Surface-mounted vs concealed hinges: A TCO Guide for Enclosures

In industrial enclosure projects, I have witnessed too many cases where cheap surface-mounted hinges were selected to “save budget,” only for the results to be disastrous.

These disasters range from equipment water damage caused by seal failure, to increased rework costs due to scratched coatings during on-site installation, and even an inability to command premium pricing because the final machine looked “cheap.”

Many decision-makers fall into a specific trap when comparing surface-mounted vs. concealed hinges: they only look at the unit price difference on the BOM (Bill of Materials).

They ignore the massive risks hidden behind that lower price tag.

This article will skip basic textbook definitions and dive straight into a Total Cost of Ownership (TCO) financial analysis. I will use engineering logic to prove why the higher-priced Concealed Hinges are often the true “economical” choice for modern industrial applications, saving you maintenance costs and elevating your brand value.

Definitions & Basic Characteristics

Before diving into cost analysis, we must establish a technical baseline. These two hinge types differ fundamentally in mechanical structure and installation logic.

Surface-Mounted Hinges

This is the traditional connection method. The main body of the hinge is installed directly on the external surfaces of the door panel and the door frame.

- Typical Structures: Butt Hinges, Flag Hinges, or Heavy-Duty Strap Hinges.

- Key Features: The structure is very simple and clearly visible to the naked eye. They easily achieve a 180° opening angle and do not require engineers to reserve complex motion clearance inside the cabinet.

Concealed Hinges

Also known as internal or invisible hinges. When the door panel is closed, the entire hinge mechanism is completely hidden within the cabinet or in the gap between the door and frame.

- Typical Structures: Multi-link mechanisms (such as U-shaped arms, 7-shaped arms), spring-loaded pin styles, or lift-off designs.

- Key Features: The external surface remains flush with no protrusions. This design offers high physical vandal resistance but requires engineers to calculate the internal Effective Volume precisely during the design phase.

Core Performance Comparison: Technical Engineering Analysis

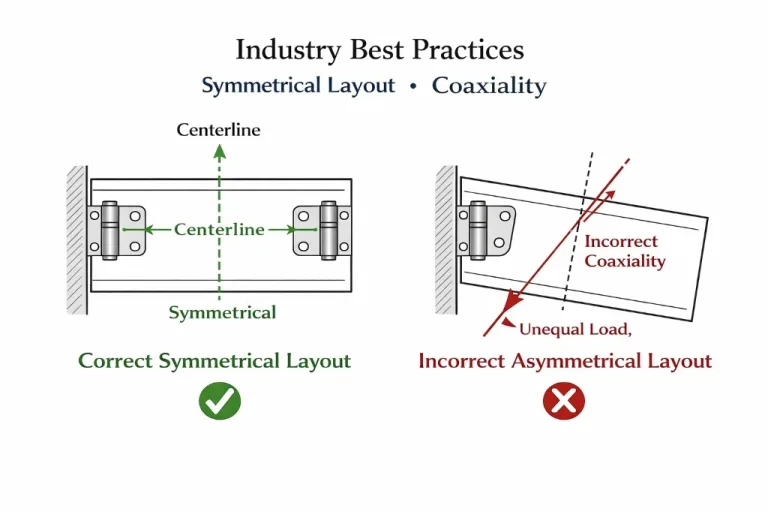

In technical decision-making, functional differences directly determine product compliance. We have found that Concealed Hinges demonstrate distinct engineering advantages in the following three key dimensions.

Security & Vandal Resistance

The Weakness of Surface-Mounted Hinges:

The hinge pin and mounting screws are completely exposed. Without additional protection, this is not just an aesthetic issue; it is a security vulnerability. In public facilities like outdoor telecom cabinets or ATMs, an attacker needs only a screwdriver or cutting tool to remove screws or cut the pin, easily removing the door.

The Advantage of Concealed Hinges:

All fasteners and mechanical structures are located inside the cabinet. When the door is closed and locked, there are no external stress points or removable parts. According to the EN 1627 standard for burglar resistance, this “inaccessible” design significantly increases the time required to force entry.

Consultant’s Advice:

If your equipment is placed in an unmanned public area, using surface-mounted hinges means you must purchase additional anti-theft padlocks or security covers. This actually increases your total cost.

Environmental Sealing & IP/NEMA Ratings

Continuity of the Gasket:

- Surface-Mounted Hinges: While you don’t necessarily need to cut the gasket, the mounting holes are often very close to the sealing path. This can easily cause uneven pressure on the gasket.

- Concealed Hinges: These allow the gasket to form a completely closed, Continuous Loop on the inside of the door frame. This is critical for achieving high-level protection.

Compression Control:

We have tested many high-end concealed hinges, and they often come equipped with 3D adjustment capabilities. Installers can fine-tune the door panel’s position (X, Y, Z axes) to ensure consistent gasket compression around the entire perimeter (usually 30%-50% compression is recommended). This is vital for passing IEC 60529 (IP65/IP66) or NEMA 250 (Type 4) water tightness tests.

Corrosion Risk:

Surface-mounted hinges are directly exposed to rain, salt spray (refer to ASTM B117 testing standards), and dust. Concealed hinges are protected by the seal and reside in the dry, clean internal environment, significantly reducing corrosion risks.

Hygienic Design & Cleaning

In food processing (FDA/NSF standards) or medical environments, surface-mounted hinges create complex geometric crevices. These gaps easily accumulate dust, bacteria, and cleaning agent residue.

In contrast, concealed hinges create a Flush external surface. Operators can easily wipe down or high-pressure wash the equipment, meeting strict hygienic design requirements.

