NEMA 4X Hinges for Coastal Projects: Procurement & Risk Guide

When managing procurement for projects in coastal regions (such as ports, offshore platforms, and seaside facilities), the primary challenge for procurement managers is balancing “initial procurement costs” with “long-term maintenance costs.”

In areas within 5 kilometers of the coastline, the environment is characterized by high salt spray and high humidity. If procurement is based solely on standard outdoor specifications, equipment often develops corrosion issues within 6 to 12 months of installation.

The consequences of improper selection include:

- Customer complaints triggered by rusted equipment appearance.

- Maintenance difficulties due to seized hinges.

- Internal electronic damage caused by seal failure.

The cost of addressing these after-sales issues is typically far higher than the price difference for high-quality hardware. This article analyzes how to select hinges based on NEMA 4X standards to reduce overall operational risks for the project.

Specification Analysis: The Substantive Difference Between IP65 and NEMA 4X

When reviewing supplier quotes or an engineer’s Bill of Materials (BOM), it is essential to clearly distinguish between IP ratings and NEMA ratings, as they represent different testing standards.

IP65 / IP66 (Focus on Dust and Water Resistance)

IP ratings (IEC 60529 standard) primarily test the equipment’s ability to prevent dust and water from entering the interior.

- Limitation: IP certification does not test the corrosion resistance of the enclosure or accessory materials themselves. A metal component prone to rust can pass an IP65 test if its coating is intact, but it will fail rapidly in a salt spray environment.

NEMA 4X (Includes Corrosion Protection Requirements)

NEMA 250 Type 4X is a standard established by the National Electrical Manufacturers Association (NEMA).

- Core Requirements: In addition to requiring dust and water resistance (equivalent to IP66), NEMA 4X explicitly requires that components must possess corrosion resistance and withstand the effects of external icing.

- Procurement Recommendation: For coastal projects, Requests for Quotation (RFQs) should explicitly require suppliers to provide products “compliant with NEMA 4X standards,” not just IP65.

Material Cost Analysis: The Basis for Choosing SS304 vs. SS316

The price of SS316 stainless steel is typically 20% to 30% higher than SS304. Below are the data and reasons supporting the choice of SS316.

SS304: Not Suitable for High Salt Spray Environments

SS304 is a general-purpose stainless steel. It performs well in inland or standard rainy environments. However, in coastal environments, the air contains chlorides. SS304 lacks the ability to resist chloride ions and typically develops brown rust spots (known as “tea staining“) after months of exposure. This is viewed by end customers as a quality defect.

SS316: A Necessary Configuration for Coastal Environments

SS316 material contains an added 2% to 3% of Molybdenum (Mo). The molybdenum element significantly improves the material’s chemical stability against chlorides, effectively preventing pitting corrosion. For coastal equipment with a design life exceeding 5 years, SS316 is the foundational material for controlling maintenance costs.

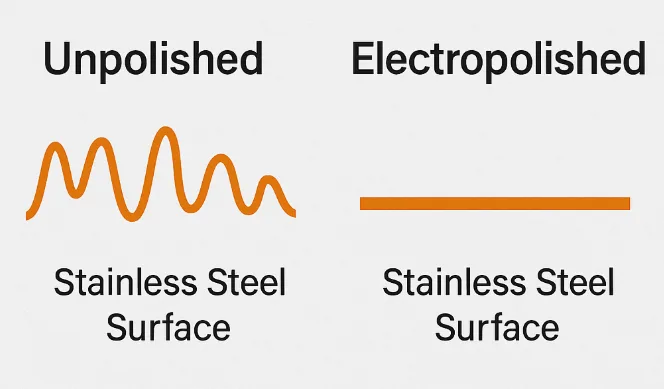

Surface Treatment: The Role of Electropolishing

Electropolishing is an electrochemical treatment process. This process removes microscopic peaks and impurities from the stainless steel surface, reducing surface roughness.

Why Electropolishing Resist Corrosion? As shown above, electropolishing eliminates surface irregularities. This leaves no hiding place for salt spray or bacteria, significantly reducing the risk of tea staining and pitting in coastal environments.

- Benefit: A smooth surface makes it difficult for salt to accumulate and allows it to be easily washed away by rain.

- Result: Data shows that electropolishing significantly extends the service life of stainless steel in marine environments.

Common Failure Modes and Solutions

In addition to material corrosion, coastal environments present physical risks. Procurement should focus on hinges with specific functions to avoid the following issues.

