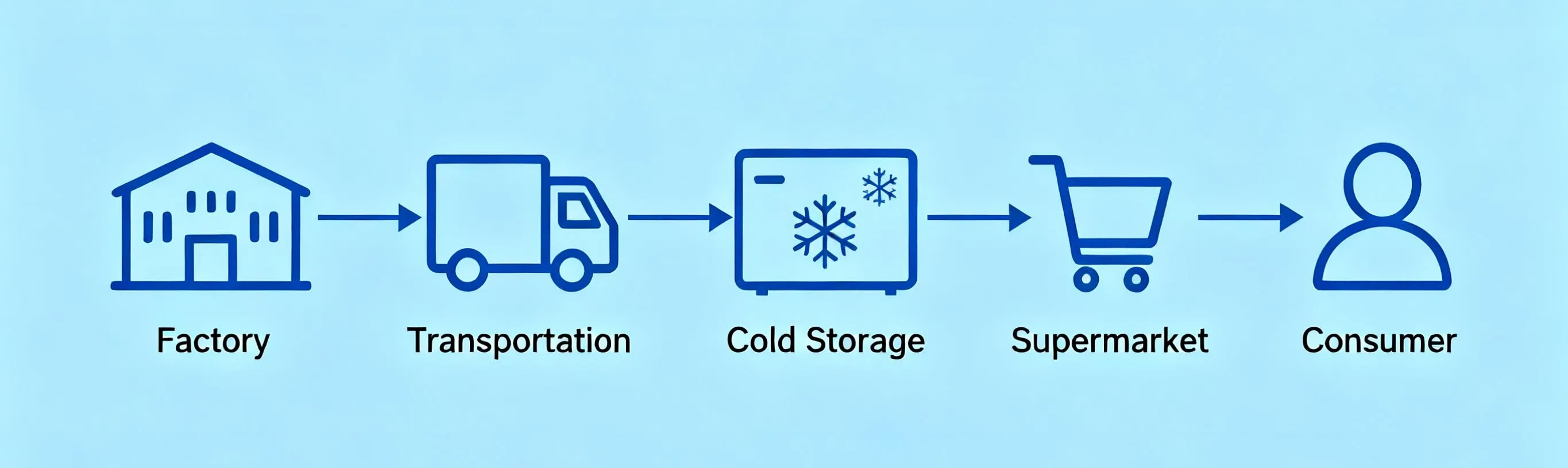

A refrigerator or freezer door might seem simple. But at -20°C or lower, hidden challenges emerge. Cold storage hinges must:

- Support heavy insulated doors

- Rotate smoothly under load

- Help form a tight seal

Ignoring these requirements can have serious consequences. Therefore, choosing the right low-temperature hinge is not just necessary. It’s a critical decision for the safety, efficiency, and energy savings of the entire cold chain system.

Distribution Centers: The Hubs of the Cold Chain

Cold Storage Interior with Forklift Moving Pallets and Frequent Door Operations

Large refrigerated warehouses are the sorting, storage, and distribution centers for perishable products (Global Cold Chain Alliance). Inside these facilities, forklifts and pallets are constantly moving. Doors can be opened and closed dozens of times per hour.

A stuck or slow-opening door can become a bottleneck for an entire shift. These centers often include cooler areas (just above freezing) and deep-freeze areas (-20°C or lower).

Hinges Face Extreme Conditions

Freezer hinges must operate under:

- Temperature range: -18°C to -60°C

- Humidity: Over 90%

- Usage: Dozens of cycles per hour

These requirements align with international cold storage standards (ISO 1496-2, ASTM)

Each hinge must fulfill:

- Low-temperature endurance

- Anti-ice & anti-corrosion performance

- Precise positioning

The High Cost of Ignoring Hinges

Overlooking this small component can lead to major failures. Engineers emphasize that hinge performance is key to cold chain efficiency and safety. Investing in specialized low-temperature hinges is therefore a strategic decision, not a minor detail.