Total Cost of Ownership (TCO) Analysis

This is the most overlooked section. We cannot simply stare at the procurement unit price; we must calculate the Total Cost of Ownership (TCO).

Initial Procurement Cost

Fact: If comparing only the price of individual components, surface-mounted hinges are indeed usually cheaper than concealed hinges. Depending on the material, the price difference can range from 30% to 200%.

Hidden Expenses: As mentioned in the security section, to compensate for the defects of surface-mounted hinges, you may need to buy extra Security Screws or protective covers. Once these accessory costs are included, the price gap narrows significantly.

Installation & Assembly Efficiency

Surface-Mounted Hinges: Typically require drilling holes in the door and frame surfaces. This not only adds processing steps but also risks scratching the anti-corrosion coating, leading to manual touch-up work later.

Concealed Hinges: Many modern industrial concealed hinges use “Quick-Install” technology (such as Spring-loaded pins or Snap-in designs). Although the initial design requires calculating clearance, on the assembly line, workers can complete installation in seconds without tools. This drastically reduces expensive manual assembly labor.

Maintenance & Replacement Costs

Costs of Exposure: If a surface-mounted hinge on outdoor equipment rusts, it requires periodic rust removal or replacement. Every on-site maintenance trip incurs travel costs and causes equipment Downtime Cost.

Concealed Advantage: Protected by the enclosure’s sealing system, the lifespan of a concealed hinge usually matches the enclosure itself, rarely requiring replacement.

4. Brand Value & Pricing Power

This is a “soft cost.” Equipment using concealed hinges looks cleaner and has a modern industrial feel.

Case Logic: Imagine you are selling a precision medical instrument worth $50,000. If it is equipped with cheap, protruding butt hinges, it directly damages the customer’s perception of the overall quality. The “premium pricing power” brought by concealed design often far exceeds the cost of the hinge itself.

Decision Matrix: When to Choose Which Solution?

To help you decide quickly, I have organized the following comparison matrix.

| Feature | Surface-Mounted Hinges | Concealed Hinges | Winner |

| Load Capacity | High | Medium/High | Surface (Generally) |

| Security | Low (Needs extra parts) | High (Physical tamper-proof) | Concealed |

| Sealing (IP/NEMA) | Risk of leakage | Excellent (Continuous loop) | Concealed |

| Aesthetics | Industrial/Rough | Clean/Modern | Concealed |

| Installation Cost | High (Drilling/Screwing) | Low (Quick-install options) | Concealed |

| Initial Part Cost | Low | Medium/High | Surface |

| TCO (Long Term) | Medium (High maintenance) | Low (Low maintenance) | Concealed |

Recommended Application Scenarios

Based on the analysis above, I propose the following specific selection suggestions for different industries:

When to Choose Surface-Mounted Hinges

- Non-Public Indoor Electrical Cabinets: If the cabinet is in a secured server room and the environment is dry, surface-mounted hinges are an economical choice.

- Heavy Machinery Guards: When the door panel is extremely heavy and aesthetics are not a priority, welded heavy-duty surface hinges provide the simplest direct load support.

- Ultra-Low Budget Projects: For disposable use or low-end market products where cost is the only consideration.

When to Choose Concealed Hinges

- Outdoor Infrastructure: Such as EV Charging Stations, 5G Base Stations, and Traffic Control Cabinets. Here, Anti-vandalism and Rust Prevention (NEMA 4X) are rigid requirements.

- High-Density Data Centers & Modular Control Consoles: In these scenarios, space efficiency is paramount. Cabinets are often “ganged” (joined side-by-side) to form a continuous wall. Surface-mounted hinges create gaps between units and disrupt this layout. Concealed hinges allow for true “zero-clearance” installation, enabling cabinets to sit flush against each other while maximizing expensive floor space utility.

- Hygienic/Clean Environments: Food and beverage production lines or laboratory equipment. An easy-to-clean surface is a prerequisite for industry compliance.

FAQ

Here are several technical questions I am frequently asked during consultations:

Q1: Concealed hinges occupy internal cabinet space. What if the equipment doesn’t fit?

A: This is a valid concern. Concealed hinges do occupy a certain “Effective Volume.”

Advice: During the CAD design phase, you must import the 3D model provided by the hinge manufacturer to simulate motion. For extremely space-constrained cabinets, you can choose “Offset” concealed hinge designs or flat-structure link hinges to minimize internal intrusion.

Q2: Is the load capacity of concealed hinges really worse than surface hinges?

A: Not necessarily. While surface hinges are structurally simpler and bulkier for the same volume, modern industrial-grade concealed hinges use high-strength steel and optimized link structures. They can fully support heavy door panels weighing 40kg or even over 100kg.

Key Point: Check the “Radial Load” and “Axial Load” data in the product datasheet and maintain a 1.5x Safety Factor.

Q3: Since they are hidden inside, can I just use carbon steel instead of stainless steel?

A: This is a common misconception. Although the internal environment is better, condensation can still occur inside cabinets.

Advice: For general indoor applications, zinc-plated carbon steel or zinc alloy is acceptable. However, for coastal, high-humidity, or chemical environments, even if the hinge is internal, I strongly recommend using 304 or 316 Stainless Steel to prevent seizure due to rust after long-term operation.

Conclusion

When evaluating surface-mounted vs. concealed hinges, the final decision should never depend solely on the price tag of a single component.

While surface-mounted hinges offer cost advantages in simple, low-risk applications, in the context of modern industrial design standards, Concealed Hinges provide security, weather resistance, and increased product value. They often deliver a higher Return on Investment (ROI).

I recommend conducting a comprehensive cost-benefit evaluation during the Design-in Phase, rather than waiting until the production phase reveals seal failures or vandalism issues to consider a change.