Hinge Alignment: The Hidden Cost of Industrial Cabinet Failure & How to Prevent It

In the design and manufacturing of industrial cabinets, heavy-duty machinery doors, and specialty vehicles, a frequently overlooked detail often leads to expensive consequences: Hinge Alignment.

Field engineers frequently encounter the following typical issues:

- Doors on industrial cabinets are difficult to close, requiring operators to apply excessive force.

- After months of operation, hinges emit abnormal noises or generate metal dust.

- Cabinets originally designed for IP65 protection ratings experience internal water ingress during the rainy season.

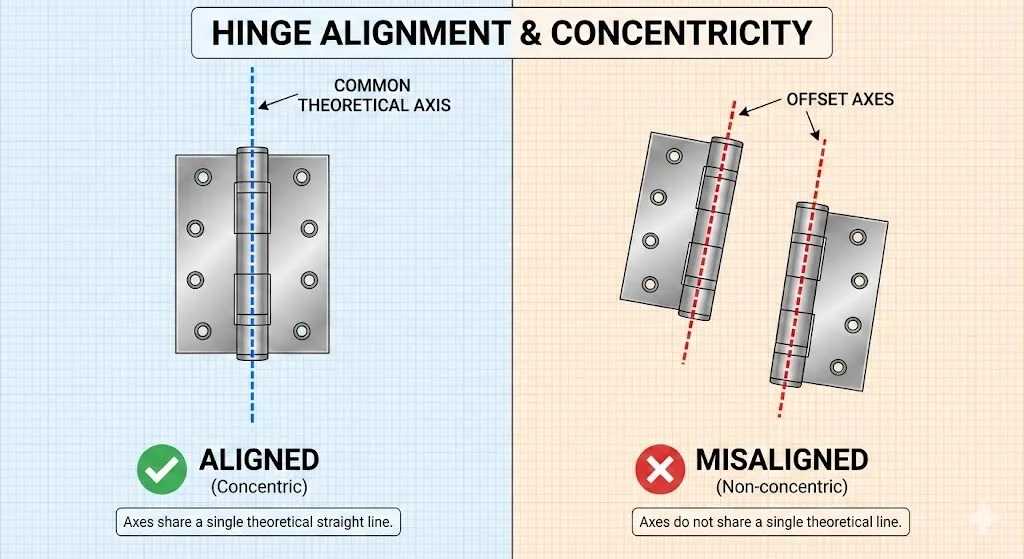

The root cause of these problems is usually not the quality of the hinge itself, but a lack of Hinge Concentricity.

What is Hinge Alignment?

In physics and engineering definitions, when a door utilizes two or more hinges, the centerlines of all hinge pins must lie on the same theoretical straight line. This is defined as concentricity.

This article analyzes—from an engineering mechanics perspective—why alignment is not just an aesthetic requirement, but a critical variable determining equipment safety, environmental sealing performance (IP rating), and service life.

The Mechanics of Misalignment

From a mechanical engineering standpoint, a hinge is a rotary bearing. When multiple bearings operate off-axis, destructive forces are generated within the system. Below are the physical manifestations of misalignment at the microscopic level.