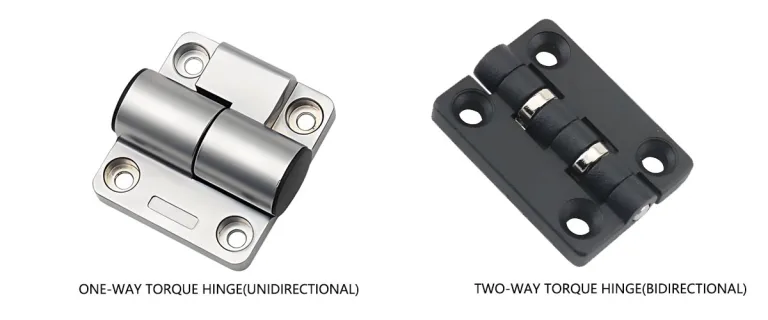

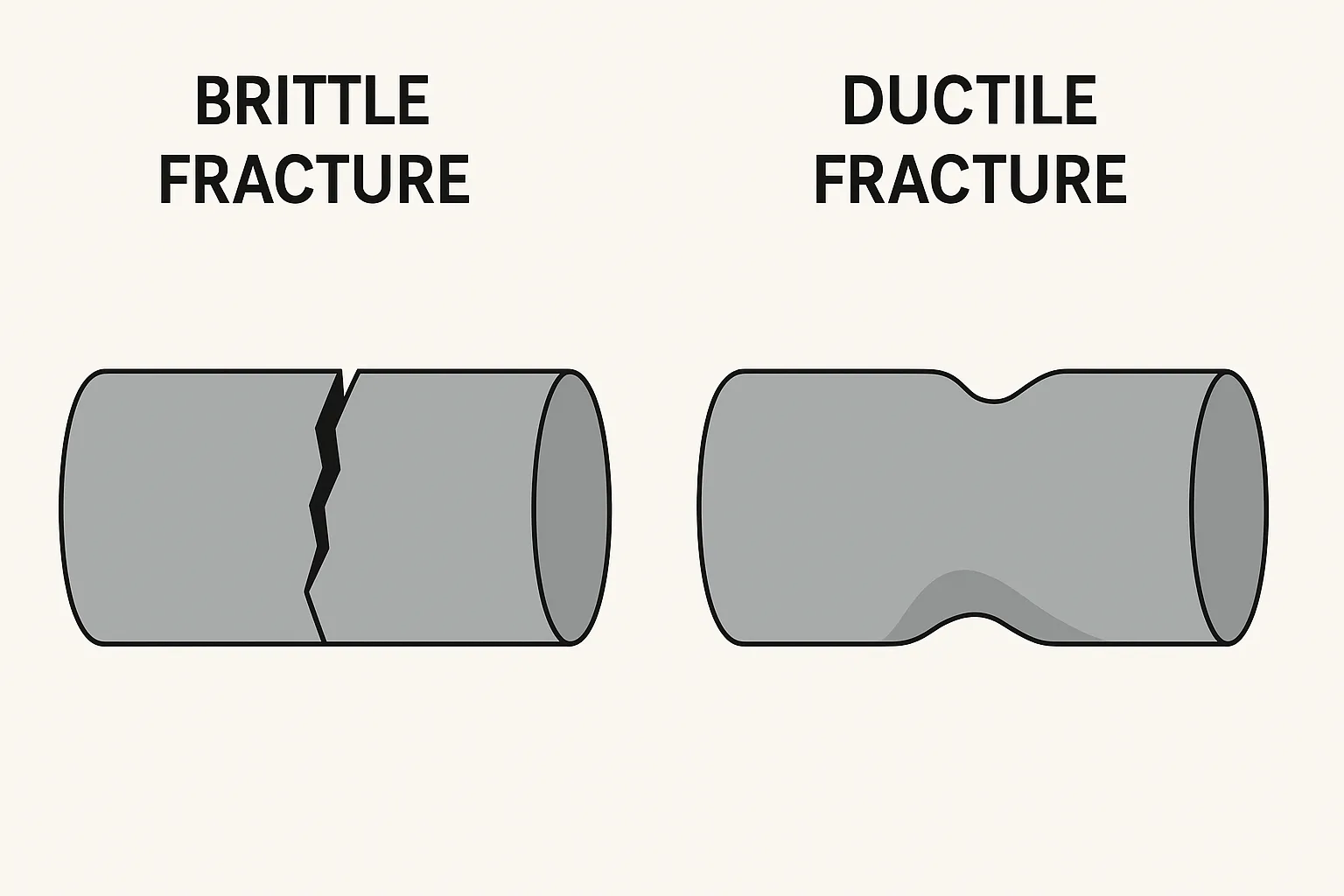

Why Metal Becomes Brittle in the Cold

Brittle vs. Ductile Fracture

Ordinary hinge steel becomes more prone to embrittlement in extreme cold. When temperatures drop below the steel’s ductile-to-brittle transition point, its strength might increase slightly, but its ability to bend without shattering disappears.

