Stainless Steel Hinge Corrosion: 5 Technical Causes and Engineering Analysis

Functional Limits of Stainless Steel Passive Films

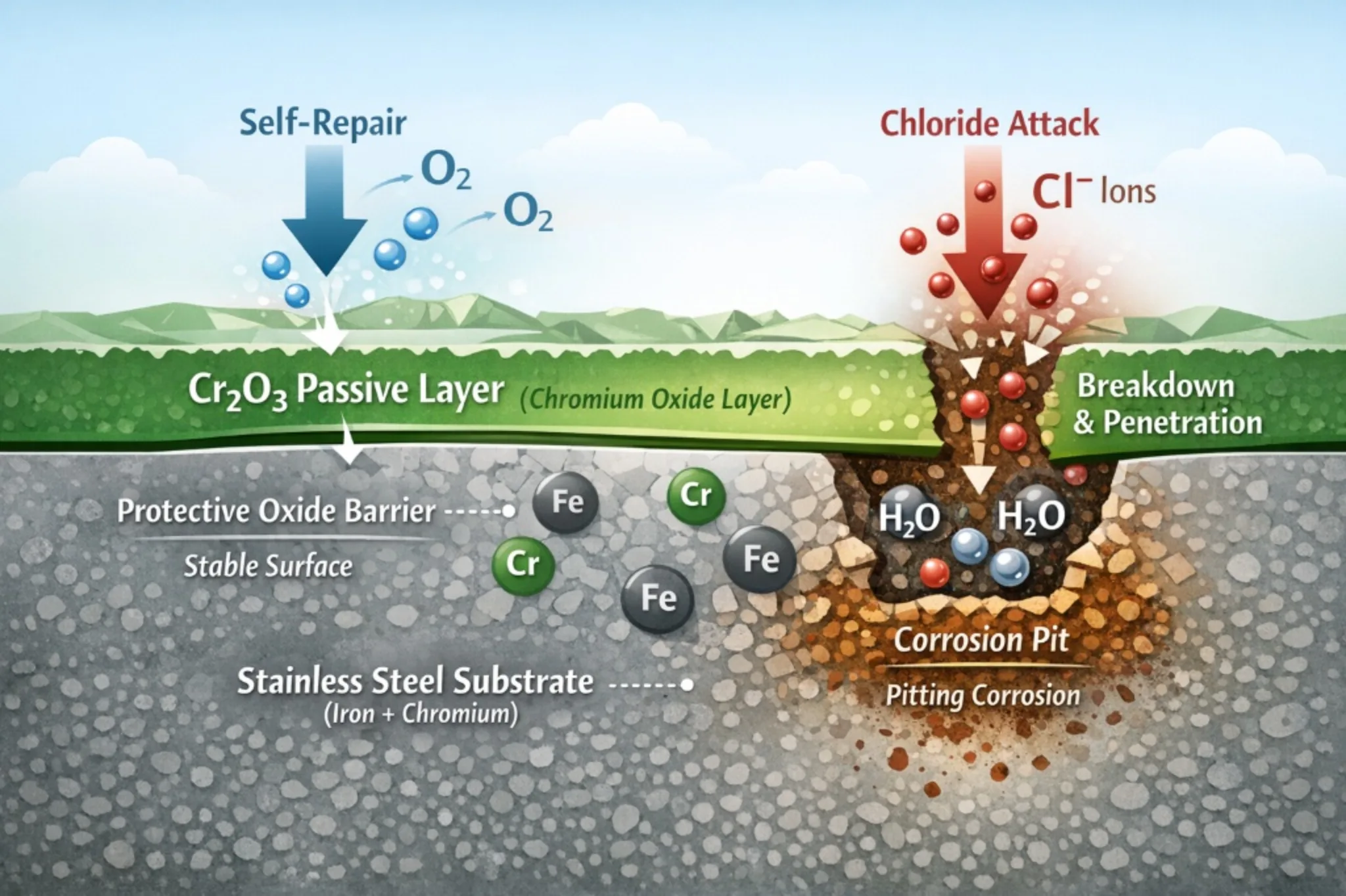

Stainless steel is not a material that is absolutely immune to oxidation. Its corrosion resistance depends on a micro-thin passive film formed on the surface. In specific industrial environments, when the rate of environmental damage exceeds the self-repair rate of this passive film, the substrate undergoes oxidation.