Shear Stress & Stress Concentration

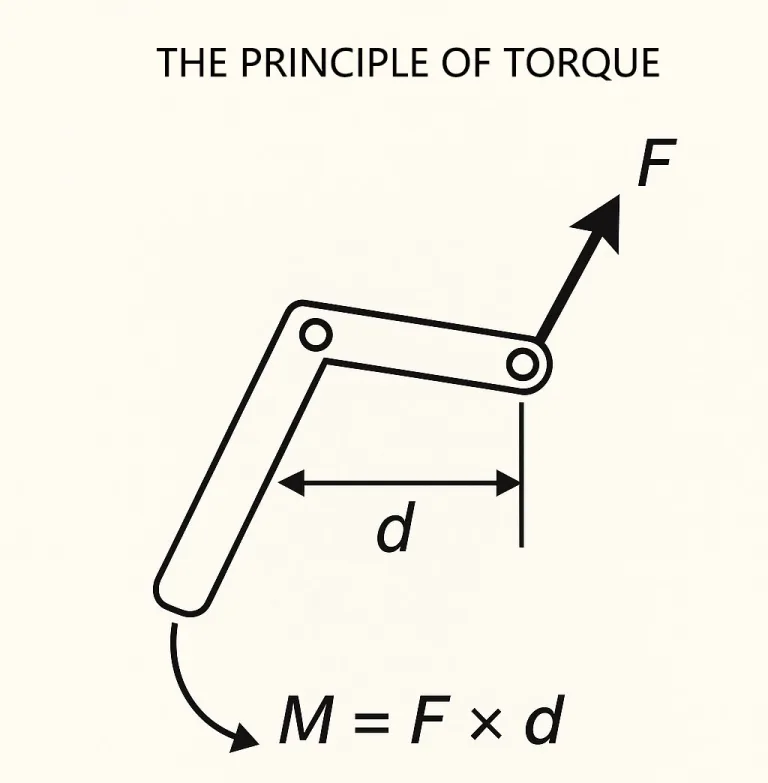

In an ideal state of alignment, the hinge withstands only radial loads (door weight) and axial loads. Once misalignment occurs, the opening and closing movement of the door panel is no longer a pure rotation.

- The leverage of the door panel converts rotational torque into Shear Force against the pin.

- This force concentrates at the contact point between the knuckle and the pin, creating a zone of stress concentration.

- Consequence: This additional stress often exceeds the material’s yield strength. Long-term accumulation leads to pin bending or even fracture.

Non-linear Increase in Friction

Misalignment destroys the internal Fit Tolerance of the hinge.

- Abnormal forced contact occurs between metal components.

- This high-pressure contact squeezes out the lubricating grease between the pin and the bushing.

- Consequence: The coefficient of friction rises sharply. Operators will feel significant “binding” or “lag.” According to field tests, severely misaligned hinges can increase the torque required to open a door by over 300%.

Fretting Corrosion & Accelerated Wear

At the microscopic level, direct metal-to-metal contact caused by misalignment triggers “Fretting Wear.”

- Phenomenon: You may observe reddish-brown powder (if steel hinges) or black powder (if aluminum or stainless steel) near the hinge area.

- Technical Impact: The hinge bore gradually enlarges into an oval shape. This leads to Door Sag, which further exacerbates misalignment, creating a vicious cycle.

The Cost of Ignoring Alignment: Three Key Failure Areas

For industrial equipment manufacturers and end-users, hinge misalignment is not merely a deviation in technical parameters; it translates directly into economic loss and safety risks.

Seal Failure & Loss of Environmental Protection

This is the most common failure mode for outdoor cabinets and electrical enclosures. To achieve IP65 or IP66 under IEC 60529, or Type 4/4X under NEMA 250 standards, the gasket must undergo uniform compression.

- Impact of Misalignment: The deviation of the hinge axis causes the door panel to tilt relative to the door frame.

- Uneven Compression: One side of the door panel over-compresses the gasket, causing permanent deformation; the other side under-compresses, forming microscopic gaps.

- Real-world Case: An alignment error of just 0.5mm is enough to allow high-pressure water or dust to penetrate the seal. This leads to short circuits and damage to expensive internal components like variable frequency drives (VFDs), PLCs, or controllers due to moisture.

Structural Damage & Safety Risks

In applications involving heavy doors (such as generator set sound enclosures or armored vehicle doors), safety risks are particularly acute.

- Metal Fatigue: Forcing the operation of misaligned hinges transfers immense reaction forces to the mounting points of the door frame and panel.

- Weld Cracking: This repetitive stress leads to tearing of the sheet metal at the hinge installation site or fatigue cracking of welds.

- Catastrophic Failure: In extreme cases, pin fracture can cause door panels weighing hundreds of kilograms to detach, causing severe physical injury to operators.

Surging Maintenance Costs

The Total Cost of Ownership (TCO) increases significantly due to hinge misalignment.

- Frequent Replacements: The service life of a standard hinge is typically tens of thousands of cycles. Under misaligned conditions, this may be shortened to just a few hundred cycles.

- Downtime: Repairing a jammed door or replacing a damaged hinge usually requires equipment shutdown. The resulting production loss often far exceeds the value of the hardware itself.

Identifying Types of Misalignment

To solve the problem, one must first accurately identify it. In industrial installations, misalignment typically falls into three basic categories.

Axial Misalignment

- Definition: The axes of two hinges are not aligned in the vertical direction.

- Manifestation: Uneven load distribution. Typically, one hinge bears the entire weight of the door, while the other remains suspended or under minimal load.

- Detection Method: Check if the gaps between the hinge knuckles are consistent.

Radial Misalignment

- Definition: The distance of the hinge axis from the edge of the door frame is inconsistent. For example, the top hinge is 20mm from the edge, while the bottom hinge is 22mm away.

