Torque Hinge Selection for Medical Devices: 3 Failure Cases & Solutions

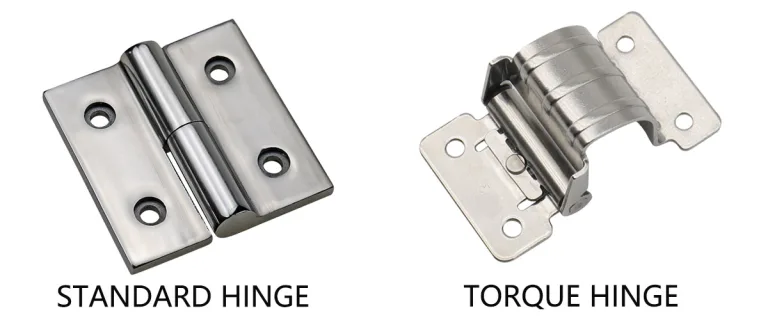

Proper torque hinge selection is a critical yet often overlooked step in designing reliable medical and laboratory equipment. Whether for a centrifuge lid or a medical monitor, the right hinge ensures safety and ergonomics. However, selecting the wrong specification can lead to corrosion, drift, and costly failures. This article analyzes three real-world failure cases to guide engineers in optimizing medical torque hinge designs according to IEC and ASTM standards.

Chemical Corrosion Leading to Hinge Seizure and Fracture

Failure Description

A branded benchtop high-speed refrigerated centrifuge was delivered to hospital pathology departments. After 6 months of use, customers reported widespread complaints.

Observed issue: The lid became difficult to open and required both hands to lift. Field measurements showed operating force exceeded 50N.

Inspection findings: Disassembly revealed visible reddish-brown rust and pitting at the hinge shaft. Internal friction plates had bonded together due to oxide expansion. In some units, hinge shafts fractured during forced opening.

Root Cause Analysis

A. Insufficient Environmental Assessment (Chemical Environment)

The design team only considered “indoor use” conditions (25°C, 50% RH). However, actual medical environments involve daily exposure to aggressive chemicals for infection control:

- Sodium hypochlorite (bleach): Highly corrosive, capable of causing rapid pitting corrosion on standard metals.

- Hydrogen peroxide: Strong oxidizing agent.

- 75% ethanol and quaternary ammonium compounds.

B. Incorrect Material Selection

The original design used SUS430 stainless steel or zinc-plated carbon steel.

- SUS430: Lacks nickel, resulting in poor resistance to chloride ions found in bleach.

- Zinc-plated carbon steel: The sacrificial coating wears off under friction, leading to rapid substrate oxidation.

Technical Solutions and Implementation Standards

Upgrade Material Grade

For environments containing chlorides (bleach), generic stainless steel is insufficient.

Requirement: Use SUS316 / 316L (UNS S31600) austenitic stainless steel. Its molybdenum content significantly improves resistance to pitting corrosion.

Reference standard: ASTM A276.

Surface Passivation

Action: Perform acid pickling and passivation to remove free iron.

Verification: Test according to ASTM A967 to ensure a dense chromium oxide layer.

Torque Miscalculation Causing Lid Drift (“Nodding” Effect)

Failure Description

A newly developed portable medical monitor featured a wide-angle tilting display.

Observed issue: At small opening angles (30°–45°), the screen could not hold position and slowly drifted closed.

Risk: Violates IEC 60601-1 Clause 9.4 (Instability Hazards) requirements and creates a pinch hazard.

