Lab Lid Slam: Safety Hazards & The Critical Role of Constant Torque Hinges

A common and dangerous hazard in laboratories occurs when instrument cabinet doors, oven covers, or fume hood sashes suddenly slam shut due to gravity or air pressure. This uncontrolled motion, stemming from the inability of traditional hinges to provide stable support, can be eliminated by Constant Torque Hinge technology. The abrupt closure risks pinching fingers, striking the body, knocking over nearby reagents and equipment, and triggering chain-reaction accidents. Beyond immediate injuries, the forceful impact damages hinges and equipment frames, leading to bent hinges, cracked covers, or loosened internal components in sensitive instruments. These incidents also increase operator stress and workload, reducing overall efficiency.

The root cause lies in traditional hinges (like standard butt hinges, spring hinges, and basic friction hinges) failing to provide stable support or controlled closing at any angle. To solve these persistent problems, labs urgently need the safe, reliable solution offered by the Constant Torque Hinge – which entirely eliminates the risk of cover rebound.

Why Traditional Hinges Fall Short

Standard Butt Hinges

These rely solely on gravity, offering no resistance or cushioning. Any slight shift in the cover’s center of gravity or lab airflow can cause the cover to suddenly drop or slam shut. They cannot hold a cover open at intermediate positions.

Spring Hinges

Use internal springs to automatically close the cover. While designed to “pull” doors shut, closing force is often unpredictable. Force spikes dramatically near the closed position, resulting in a loud, dangerous “SLAM!”. This violent impact easily pinches fingers and can cause cover rebound due to energy kickback. Spring hinges also fail to hold position at any angle – requiring constant hand support. Springs fatigue over time, leading to excessive force initially and insufficient force later, compromising safety and reliability.

Basic Friction Hinges

While friction allows some positional hold, the friction level is usually fixed or crudely adjustable. This design struggles to “precisely match” covers of varying weights and sizes. Too little friction lets heavy covers slide; too much friction makes lightweight covers hard to open/close. Furthermore, friction often changes during closing, still posing a risk of sudden slamming.

Summary

These traditional solutions perform poorly in safety, control, and adaptability. Unstable holding and violent closing speeds create inherent hazards for lab covers and doors.

How Constant Torque Hinges Work & Their Advantages

A Constant Torque Hinge is specially engineered to deliver near-constant rotational resistance (torque) throughout its entire opening/closing range. This enables positional stability at any angle and a smooth, controlled close.

Its core typically includes a precision shaft, friction materials, and a compression mechanism:

- The shaft is high-strength alloy

- Friction discs use engineered plastics, wear-resistant fibers, or composites

- Compression often involves spring washers (disc springs) or cam structures

These components work in concert to generate stable, controlled friction torque that counterbalances the cover’s gravitational torque.

The torque level is primarily determined by the hinge’s internal design and pre-load, not the cover’s angle (within its normal range). This means the hinge provides the same “holding force” regardless of how far the cover is open, achieving true positional stability at any point.

Operators can release the cover at any position from 0° to 135° (or more) without fear of it falling. Furthermore, during closing, the Constant Torque Hinge ensures a uniform, controlled speed: constant resistance absorbs kinetic energy as the cover descends. Instead of a jarring “SLAM!”, the cover closes gently and silently. This effectively dissipates inertia, eliminating rebound risk completely.

Many models offer adjustable torque via a screw or knob, allowing fine-tuning to perfectly match different cover weights, providing both flexibility and precision.

Using high-quality friction materials and robust construction, Constant Torque Hinges maintain stable torque output over tens of thousands of cycles with minimal degradation. This long-term reliability means lab equipment retains its original safety and user experience throughout its lifespan, without frequent hinge replacements or repairs.

Constant Torque Hinges: A Safety Essential for Labs

Prevent Pinching & Impact Injuries

Constant Torque Hinges prevent covers from falling unexpectedly, eliminating slam accidents. This protects both researchers and occasional lab visitors from pinched fingers or head impacts, significantly enhancing operational safety.

Protect Precision Instruments

Lab equipment often contains sensitive optical or electronic components vulnerable to shock. Constant Torque Hinges ensure covers close slowly, preventing violent impacts that damage equipment frames and internals. This avoids dented enclosures and prevents vibration-induced measurement drift or component loosening, reducing repair and recalibration costs long-term.

Boost Efficiency & User Experience

With Constant Torque Hinges, researchers work hands-free: covers stay securely open at any angle, freeing hands for sampling or instrument operation. Labs become quieter, eliminating jarring “SLAM!” noises. The consistent, effortless feel makes daily tasks smoother and significantly improves user satisfaction.