- Manifestation: The door panel cannot close flush, or a “spring-back” phenomenon occurs during closing.

- Detection Method: Use calipers to measure the distance from the center of each hinge to the door edge.

Angular Misalignment

- Definition: The mounting surfaces of the hinges are not parallel. This is usually caused by welding deformation of the cabinet frame or sheet metal Bending Tolerance.

- Manifestation: The hinge axes present a “scissor-like” cross. This is the most severe type of misalignment and causes extreme internal stress.

- Reference Standard: According to ISO 2768-m (General Tolerances), linear tolerances for sheet metal are typically wide; without control, they easily lead to angular misalignment.

Engineer’s Guide: Ensuring Perfect Alignment

As industry consultants, we recommend adopting the following strategies during the design and manufacturing phases to eliminate or compensate for alignment errors.

Best Practices During Installation

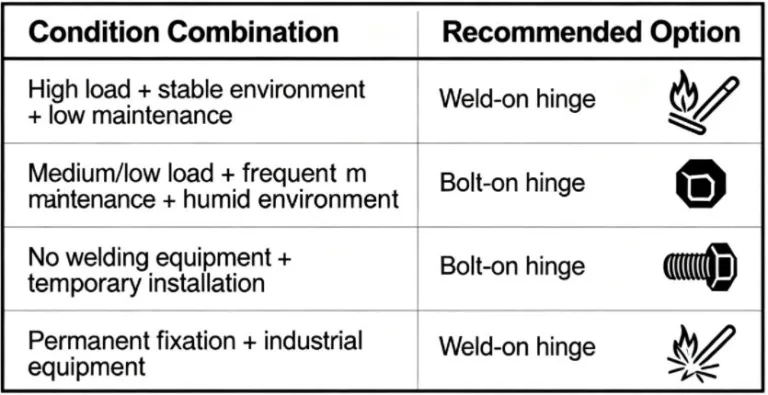

For weld-on hinges or hinges with fixed holes, process control is paramount.

- Use Jigs: Do not rely on manual measurement and marking. Use dedicated positioning jigs to control installation hole error within 0.1mm.

- Concentricity Rod Calibration: Before welding or tightening screws, pass a long steel rod (concentricity rod) through the axis holes of all hinges simultaneously. If the rod rotates freely, concentricity is good.

- Welding Sequence:

- Perform a Tack Weld first.

- Install the door panel and test for smooth swing.

- If there is no resistance, proceed to full welding. This prevents displacement caused by thermal deformation.

Material Selection: Adjustable Hinges

In realistic industrial manufacturing, completely eliminating cabinet frame tolerances is uneconomical. Therefore, the most effective engineering solution is to select Adjustable Hinges.

Why Recommend Adjustable Hinges?

These hinges allow for micro-adjustment of the door panel position after installation. They are generally categorized as:

- 2D Adjustment: Allows for Up/Down (Vertical) and Left/Right (Horizontal) adjustment.

- 3D Adjustment: Adds Forward/Backward (Depth) adjustment functionality.

Application Advantages:

- Tolerance Compensation: Capable of absorbing errors of +/- 2mm or greater generated during sheet metal bending and welding.

- Restoring Sealing Performance: When gaskets age and thin over time, the hinge can be adjusted for depth to re-compress the seal, ensuring continued compliance with NEMA 4X or IP66 standards.

- Reduced Scrap Rate: Even if the door frame manufacturing is not perfect, the door panel fit can be perfected through hinge adjustment, eliminating the need for rework.

Rigidity & Material Selection

For heavy-load applications, deformation of the hinge itself can also lead to misalignment.

- Recommendation: Select high-rigidity materials. Stainless Steel 316 (ASTM A276 Grade 316) or Cast Steel offers better resistance to deformation compared to stamped steel.

- Reference Standard: Ensure material strength meets application load requirements; if necessary, refer to ASME mechanical design standards for Finite Element Analysis (FEA).

Conclusion

Hinge alignment is not solely the responsibility of the installer; it is the foundation of successful industrial design.

A well-aligned hinge system ensures:

- Smooth operation, enhancing the perceived quality of the product.

- Stable sealing performance, protecting expensive internal equipment.

- Reduced maintenance costs, extending the overall equipment lifecycle.

In today’s industrial manufacturing landscape, which demands high precision and high reliability, ignoring concentricity is an unacceptable risk.