Root Cause Analysis

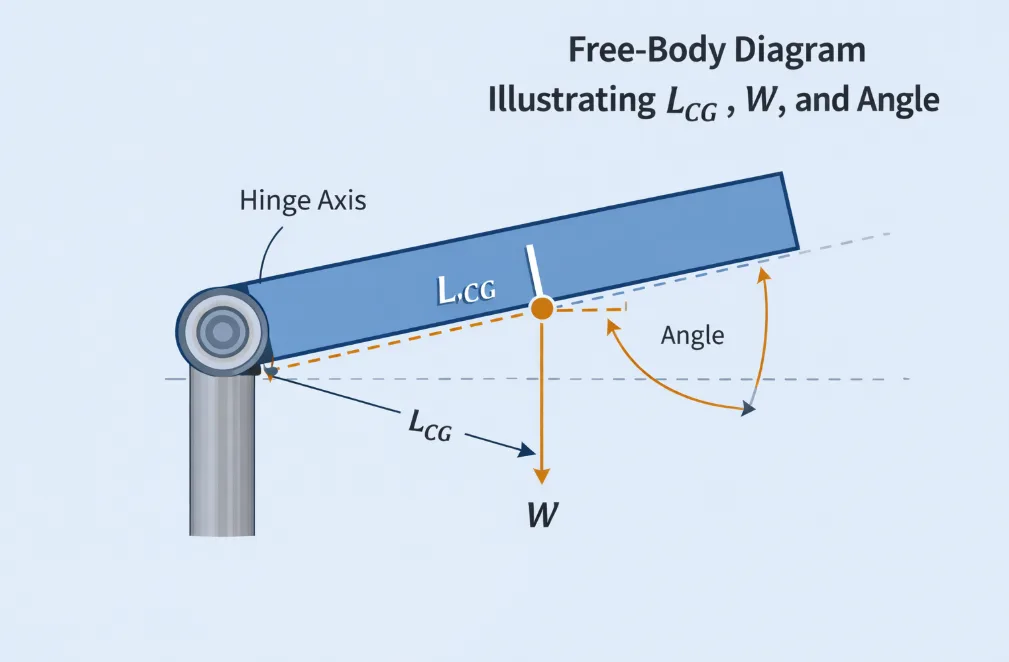

A. Oversimplified Calculation Model

Engineers assumed the center of gravity (CG) was at the geometric center. In reality, internal components (batteries, heat sinks) shifted the CG outward, increasing the effective moment arm.

B. Ignoring Manufacturing Tolerance

The engineer selected a hinge with a nominal torque matching the calculated load exactly (1:1 ratio). Given the industrial tolerance of ±10%, a hinge at the lower limit failed to support the load.

Corrective Actions and Calculation Procedure

Use an Accurate Torque Formula

Calculate torque based on the actual Center of Gravity (CG) rather than just the geometric center.

Formula: Torque (T) = L(cg) x W x 0.5 x cos(Angle)

Where:

- L(cg): Distance from the hinge axis to the actual Center of Gravity.

- W: Total weight of the lid/screen.

- Angle: The angle of the lid relative to the horizontal plane.

- 0.5: Coefficient assuming a standard dual-hinge configuration where the load is shared equally. (Note: For single hinge designs, remove this coefficient).

(Formula Reference: Based on standard static equilibrium principles, e.g., Shigley’s Mechanical Engineering Design)

Apply a Safety Factor (Safety Margin)

- Recommended: 1.2 (20% margin).

- Note: This covers manufacturing tolerances and minor wear without inducing excessive stress relaxation.

Asymmetric Torque

Select hinges with lower opening torque (e.g., 1.5 N-m) and higher closing torque (e.g., 2.5 N-m) to improve ergonomics.

Damping Failure Over Product Life Cycle

Failure Description

A PCR analyzer access door failed after one year of use. Field reports indicated a complete loss of holding capability.

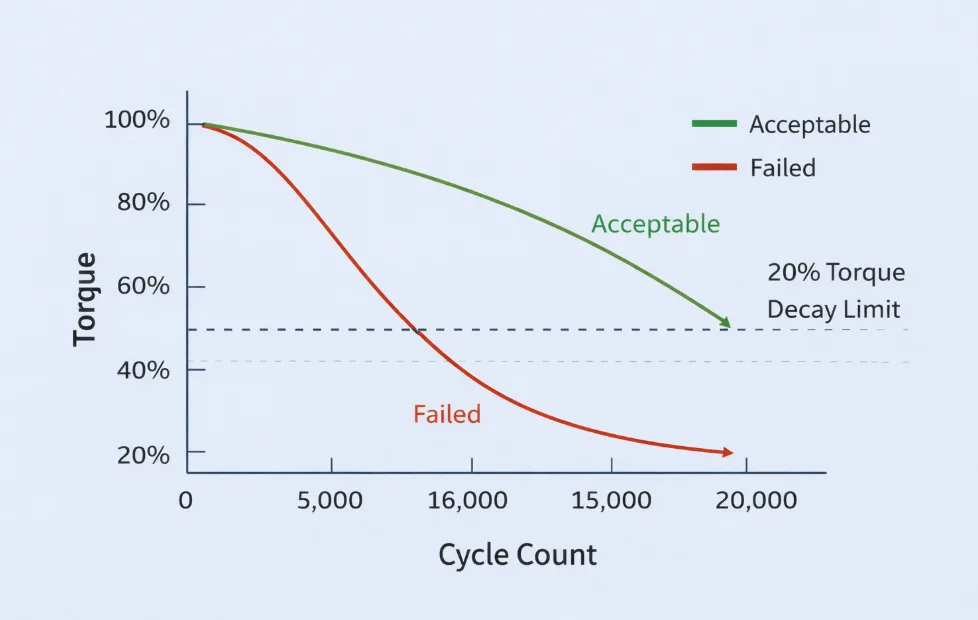

Data: Torque measurements on returned units showed a drop from 2.5 N·m to <0.5 N·m after approximately 15,000 cycles.

