How to Determine Whether Your Application Requires a one-way and two-way torque hinges

Introduction: The Importance of Torque Hinges and the Challenges of Selection

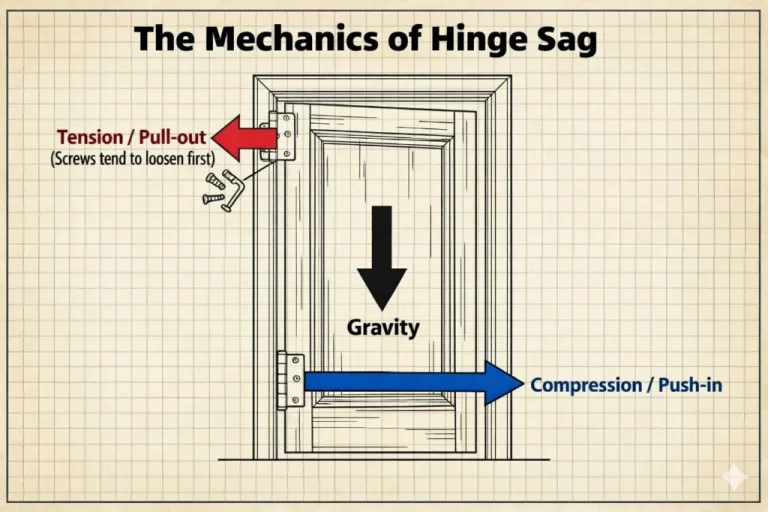

Torque hinges are widely used in electronic devices, medical equipment, and industrial machinery, such as laptop screens, car multimedia displays, and operating tables, all of which rely on torque hinges for support. In these devices, torque hinges are responsible for damping support and positioning fixation, ensuring that screens or panels remain stable at the desired angle. If the wrong type is selected, it may lead to hinge malfunction, triggering a chain of risks: issues such as cost waste, uncontrolled panel drops, equipment damage, or degraded user experience frequently occur.

Proper selection is critical to product performance. This article will start with the definitions of one-way or two-way torque hinge(Unidirectional vs. Bidirectional Torque Hinges), providing a systematic evaluation framework to help engineers, designers, and procurement personnel select the appropriate hinge type based on actual needs. By analyzing scenario requirements from multiple dimensions, we avoid erroneous decisions caused by empirical selection, achieving precise matching of needs and rejecting over-engineering.