According to data analyzed between 2024 and 2025 across 150 failed samples, non-passivated stainless steel in industrial environments with relative humidity higher than 85% has a 40% probability of developing red rust within 168 hours. This phenomenon is typically linked to imbalances in chemical composition, surface treatment defects, or incorrect installation environments. This article analyzes the physical and chemical factors leading to such failures and provides verification methods based on international standards.

Passivation Layer Degradation and Failure Mechanisms

The core of stainless steel’s corrosion resistance lies in its chromium content. When chromium levels exceed 10.5%, it combines with oxygen to form a dense chromium oxide film (Cr2O3).

Chloride-Induced Pitting Corrosion

- In high salt spray or coastal environments, chloride ions penetrate weak points in the passive film.

- Chloride ions induce pitting corrosion, causing small black or red rust spots on the surface.

- Reference Standard: ASTM G48.

Mechanical Damage and Self-Repair Limits

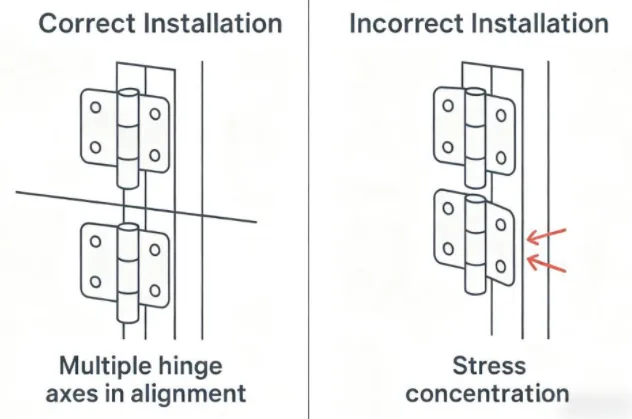

- Hard object scratches during installation physically sever the passive layer.

- If oxygen supply in the environment is insufficient, the oxide film cannot complete in-situ repair.

- Due to a lack of effective passivation, exposed iron atoms quickly combine with water molecules to form Fe2O3.

Pitting Resistance Equivalent Number (PREN)

The PREN value is a quantitative index used to measure the pitting resistance of stainless steel. The standard PREN value for Stainless Steel Hinges made of Grade 304 is typically between 18.0 and 20.0, while upgrading from Grade 304 to Grade 316 provides a value exceeding 24.0 due to the addition of molybdenum.

- Calculation Formula: PREN = %Cr + 3.3 x (%Mo + 0.5 x %W) + 16 x %N.

- Reference Standard: ASTM A240.

Material Integrity Case Study: Field Failure Analysis

Low-price competition has led to “pseudo-stainless” products in the supply chain that do not meet engineering standards.

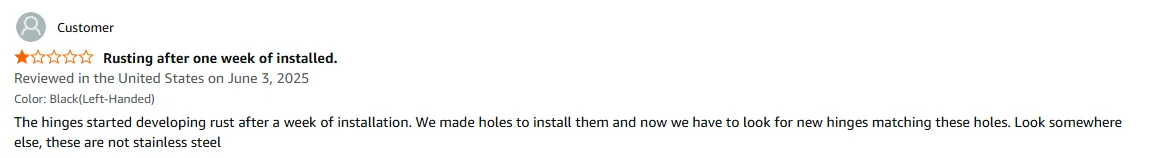

Field Evidence: Voice of Customer (VoC) Analysis

Real-world failure cases provide the most definitive evidence of material discrepancies. Below is a case study of early-onset corrosion after field installation:

“Rusting after one week of installed. The hinges started developing rust after a week of installation. We made holes to install them and now we have to look for new hinges matching these holes. Look somewhere else, these are not stainless steel.”— Amazon Customer Review, June 3, 2025

| Customer Feedback | Engineering Diagnosis | Technical Solution/SOP |

|---|---|---|

| Rust after 1 week | Failure timeline (<168h) indicates Grade 201 substitution or high manganese alloy. | Require XRF Elemental Fingerprinting to verify Ni content (>8.0%). |

| Rust after drilling holes | Cross-Contamination: Carbon steel bits embedded iron particles into the stainless substrate. | Use Cobalt (Co) drill bits and apply ASTM A380 passivation paste post-drilling. |

| Mismatched holes | Dimensional inconsistency due to low-precision manufacturing. | Utilize Precision Investment Casting to ensure ±0.1mm dimensional tolerance. |

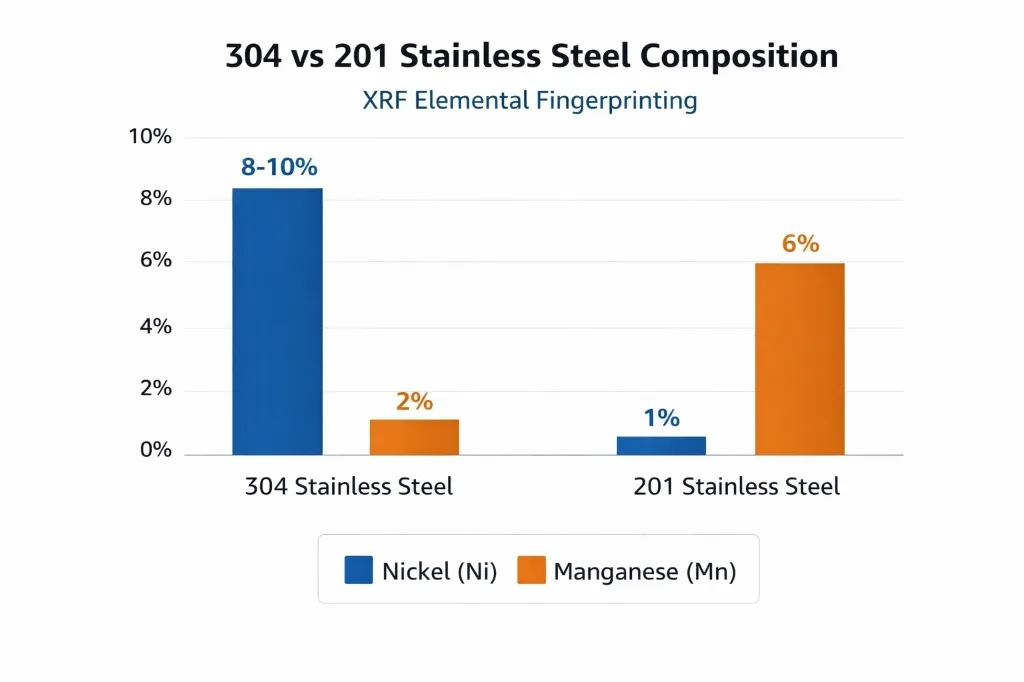

Material Substitution: Technical Identification of Grade 201 Fraud

Substitution of Grade 304 with Grade 201 is a primary cause of premature corrosion, often used to reduce material costs by 30% to 50%.

XRF Elemental Fingerprinting for Verification:

- Manganese (Mn) Content: Grade 201 Typically contains 5.5% to 7.5% Mn, whereas Grade 304 is restricted to a maximum of 2.0%.

- Nickel (Ni) Content: Authentic Grade 304 must contain 8.0% to 10.5% Ni, while fraudulent samples often show Ni levels as low as 1.0% to 1.5%.

- Chromium (Cr) Content: Grade 201 often has lower Cr levels (13% – 15%) compared to the 17.5% – 19.5% required for Grade 304.

