Heavy-Duty Torque Hinge Selection Guide (10-20kg): The No-Math Lookup Table

When an industrial access panel reaches the 10kg to 20kg (22-44 lbs) weight class, it ceases to be a simple structural component; it becomes the core of the Human-Machine Interface (HMI) experience.

At this load, user expectations for Position Control become extremely demanding. The lid must feel as smooth as a premium laptop hinge yet possess industrial-grade stability against vibration.

The Common Engineering Trap:

Traditional selection methods often fail here. Engineers mistakenly scale up standard hinges (resulting in lids that slam shut) or introduce bulky gas struts (sacrificing space and infinite positioning).

- Safety Risk: A heavy lid (e.g., 20kg) falling freely under gravity can generate significant impact force, potentially causing severe crushing injuries or even fatalities if it strikes a person.

- Operational Failure: Oversized torque makes the lid impossible to lift with one hand.

- Component Damage: Lack of damping leads to impact damage on sensitive internal electronics.

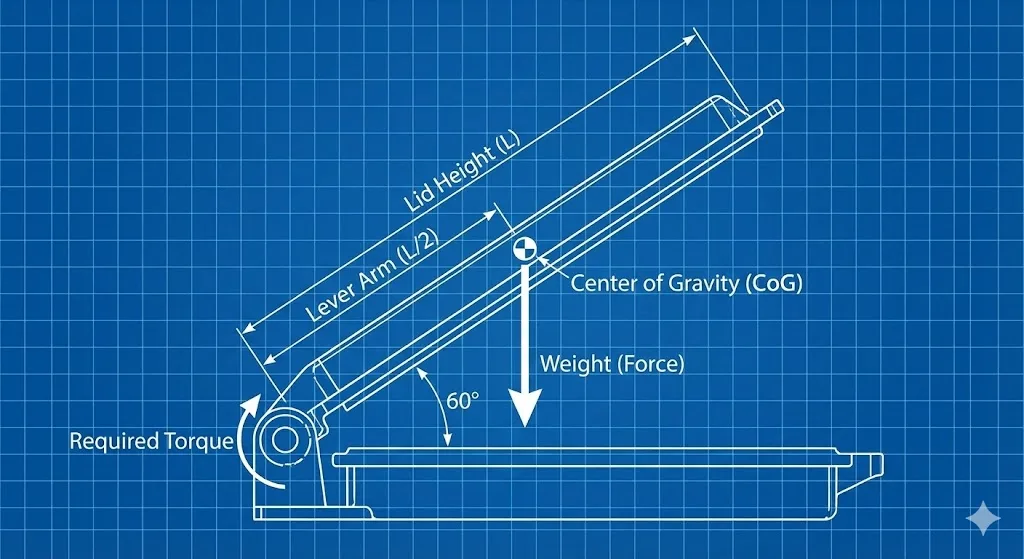

The real challenge lies in balancing gravity against friction. To help design teams bypass complex physics calculations, we have compiled this Quick-Reference Torque Selection Guide. Based on ASTM F1578 testing standards and real-world industrial data, this guide allows you to match the perfect heavy-duty torque hinge solution in under 30 seconds.

The Core Asset: 10-20kg Lid Torque Lookup Table

To streamline your workflow, we generated the table below based on standard engineering assumptions:

Center of Gravity (CoG): Located at the geometric center (50% of lid length).

Safety Factor: Includes a 20% buffer to account for friction loss and dynamic loading.

Logic: Based on the formula T = m × g × (L/2) × 1.2 .

How to Use:

Find your lid Height/Length in the left column.

Find your lid Weight in the top row.

The intersecting cell shows the Recommended Total Torque (N·m).

Heavy-Duty Torque Hinge Selection Matrix

| Lid Height (mm) \ Weight (kg) | 10 kg (22 lbs) | 12 kg (26.5 lbs) | 15 kg (33 lbs) | 18 kg (39.7 lbs) | 20 kg (44 lbs) |

| 300 mm (CoG 0.15m) | 18 N·m | 22 N·m | 27 N·m | 32 N·m | 36 N·m |

| 400 mm (CoG 0.20m) | 24 N·m | 29 N·m | 36 N·m | 43 N·m | 48 N·m |

| 500 mm (CoG 0.25m) | 30 N·m | 36 N·m | 45 N·m | 53 N·m | 60 N·m |

| 600 mm (CoG 0.30m) | 36 N·m | 43 N·m | 53 N·m | 64 N·m | 72 N·m |

| 800 mm (CoG 0.40m) | 48 N·m | 57 N·m | 71 N·m | 85 N·m | 96 N·m |

Example Application:

If your lid weighs 15kg and is 500mm long:

- Chart Result: 45 N·m Total Torque.