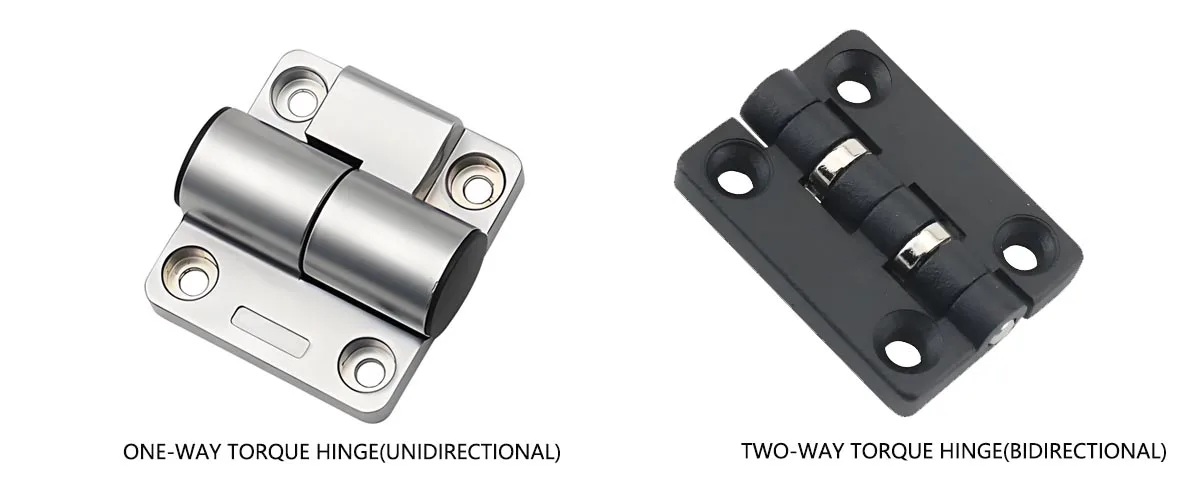

Basic Concept Analysis: One-Way vs. Two-Way Torque Hinges

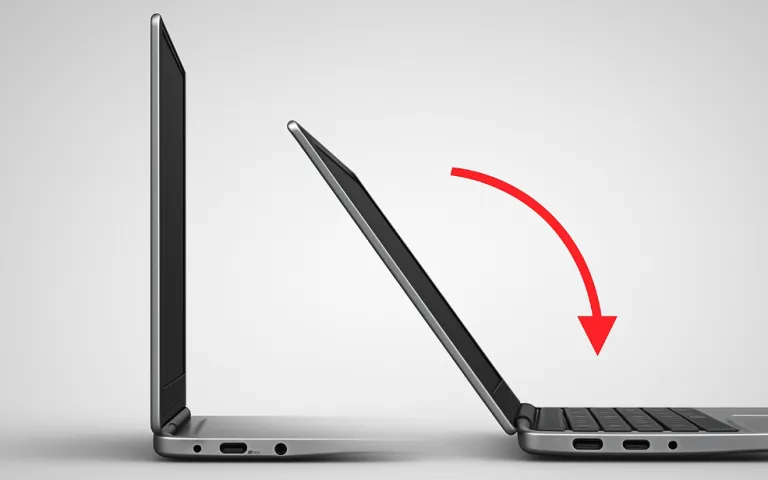

One-way torque hinges(Unidirectional Torque Hinge) provide torque resistance in only one direction, with no torque restrictions in the opposite direction. For example, they provide resistance to support the laptop screen when opening it, but do not generate additional resistance when closing it. This type of hinge structure typically incorporates a one-way bearing or ratchet mechanism internally, applying friction in only one direction. This allows the door panel or cover to open more easily while closing naturally under gravity without additional resistance. One-way torque hinges have a relatively simple structure and lower cost, commonly used in flip-style devices requiring “easy opening/closing with fixed opening angle.”

Two-way torque hinges provide controllable resistance in both opening and closing directions, enabling suspension at any angle. Typically, friction plate assemblies, helical springs, or other constant torque mechanisms are used to maintain constant torque throughout the entire range of motion (i.e., constant torque hinges), ensuring smooth, controllable damping effects during both opening and closing processes. For example, in operating rooms, lighting fixtures or medical instrument displays require precise positioning at multiple angles. The two-way torque hinge meets the requirement for suspension at any angle without sagging.

Comparison Table

| Characteristic | One-Way Torque Hinge | Two-Way Torque Hinge |

|---|---|---|

| Resistance Direction | One-way (one-way damping) | Two-way (bidirectional uniform damping) |

| Hovering at Any Angle | Typically not supported | Supported (constant torque maintenance) |

| Structural Complexity | Lower | Higher |

| Cost | Lower | Higher |

| Typical Applications | Flip-top devices, upper/lower panels | Multi-angle adjustable screens, movable arms |

Key Decision Factors: Evaluate Your Needs Across 7 Dimensions

Movement Direction Requirements

Scenario Analysis: Consider whether bidirectional support is needed during device opening and closing.

Decision Criteria: If operation occurs only in one direction and closure is gravity-assisted, a one-way hinge is sufficient. For bidirectional operation with position fixing, choose a two-way hinge.

Necessity of the Hover Function

Scenario Analysis: Is the panel required to stop at any angle?

Decision Criteria: If hovering at any angle is needed, a two-way torque hinge is required.

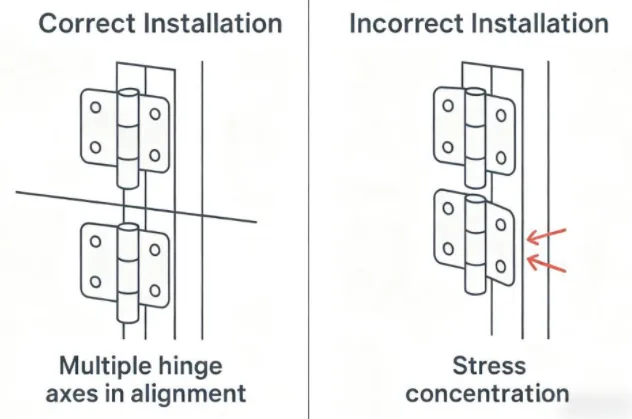

Load and Torque Stability

Scenario Analysis: Analyze the load and the sensitivity of the device to impacts.

Decision Criteria: For heavy or fragile loads, choose two-way hinges for cushioning and stability.

