Preventing Door Failure: Heavy-Duty Riveted Hinges for High-Vibration Environments

The reliability of industrial cabinets often fails in the details. Many engineering teams focus heavily on structural strength, IP ratings (sealing), and corrosion resistance grades. However, hinges are frequently treated as mere ‘commodity hardware,’ often overlooking the critical stability provided by Heavy-Duty Riveted Hinges in high-vibration environments

It is often not until an accident occurs that the severity of the problem is realized.

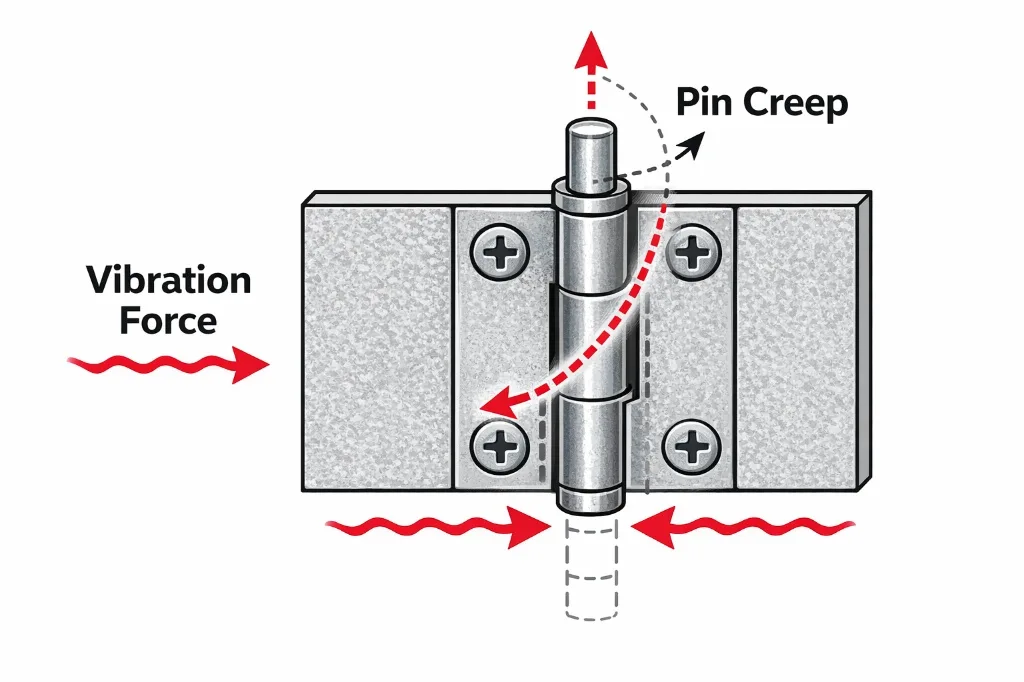

In scenarios such as diesel generator sets, mobile machinery, railway equipment, mining vehicles, and industrial HVAC units, cabinets and door panels are subjected to long-term, intense vibration. This continuous vibration triggers a very typical failure phenomenon known as Pin Creep.

Simply put, the pin in a loose-pin hinge shifts little by little. It might “climb” upwards, or it might “slide” downwards. Initially, the movement is microscopic. After a few weeks, it can reach the millimeter scale. Eventually, the door panel may sag or even fall off completely.

This is not a “probability event.” In high-vibration environments, this is a clear failure path. And once it happens, the cost is extremely high.

The Reality in the Field: From “A Little Loose” to “Catastrophic Failure”

Many maintenance personnel have seen this situation. After a unit has been running for a while, the door starts to deform. Gaps widen. Closing the door becomes tight. Then, the door begins to sag.

Some teams attempt remedial measures first. For example, they periodically hammer the pin back in, add temporary locking screws, or use retaining rings and cotter pins as a failsafe.

These methods can provide short-term relief, but they do not address the root cause. The vibration remains. The wear remains. The pin will continue to move.

The most critical point is this: The design of a loose-pin hinge inherently allows the pin to be removed. In an environment with strong vibration and shock, it is intrinsically unsafe.