Low-grade carbon steel (like “Grade 2” fasteners) is especially susceptible to brittle fracture in cold storage. By contrast, 304 stainless steel retains good toughness at low temperatures and remains ductile even at −20 °C, making it far more reliable for cold storage applications.

Special Alloys Prevent Catastrophic Failure

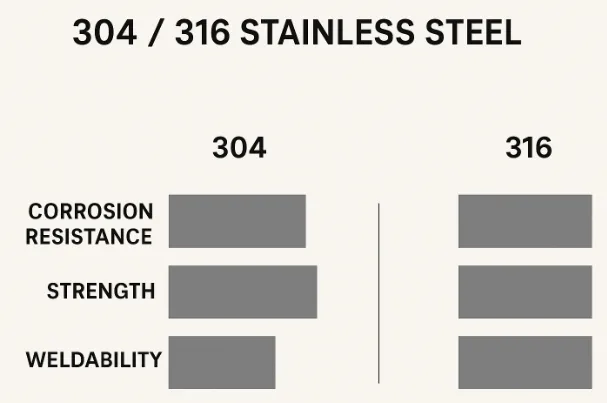

304 vs. 316 Stainless Steel Properties

Comparison of common vs. specialized materials:

| Material | Performance at Low Temp | Notes |

|---|---|---|

| Low-grade carbon steel | Very brittle below −20 °C | Susceptible to ductile–brittle transition, fracture risk increases. |

| 304 stainless steel | Maintains good toughness down to cryogenic temps | Strength increases as temperature decreases; still ductile at −20 °C. |

| 316 stainless steel | Excellent toughness even below −40 °C | Also offers ~50% better chloride corrosion resistance than 304. |

| Titanium pins | High strength and toughness at cryogenic temps | Suitable for hinges used at −60 °C and below. |

The Domino Effect of Fatigue

After thousands of cycles, these cracks can connect, leading to hinge failure. A damaged hinge can cause the door to jam or sag, rendering the cold room unusable. This results in product loss, financial damage, and even safety incidents.

Specialized cold storage alloys maintain toughness and ductility at low temperatures, preventing fatigue fracture. Simply put, only hinges made from proven low-temperature steels or alloys can withstand the daily rigors of a freezer.

Lubricant Freezing Increases Friction

Common lubricants can solidify in sub-zero environments. Standard mineral oils and greases may gel or solidify below their pour point, hindering flow. At low temperatures, paraffin in oils can crystallize, and grease can become hard like rubber.

The Real-World Impact of Frozen Grease

Consequences when standard grease is used in -20°C freezers:

- Hinges may seize completely

- Doors become excessively difficult to open (risk of injury)

- Thickened grease no longer separates metal surfaces

- Friction and wear increase drastically

The Solution: Specialty Low-Temp Lubricants

Examples of suitable lubricants:

- Silicone-based greases: Pour point < -60°C, remain fluid, water-repellent

- PFPE oils: Stay fluid at -60°C

- Dry films (PTFE, MoS₂): Lubrication without liquid oils

Frost Buildup: When Doors Freeze Shut

Condensing moisture in the air can freeze hinges solid (OSHA Cold Stress Guide). In cold storage environments, even small amounts of moisture will condense on cold surfaces, including hinges. Once liquid condenses and freezes, the hinge pin can become locked in place, making the door impossible to open or close.