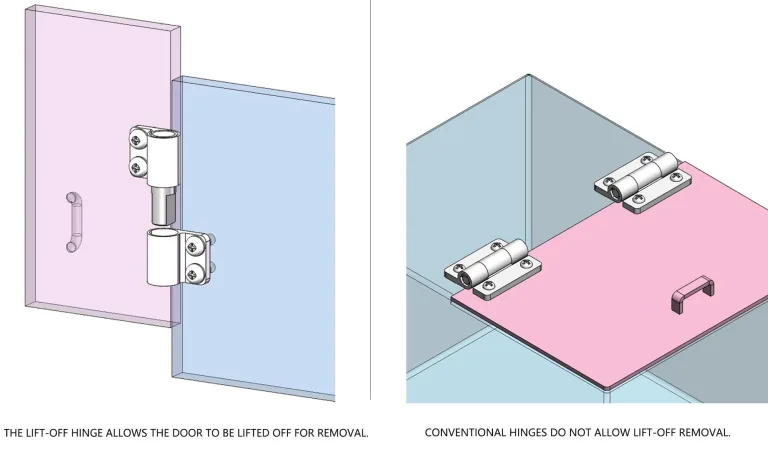

Space and Installation Constraints

Scenario Analysis: Compare the size and mounting space needed.

Decision Criteria: Use a one-way hinge in compact designs; use two-way hinges if space allows and functionally necessary.

Environmental Resistance

Scenario Analysis: Consider exposure to vibration or extreme temperatures.

Decision Criteria: In harsh environments, prioritize two-way constant torque hinges with robust materials and lubrication.

Lifespan and Maintenance Costs

Scenario Analysis: Frequency and durability of usage.

Decision Criteria: Choose simpler one-way hinges for longer life and less maintenance; establish maintenance plans for two-way hinges.

Regulatory and Safety Requirements

Scenario Analysis: Identify if the application is bound by safety standards (e.g., medical, automotive).

Decision Criteria: If accidental falling must be prevented, select two-way hinges.

In-Depth Analysis of Typical Application Scenarios

Best Practices for One-Way Torque Hinges

- Laptop Screens: Need support when opening, fall freely when closing.

- Outdoor Instrument Case Lids: Require support only when open.

Selection Logic: Use where opening/closing is straightforward, and cost/reliability are key concerns.

Scenarios Where Two-Way Torque Hinges Are Indispensable

- Surgical Lights and Medical Displays: Require adjustable angle positioning.

- Rear-Seat Entertainment Screens in Vehicles: Need to resist vibration.

- Industrial Robotic Arm Control Screens: Require multi-angle locking.

Selection Logic: Use in high-interactivity or multi-angle adjustment applications.

Common Misuse Scenarios

- Misuse of One-Way Hinges: e.g., for VR mounts requiring hovering.

- Overuse of Two-Way Hinges: e.g., for static access panels where extra cost is unjustified.

Summary: Understand the motion and functional requirements to avoid both under-specification and over-engineering.

