Why Torque Hinges Matter in Medical and Industrial Equipment

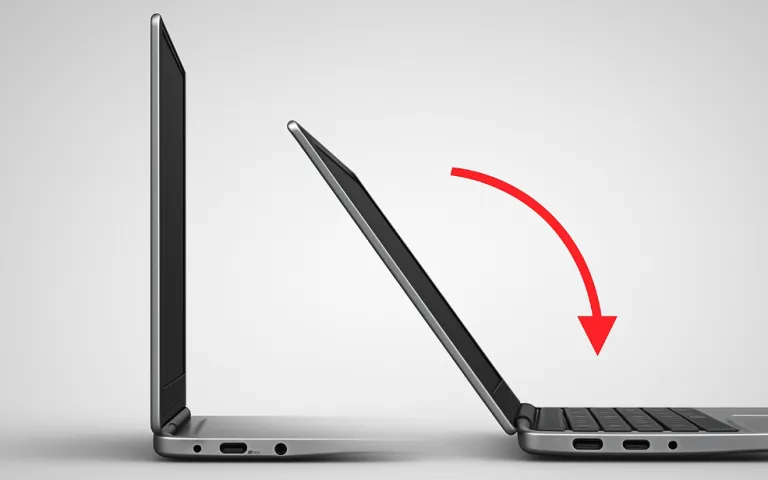

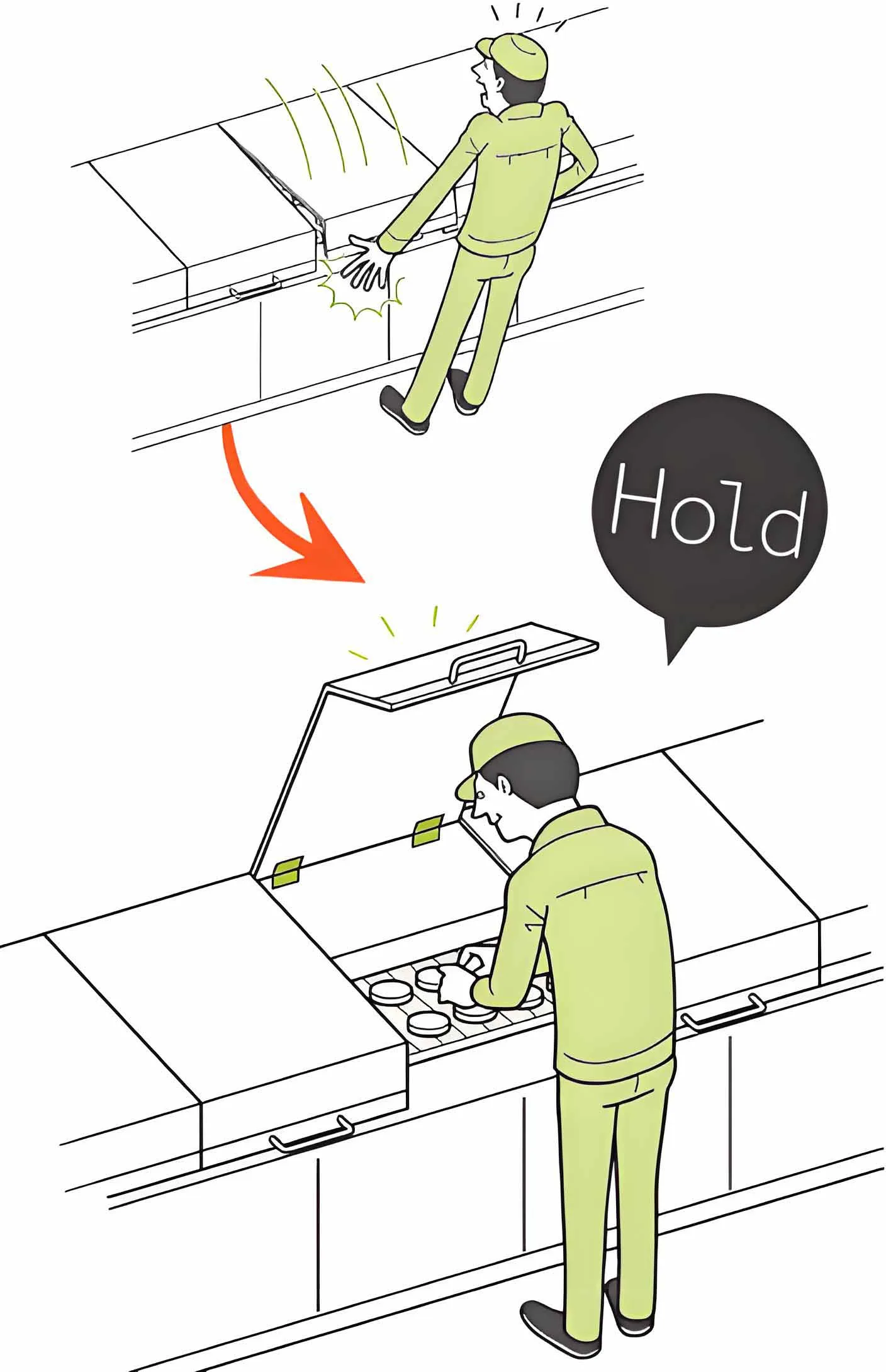

With torque hinges, machinery access doors won’t suddenly swing shut. Image source:sugatsune

Modern torque hinges solve a critical problem: they hold heavy lids, panels, or displays at any chosen angle without dropping or slamming. These hinges use internal friction or springs to provide a controlled resisting torque.

👉 In practice:

- A monitor arm stays in place once adjusted.

- A machinery access panel won’t suddenly swing shut.

Torque hinges are built for reliability, resisting wear and typically requiring no frequent maintenance — making them ideal for hospitals and factories.

What Is a Torque Hinge?

A torque hinge (also called a friction hinge or position-control hinge) is a mechanical hinge that uses internal friction or springs to resist rotation.

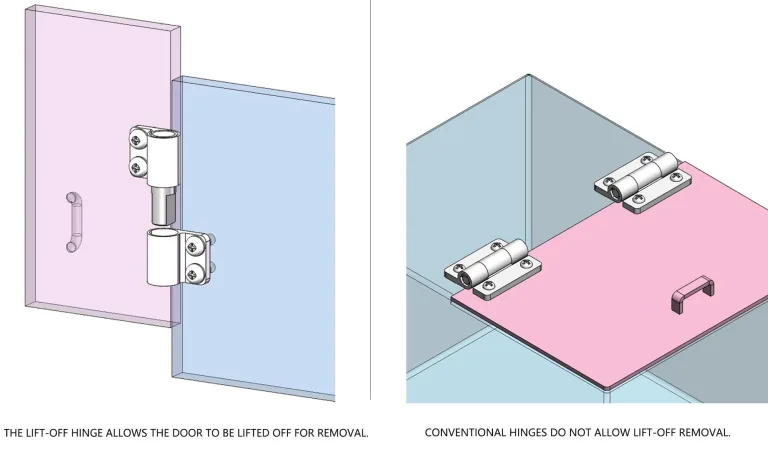

🔑 Key difference vs. normal hinges:

- Normal hinge: swings freely, no holding force.

- Torque hinge: provides a steady opposing force so panels and lids stay at any set angle.

A cover with a torque hinge can stop and hold at any position

A cover with a standard hinge cannot stop at any position

📌 Example applications:

- Laptop screens (small torque hinges).

- Industrial/medical equipment (larger torque hinges for monitors, covers, or doors).

HTAN: Torque hinges are “suitable for holding lids, doors, panels or display devices at specific angles for extended periods.”(Reference: Lab Lid Slam: Safety Hazards & The Critical Role of Constant Torque Hinges)

How Torque Hinges Work

Inside a torque hinge:

- Springs, friction plates, or damping elements generate resisting torque.

- When the panel tries to move, the hinge pushes back with steady force.

📊 Torque requirement formula:

Torque ≈ (Weight × Distance) / 2- Weight: panel weight

- Distance: horizontal distance from hinge axis to panel’s center of gravity

👉 Always choose a hinge with resistive torque > panel torque (with safety margin).

Torque Ratings in Practice

- Common Units: N·m (SI) or kgf·cm (metric).

- Manufacturer ranges: HTAN offers from 0.006 N·m (58 gf·cm) up to 7 N·m (70 kgf·cm) depending on size.

📌 For heavy or large panels → use multiple hinges to share torque load.

Key Types of Torque Hinges

One-Way (Unidirectional) Torque Hinge

- Generates resistance in only one direction.

- Example: Lid opens easily, but resists closing to prevent slamming.