Once a door panel falls, it can cause equipment downtime, result in personnel injury, or trigger collateral damage such as severed cables, deformed panels, or seal failure. In industries like power generation, mining, and transportation, these risks are typically unacceptable.

Why Do Loose-Pin Hinges Fail? The Core Mechanism

To understand the solution, one must first understand the failure mechanism.

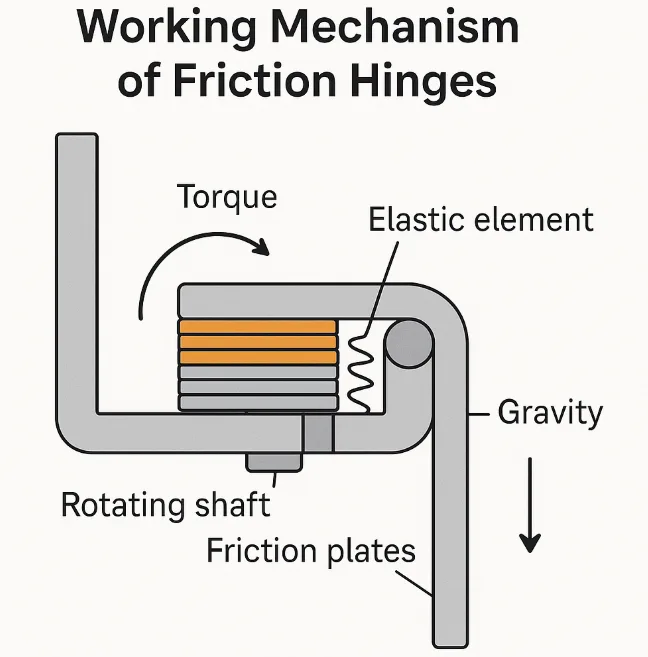

In a vibrating environment, the hinge undergoes continuous micromotion (fretting). There is friction between the pin and the hinge barrel (knuckle). This friction temporarily holds the pin in place.

However, vibration constantly applies tiny lateral forces and shocks. Every micromotion consumes a portion of that frictional holding capacity. This is similar to the process of a bolt gradually loosening under vibration. Each shock pushes it a tiny bit further. Accumulated over time, this results in visible displacement.

If the hinge pin lacks a locking structure, the fact that the pin is “movable” means it is “capable of failure.” Especially in scenarios involving vertical bumping or jolting, the pin is prone to “climbing” upward.

This is the essence of Pin Creep.

- It is not a material problem.

- It is not an installation problem.

- It is a structural risk.

To cure it, you must use a structural method to eliminate the “possibility of axial movement.

The Ultimate Solution: Riveted Hinges (Spun Pin Hinges)

Riveted hinges, also known as spun pin hinges, have a very clear key feature: The ends of the pin are permanently riveted or spun fixed.

During manufacturing, the pin is slightly longer than the total height of the hinge. After assembly, both ends are formed via spinning or orbital riveting to create a head. The diameter of this riveted head is larger than the hinge knuckle diameter. Therefore, the pin cannot be pulled out, nor can it slide axially.

Unless grinding tools are used to destroy the riveted head, the pin will not detach during normal use. This structurally eliminates Pin Creep.

For high-vibration scenarios, this is a “physical lock.” It does not rely on friction, adhesives, or temporary accessories. It relies on the structure itself.

Therefore, it is considered the most reliable choice for high-vibration cabinet doors. Many engineers refer to it as “Fit and Forget.” Once installed, there is virtually no worry about pin detachment.

Three Key Engineering Advantages: Vibration Resistance, Security, and Load Bearing

Riveted hinges offer more than just “keeping the pin in.” They bring system-level reliability improvements.

“Immunity-Level” Vibration Resistance

Since the pin cannot move, vibration cannot “walk it out.” This means the risk of door sag is significantly reduced, maintenance frequency drops, and the probability of failure is minimized. For generator sets, mobile equipment, and transport gear, this is the most direct value.