- Configuration: We recommend installing two (2) hinges rated at 22.5 N·m each, mounted symmetrically.

Why Add a “Safety Factor”? (The 20% Rule)

You might ask: Theoretical calculation yields 36.75 N·m. Why do you recommend 45 N·m?

In industrial engineering, relying solely on static calculation ($F \times L$) is negligent. According to ASTM F1578 (Standard Practice for Contact Closure Cycling) and general industry norms, you must account for three critical variables:

- Torque Decay:All friction-based damping hinges experience wear. Typically, after 20,000 cycles, torque output may drop by 10% to 15%. The buffer ensures the lid holds position even at the end of its lifecycle.

- Dynamic Loading:Operators rarely open lids slowly. Fast actuation creates inertia. If torque equals gravity exactly, the lid may “overshoot” or fail to stop instantly upon release.

- Thermal Variance:Internal damping grease exhibits non-linear viscosity characteristics under thermal stress.

- High Temp: Grease thins, reducing resistance.

- Low Temp: Grease thickens, increasing resistance.The 20% Safety Factor covers these uncontrolled environmental variables.

Advanced Strategies: Special Solutions for 10-20kg Loads

For this specific weight class, simply “picking a big hinge” isn’t always the best UX strategy. To elevate the user experience, consider these advanced configurations:

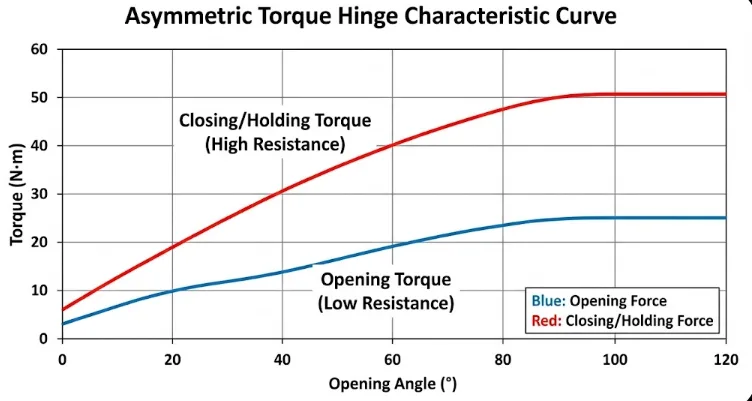

Solution A: Asymmetric Torque Technology

Lifting a 20kg lid requires overcoming significant gravity. If the torque hinge provides equal resistance in both directions, the user will struggle to open it.

The Engineering Fix: Select a hinge with Asymmetric Torque.

- Opening Direction: Low damping (e.g., 60% of rated torque) to assist the user in lifting.

- Closing Direction: High damping (e.g., 100% of rated torque) to fight gravity, preventing slamming and ensuring free-stop capability.

Solution B: Dual Hinge Configuration

For lids wider than 600mm, we strongly advise against using a single high-torque hinge (e.g., one 50 N·m unit on one side).

The Risk: High localized stress can tear the sheet metal mounting points or cause lid warping.

The Engineering Fix: Always use a Dual Hinge layout.

If the requirement is 50 N·m, use two 25 N·m hinges. This distributes mechanical stress evenly across the chassis and ensures a smooth axis of rotation.

When to Avoid This Table (Pitfall Guide)

The lookup table above covers 90% of standard industrial scenarios. However, you must perform precise calculations if your project involves the following:

Center of Gravity (CoG) Shift:Does your lid have a mounted monitor, fan, or heavy handle? If so, the CoG is no longer at the geometric center (50%). An outward shift increases the lever arm significantly, rendering the table values insufficient.

Negative Angles:If the lid must hold position at a downward angle (<0°) or hyperextend past 135°, the gravitational moment curve changes drastically.

High-Vibration Environments : For mobile machinery or ambulances, static friction is often insufficient to resist dynamic vibration. Refer to ISO 16750-3 (Road Vehicles – Environmental Conditions) . You will likely need a much higher safety factor (30%–40%).