Operational Delays and Safety Risks

Consequences of frozen hinges:

- Staff wasting time with heaters or blow dryers

- Workflow interruptions

- Safety hazards (doors slamming shut, pallets tipping)

Proactive Measures Are Key

Recommended measures:

- Heat door frames and seals to reduce frost

- Use heating and anti-frost systems for hinges

- Prevent condensation as a first priority

Specialized Design & Materials for Sub-Zero Hinges

Special Materials Prevent Brittle Fracture

Typical materials used:

- Austenitic stainless steel (304, 316, 316L)

- Titanium or nickel-steel pins (for -60°C use)

Advanced Composites for Smooth Operation

Features:

- PTFE or PTFE-graphite bushings

- Low thermal expansion plastics

- Corrosion-resistant coatings: epoxy primer, nickel, chrome, fluorocarbon

- Salt spray resistance: 1000+ hours

Advanced Lubrication Technology

Options:

- Dry film (PTFE, MoS₂) coatings

- Hybrid lubrication: solid + low-temp grease

- Service life: 12–18 months before re-lubrication

Precision Design and Sealing

Key design elements:

- PTFE thermal break strips: reduce surface conduction by 5–8°C

- Drainage channels: remove condensation

- Heating wires in hinge pins: ~0.5W auto-activation below 2°C

- Sealing materials: EPDM gaskets, ABS dust covers

- Corrosion protection: electrophoretic primer, passivation, fluorocarbon topcoat (>1000h salt spray)

The Advantages of Low-Temperature Hinges

The Advantages of Low-Temperature Hinges

Smooth Operation and Enhanced Safety

High-quality cold chain hinges make operations safer and more efficient:

- Reduce resistance for staff and forklifts

- Enable fast, tight-sealing doors

- May include soft-close, light springs, or gas struts

- Predictable door movement reduces pinching hazards and jams

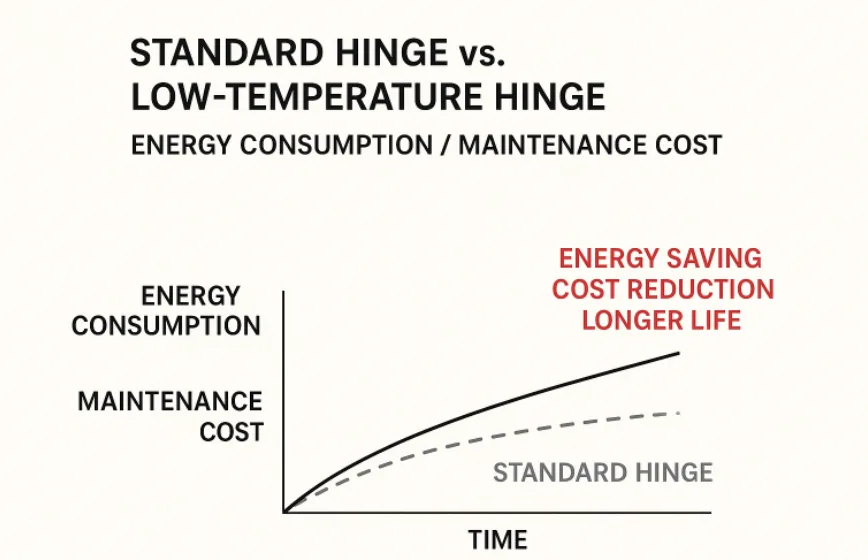

Energy Savings and Lower Operating Costs

- Studies (e.g., DOE energy reports) indicate that well-sealed, smoothly operating cold storage doors can reduce refrigeration losses significantly—potentially saving several kWh per unit per day depending on door size, insulation, and operating conditions

- Annual savings: Thousands of dollars

- Reduced maintenance and downtime lower overall costs

Extended Equipment Lifespan

- Hinges distribute weight evenly, preventing door sag and seal tearing

- High-quality hinges maintain alignment within a few millimeters

- Some include backup pins for extra safety

Selecting and Maintaining Low-Temperature Hinges

Key Selection Criteria

Checklist for hinge selection:

- Material certification: use austenitic stainless steel (304 or 316L minimum) with certified low-temperature impact toughness. For food-related applications, ensure materials also comply with FDA or equivalent food-contact safety regulations

- Load capacity: Match door weight/height (>3m doors need thicker steel or multiple hinges)

- Temperature rating: Verify hinge’s minimum operating temp

- Brand reliability: Review dimensions, specs, test reports

Routine Inspection and Lubrication

Maintenance cycle:

- Frequency: Every 6–12 months

- Tasks:

- Check looseness, corrosion, frost

- Tighten bolts

- Clean residues

- Apply silicone/synthetic grease

Looking to the Future

Cold storage hinges may seem like small components, but their impact on the entire cold chain is profound. The smooth operation of every refrigerator or freezer door is directly related to temperature control efficacy.