Bi-Directional Torque Hinge

- Provides torque in both opening and closing directions.

- Holds flap at any angle between 0°–180°.

Position-Control (Constant-Torque) Hinge

- Provides uniform torque across its range.

- Eliminates need for gas struts or lid stays.

- Common in medical monitors, diagnostic equipment.

Compact (Low-Profile) Torque Hinge

- Designed for space-constrained applications.

- Example: HTAN XG11-075 hinge — embedded, concealed, press-fit.

Core Performance Metrics

When evaluating torque hinges, engineers look at:

orque Rating

- Must meet/exceed panel torque.

- Specified in N·m or kgf·cm.

Cycle Life (Durability)

- Standard torque hinges: 10,000–25,000 cycles.

- Premium models: 50,000+ cycles.

- Example: HTAN tested hinges at 40,000 cycles; Southco’s ST-7A2 offers 2× cycle life vs older models.

Load Capacity & Angular Range

- Typically up to 180° swing.

- Heavy panels require multiple hinges.

- Specialized models allow multi-axis motion.

Applications in Medical Devices

Medical devices demand precision, stability, and hygiene.

Benefits of Torque Hinges:

- Precision & Stability: Imaging monitors and surgical lights stay at exact positions.

- Safety: Prevents sudden drops/slams.

- Cleanability: Stainless steel & sealed hinges resist corrosion and cleaning agents.

Common Medical Applications:

- Display Monitors & Touch Screens

- Surgical Lighting (multi-joint, no drift)

- Medical Carts & Cabinets (hands-free lids)

- Diagnostic Equipment Covers

Applications in Industrial Equipment

Industrial use requires robust and durable hinges.

Challenges Solved:

- Vibration resistance

- Harsh environments (chemicals, dust, temperature extremes)

- Heavy-duty loads

Common Industrial Applications:

- Control Panels & Access Doors

- Protective Machinery Covers

- Vehicle Consoles & Heavy Equipment Panels

Comparison: Torque Hinges vs. Alternatives

| Feature | Ordinary Hinge | Gas Spring/Strut | Torque Hinge (Friction) |

|---|---|---|---|

| Position Holding | ❌ No | ✅ Yes (open only) | ✅ Yes – any angle |

| Space Requirement | ✅ Minimal | ❌ High | ✅ Low (compact) |

| Maintenance | ✅ Low | ❌ Moderate (leaks) | ✅ Very low (sealed) |

| Cycle Life | Variable | Medium | ✅ High (20k–100k+) |

| Cost & Complexity | ✅ Low | Moderate–High | Moderate (precision) |

How to Choose the Right Torque Hinge

- Calculate Required Torque

- Use formula: (Weight × Distance)/2

- Add 25–50% safety margin

- Check Parameters

- Torque Range (fixed or adjustable)

- Cycle Life (choose ≥ expected product lifetime)

- Material (stainless steel, anodized aluminum)

- Environment (chemicals, moisture, outdoor)

- Mounting (surface, embedded, flush)

- Brands & Certifications

- Trusted brands: Southco, HTAN, Reell, TorqMaster

- Look for ISO 9001, RoHS/REACH compliance, FDA-approved materials

Future Trends in Torque Hinges

- Smart Hinges: Built-in sensors for angle/load reporting, predictive maintenance.

- Advanced Materials: Lightweight composites, PVD coatings, polymer friction elements.

- Additive Manufacturing: Custom-designed hinge internals for robotics and medical devices.

FAQ

- Difference vs normal hinge? Normal = free swing, Torque = position holding.

- Does my device need torque hinges? Yes, if it has adjustable lids/screens that must stay in place.

- Replacement cycle? Standard 10k–25k cycles; premium 50k+.

- Maintenance required? Usually maintenance-free. Replace when resistance drops.

- Does brand matter? Yes. Choose certified manufacturers (Southco, HTAN, Reell).

Conclusion

Torque hinges are mission-critical for both medical and industrial applications:

✅ Safety: Prevent accidents, drops, and slams.

✅ Efficiency: Hold equipment at any position smoothly.

✅ Durability: Withstand tens of thousands of cycles.

✅ Space-Saving: Replace bulky struts/rods.

As IoT and automation expand, torque hinges will evolve further — becoming smarter, lighter, and more durable, ensuring they remain indispensable in critical equipment design.