Lab Data: Riveted vs. Loose-Pin Performance

To quantify the reliability gap, we compared our heavy-duty riveted hinges against standard loose-pin counterparts in a controlled vibration test (Simulating ASTM D4728 Random Vibration profiles).

| Test Metric | Standard Loose-Pin Hinge (304 SS) | Heavy-Duty Riveted Hinge (304 SS) | Improvement |

|---|---|---|---|

| Axial Pin Movement (After 50h Vibration) | 2.4mm (Visible Creep) | 0.0mm (No Movement) | 100% Stability |

| Ultimate Tensile Strength | 4,500 N | 6,200 N | +37% Strength |

| Fatigue Life (Cycles) | ~25,000 Cycles | >50,000 Cycles | 2x Lifespan |

Note: Data based on internal testing of 50x50mm hinges with 6mm pin diameter.

Enhanced Tamper Resistance (Security)

With loose-pin hinges, the pin can often be tapped out from the outside, allowing the door to be removed. This is a significant security vulnerability for outdoor cabinets.

The pin of a riveted hinge is non-removable. The door cannot be dismantled by knocking out the pin. This is crucial for outdoor scenarios like power distribution boxes, telecom cabinets, and traffic signal boxes.

Heavy-Duty Structure for Heavy Doors

Heavy-duty riveted hinges are usually equipped with thicker leaves, larger diameter pins, and higher-strength materials. The overall structure is more stable, with less deformation and longer fatigue life.

In environments with high-frequency opening/closing superimposed with vibration, this structural advantage is amplified. It reduces slop (play), reduces sagging, and minimizes abnormal wear.

Typical Failure Modes in High-Vibration Scenarios (An FMEA Perspective)

To make selection more systematic, let’s break down common risks using FMEA logic, following the structured approach commonly defined in SAE J1739 (and aligned with the AIAG/VDA FMEA framework widely used in high-reliability manufacturing).

Pin Migration (Creep)

- Cause: Accumulation of vibrational micromotion.

- Consequence: Door sagging or falling off.

- Prevention: Use a fixed (riveted) pin structure.

Hinge Leaf Fatigue Cracking

- Cause: Door is too heavy, insufficient number of hinges, or insufficient material thickness.

- Consequence: Door misalignment or detachment.

- Prevention: Increase specifications, increase the number of hinges, and verify fatigue life.

Wear and Slop (Looseness)

- Cause: Micromotion friction caused by vibration.

- Consequence: Widened door gaps, poor sealing, uneven load distribution.

- Prevention: Designs incorporating bearings/bushings and regular lubrication.

Strength Reduction due to Corrosion

- Cause: Salt spray, rain, chemical corrosion.

- Consequence: Hinge seizure, fracture, drastically shortened lifespan.

- Prevention: Select Stainless Steel or high-grade surface treatments, and perform corrosion resistance verification.

Mounting Looseness

- Cause: Bolts backing out due to vibration.

- Consequence: Hinge shifting, door misalignment, abnormal structural stress.

- Prevention: Use anti-loosening measures (Nyloc nuts, Loctite) or optimize the mounting structure.

Typical Applications: Which Industries Need This Most?

Riveted hinges are not just a “more expensive” option. In many scenarios, they are the “correct standard configuration.”

Power Generation Equipment

Vibration in diesel and gas engines is persistent. Control cabinets, sound attenuation enclosures, and access doors are under constant vibration. Loose-pin hinges have a high failure risk. Riveted hinges are better suited for long-term deployment.

Transportation and Mobile Equipment

Truck toolboxes, construction machinery compartments, and railway equipment boxes operate in bumpy and shocking conditions daily. A falling door not only damages equipment but can also trigger traffic safety risks. The value of fixed-pin hinges here is immediate.

HVAC and Compressed Air Systems

Large unit doors are typically heavy, and there are vibration sources from internal rotating machinery. Light-duty hinges have a short lifespan. Heavy-duty riveted hinges maintain door alignment and seal stability over the long term.

🛠️ Field Case Study: Retrofitting Mining Generators

The Problem: A gold mining site in Western Australia reported that the access doors on their mobile lighting towers were sagging within 3 months of deployment. The continuous vibration from the diesel engines caused the standard hinge pins to work loose, leading to IP65 seal failures and dust ingress.