Specialized low-temperature hinges ensure doors function as intended, safeguarding food safety, worker safety, and operational efficiency. In the future, hinges may become smarter: integrating temperature sensors, IoT wear alerts, and new composite materials to reduce weight and thermal conduction.

At this stage, ensuring every hinge is built to withstand the cold is a wise practice for any cold chain operator.

In short, cold chain operators should remember: the reliability of the entire system may depend on these “tiny guardians.” With the right design and maintenance, the cold chain becomes safer, more efficient, and more sustainable.

Engineering Calculations and Testing Methods

While hinge selection and maintenance practices provide practical guidance, engineers and designers often require quantitative methods to validate performance. The following section outlines key engineering calculations and standardized testing methods relevant to low-temperature hinges:

Material Toughness Evaluation

- Method: Charpy V-notch impact test (ASTM E23) at sub-zero temperatures.

- Purpose: Measure absorbed impact energy (J) to confirm ductility retention at −20 °C, −40 °C, or below.

- Application: Compare 304 vs. 316 stainless steel and specialty alloys.

Fatigue Life Estimation

- Method: S–N curve (stress vs. number of cycles) or Goodman diagram for combined stress analysis.

- Formula: Nf=f(σaσult,R)N_f = f\left(\frac{\sigma_a}{\sigma_{ult}}, R\right)Nf=f(σultσa,R) where NfN_fNf = fatigue cycles to failure, σa\sigma_aσa = stress amplitude, σult\sigma_{ult}σult = ultimate tensile strength, RRR = load ratio.

- Application: Estimate hinge life under 20–50 door cycles/hour.

Thermal Load & Energy Loss

- Method: Heat leakage calculation through door seals.

- Formula: Q=U⋅A⋅ΔTQ = U \cdot A \cdot \Delta TQ=U⋅A⋅ΔT where QQQ = heat gain (W), UUU = overall heat transfer coefficient (W/m²·K), AAA = door area (m²), ΔT\Delta TΔT = temperature difference (K).

- Application: Quantify energy savings when hinges maintain proper sealing.

Lubricant Performance Testing

- Method:

- Pour point determination (ASTM D97).

- Low-temperature torque resistance (ASTM D1478).

- Purpose: Verify lubricant fluidity and low-friction behavior at −40 °C to −60 °C.

- Application: Select silicone-based greases, PFPE oils, or PTFE dry films for reliable hinge motion.

Corrosion Resistance Validation

- Method: Salt spray test (ASTM B117).

- Target: >1000 hours resistance for hinges in humid cold storage environments.

FAQ

Q:Why are cold storage hinges critical for the cold chain?

A:Cold storage hinges are vital for food safety and energy efficiency. They support heavy, insulated doors and maintain a tight seal. A failed hinge can lead to a loss of cold air, higher energy costs, and spoiled products, making them a crucial component for reliable cold chain operations.

Q:What happens to steel hinges at low temperatures?

A: At low temperatures, ordinary carbon steel becomes brittle and prone to fracture due to the ductile-to-brittle transition. In contrast, 304 stainless steel retains good toughness even at −20 °C and below, making it far more reliable for cold storage use. 316 stainless steel offers similar toughness with the added advantage of better chloride corrosion resistance, which is valuable in humid or salted environments. For ultra-low temperatures (below −60 °C), nickel-steel or titanium pins are recommended to ensure long-term reliability.

Q:Why do cold room doors freeze shut?

A:Cold room doors freeze shut because moisture condenses on the hinges and seals, then freezes solid. This can make the door impossible to open and poses a safety hazard. To prevent this, operators use heated hinge systems or anti-frost seals.

Q:What type of lubricants work best for freezer hinges?

A:Standard lubricants thicken or freeze in sub-zero conditions, causing hinge seizure. The best lubricants for freezer hinges are silicone-based greases or PFPE synthetic oils, which remain fluid at very low temperatures. Dry film coatings like PTFE also work well.

Q:How do I choose and maintain the best low-temperature hinges?

A:When choosing a hinge, consider its material (e.g., 316 stainless steel), load capacity, and temperature rating. For maintenance, inspect hinges every 6-12 months, tighten any loose bolts, remove any frost buildup, and apply an appropriate cold-temperature lubricant.