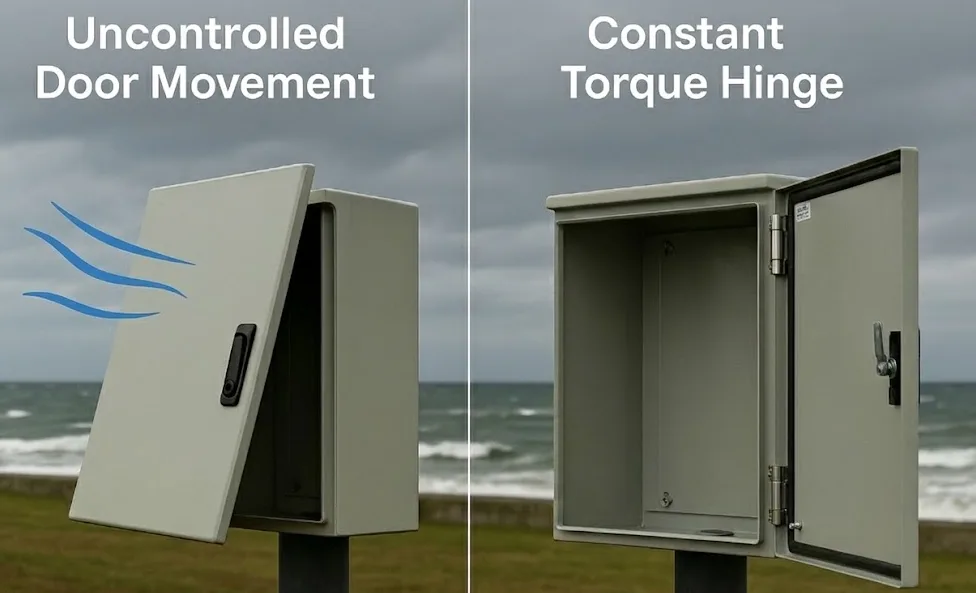

Risk 1: Wind Loading Causing Uncontrolled Door Movement

Figure: Risk vs. Solution – Managing Wind Loads Standard hinges allow dangerous uncontrolled movement in wind (left). Constant Torque Hinges hold the door steady for safe, hands-free maintenance (right)

Wind speeds in coastal areas are high. Standard hinges without damping allow the door to be slammed by the wind when opened, potentially damaging equipment or injuring personnel.

- Solution: Procure Constant Torque Hinges. These hinges contain internal friction damping that counteracts wind force, keeping the door stationary at any angle.

Risk 2: Seal Leakage Due to Gasket Compression Set

Sealing gaskets undergo permanent deformation after long-term use, resulting in reduced door sealing pressure.

- Solution: Procure Adjustable Hinges. These hinges allow for fine-tuning of the door position (typically with a 3-5mm adjustment range) after installation, restoring NEMA 4X-level sealing by re-compressing the gasket.

Risk 3: Galvanic Corrosion

When stainless steel hinges are installed directly onto aluminum alloy or galvanized steel cabinets in the presence of salt water, the potential difference causes rapid corrosion of the aluminum.

- Solution: Use Isolation Washers. Ensure the procurement list includes isolation washers. Placing non-conductive material (such as EPDM rubber or plastic) between two different metals is the standard practice for physically blocking galvanic corrosion.

Supplier Acceptance Standards

To ensure the quality of procured products meets NEMA 4X requirements, it is recommended to require suppliers to provide the following two key documents for verification.

Salt Spray Test Report

Request a third-party test report conducted according to ASTM B117 or ISO 9227 standards.

- Pass Standard: The report shows a testing duration of 1000 hours or more, with no red rust generated on the sample surface.

- Note: Products that only pass 96-hour or 200-hour tests are not suitable for long-term coastal applications.

Mill Certificate

Request a chemical composition analysis table for the raw steel material.

- Audit Focus: Check the content of Mo (Molybdenum) in the chemical composition column.

- Requirement: The Molybdenum content of SS316 should be between 2.0% – 3.0%. If the Molybdenum content is missing or below 2%, the material does not possess 316-level corrosion resistance.

Summary and Recommendations

In coastal industrial projects, hinge selection is directly related to the equipment’s protection rating and service life. Although SS316 material and electropolishing processes increase the initial procurement budget, they prevent future costs associated with on-site replacement and repair. From a Total Cost of Ownership (TCO) perspective, this is an economically rational choice.

Procurement Recommendations Summary:

- Clarify Standards: Specify NEMA 4X standards and SS316 material in inquiries.

- Focus on Process: Prioritize products that have undergone electropolishing.

- Strict Acceptance: Must audit the 1000-hour salt spray test report and the mill certificate.

Need Cost Budgeting Assistance for Specific Projects?

We provide a full range of NEMA 4X hinge products and detailed technical specifications. Please contact our team for material selection advice and detailed quotations tailored to marine environments.

FAQ

Q1: If the budget is limited, can SS304 be used for coastal projects?

If the project involves short-term temporary facilities, or if there is dedicated personnel to perform regular freshwater cleaning and maintenance, SS304 can serve as a compromise. However, for long-term deployments and unmanned facilities, the risk of SS304 developing appearance rust is extremely high, and its use is not recommended.

Q2: What are the risks of low-priced SS316 hinges on the market?

Low-priced products are often cast from recycled scrap, contain high levels of impurities, and may have casting defects such as shrinkage porosity, leading to reduced corrosion resistance. It is recommended to request a salt spray test report from a third-party laboratory and verify the chemical composition in the mill certificate.

Q3: Are there special requirements for installation screws?

Yes. SS316 material screws must be used. If standard stainless steel screws are used to install SS316 hinges, the screws will corrode and break first, causing the hinge to detach.

Q4: Will Constant Torque Hinges significantly increase costs?

The unit price of Constant Torque Hinges is higher than standard hinges. However, in environments with high wind loads, they replace the function of “wind stays” or “gas springs,” reducing the number of components and installation labor. On a comprehensive basis, the total cost is often equal or lower.