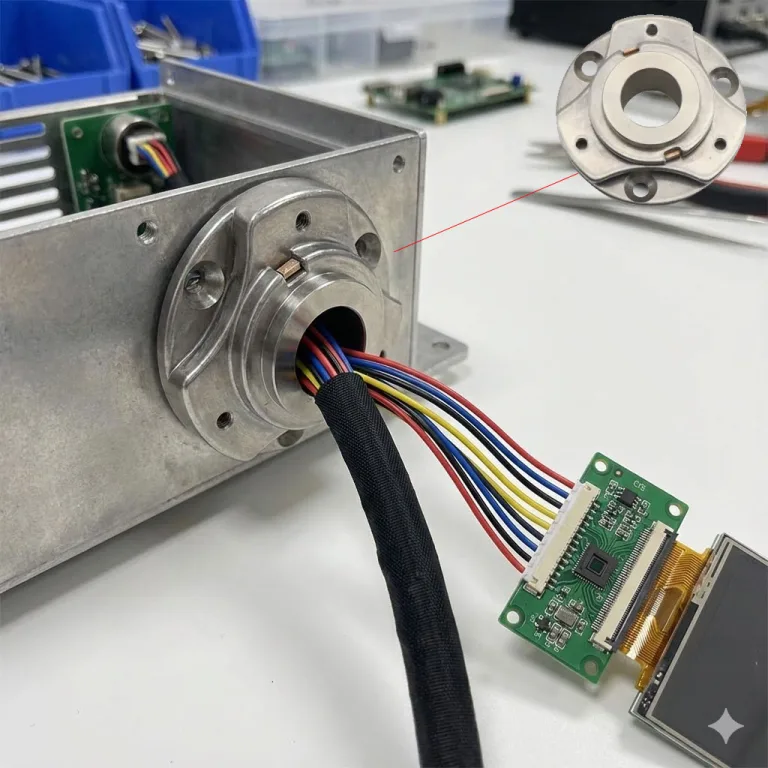

Verified field reports highlight a consistent pattern: budget-grade hinges develop severe red rust within only seven days of installation. This rapid oxidation typically concentrates near installation holes or friction joints where the protective coating has been compromised by tool stress or mechanical wear.

- Symptom: Rapid “red rust” blooming within 168 hours of exposure to normal humidity.

- Engineering Diagnosis: This failure timeline is characteristic of non-passivated Grade 201 or high-manganese alloys. Authentic Grade 304 will resist visible red rust for significantly longer.

- Structural Risk: This structural risk is especially critical for Heavy Duty Hinges used in industrial enclosures, where screw snapping can lead to catastrophic door failure.

Process Contamination and Supply Chain Risks

- Cross-Contamination: If a production line processes both carbon steel and stainless steel, carbon steel particles can become embedded in the stainless surface, creating electrochemical corrosion cells. Reference Standard: ASTM A380.

- Lack of Passivation: A lack of this final manufacturing step leaves residual free iron ions. Reference Standard: ASTM A967.

- Hardware Incompatibility: Using galvanized screws with stainless hinges creates galvanic corrosion.

Standard Operating Procedures (SOP) for Material Verification

To guarantee long-term durability, every batch should undergo a professional Passivation Process and be verified via Neutral Salt Spray (NSS) Testing according to ISO 9227.

Neutral Salt Spray (NSS) Testing

- Conditions: 5% sodium chloride solution, pH 6.5 to 7.2.

- Failure Threshold: Rust is defined as red rust appearing on >0.1% of the surface area.

- Grade 304 should pass 72 hours; Grade 316 should pass 168 hours.

- Reference Standard: ISO 9227.