Call to Action:

Does your device fit these complex criteria? Relying on the table is risky. Please refer to our in-depth technical guide: [ Precise Torque Calculation Formula for 30kg Heavy Industrial Lids ] for the complete physics breakdown.

Frequently Asked Questions (FAQ)

Q1: How many torque hinges should I install on a 15kg lid?

Recommendation: Two (2).

Beyond sharing the mechanical load, dual mounting prevents torsion (twisting) of the lid during movement, ensuring the friction mechanism wears evenly. The sum of both hinges should equal or slightly exceed the target torque (e.g., 45 N·m).

Q2: Why not use a standard hinge with a gas strut?

Standard hinges combined with gas struts (dampers) usually offer only “Soft Close” functionality. They lack Position Control (the ability to stop at 45° or 60° for maintenance).

Furthermore, gas struts occupy significant internal volume and rely on seals that degrade over time. A purely mechanical torque hinge is maintenance-free and compact.

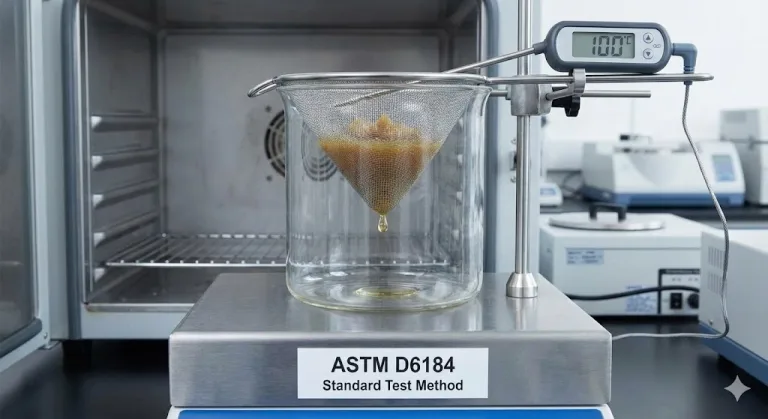

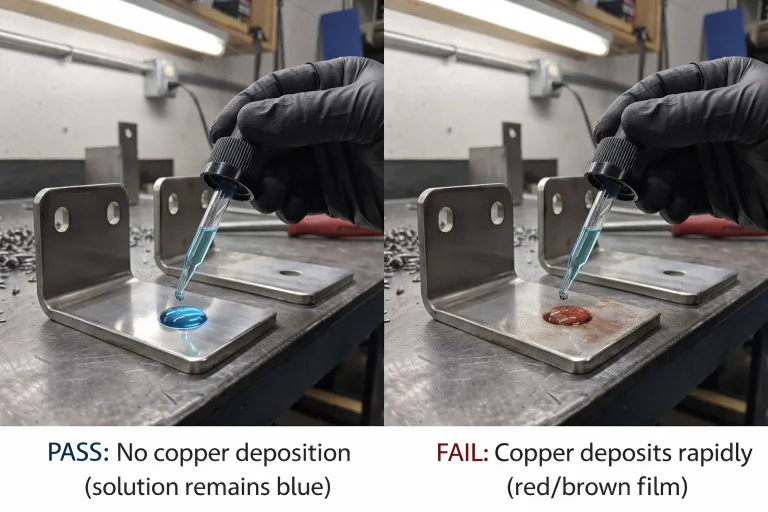

Q3: What material should I choose for outdoor cabinets?

Standard zinc-plated carbon steel will fail outdoors.

Per ASTM B117 salt spray standards , we recommend SUS316 Stainless Steel or hardened steel cores with specialized anti-corrosion coatings (like Dacromet). Internal grease must also be upgraded to wide-temperature synthetic lubricants (-40°C to 80°C) to prevent the hinge from “freezing” in winter.

Conclusion

Selecting the right torque hinge for a 10-20kg heavy-duty lid is not just about functionality; it is a commitment to operational safety.

By using the Torque Selection Lookup Table provided above, you can lock in your design parameters in seconds and avoid costly rework caused by estimation errors. Always remember: Adding a 20% Safety Factor to theoretical values is the golden rule for long-term industrial reliability.

Next Step:

Unsure of your lid’s exact Center of Gravity? Worried about installation space constraints?

Contact our Engineering Team. We offer free CAD CoG Simulation and Selection Services to ensure your heavy-duty lid design is foolproof.