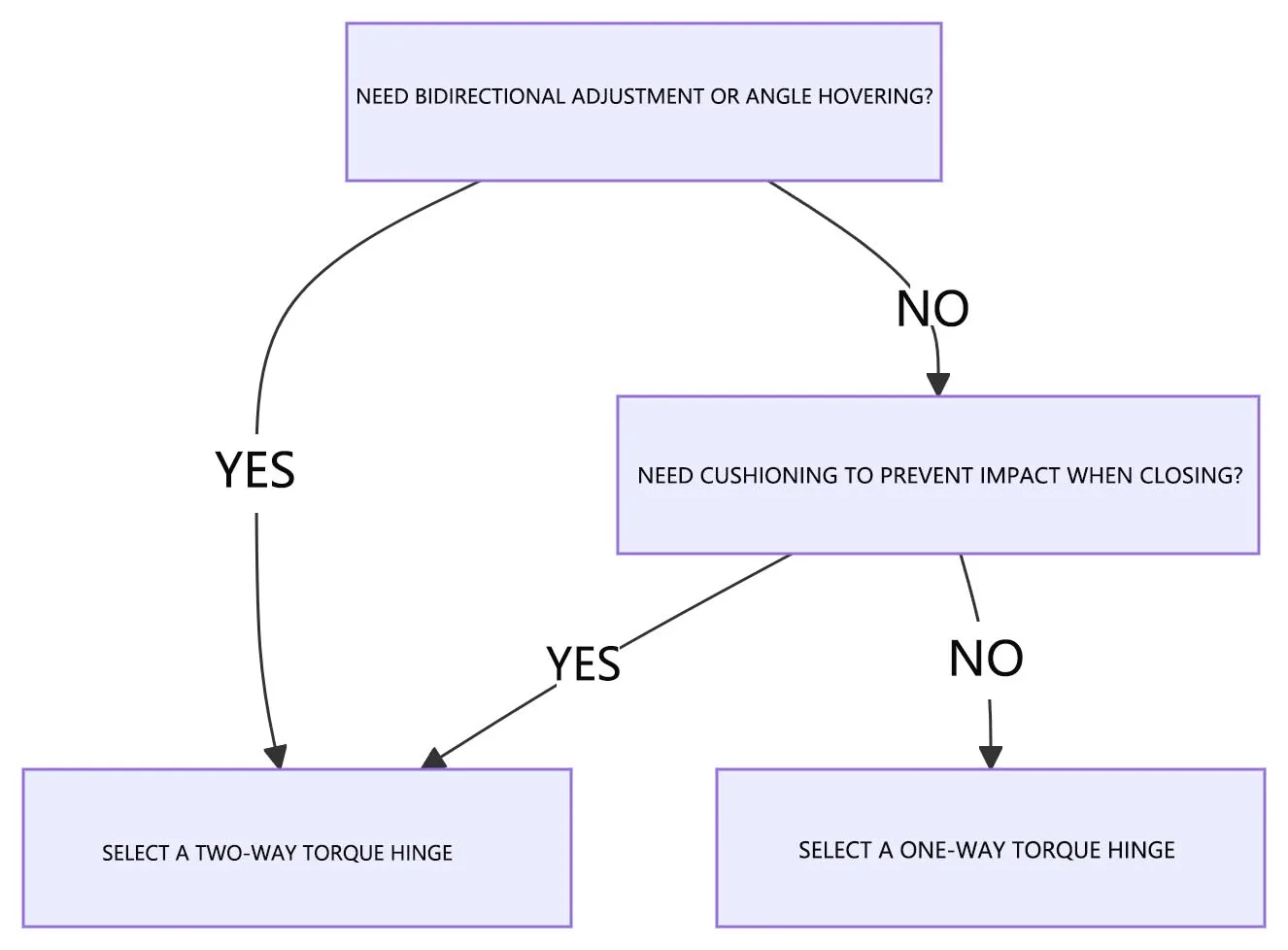

Component Selection Flowchart and Toolkit

Selection Flowchart

Use the following checklist to quickly determine which hinge to choose:

- Bidirectional resistance or angle locking needed?

- Frequent angle adjustments?

- Free-fall allowed when closing?

- Heavy or sensitive load?

- Limited installation space?

- Exposure to vibration/extreme temperature?

- Lifespan/maintenance restrictions?

- Safety/anti-drop regulations applicable?

Each “yes” to two-way-functional needs leans toward choosing a two-way torque hinge.

Cost and Supply Chain Considerations

Two-way torque hinges are 30%–50% more expensive due to added components and complexity. For cost-sensitive applications, one-way hinges may suffice. For long lead times (up to 12 weeks for custom parts), early planning is necessary. Choose suppliers based on precision, cost, and availability:

Conclusion: Precisely Match Requirements, Avoid Over-Engineering

Select hinges based on actual functional needs:

- One-way: For “simple open/close + cost priority”

- Two-way: For “interactive positioning + safety”

Avoid empirical bias and follow a structured decision-making process to ensure optimal performance and cost-efficiency.

FAQ

Q: What is the difference between one-way and two-way torque hinges?

A: One-way hinges provide damping in one direction; two-way hinges provide resistance in both, allowing hovering at any angle. The former is simpler and cheaper; the latter is more complex and costly.

Q: My device needs to be fixed at any angle at any time. Which hinge should I choose?

A: A two-way torque hinge is required for angle fixation and anti-drop performance.

Q: Why is a two-way torque hinge significantly more expensive than a one-way hinge? Is it worth the investment?

A: The complexity of added components increases cost by ~30%. When two-way control is essential, the investment is justified.

Q: How do you determine the required torque value?

A: Use torque = weight × distance ÷ effective length, add safety margin, and consult manufacturer guidelines.