Enhance Equipment Quality & Value

Instruments featuring premium Constant Torque Hinges project quality and attention to detail. They demonstrate the manufacturer’s commitment to safety and refinement, representing high-standard modern lab design. This reduces repair/replacement costs due to hinge failure, ensuring sustainable and economical lab operation.

These advantages make the Constant Torque Hinge not just a lab safety essential, but a necessary choice for enhancing work quality and equipment reliability.

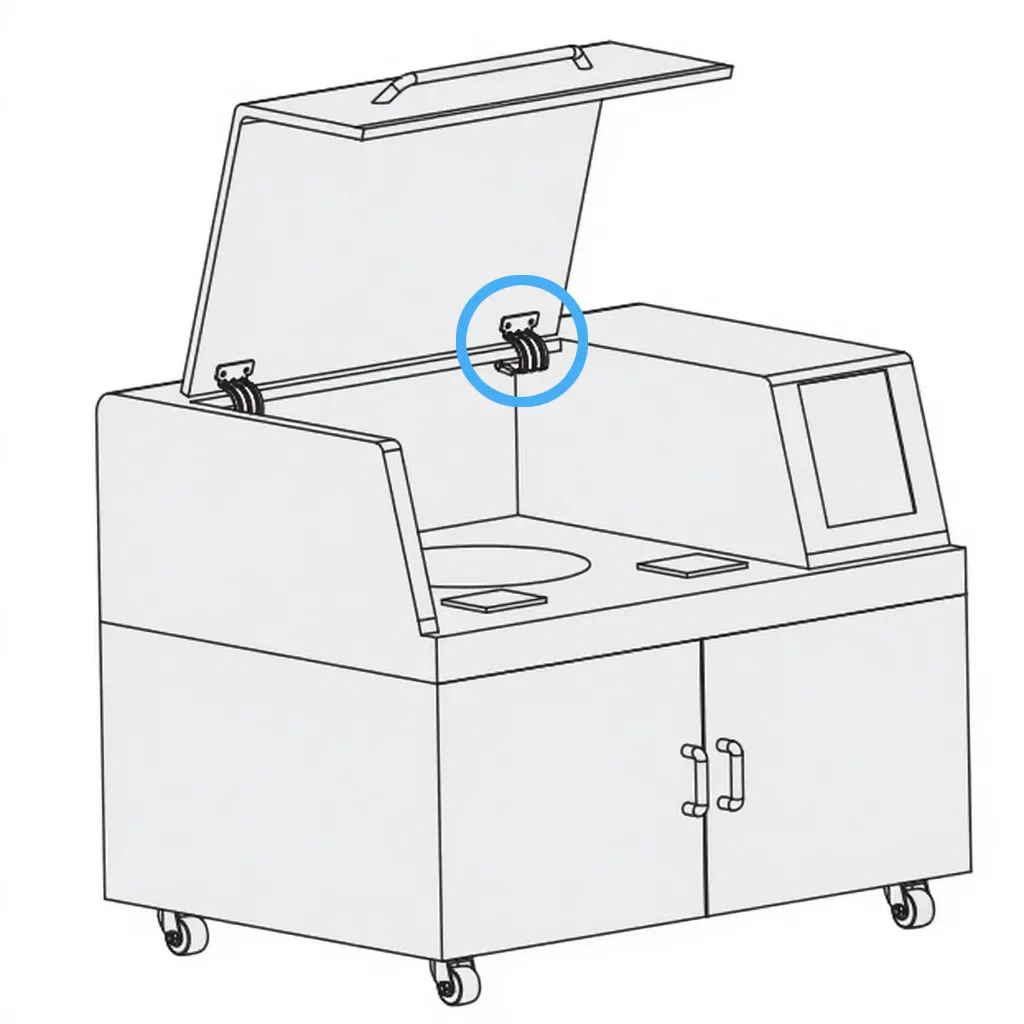

Applications: Where Are Constant Torque Hinges Needed?

Constant Torque Hinges are ideal for diverse lab and precision equipment settings, especially where covers or doors require secure positional stability:

Analytical Instruments:

Sample chamber doors/maintenance covers on spectrometers (UV-Vis, IR, AA, ICP), chromatographs (HPLC, GC), and mass spectrometers. Constant Torque Hinges ensure doors stay reliably open during sampling or maintenance.

Lab Furniture:

Doors on chemical reagent cabinets, safety cabinets (acid/base, flammable), fume hood sashes, and overhead cabinet doors. Installing Constant Torque Hinges prevents doors from closing unexpectedly, avoiding pinches and impacts.

Bio-Medical Equipment:

Doors/covers on biosafety cabinets, laminar flow hoods, incubators, autoclaves. These often require doors to remain open during extended procedures – Constant Torque Hinges provide secure holding.