The Fix: The maintenance team retrofitted the fleet with Heavy-Duty Riveted Hinges (Grade 316 SS). Unlike the previous hardware, these hinges required no retaining clips or thread-locker.

The Result:

- Zero pin detachments recorded over a 12-month operational period.

- Maintenance checks on door alignment were reduced from weekly to quarterly.

- Seal integrity was maintained, protecting the internal electronics from conductive dust.

Selection Guide: How to Choose Materials and Specifications

Choosing the right hinge isn’t just about checking if it’s “riveted.” You must also consider material, thickness, pin diameter, load capacity, and environmental compatibility.

Material Recommendations

- 304 Stainless Steel: Suitable for most outdoor and general corrosive environments. High cost-performance ratio.

- 316 Stainless Steel: Suitable for coastal, marine engineering, and chemical environments with strong corrosion. Longer lifespan.

- Zinc-Plated Carbon Steel: Suitable for indoor or low-corrosion environments. Low cost, but higher maintenance requirements.

Load Bearing and Quantity Recommendations

The heavier the door, the less you should skimp on the number of hinges.

- General Advice:

- Standard doors: At least 3 hinges.

- Tall or heavy doors: Suggest 4 or more hinges.

- Actual load per hinge should ideally be kept under 70% of its rated value.

- Always maintain a safety factor of at least 20%.

Thickness and Pin Diameter

- Door Weight <30kg: ~3mm thickness is usually sufficient.

- Door Weight 30–80kg: Suggest 4–5mm thickness, with a larger pin diameter.

- Door Weight >100kg: Suggest custom thicker leaves and increasing the number of hinges.

Installation Best Practices for Vibration Immunity

Even the best hinge can fail if installed incorrectly. For high-vibration cabinets, follow these protocol specifications:

- Fastener Selection: Never use standard nuts. Always specify Nyloc nuts or apply industrial thread-locker (e.g., Loctite 243) to mounting bolts.

- Torque Verification: Ensure mounting bolts are torqued to the specific yield strength of the screw grade (e.g., M6 8.8 bolts approx. 9-10 Nm) to prevent “fastener back-out.”

- Alternating Orientation: (Optional) For extreme cases, some engineers install the top and bottom riveted hinges in opposite orientations (if the design permits) to neutralize lateral stress vectors.

The Value of Customization: When Off-the-Shelf Isn’t Enough

Many OEM cabinets do not follow standard structures. Hole patterns differ, door frames have steps/offsets, seal gaskets have varying thicknesses, or space is limited.

In these cases, a supplier capable of customization is vital. Common customizations include:

- Custom hole patterns and countersinking methods.

- Custom bends and offsets to ensure the door sits flush.

- Mixed material designs (e.g., SS pin with Carbon Steel leaf) to balance cost and corrosion resistance.

- Surface treatments and laser marking.

The meaning of customization isn’t just “it fits.” More importantly, it means “it fits precisely, lasts long, and has fewer issues.” This is critical for mass-produced products.

Compliance & Standards

Our riveted hinges are manufactured to meet the rigorous demands of industrial compliance:

- RoHS & REACH Compliant: Safe for global supply chains.

- Salt Spray Testing: Tested in accordance with ASTM B117 (up to 500 hours for 316SS).

- Suitable for: Enclosures rated NEMA 4X / IP66.

Conclusion

In high-vibration industrial environments, the failure risk of loose-pin hinges is very real. Pin creep accumulates gradually, eventually leading to door sag or detachment. This brings downtime, repairs, and even safety accidents.

Riveted hinges eliminate Pin Creep structurally by permanently fixing the pin, while simultaneously improving tamper resistance and load-bearing capacity. This is the most investment-worthy upgrade for high-vibration cabinet doors.

If your equipment operates long-term in a vibrating environment, do not wait for a problem to occur. It is recommended to adopt heavy-duty riveted hinges during the design phase. Move the risk management upstream, minimize maintenance costs, and keep safety under control.