Root Cause Analysis

A. Invalid Accelerated Testing (The “60 RPM” Myth)

The manufacturer tested the hinge lifespan using a motor running at 60 RPM to save time.

The Physics: High-speed rotation generates frictional heat that cannot dissipate. This temporarily lowers grease viscosity, masking potential wear issues. The hinge passed the lab test but failed in the real world (manual operation at ~5-10 RPM).

B. Grease Degradation

The generated heat or environmental temperature caused the grease to carbonize or migrate, leading to metal-on-metal abrasion.

Solutions and Validation Standards

Realistic Lifecycle Testing

Requirement: Limit test speed to 5–10 RPM to simulate human operation and prevent thermal buildup.

Goal: Demonstrate 20,000+ cycles with <20% torque decay.

Temperature Stability

Grease: Ensure functional range of -20°C to 80°C.

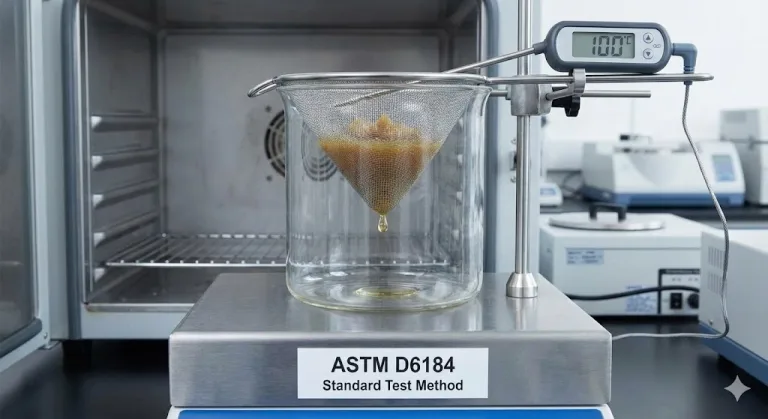

Standard: ASTM D217 for grease consistency.

Engineer’s Selection Checklist

- Load Calculation: Calculated based on Center of Gravity, not geometric center?

- Safety Factor: Applied a 20% margin (avoiding excessive margins like 50% to prevent stress relaxation)?

- Material: Specified SUS316 if exposed to bleach/chlorides?

- Test Protocol: Verified that life testing was performed at low speed (<10 RPM)?

- Compliance: Lubricant complies with ISO 10993 (biocompatibility)?

FAQ

Q1: Should I use a 50% safety factor to be safe?

A: No. While a margin is necessary, an excessive safety factor (e.g., 50%) increases the initial stress on the hinge materials. High initial stress accelerates material creep (stress relaxation). Furthermore, elevated temperatures exponentialize this effect following the Arrhenius equation. Therefore, a 10%–20% margin is optimal to balance reliability and material longevity.

Q2: Why did my hinge fail even though it passed the supplier’s life test?

A: Check the test speed. Many suppliers use high-speed motors (e.g., 60 RPM) to rush the test. This creates frictional heat that artificially lubricates the system, hiding wear. Real-world manual operation is much slower and harsher on the friction surfaces.

Q3: How do I prevent rust in a cleanroom environment?

A: Use SUS316 stainless steel and ensure the surface is passivated (ASTM A967). Avoid carbon steel entirely, even if plated, as the plating will eventually wear through.

Q4: What is the difference between static and dynamic torque?

A: Static torque is the force to start movement; dynamic is the force to keep it moving. A quality hinge minimizes the difference (stiction) to provide a premium, silky feel.

Conclusion: Reliability Is Built on Detail

Medical equipment reliability is not based on chance, but on disciplined engineering calculation and strict adherence to standards.

The correct selection process follows this logic:

- Analyze Conditions: Chemical exposure (choose SUS316) and Usage (test at human speeds).

- Calculate Parameters: Accurate CG and reasonable Safety Factor (20%).

- Verify Compliance: FDA materials and ISO standards.

Proper upfront material selection and validation testing are the most effective ways to reduce Total Cost of Ownership (TCO) across the product lifecycle.