Optical & Electron Microscopes:

Protective covers and sample chamber doors. Often heavy, these covers demand exceptional closing stability and control – delivered by Constant Torque Hinges.

General Lab Equipment:

Doors/covers on ovens, muffle furnaces, shakers, centrifuges. Constant Torque Hinges reliably hold covers open during loading/unloading.

Special Environments:

For equipment in cleanrooms, ESD-controlled areas, or corrosive environments, choose Constant Torque Hinges made from specialized materials (stainless steel, coatings, polymer alloys) for corrosion resistance and cleanability.

Constant Torque Hinges vs. Traditional Hinges

| Feature | Butt Hinges | Spring Hinges | Basic Friction Hinges | Constant Torque Hinges |

|---|---|---|---|---|

| Positional Stability | None | Hold only closed | Poor, slip prone | Secure at any angle (0°–135°+) |

| Closing Control | None | Uneven, slams | Uneven friction | Constant resistance, smooth close |

| Safety | Frequent slam & rebound | Slam & rebound risk | Slip & impact risk | Eliminates slam & rebound |

| Lifetime & Maintenance | Durable but unsafe | Springs fatigue | Wear changes friction | Minimal torque change, long life |

| Load Adaptability | Poor | Fixed force | Fixed friction level | Adjustable torque, multiple ratings |

This comparison shows the clear, irreplaceable advantages of Constant Torque Hinges in safety, control, user experience, and long-term cost. Investing slightly more upfront for premium hinges prevents significantly more expensive accidents and repairs later.

Buying Guide: Choosing the Right Constant Torque Hinge for Your Lab

Torque Rating

Calculate the required holding torque (N·m or in-lbs) based on cover weight and dimensions. It must slightly exceed the cover’s gravitational torque. Include a safety margin – slightly higher torque is better than too low.

Size & Mounting

Check hinge hole spacing, shaft diameter, and mounting type (surface or concealed) for compatibility with your equipment. Consider material and finish (e.g., stainless steel, corrosion-resistant coating) for your lab environment.

Material

Labs may encounter chemicals or require cleanroom/ESD compliance. Choose corrosion-resistant, low-particulate materials like stainless steel, fluoropolymer-coated steel, or high-performance engineering plastics.

Opening Angle

Ensure the hinge’s maximum opening angle (e.g., 135°, 165°) meets your equipment’s needs.

Torque Adjustability

If cover weight might vary or fine-tuning is desired, prioritize models with adjustable torque (via screw or knob adjusting internal compression).

Certifications & Quality

Select reputable brands and products meeting international standards (e.g., ISO, ASTM, DIN). Leading manufacturers provide torque data and lifecycle test reports for accurate selection.

Expert Consultation

Discuss your specific application with equipment manufacturers or specialized hinge suppliers to get tailored recommendations ensuring the perfect fit for your lab.

Installation & Maintenance Tips

Proper Installation

Follow instructions precisely. Ensure hinge shafts are aligned, gaps between hinge/cover/frame are uniform, and fasteners are tight (but avoid over-compressing friction elements). Test opening/closing immediately after installation to verify hold and close performance.

Load Testing

Test the cover under actual load to confirm positional stability and closing behavior. Adjust or replace the hinge if torque is insufficient or excessive.

Regular Inspection

Periodically check for loose fasteners, unusual noises, or signs of torque loss. Replace hinges showing corrosion or significant friction surface wear.

Cleaning & Care

Constant Torque Hinges generally require NO lubrication (it degrades friction performance). Clean only with a dry cloth or mild detergent; avoid strong acids/bases contacting friction surfaces directly. Proper care extends hinge life significantly.

Case Studies & Industry Trends

Laboratories implementing Constant Torque Hinges report near-elimination of pinch injuries and cover impact damage. Users save effort previously spent managing covers and feel more confident during delicate tasks. Equipment manufacturers see reduced warranty claims related to hinges and higher user satisfaction.

As lab safety standards tighten, intelligent safety components like Constant Torque Hinges are becoming the new baseline. Concurrently, rising demands for ergonomics and comfort drive development of even higher-performance hinges, such as versions rated for extreme temperatures, ESD protection, or higher IP dust ratings.

Conclusion: Safety is Paramount – Choose the Right Hinge for Total Protection

Lab cover rebound may seem minor but can have severe consequences. The Constant Torque Hinge, with its consistent holding force and gentle closing action, is the crucial technology to eliminate this hazard. It safeguards personnel, protects sensitive instruments, and preserves the lab environment.

When evaluating cost-effectiveness, the investment in the correct hinge delivers safety benefits and user experience improvements that far outweigh the initial expense. Choosing and implementing Constant Torque Hinges is a smart, responsible decision for lab safety and scientific integrity.