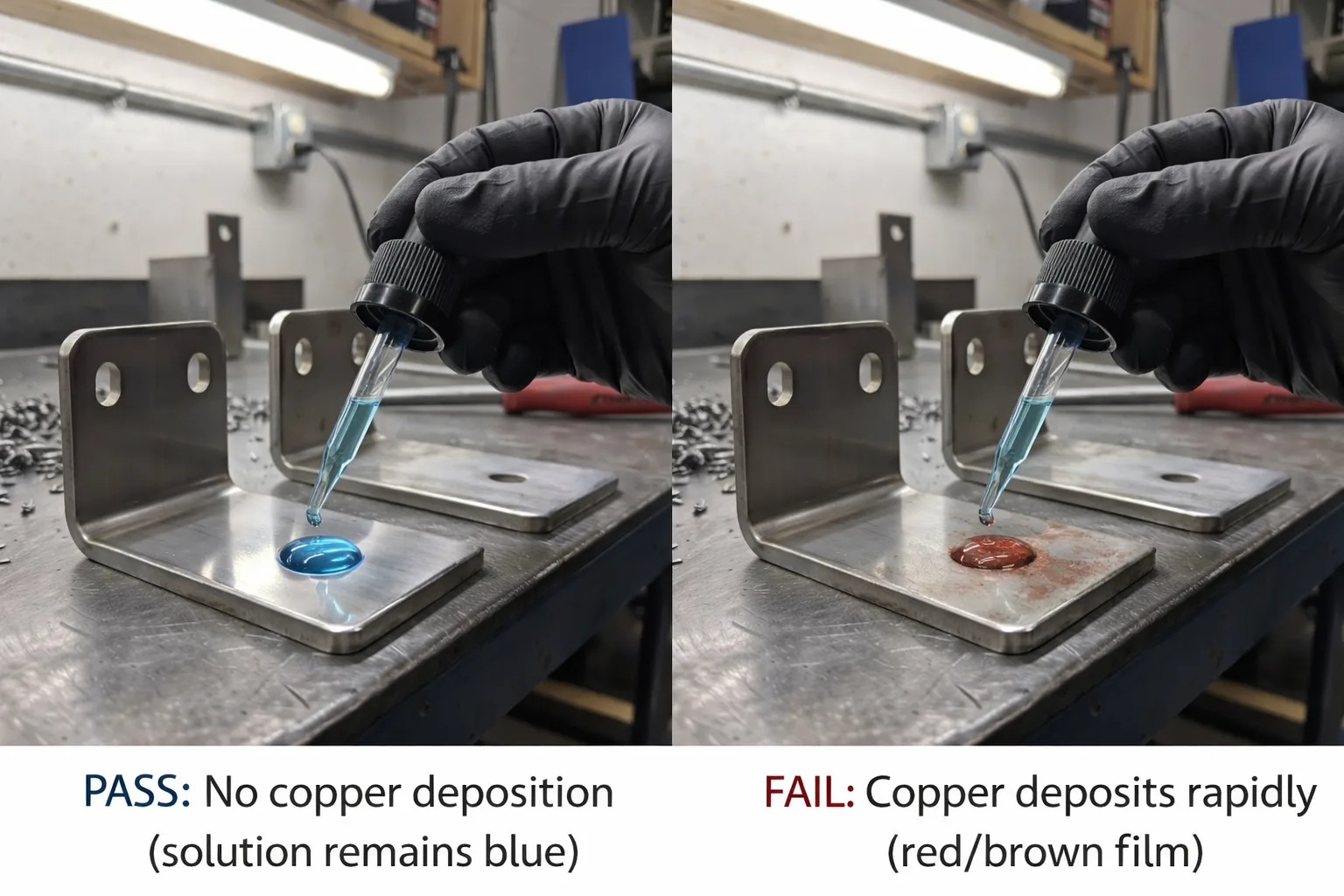

Copper Sulfate Titration Test

Apply test droplets to the surface for 6 minutes. If a copper color (red) appears, it proves inadequate passivation. Execution Basis: ASTM A380 appendix.

Summary and Procurement Checklist

- [ ] Does the supplier provide a Material Test Report (MTR) complying with EN 10204?

- [ ] Do the LH/RH designations and rising stroke match CAD specifications?

- [ ] Does the BOM specify vibration-proof hardware (e.g., Nyloc Nuts)?

- [ ] Does the packaging comply with ISO 11607 to prevent physical damage?

Conclusion

This technical study of 150 failed samples proves stainless steel’s resistance depends on a micro-thin passive film. In high humidity, non-passivated steel has a 40% rust probability within 168 hours. Major failures stem from chloride pitting, mechanical damage, and Grade 201 material fraud. Verification via XRF testing and ASTM A380 titration is essential to ensure industrial integrity.

Technical Reviewer: Senior Application Engineer (10+ Years in Industrial Hardware QC)

Last Updated: February 2026

Editorial Policy: Based on verified laboratory testing and international engineering standards. Data derived from internal QC sampling.